belt INFINITI QX56 2010 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 3641 of 4210

PRECAUTIONSST-3

< PRECAUTION >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005399828

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wheel Rotation After Battery Disconnect

INFOID:0000000005288074

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecti ng both battery cables with the ignition knob in the

″ LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS , an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

Revision: April 20092010 QX56

Page 3650 of 4210

ST-12

< SYMPTOM DIAGNOSIS >

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

SYMPTOM DIAGNOSIS

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000005147864

Use chart below to help you find the cause of the symp tom. If necessary, repair or replace these parts.

×: ApplicableReference page

ST-13, "

Checking Fluid Level

"

ST-13, "

Air Bleeding Hydraulic System

"

ST-36ST-36ST-36ST-13ST-35ST-37

EM-13, "

Checking Drive Belts

"

ST-35ST-35ST-37ST-35ST-20ST-37

DLN-184, "

NVH Troubleshooting Chart

"

DLN-208, "

NVH Troubleshooting Chart

"

FAX-5, "

NVH Troubleshooting Chart

"

FSU-5, "

NVH Troubleshooting Chart

"

WT-43, "

NVH Troubleshooting Chart

"

WT-43, "

NVH Troubleshooting Chart

"

FAX-5, "

NVH Troubleshooting Chart

"

BR-6, "

NVH Troubleshooting Chart

"

Possible cause and suspect-

ed parts

Fluid level

Air in hydraulic system

Outer socket ball joint swinging force

Outer socket ball joint rotating torque

Outer socket ball joint end play

Steering fluid leakage

Steering wheel play

Steering gear rack sliding force

Drive belt looseness

Improper steering wheel

Improper installation or looseness of tilt lock lever

Mounting rubber deterioration

Steering column deformation or damage

Improper installation or looseness of steering column

Steering linkage looseness

PROPELLER SHAFT

FRONT FINAL DRIVE

WHEEL HUB

SUSPENSION

TIRES

ROAD WHEEL

DRIVE SHAFT

BRAKES

Symptom

Noise

× × ××××× × × ××××××× ×

Shake ×××× ××××× ×

Vibration ××××× × ××× ×

Shimmy ××× × ×××× ×

Shudder × × ×××× ×

Revision: April 20092010 QX56

Page 3655 of 4210

POWER STEERING OIL PUMPST-17

< ON-VEHICLE REPAIR >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

POWER STEERING OIL PUMP

On-Vehicle Inspection and ServiceINFOID:0000000005147869

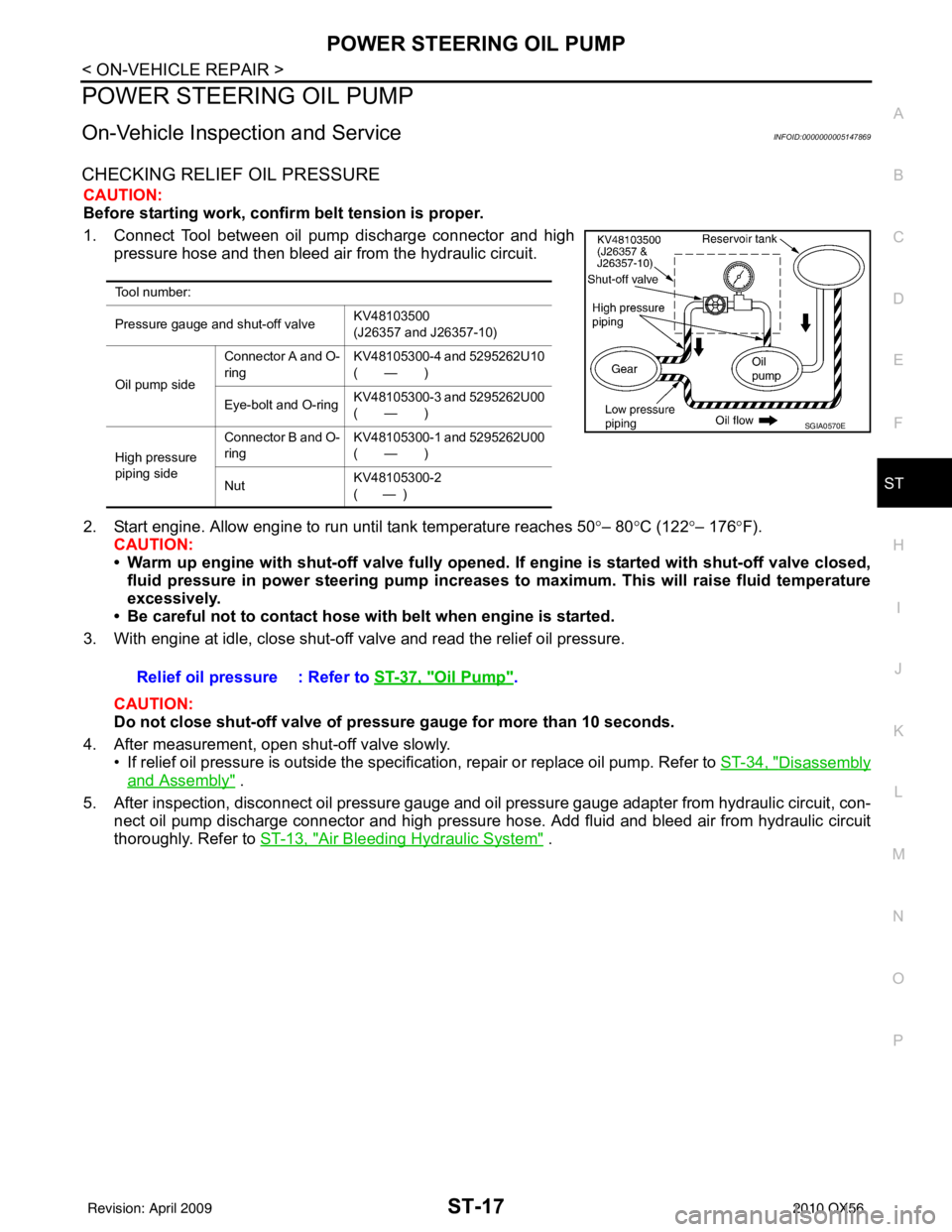

CHECKING RELIEF OIL PRESSURE

CAUTION:

Before starting work, confirm belt tension is proper.

1. Connect Tool between oil pump discharge connector and high pressure hose and then bleed air from the hydraulic circuit.

2. Start engine. Allow engine to run until tank temperature reaches 50 °– 80° C (122° – 176°F).

CAUTION:

• Warm up engine with shut-off valve fully opened. If engine is started with shut-off valve closed,

fluid pressure in power steering pump increases to maximum. This will raise fluid temperature

excessively.

• Be careful not to contact hose with belt when engine is started.

3. With engine at idle, close shut-off valve and read the relief oil pressure.

CAUTION:

Do not close shut-off valve of pressure gauge for more than 10 seconds.

4. After measurement, open shut-off valve slowly. • If relief oil pressure is outside the specification, repair or replace oil pump. Refer to ST-34, "

Disassembly

and Assembly" .

5. After inspection, disconnect oil pressure gauge and oil pressure gauge adapter from hydraulic circuit, con-

nect oil pump discharge connector and high pressure hose. Add fluid and bleed air from hydraulic circuit

thoroughly. Refer to ST-13, "

Air Bleeding Hydraulic System" .

Tool number:

Pressure gauge and shut-off valve KV48103500

(J26357 and J26357-10)

Oil pump side Connector A and O-

ring

KV48105300-4 and 5295262U10

(—)

Eye-bolt and O-ring KV48105300-3 and 5295262U00

(—)

High pressure

piping side Connector B and O-

ring

KV48105300-1 and 5295262U00

(—)

Nut KV48105300-2

( — )

SGIA0570E

Relief oil pressure : Refer to

ST-37, "Oil Pump".

Revision: April 20092010 QX56

Page 3664 of 4210

ST-26

< REMOVAL AND INSTALLATION >

POWER STEERING OIL PUMP

POWER STEERING OIL PUMP

Removal and InstallationINFOID:0000000005147874

REMOVAL

1. Drain power steering fluid from reservoir tank.

2. Remove engine room cover. Refer to EM-24, "

Removal and Installation".

3. Remove air duct assembly. Refer to EM-25, "

Removal and Installation".

4. Remove power steering reservoir tank.

5. Remove serpentine drive belt belt from auto tensioner and power steering pump. Refer to EM-13,

"Removal and Installation".

6. Disconnect pressure sensor electrical connector.

7. Remove high pressure and low pressure piping from power steering oil pump. Refer to ST-27

.

8. Remove bolts, then remove power steering pump.

INSTALLATION

Installation is in the reverse order of removal. Refer to ST-27 for tightening torque.

• After installation, bleed air. Refer to ST-13, "

Air Bleeding Hydraulic System".

NOTE:

Belt tension is automatic and requires no adjustment.

Revision: April 20092010 QX56

Page 3676 of 4210

STR-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION STR

A

STR

N

O P

CONTENTS

STARTING SYSTEM

PRECAUTION ....... ........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

Precaution for Power Generation Variable Voltage

Control System ..........................................................

3

PREPARATION ............................................4

PREPARATION .............................................. .....4

Special Service Tool ........................................... ......4

Commercial Service Tool ..........................................4

BASIC INSPECTION ....................................5

DIAGNOSIS AND REPAIR WORKFLOW ..... .....5

Work Flow ........................................................... ......5

FUNCTION DIAGNOSIS ...............................8

STARTING SYSTEM ...................................... .....8

System Diagram .................................................. ......8

System Description ...................................................8

Component Parts Location ........................................8

Component Description ............................................9

COMPONENT DIAGNOSIS .........................10

B TERMINAL CIRCUIT .....................................10

Description ........................................................... ....10

Diagnosis Procedure ...............................................10

S CONNECTOR CIRCUIT .................................12

Description ...............................................................12

Diagnosis Procedure ...............................................12

STARTING SYSTEM .........................................14

Wiring Diagram .................................................... ....14

SYMPTOM DIAGNOSIS ..............................18

STARTING SYSTEM .........................................18

Symptom Table ................................................... ....18

ON-VEHICLE REPAIR .................................19

STARTER MOTOR ...........................................19

Removal and Installation ..................................... ....19

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... ...

20

STARTER MOTOR ...........................................20

Starter .................................................................. ....20

Revision: April 20092010 QX56

Page 3677 of 4210

STR-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005315461

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005315460

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: April 20092010 QX56

Page 3698 of 4210

TM-3

CEF

G H

I

J

K L

M A

B

TM

N

O P

Diagnosis Procedure ...........................................

....

80

P1752 INPUT CLUTCH SOLENOID ..................82

Description .......................................................... ....82

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ....

82

On Board Diagnosis Logic ......................................82

Possible Cause .......................................................82

DTC Confirmation Procedure ..................................82

Diagnosis Procedure ...............................................82

P1757 FRONT BRAKE SOLENOID ...................84

Description .......................................................... ....84

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ....

84

On Board Diagnosis Logic ......................................84

Possible Cause .......................................................84

DTC Confirmation Procedure ..................................84

Diagnosis Procedure ...............................................84

P1762 DIRECT CLUTCH SOLENOID ................86

Description .......................................................... ....86

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ....

86

On Board Diagnosis Logic ......................................86

Possible Cause .......................................................86

DTC Confirmation Procedure ..................................86

Diagnosis Procedure ...............................................86

P1767 HIGH AND LOW REVERSE CLUTCH

SOLENOID .........................................................

88

Description .......................................................... ....88

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ....

88

On Board Diagnosis Logic ......................................88

Possible Cause .......................................................88

DTC Confirmation Procedure ..................................88

Diagnosis Procedure ...............................................88

P1772 LOW COAST BRAKE SOLENOID .........90

Description .......................................................... ....90

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ....

90

On Board Diagnosis Logic ......................................90

Possible Cause .......................................................90

DTC Confirmation Procedure ..................................90

Diagnosis Procedure ...............................................90

P1774 LOW COAST BRAKE SOLENOID .........92

Description .......................................................... ....92

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ....

92

On Board Diagnosis Logic ......................................92

Possible Cause .......................................................92

DTC Confirmation Procedure ..................................92

Diagnosis Procedure ...............................................93

MAIN POWER SUPPLY AND GROUND CIR-

CUIT ....................................................................

94

Diagnosis Procedure ........................................... ....94

CLOSED THROTTLE POSITION AND WIDE

OPEN THROTTLE POSITION CIRCUIT ...........

96

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ....

96

Diagnosis Procedure ...............................................96

BRAKE SIGNAL CIRCUIT ................................97

CONSULT-III Reference Va lue in Data Monitor

Mode .................................................................... ....

97

Diagnosis Procedure ...............................................97

TOW MODE SWITCH .......................................98

Description ...............................................................98

Diagnosis Procedure ...............................................98

A/T SHIFT LOCK SYSTEM ...............................99

Description ...............................................................99

Terminals And Reference Values ............................99

Wiring Diagram - A/T SH IFT LOCK SYSTEM - .....100

Component Inspection ......................................... ..103

ECU DIAGNOSIS .......................................106

TCM .................................................................106

Reference Value .................................................. ..106

Wiring Diagram — A/T CONTROL SYSTEM — .. ..108

Fail-Safe .............................................................. ..117

DTC Inspection Priority Chart ................................119

DTC No. Index .......................................................119

DTC Alphabetical Index .........................................120

SYMPTOM DIAGNOSIS ............................121

SYSTEM SYMPTOM .......................................121

Symptom Table ................................................... ..121

PRECAUTION ............................................143

PRECAUTIONS ...............................................143

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ..

143

Precaution for On Board Diagnosis (OBD) System

of A/T and Engine ................................................ ..

143

Precaution .............................................................143

Service Notice or Precaution .................................144

PREPARATION .........................................146

PREPARATION ...............................................146

Special Service Tool ............................................ ..146

Commercial Service Tool ......................................147

ON-VEHICLE MAINTENANCE ..................148

A/T FLUID .......................................................148

Checking the A/T Fluid (ATF) .............................. ..148

Changing the A/T Fluid (ATF) ................................150

A/T FLUID COOLER .......................................152

A/T Fluid Cooler Cleaning .....................................152

Inspection ..............................................................154

Revision: April 20092010 QX56

Page 3838 of 4210

PRECAUTIONSTM-143

< PRECAUTION >

CEF

G H

I

J

K L

M A

B

TM

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005148716

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

Precaution for On Board Diagnosis (OBD) System of A/T and EngineINFOID:0000000005148717

The ECM has an on board diagnostic system . It will light up the malfunction indicator lamp (MIL) to warn the

driver of a malfunction causing emission deterioration.

CAUTION:

• Be sure to turn the ignition switch “OFF” and disconnect the negative battery cable before any repair or inspection work. The open/short circuit of related switches, sen sors, solenoid valves, etc. Will

cause the MIL to light up.

• Be sure to connect and lock the connectors secure ly after work. A loose (unlocked) connector will

cause the MIL to light up due to an open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

• Be sure to route and secure the harnesses properly after work. Interference of the harness with a

bracket, etc. May cause the MIL to li ght up due to a short circuit.

• Be sure to connect rubber tubes properly afte r work. A misconnected or disconnected rubber tube

may cause the MIL to light up due to a malfunction of the EGR system or fuel injection system, etc.

• Be sure to erase the unnecessary malfunction informa tion (repairs completed) from the TCM and

ECM before returning the vehicle to the customer.

PrecautionINFOID:0000000005148718

NOTE:

If any malfunctions occur in th e RE5R05A model transmission, repl ace the entire transmission assem-

bly.

• Before connecting or disconn ecting the TCM harness connec-

tor, turn ignition switch “O FF” and disconnect negative bat-

tery cable. Because battery voltage is applied to TCM even if

ignition switch is turned “OFF”.

SEF289H

Revision: April 20092010 QX56

Page 3963 of 4210

VTL-1

VENTILATION, HEATER & AIR CONDITIONER

C

DE

F

G H

J

K L

M

SECTION VTL

A

B

VTL

N

O P

CONTENTS

VENTILATION SYSTEM

PRECAUTION ....... ........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

Precaution for Working with HFC-134a (R-134a) ......3

Precaution for Procedure without Cowl Top Cover ......3

PREPARATION ............................................4

PREPARATION .............................................. .....4

Commercial Service Tool .................................... ......4

FUNCTION DIAGNOSIS ...............................5

IN-CABIN MICROFILTER .............................. .....5

Description .......................................................... ......5

ON-VEHICLE MAINTENANCE .....................6

IN-CABIN MICROFILTER .............................. .....6

Removal and Installation ...........................................6

ON-VEHICLE REPAIR .... ..............................7

CONTROL UNIT ..................................................7

Removal and Installation ...........................................7

IN-VEHICLE SENSOR ................................... .....9

Removal and Installation ...........................................9

OPTICAL SENSOR ........................................ ....10

Removal and Installation .........................................10

INTAKE SENSOR ..............................................11

Removal and Installation .........................................11

BLOWER MOTOR .......................................... ....12

Component .......................................................... ....12

Removal and Installation .........................................12

VARIABLE BLOWER CONTROL .....................14

Components ............................................................14

Removal and Installation .........................................15

HEATER & COOLING UNIT ASSEMBLY ........16

Component ..............................................................16

Removal and Installation .........................................17

EVAPORATOR .................................................19

Removal and Installation for Front Evaporator ........19

Removal and Installation for Rear Evaporator .........20

EXPANSION VALVE .........................................22

Removal and Installation for Rear Expansion

Valve .................................................................... ....

22

HEATER CORE .................................................23

Component ..............................................................23

Removal and Installation .........................................24

DEFROSTER DOOR MOTOR ..........................26

Removal and Installation .........................................26

INTAKE DOOR MOTOR ...................................27

Removal and Installation .........................................27

MODE DOOR MOTOR ......................................28

Components ............................................................28

Removal and Installation .........................................29

AIR MIX DOOR MOTOR ...................................30

Component ..............................................................30

Removal and Installation .........................................31

DUCTS AND GRILLES .....................................33

Component ..............................................................33

Removal and Installation .........................................36

Revision: April 20092010 QX56

Page 3964 of 4210

VTL-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005403098

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005403099

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: April 20092010 QX56