service interval INFINITI QX56 2009 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 2402 of 4171

![INFINITI QX56 2009 Factory Service Manual POWER SUPPLY AND GROUND CIRCUIT FOR CONTROLLER

HAC-89

< COMPONENT DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

POWER SUPPLY AND GROUND CIRCUIT FOR CONTROLLER

Component De INFINITI QX56 2009 Factory Service Manual POWER SUPPLY AND GROUND CIRCUIT FOR CONTROLLER

HAC-89

< COMPONENT DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

POWER SUPPLY AND GROUND CIRCUIT FOR CONTROLLER

Component De](/img/42/57031/w960_57031-2401.png)

POWER SUPPLY AND GROUND CIRCUIT FOR CONTROLLER

HAC-89

< COMPONENT DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

POWER SUPPLY AND GROUND CIRCUIT FOR CONTROLLER

Component DescriptionINFOID:0000000003775385

COMPONENT DESCRIPTION

A/C auto amp.

The A/C auto amp. has a built-in microcomputer which processes

information sent from various sensors needed for air conditioner

operation. The air mix door motors, mode door motor, intake door

motor, defroster door motor, blower motor and compressor are then

controlled.

The A/C auto amp. is unitized with control mechanisms. When the

various switches and temperature dials are operated, data is input to

the A/C auto amp.

Self-diagnostic functions are also bu ilt into the A/C auto amp. to pro-

vide quick check of malfunctions in the auto air conditioner system.

Potentio Temperature Control (PTC)

There are two PTCs (driver and passenger) built into the A/C auto

amp. They can be set at an interval of 0.5 °C (1.0 °F) in the 18° C

(60 °F) to 32 °C (90° F) temperature range by rotating the temperature

dial. The set temperature is displayed.

A/C Auto Amp. Com ponent Function CheckINFOID:0000000003775386

SYMPTOM: A/C system does not come on.

INSPECTION FLOW

1.CONFIRM SYMPTOM BY PERFORMING OPERATIONAL CHECK - AUTO MODE

1. Press AUTO switch.

2. Display should indicate AUTO. Confirm that the compressor clutch engages (sound or visual inspection). (Discharge air and blower speed will depend on ambient, in-vehicle and set temperatures.)

Can a symptom be duplicated?

YES >> GO TO 3.

NO >> GO TO 2.

2.PERFORM COMPLETE OPERATIONAL CHECK

Perform a complete operational check and check for any symptoms. Refer to HAC-4, "

Operational Check

(Front)".

Can a symptom be duplicated?

YES >> Refer to HAC-3, "How to Perform Trouble Diagnosis For Quick And Accurate Repair".

NO >> System OK.

3.CHECK FOR SERVICE BULLETINS

Check for any service bulletins.

>> GO TO 4.

4.CHECK POWER AND GROUND CIRCUIT

AWIIA0573ZZ

AWIIA0211GB

Revision: December 20092009 QX56

Page 2682 of 4171

PERIODIC MAINTENANCEMA-9

< ON-VEHICLE MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

(1) After 60,000 miles (96,000 km) or 48 months, inspect every 15,000 miles (24,000 km) or 12 months. Replace the drive belts i

f found

damaged or if the auto belt tensioner reading reaches the maximum limit.

(2) If operating mainly in dusty conditions, more frequent maintenance may be required.

(3) Maintenance-free item. For service procedures, go to the FL section.

(4) After 60,000 miles (96,000 km) or 48 months, replace every 30,000 miles (48,000 km) or 24 months.

(5) Periodic maintenance is not required. However, if valve noise increases, inspect valve clearance.

* Maintenance items and inte rvals with “*” are recommended by NISSAN for reliable vehicle operation. The owner need not perform

such maintenance in order to maintain the emission warranty or manufacturer recall liability. Other maintenance items and inter vals are

required.

CHASSIS AND BODY MAINTENANCE

Abbreviations: R = Replace. I = Inspect. Correct or replace if necessary.

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Reference

Section -

Page or -

Content Title

Perform at number of miles, kilo-

meters or months, whichever

comes first. Miles x 1,000

(km x 1,000) Months 33.75

(54)27 37.5

(60) 30 41.25

(66)33 45

(72) 36 48.75

(78)39 52.5

(84) 42 56.25

(90)45 60

(96) 48

Drive belts NOTE (1) I*MA-14

Air cleaner filter NOTE (2) [R]MA-17

EVAP vapor lines I*MA-20

Fuel lines I*MA-17

Fuel filter NOTE (3) —

Engine coolant NOTE (4) R*MA-14

Engine oil R R R R R R R R MA-18

Engine oil filterR R R R R R R R MA-18

Spark plugs (Iridium-tipped type)Replace every 105,000 miles (169,000 km).MA-19

Intake and exhaust valve clear-

ance*NOTE (5)

EM-18

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

Section

- Page or

- Content

Title

Perform at number of miles, kilometers or

months, whichever comes first. Miles x

1,000(km x

1,000)

Months 3.75

(6)

3 7.5

(12)

6 11 . 2 5

(18)

9 15

(24)

12 18.75

(30)

15 22.5

(36)

18 26.25

(42)

21 30

(48)

24

Brake lines and cables IIMA-30

Brake pads and rotors II I IMA-30

Automatic transmission fluid, transfer fluid and

differential gear oil NOTE (1)

IIMA-23

,

MA-25

,

MA-27

,

MA-26

Steering gear and linkage, axle and suspension

parts II I I

MA-31,

MA-32

Tire Rotation NOTE (2) MA-29

Drive shaft boots and propeller shaft (4WD)II I IMA-26

Exhaust system II I IMA-22

In-cabin microfilter RRMA-22

Revision: December 20092009 QX56

Page 2683 of 4171

MA-10

< ON-VEHICLE MAINTENANCE >

PERIODIC MAINTENANCE

(1) If towing a trailer, or using a car-top carrier, or driving on rough or muddy roads, change (not just inspect) oil at every 30,000 miles

(48,000 km) or 24 months. Using automatic transmission fluid other than Genui ne NISSAN Matic S ATF or Matic J ATF will cause

deterioration in driveability and automatic transmission durability, and may damage the automatic transmission, which is not

covered by the INFINITI new vehicle limited warranty.

(2) Refer to “Tire rotation” unde r the “General maintenance” heading earlier in this section.

Schedule 2INFOID:0000000003776983

EMISSION CONTROL SYSTEM MAINTENANCE

Abbreviations: R = Replace. I = Inspect. Correct or r eplace if necessary. [ ]: At the mileage intervals only

(1) After 60,000 miles (96,000 km) or 48 months, inspect every 15,000 miles (24,000 km) or 12 months. Replace the drive belts if found

damaged or if the auto belt tensioner reading reaches the maximum limit.

(2) Maintenance-free item. For service procedures, go to FL section.

(3) After 60,000 miles (96,000 km) or 48 months, replace every 30,000 miles (48,000 km) or 24 months.

(4) Periodic maintenance is not required. However, if valve noise increases, inspect valve clearance.

* Maintenance items and intervals with “*” are recommended by NISSAN for reliable vehicle operation. The owner need not perform

such maintenance in order to maintain the emission warranty or manufacturer recall liability. Other maintenance items and inter vals are

required.

CHASSIS AND BODY MAINTENANCE

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Reference

Section

- Page or

- Content

Title

Perform at number of miles, kilometers or

months, whichever comes first. Miles x

1,000(km x

1,000)

Months 33.75

(54)

27 37.5

(60)

30 41.25

(66)

33 45

(72)

36 48.75

(78)

39 52.5

(84)

42 56.25

(90)

45 60

(96)

48

Brake lines and cables IIMA-30

Brake pads and rotors IIIIMA-30

Automatic transmission fluid, transfer fluid and

differential gear oil NOTE (1)

IIMA-23

,

MA-25

,

MA-27

,

MA-26

Steering gear and linkage, axle and suspen-

sion parts IIIIMA-31,

MA-32

Tire Rotation NOTE (2) MA-29

Drive shaft boots and propeller shaft (4WD)IIIIMA-26

Exhaust system IIIIMA-22

In-cabin microfilter RRMA-22

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Reference

Section - Page

or - Content Ti- tle

Perform at number of miles, kilometers

or months, whichever comes first. Miles x 1,000

(km x 1,000)

Months 7.5

(12)

6 15

(24)

12 22.5

(36)

18 30

(48)

24 37.5

(60)

30 45

(72)

36 52.5

(84)

42 60

(96)

48

Drive belts NOTE (1) I*MA-14

Air cleaner filter [R][R]MA-17

EVAP vapor lines I*I*MA-20

Fuel lines I*I*MA-17

Fuel filter NOTE (2) —

Engine coolant NOTE (3) R*MA-14

Engine oil R R R R R R R R MA-18

Engine oil filterR R R R R R R R MA-18

Spark plug (Iridium - tipped type) Replace every 105,000 miles (169,000 km).MA-19

Intake and exhaust valve clearance* NOTE (4) EM-18

Revision: December 20092009 QX56

Page 2702 of 4171

CHASSIS AND BODY MAINTENANCEMA-29

< ON-VEHICLE MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

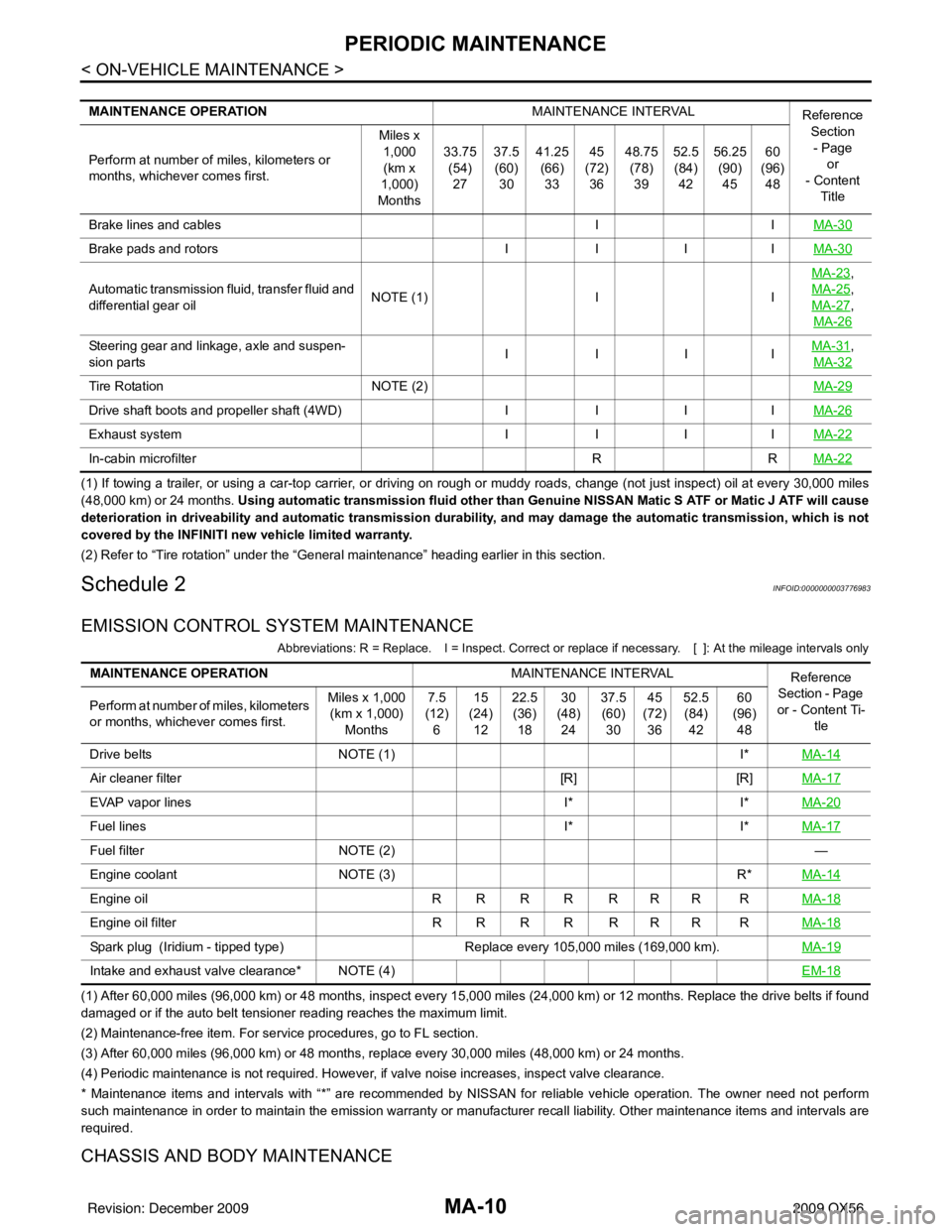

3. Install balance weight in the position shown.

CAUTION:

• Do not install the inner bala nce weight before installing

the outer balance weight.

• Before installing the balance weight, be sure to clean the mating surface of the road wheel.

• When installing balance weight (1) to road wheel, set it into the grooved area (A) on the inner wall of the road wheel as shown

so that the balance weight cent er (B) is aligned with the bal-

ancer machine indication position (angle) (C).

CAUTION:

• Always use genuine NISSAN adhesive balance weights.

• Balance weights are non-re usable; always replace with

new ones.

• Do not install more than th ree sheets of balance weight.

4. If calculated balance weight value exceeds 50 g (1.76 oz), install two balance weight sheets in line with each other as shown.

CAUTION:

Do not install one balance weight sheet on top another.

5. Start balancer machine again.

6. Install balance weight on inner side of road wheel in the bal- ancer machine indication position (angle).

CAUTION:

Do not install more than two balance weights.

7. Start balancer machine. Make sure that inner and outer residual imbalance values are 5 g (0.17 oz) each or below.

8. If either residual imbalance value exceeds 5 g (0.17 oz), repeat installation procedures.

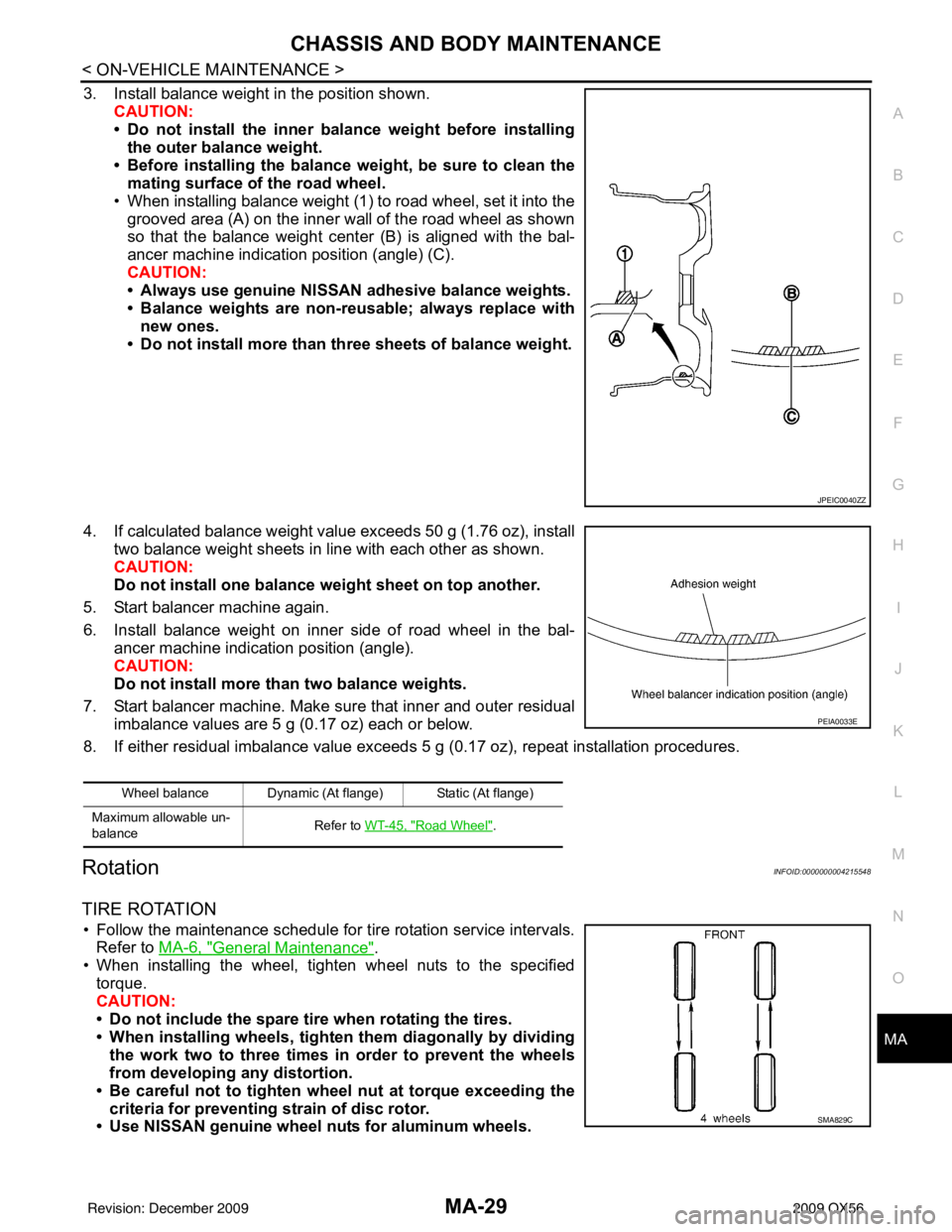

RotationINFOID:0000000004215548

TIRE ROTATION

• Follow the maintenance schedule for tire rotation service intervals.

Refer to MA-6, "

General Maintenance".

• When installing the wheel, tighten wheel nuts to the specified

torque.

CAUTION:

• Do not include the spare tire when rotating the tires.

• When installing wheels, tighte n them diagonally by dividing

the work two to three times in order to prevent the wheels

from developing any distortion.

• Be careful not to tighten wh eel nut at torque exceeding the

criteria for preventing strain of disc rotor.

• Use NISSAN genuine wheel nuts for aluminum wheels.

JPEIC0040ZZ

Wheel balance Dynamic (At flange) Static (At flange)

Maximum allowable un-

balance Refer to WT-45, "

Road Wheel".

PEIA0033E

SMA829C

Revision: December 20092009 QX56

Page 4084 of 4171

WT-42

< ON-VEHICLE REPAIR >

WHEEL AND TIRE ASSEMBLY

3. Install balance weight in the position shown.CAUTION:

• Do not install the inner bala nce weight before installing

the outer balance weight.

• Before installing the balance weight, be sure to clean the mating surface of the road wheel.

• When installing balance weight (1) to road wheel, set it into the grooved area (A) on the inner wall of the road wheel as shown

so that the balance weight center (B) is aligned with the bal-

ancer machine indication position (angle) (C).

CAUTION:

• Always use genuine NISSAN adhesive balance weights.

• Balance weights are non-reusable; always replace withnew ones.

• Do not install more than three sheets of balance weight.

4. If calculated balance weight value exceeds 50 g (1.76 oz.), install two balance weight sheets in line with each other as

shown.

CAUTION:

Do not install one balance weight sheet on top another.

5. Start balancer machine again.

6. Install balance weight on inner side of road wheel in the bal- ancer machine indication position (angle).

CAUTION:

Do not install more than two balance weights.

7. Start balancer machine. Make sure that inner and outer residual imbalance values are 5 g (0.17 oz.) each or below.

8. If either residual imbalance value exceeds 5 g (0.17 oz.), repeat installation procedures.

TIRE ROTATION

• Follow the maintenance schedule for tire rotation service intervals.

Refer to MA-6, "

General Maintenance".

• When installing the wheel, tighten wheel nuts to the specified

torque.

CAUTION:

• Do not include the spare tire when rotating the tires.

• When installing wheels, tighten them diagonally by dividing

the work two to three times in order to prevent the wheels

from developing any distortion.

• Be careful not to tighten wheel nut at torque exceeding the criteria for preventing strain of disc rotor.

• Use NISSAN genuine wheel nuts for aluminum wheels.

JPEIC0040ZZ

Wheel balance Dynamic (At flange) Static (At flange)

Maximum allowable un-

balance Refer to

WT-45, "

Road Wheel".

PEIA0033E

Wheel nut tightening

torque : 133 N·m (14 kg-m, 98 ft-lb)

SMA829C

Revision: December 20092009 QX56