Air INFINITI QX56 2010 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 476 of 4210

FRONT DISC BRAKEBR-31

< ON-VEHICLE REPAIR >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

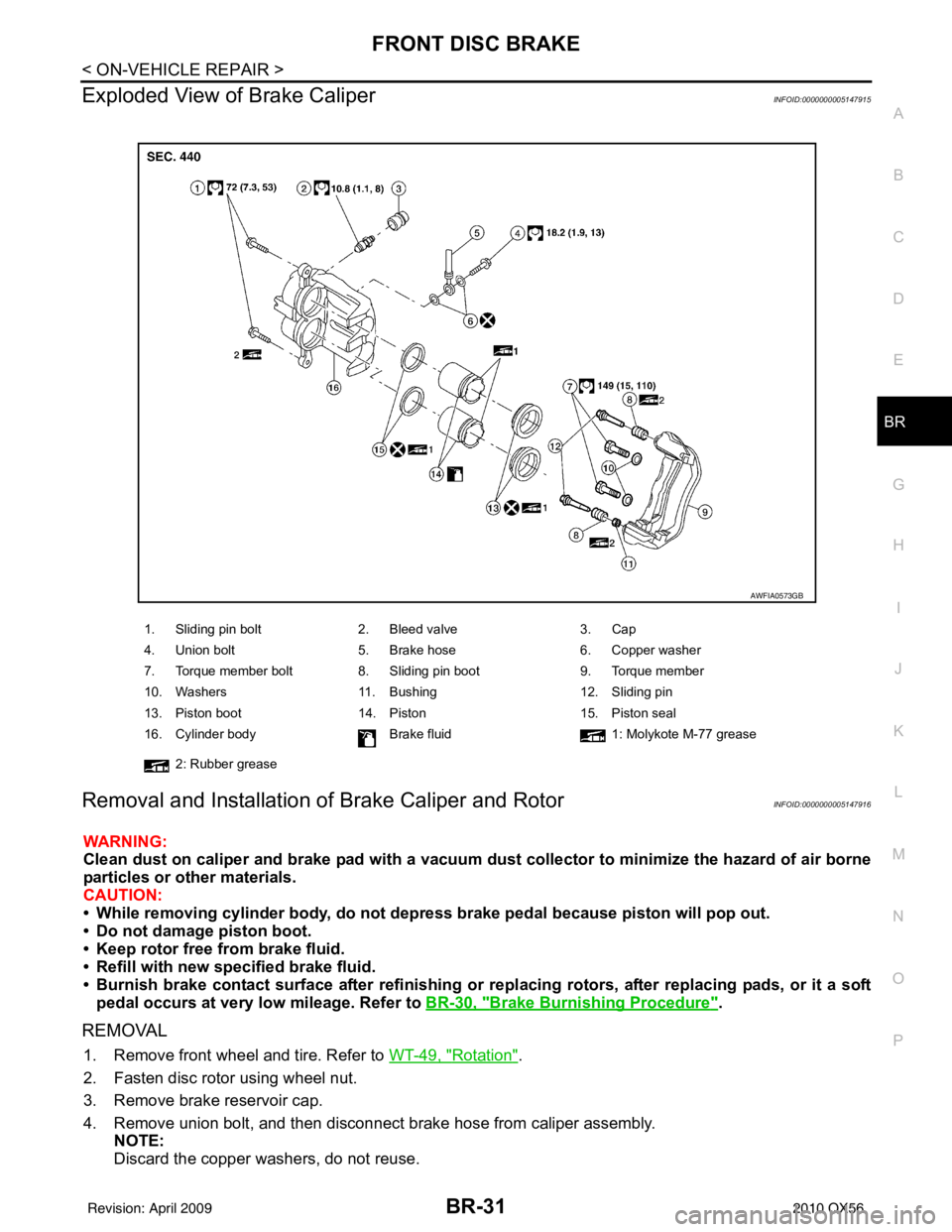

Exploded View of Brake CaliperINFOID:0000000005147915

Removal and Installation of Brake Caliper and RotorINFOID:0000000005147916

WARNING:

Clean dust on caliper and brake pad with a vacuum dust collector to minimize the hazard of air borne

particles or other materials.

CAUTION:

• While removing cylinder bod y, do not depress brake pedal because piston will pop out.

• Do not damage piston boot.

• Keep rotor free from brake fluid.

• Refill with new specified brake fluid.

• Burnish brake contact surface after refinishing or replacing rotors, after replacing pads, or it a soft

pedal occurs at very low mileage. Refer to BR-30, "

Brake Burnishing Procedure".

REMOVAL

1. Remove front wheel and tire. Refer to WT-49, "Rotation".

2. Fasten disc rotor using wheel nut.

3. Remove brake reservoir cap.

4. Remove union bolt, and then disconnect brake hose from caliper assembly. NOTE:

Discard the copper washers, do not reuse.

1. Sliding pin bolt 2. Bleed valve 3. Cap

4. Union bolt 5. Brake hose 6. Copper washer

7. Torque member bolt 8. Sliding pin boot 9. Torque member

10. Washers 11. Bushing 12. Sliding pin

13. Piston boot 14. Piston 15. Piston seal

16. Cylinder body Brake fluid1: Molykote M-77 grease

2: Rubber grease

AWFIA0573GB

Revision: April 20092010 QX56

Page 477 of 4210

BR-32

< ON-VEHICLE REPAIR >

FRONT DISC BRAKE

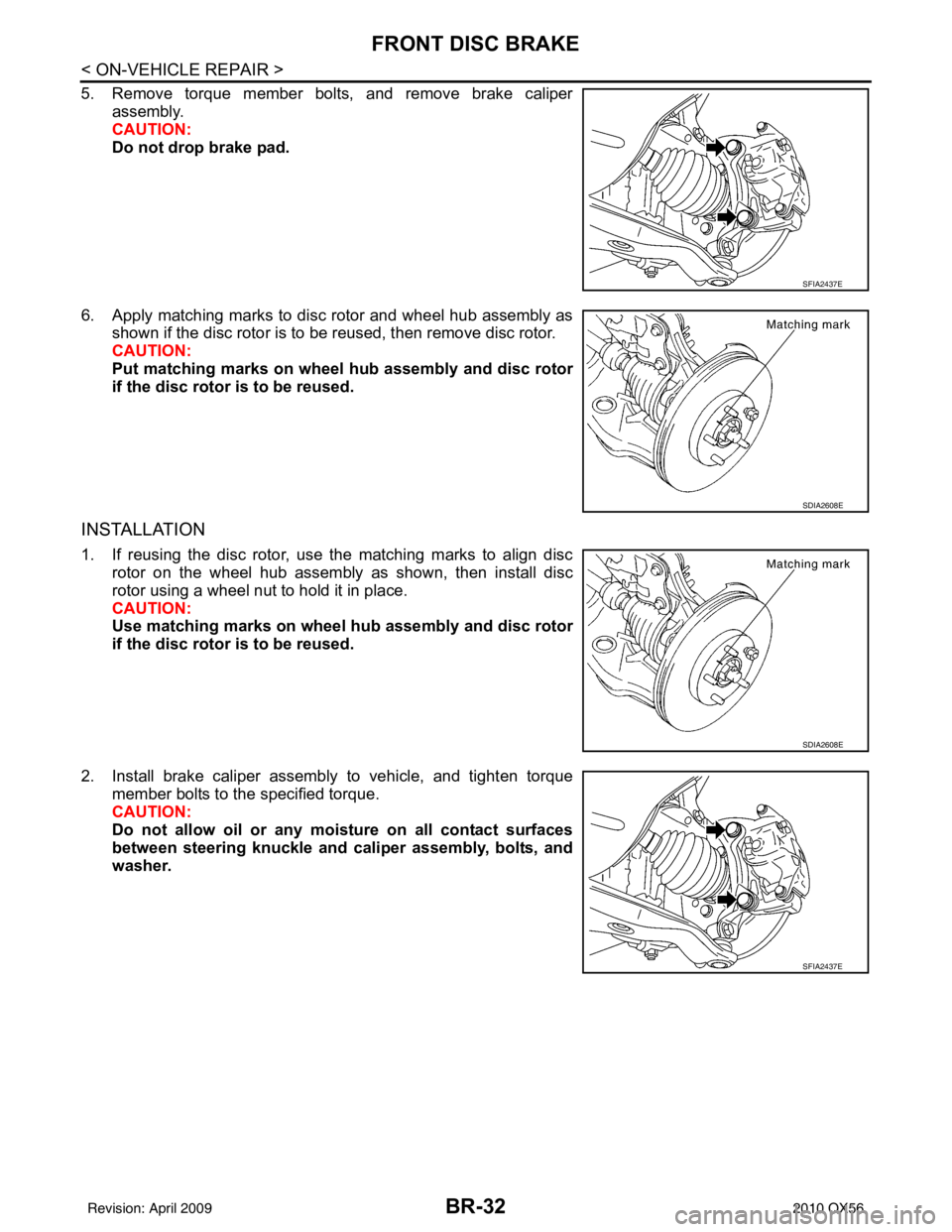

5. Remove torque member bolts, and remove brake caliperassembly.

CAUTION:

Do not drop brake pad.

6. Apply matching marks to disc rotor and wheel hub assembly as shown if the disc rotor is to be reused, then remove disc rotor.

CAUTION:

Put matching marks on wheel hub assembly and disc rotor

if the disc rotor is to be reused.

INSTALLATION

1. If reusing the disc rotor, use the matching marks to align discrotor on the wheel hub assembly as shown, then install disc

rotor using a wheel nut to hold it in place.

CAUTION:

Use matching marks on wheel hub assembly and disc rotor

if the disc rotor is to be reused.

2. Install brake caliper assembly to vehicle, and tighten torque member bolts to the specified torque.

CAUTION:

Do not allow oil or any moisture on all contact surfaces

between steering knuckle and caliper assembly, bolts, and

washer.

SFIA2437E

SDIA2608E

SDIA2608E

SFIA2437E

Revision: April 20092010 QX56

Page 478 of 4210

FRONT DISC BRAKEBR-33

< ON-VEHICLE REPAIR >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

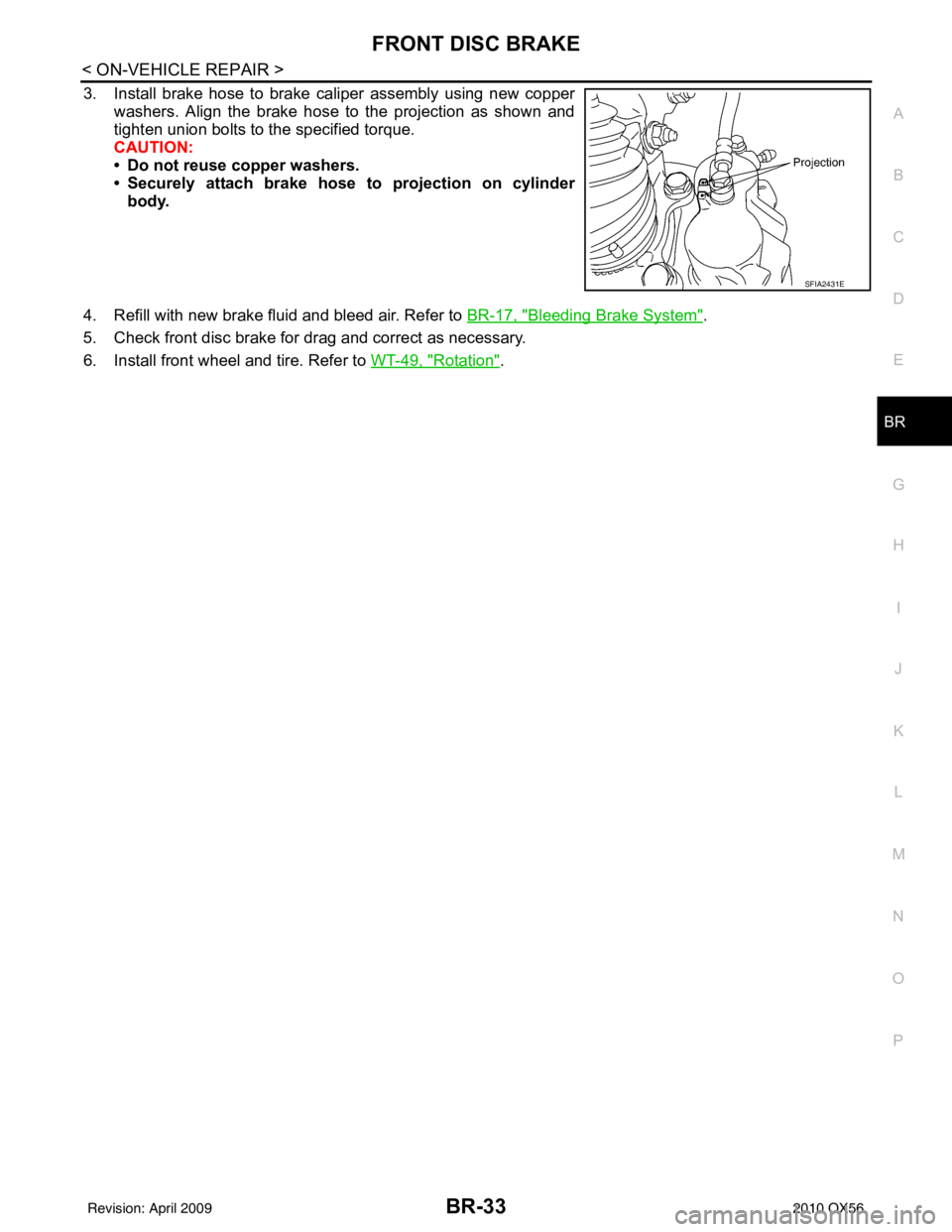

3. Install brake hose to brake caliper assembly using new copper washers. Align the brake hose to the projection as shown and

tighten union bolts to the specified torque.

CAUTION:

• Do not reuse copper washers.

• Securely attach brake hose to projection on cylinderbody.

4. Refill with new brake fluid and bleed air. Refer to BR-17, "

Bleeding Brake System".

5. Check front disc brake for drag and correct as necessary.

6. Install front wheel and tire. Refer to WT-49, "

Rotation".

SFIA2431E

Revision: April 20092010 QX56

Page 479 of 4210

BR-34

< ON-VEHICLE REPAIR >

REAR DISC BRAKE

REAR DISC BRAKE

Exploded View of Brake PadsINFOID:0000000005147917

Removal and Installation of Brake PadINFOID:0000000005147918

WARNING:

Clean dust on caliper and brake pad with a vacuum dust collector to minimize the hazard of air borne

particles or other materials.

CAUTION:

• While removing cylinder body, do not depress brake pedal because piston will pop out.

• It is not necessary to disconnect brake hose connection except for disassembly or replacement of

caliper assembly. In this case, ha ng cylinder body with a wire so as not to stretch brake hose.

• Do not damage piston boot.

• If any shim is subject to serious corrosion, replace it with a new one.

• Always replace shim and shim cover as a set when replacing brake pads.

• Keep rotor free from brake fluid.

• Burnish the brake pads and disc rotor mutually contacting surfaces, after refinishing or replacing

rotors, after replacing pads, or if a soft pedal occurs at very low mileage.

REMOVAL

1. Remove rear wheel and tires using power tools.

2. Partially drain some brake fluid from the reservoir.

3. Remove the sliding sleeves and sliding pin bolts from the cylinder body.

4. Support the cylinder body with wire, remove pads, shims, cover and retainers.

INSTALLATION

1. Push piston in using suitable tool.

CAUTION:

By pushing in piston, brake fluid returns to mast er cylinder reservoir tank. Watch the brake fluid

level in the reservoir tank.

NOTE:

Using a suitable tool, makes it easier to push in the piston.

1. Inner shim cover 2. Outer pad3. Outer multi-layered shim

4. Pad wear sensor 5. Inner pad (RH)6. Pad retainer

7. Inner pad 8. Inner shim

1: Molykote M-77 grease

AWFIA0293GB

Revision: April 20092010 QX56

Page 480 of 4210

REAR DISC BRAKEBR-35

< ON-VEHICLE REPAIR >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

2. Apply Molykote M-77 grease to knuckle slide where brake pad contacts and to the outer multi-layered

shim, pad retainers and inner shim.

CAUTION:

Do not get grease on the brake pads or brake rotor friction surfaces.

3. Install pads, shims, cover and retainers to cylinder body.

4. Apply rubber grease to the sliding sleeves and install cylinder body, sliding sleeves and sliding pin bolts and tighten to specification. Refer to BR-35, "

Exploded View of Brake Caliper".

5. Check rear disc brake for drag.

6. Install rear wheel and tires. Refer to WT-49, "

Rotation".

Brake Burnishing ProcedureINFOID:0000000005147919

Burnish contact surfaces between disc rotors and pads according to following procedure after refinishing or

replacing rotors, after replacing pads, or if a soft pedal occurs at very low mileage.

CAUTION:

• Be careful of vehicle speed because the brake does not operate easily until pad and disc rotor are securely seated.

• Only perform this procedure under safe road and traffic conditions. Use extreme caution.

1. Drive vehicle on straight, flat road.

2. Depress brake pedal with the power to stop vehicle within 3 to 5 seconds until the vehicle stops.

3. Drive without depressing brake for a few minutes to cool the brake.

4. Repeat steps 1 through 3 until pad and disc rotor are securely seated.

Exploded View of Brake CaliperINFOID:0000000005147920

1. Union bolt 2. Brake hose 3. Copper washer

4. Cap 5. Bleed valve 6. Sliding pin bolt

7. Cylinder body 8. Piston seal 9. Piston

10. Piston boot 11. Knuckle slide 12. Sliding sleeve boot

AWFIA0423GB

Revision: April 20092010 QX56

Page 481 of 4210

BR-36

< ON-VEHICLE REPAIR >

REAR DISC BRAKE

Removal and Installation of Brake Caliper and Disc Rotor

INFOID:0000000005147921

WARNING:

Clean dust on caliper and brake pad with a vacuum dust collector to minimize the hazard of air borne

particles or other materials.

CAUTION:

• While removing cylinder body, do not depress brake pedal because piston will pop out.

• Do not damage piston boot.

• Keep rotor free from brake fluid.

• Refill with new specified brake fluid.

• Burnish brake contact surface after refinishing or re placing rotors, after replacing pads, or it a soft

pedal occurs at very low mileage. Refer to BR-35, "

Brake Burnishing Procedure".

REMOVAL

1. Remove rear wheel and tire using power tool.

2. Fasten disc rotor using wheel nut.

3. Remove brake reservoir cap.

4. Remove union bolt and cylinder body bolts, then remove cylin-

der body.

NOTE:

Discard the copper washers, do not reuse.

5. Apply matching marks to disc rotor and wheel hub assembly if the disc rotor is to be reused, then remove disc rotor.

CAUTION:

Put matching marks on wheel hub assembly and disc rotor

if the disc rotor is to be reused.

INSTALLATION

1. If reusing the disc rotor, use the matching marks to align disc rotor on the wheel hub assembly, then install

disc rotor using a wheel nut to hold it in place.

CAUTION:

Use matching marks on wheel hub assembly and di sc rotor if the disc rotor is to be reused.

2. Install cylinder body and tighten cylinder body bolts to specification. CAUTION:

Before installing cylinder body to the vehic le, wipe off mating surface of cylinder body.

3. Install brake hose to cylinder body with new copper washers and tighten union bolt to specification.

CAUTION:

• Do not reuse copper washers.

• Securely attach brake hose to projection on cylinderbody.

4. Refill with new brake fluid and bleed. Refer to BR-17, "

Bleeding

Brake System".

5. Check rear disc brake for drag and correct as necessary.

6. Install rear wheel and tire. Refer to WT-49, "

Rotation".

13. Sliding sleeveB. Brake fluid R. Rubber grease

M. Molykote M-77 Front

LFIA0211E

SFIA1137E

Revision: April 20092010 QX56

Page 484 of 4210

FRONT DISC BRAKEBR-39

< DISASSEMBLY AND ASSEMBLY >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

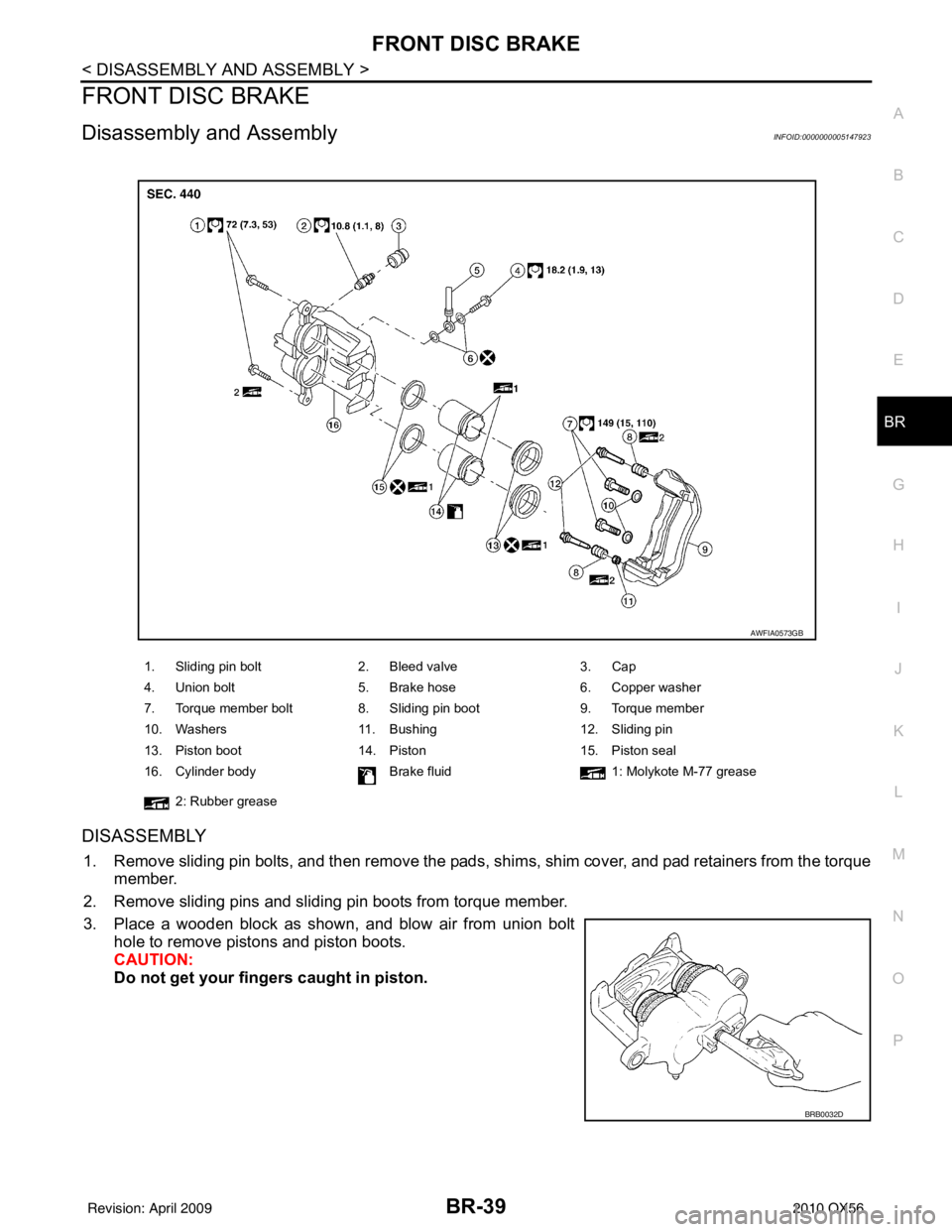

FRONT DISC BRAKE

Disassembly and AssemblyINFOID:0000000005147923

DISASSEMBLY

1. Remove sliding pin bolts, and then remove the pads, sh ims, shim cover, and pad retainers from the torque

member.

2. Remove sliding pins and sliding pin boots from torque member.

3. Place a wooden block as shown, and blow air from union bolt hole to remove pistons and piston boots.

CAUTION:

Do not get your fingers caught in piston.

1. Sliding pin bolt 2. Bleed valve 3. Cap

4. Union bolt 5. Brake hose 6. Copper washer

7. Torque member bolt 8. Sliding pin boot 9. Torque member

10. Washers 11. Bushing 12. Sliding pin

13. Piston boot 14. Piston 15. Piston seal

16. Cylinder body Brake fluid1: Molykote M-77 grease

2: Rubber grease

AWFIA0573GB

BRB0032D

Revision: April 20092010 QX56

Page 487 of 4210

BR-42

< DISASSEMBLY AND ASSEMBLY >

REAR DISC BRAKE

REAR DISC BRAKE

Disassembly and AssemblyINFOID:0000000005147924

DISASSEMBLY

1. Remove pads from cylinder body.

2. Remove sliding sleeve and boot from cylinder body.

3. Place a wooden block as shown, and blow air into union bolthole to remove piston and piston boot.

CAUTION:

Do not get your fingers caught in piston.

1. Union bolt 2. Brake hose3. Copper washer

4. Cap 5. Bleed valve6. Sliding pin bolt

7. Cylinder body 8. Piston seal9. Piston

10. Piston boot 11. Knuckle slide12. Sliding sleeve boot

13. Sliding sleeve B. Brake fluidR. Rubber grease

M. Molykote M-77 Front

AWFIA0423GB

BRD0041D

Revision: April 20092010 QX56

Page 491 of 4210

BR-46

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Brake Booster

INFOID:0000000005147927

Unit: mm (in)

Check ValveINFOID:0000000005147928

Front Disc BrakeINFOID:0000000005147929

Unit: mm (in)

Rear Disc BrakeINFOID:0000000005147930

Unit: mm (in)

Output rod length [at -66.7 kPa (-500 mmHg, -19.69 inHg) vacuum] 15.6 - 15.9 (0.614 - 0.626)

Input rod installation length (B) 151 (5.94)

SBR208E

WFIA0382E

Vacuum leakage

[at vacuum of – 66.7 kPa(– 500 mmHg, – 19.69 inHg)]Within 1.3 kPa (10 mmHg, 0.39 inHg) of vacuum for 15 seconds

Brake model

AD41VA

Brake pad Standard thickness (new)

12.0 (0.476)

Repair limit thickness 1.0 (0.039)

Disc rotor Standard thickness (new)

30 (1.181)

Repair limit thickness 28 (1.102)

Maximum uneven wear (measured at 8 positions) 0.015 (0.0006)

Runout limit (with it attached to the vehicle) 0.03 (0.001)

Brake model AD14VE

Brake pad Standard thickness (new)

12.0 (0.472)

Repair limit thickness 1.0 (0.039)

Revision: April 20092010 QX56

Page 492 of 4210

SERVICE DATA AND SPECIFICATIONS (SDS)BR-47

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

DE

G H

I

J

K L

M A

B

BR

N

O P

Disc rotor Standard thickness (new)

14.0 (0.551)

Repair limit thickness 12.0 (0.472)

Maximum uneven wear (measured at 8 positions) 0.015 (0.0006)

Runout limit (with it attached to the vehicle) 0.05 (0.002)

Brake model

AD14VE

Revision: April 20092010 QX56