fuel INFINITI QX56 2010 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 2102 of 4210

EXL-126

< ECU DIAGNOSIS >

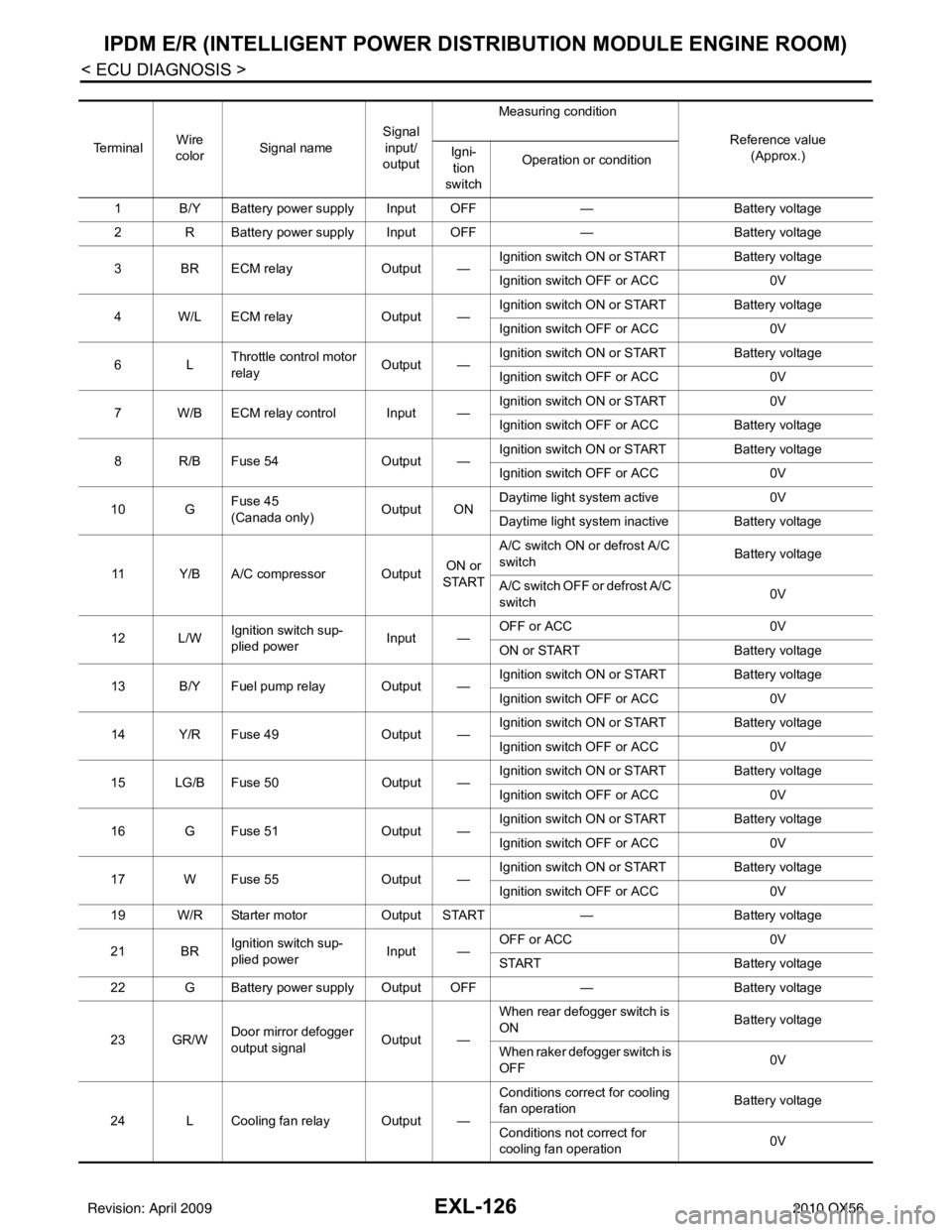

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

Te r m i n a lWire

color Signal name Signal

input/

output Measuring condition

Reference value(Approx.)

Igni-

tion

switch Operation or condition

1 B/Y Battery power supply Input OFF —Battery voltage

2 R Battery power supply Input OFF —Battery voltage

3 BR ECM relay Output —Ignition switch ON or START

Battery voltage

Ignition switch OFF or ACC 0V

4 W/L ECM relay Output —Ignition switch ON or START

Battery voltage

Ignition switch OFF or ACC 0V

6L Throttle control motor

relay Output —Ignition switch ON or START

Battery voltage

Ignition switch OFF or ACC 0V

7 W/B ECM relay control Input — Ignition switch ON or START

0V

Ignition switch OFF or ACC Battery voltage

8 R/B Fuse 54 Output —Ignition switch ON or START

Battery voltage

Ignition switch OFF or ACC 0V

10 G Fuse 45

(Canada only) Output ONDaytime light system active

0V

Daytime light system inactive Battery voltage

11 Y/B A/C compressor Output ON or

START A/C switch ON or defrost A/C

switch

Battery voltage

A/C switch OFF or defrost A/C

switch 0V

12 L/W Ignition switch sup-

plied power Input —OFF or ACC

0V

ON or START Battery voltage

13 B/Y Fuel pump relay Output — Ignition switch ON or START

Battery voltage

Ignition switch OFF or ACC 0V

14 Y/R Fuse 49 Output —Ignition switch ON or START

Battery voltage

Ignition switch OFF or ACC 0V

15 LG/B Fuse 50 Output —Ignition switch ON or START

Battery voltage

Ignition switch OFF or ACC 0V

16 G Fuse 51 Output —Ignition switch ON or START

Battery voltage

Ignition switch OFF or ACC 0V

17 W Fuse 55 Output —Ignition switch ON or START

Battery voltage

Ignition switch OFF or ACC 0V

19 W/R Starter motor Output START—Battery voltage

21 BR Ignition switch sup-

plied power

Input —OFF or ACC

0V

START Battery voltage

22 G Battery power supply Output OFF —Battery voltage

23 GR/W Door mirror defogger

output signal Output —When rear defogger switch is

ON

Battery voltage

When raker defogger switch is

OFF 0V

24 L Cooling fan relay Output — Conditions correct for cooling

fan operation

Battery voltage

Conditions not correct for

cooling fan operation 0V

Revision: April 20092010 QX56

Page 2104 of 4210

EXL-128

< ECU DIAGNOSIS >

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

43 L/Y Wiper auto stop signal Input ON or

START Wiper switch OFF, LO, INT Battery voltage

44 BR Daytime light relay

control

(Canada only) Input ONDaytime light system active

0V

Daytime light system inactive Battery voltage

45 G/W Horn relay control Input ON When door locks are operated

using Intelligent Key (OFF

→

ON)* Battery voltage

→ 0V

46 GR Fuel pump relay con-

trol Input —Ignition switch ON or START

0V

Ignition switch OFF or ACC Battery voltage

47 O Throttle control motor

relay control Input —Ignition switch ON or START

0V

Ignition switch OFF or ACC Battery voltage

48 B/R Starter relay (inhibit

switch) Input

ON or

START Selector lever in "P" or "N"

0V

Selector lever any other posi-

tion Battery voltage

49 R/L Trailer tow relay

(With trailer tow)

Illumination

(Without trailer tow) Output ONLighting

switch must

be in the 1st

position OFF

0V

ON Battery voltage

50 W/R Front fog lamp (LH) Output ON or

START Lighting

switch must

be in the 2nd

position

(LOW beam

is ON) and

the front fog

lamp switch OFF

0V

ON Battery voltage

51 W/R Front fog lamp (RH) Output ON or

START Lighting

switch must

be in the 2nd

position

(LOW beam

is ON) and

the front fog

lamp switch OFF

0V

ON Battery voltage

52 L LH low beam head-

lamp

Output — Lighting switch in 2nd position Battery voltage

54 R/Y RH low beam head-

lamp Output — Lighting switch in 2nd position Battery voltage

55 G LH high beam head-

lamp Output —Lighting switch in 2nd position

and placed in HIGH or PASS

position Battery voltage

56 Y

(With

DTRL)

L/W

(Without DTRL) RH high beam head-

lamp

Output —Lighting switch in 2nd position

and placed in HIGH or PASS

position

Battery voltage

57 R/LPa

rking, license, and

tail lamp Output ONLighting

switch 1st po-

sition OFF

0V

ON Battery voltage

59 B Ground Input ——0V

Te r m i n a l

Wire

color Signal name Signal

input/

output Measuring condition

Reference value(Approx.)

Igni-

tion

switch Operation or condition

Revision: April 20092010 QX56

Page 2121 of 4210

ADJUSTMENT AND INSPECTIONEXL-145

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

ON-VEHICLE REPAIR

ADJUSTMENT AND INSPECTION

HEADLAMP

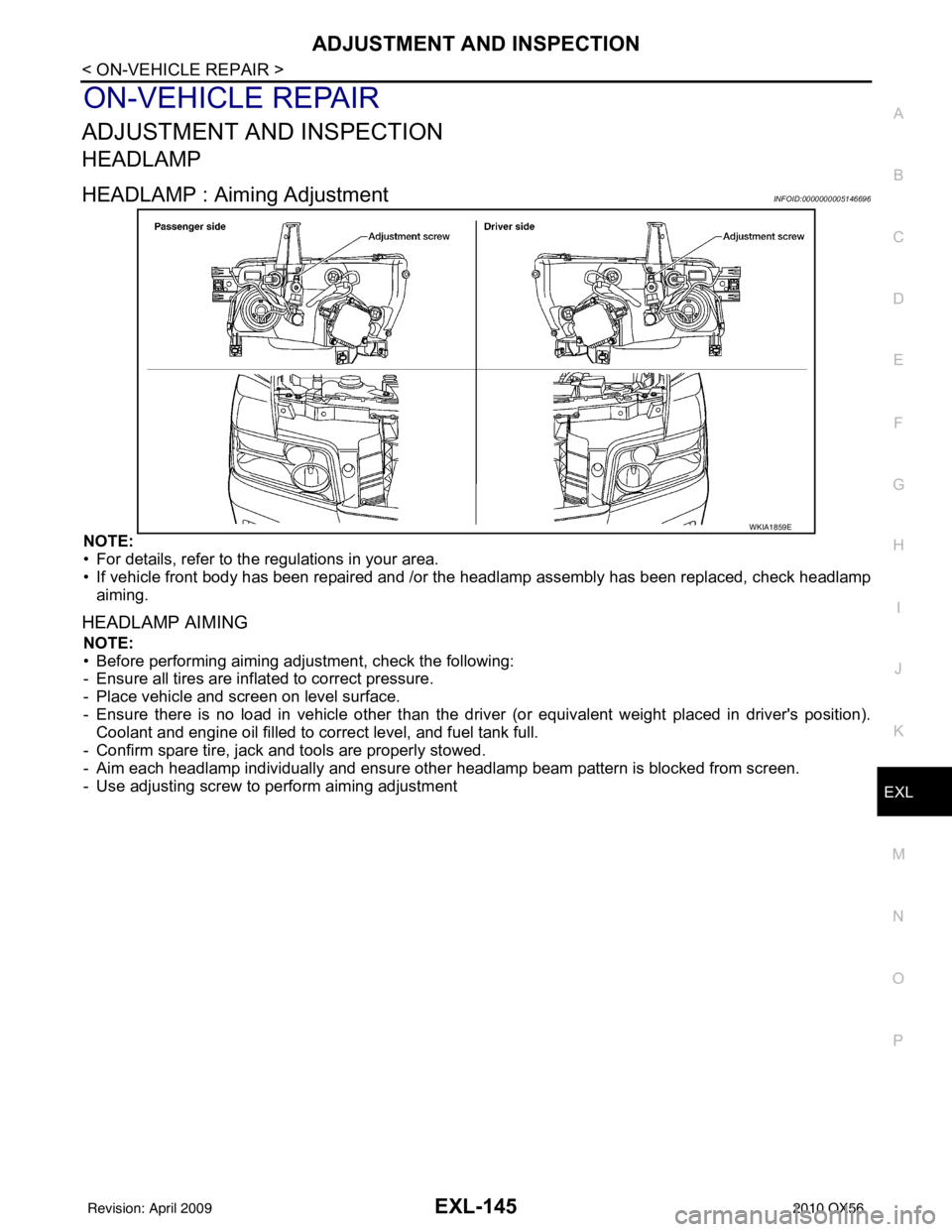

HEADLAMP : Aiming AdjustmentINFOID:0000000005146696

NOTE:

• For details, refer to the regulations in your area.

• If vehicle front body has been repaired and /or the headlamp assembly has been replaced, check headlamp

aiming.

HEADLAMP AIMING

NOTE:

• Before performing aiming adjustment, check the following:

- Ensure all tires are inflated to correct pressure.

- Place vehicle and screen on level surface.

- Ensure there is no load in vehicle other than the driver (or equivalent weight placed in driver's position). Coolant and engine oil filled to correct level, and fuel tank full.

- Confirm spare tire, jack and tools are properly stowed.

- Aim each headlamp individually and ensure other headlamp beam pattern is blocked from screen.

- Use adjusting screw to perform aiming adjustment

WKIA1859E

Revision: April 20092010 QX56

Page 2123 of 4210

ADJUSTMENT AND INSPECTIONEXL-147

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

• See that vehicle is unloaded (except for full levels of coolant, engine oil and fuel, and spare tire, jack, and tools). Have the driver

or equivalent weight placed in driver seat.

Adjust aiming in the vertical direction by turning the adjustment

screw.

NOTE:

Access adjustment screw from underneath front bumper. Turn screw

clockwise to raise pattern and c ounterclockwise to lower pattern.

1. Set the distance between the screen and the center of the fog lamp lens as shown.

2. Turn front fog lamps ON.

3. Adjust front fog lamps using adjusting screw so that the top edge of the high intensity zone is 200 mm (7.9 in) below the height of

the fog lamp centers as shown.

• When performing adjustment, if necessary, cover the head-lamps and opposite fog lamp.

SEL350X

MEL327G

MEL328GA

Revision: April 20092010 QX56

Page 2183 of 4210

FL-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION FL

A

FL

N

O P

CONTENTS

FUEL SYSTEM

PRECAUTION ....... ........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

FUEL SYSTEM ....................................................4

General Precaution ............................................. ......4

PREPARATION ............................................5

PREPARATION .............................................. .....5

Special Service Tool ........................................... ......5

Commercial Service Tool ..........................................5

BASIC INSPECTION ....................................6

FUEL SYSTEM ............................................... .....6

Checking Fuel Line ............................................. ......6

REMOVAL AND INSTALLATION ................7

FUEL LEVEL SENSOR UNIT, FUEL FILTER

AND FUEL PUMP ASSEMBLY .........................

7

Removal and Installation ..................................... .....7

FUEL TANK ......................................................11

Removal and Installation ..................................... ....11

DISASSEMBLY AND ASSEMBLY ..............16

FUEL LEVEL SENSOR UNIT, FUEL FILTER

AND FUEL PUMP ASSEMBLY ........................

16

Disassembly and Assembly ................................. ....16

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... ...

17

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

17

Standard and Limit .............................................. ....17

Revision: April 20092010 QX56

Page 2186 of 4210

FL-4

< PRECAUTION >

FUEL SYSTEM

FUEL SYSTEM

General PrecautionINFOID:0000000005149530

WARNING:

When replacing fuel line parts, be sure to observe the following.

• Put a “CAUTION: FLAMMABLE” sign in the workshop.

• Be sure to work in a well ventilate d area and furnish workshop with a CO

2 fire extinguisher.

• Do not smoke while servicing fuel system. Keep open flames and sparks away from the work area.

CAUTION:

• Before removing fuel line parts, carry out the following procedures:

- Put drained fuel in an explosi on-proof container and put the lid on securely. Keep the container in

safe area.

- Release fuel pressure from the fuel lines. Refer to EC-489, "

Fuel Pressure Check" .

- Disconnect the battery negative terminal.

• Always replace O-rings and clamps with new ones.

• Do not kink or twist hoses when they are being installed.

• After connecting the fuel t ube quick connectors, make sure

the quick connectors are secure.

Ensure that the connector and resin tube do not contact any

adjacent parts.

• After installing tubes, make su re there is no fuel leakage at

connections in the following steps.

- Apply fuel pressure to fuel lines with turning ignition switch

ON (with engine stopped). Th en check for fuel leaks at con-

nections.

- Start the engine and rev it up and check for fuel leaks at con-

nections.

• Use only a Genuine NISSAN fuel filler cap as a replacement. If an incorrect fuel filler cap is used, the MIL may come on.

• For servicing “Evaporative Emission System” parts, refer to EC-493, "

Removal and Installation" .

• For servicing “On Board Refueling Vapor Recovery (ORVR)”

parts, refer to EC-491, "

How to Detect Fuel Vapor Leakage" .

PBIC1268E

Revision: April 20092010 QX56

Page 2187 of 4210

PREPARATIONFL-5

< PREPARATION >

C

DE

F

G H

I

J

K L

M A

FL

NP

O

PREPARATION

PREPARATION

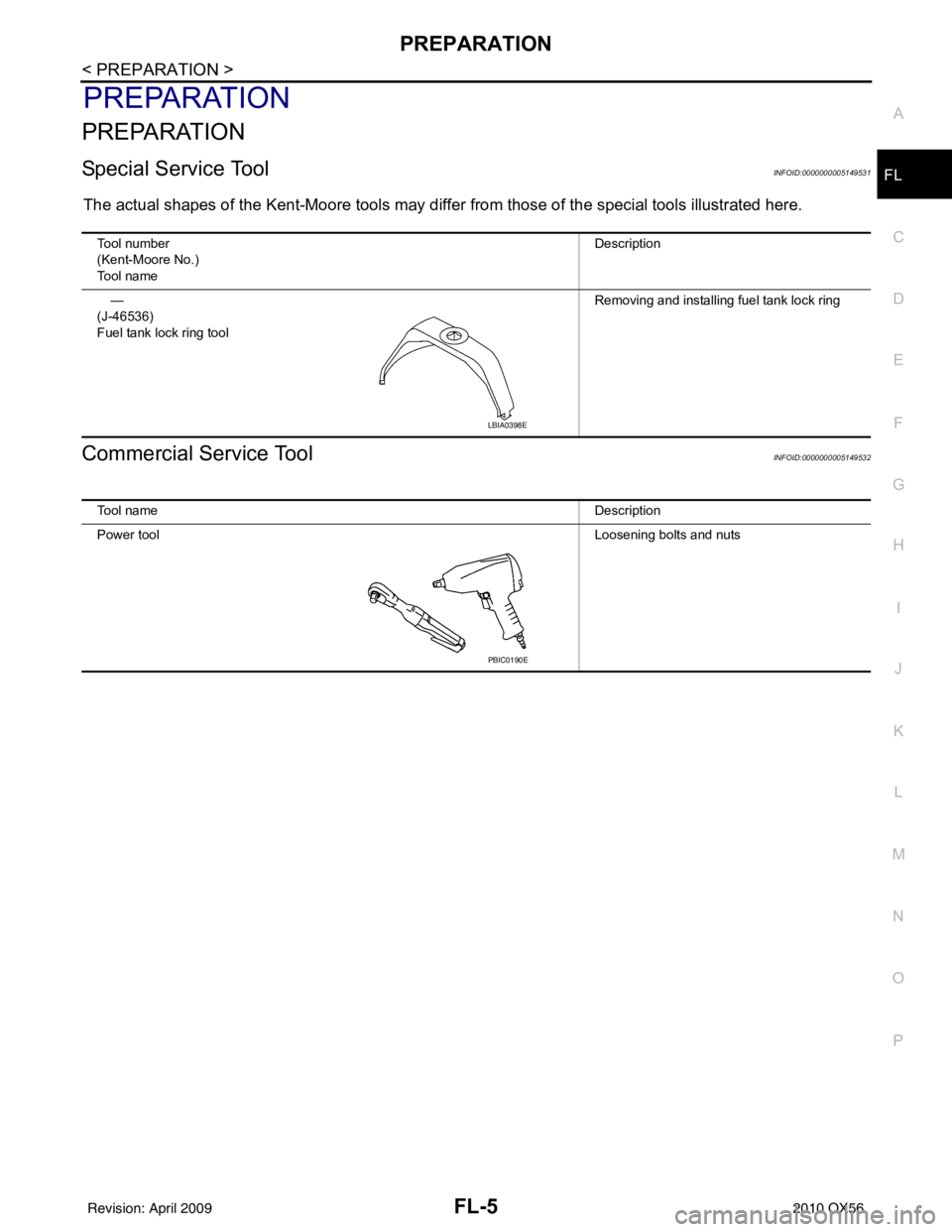

Special Service ToolINFOID:0000000005149531

The actual shapes of the Kent-Moore

tools may differ from those of the special tools illustrated here.

Commercial Service ToolINFOID:0000000005149532

Tool number

(Kent-Moore No.)

Tool name Description

—

(J-46536)

Fuel tank lock ring tool Removing and installing fuel tank lock ring

LBIA0398E

Tool name

Description

Power tool Loosening bolts and nuts

PBIC0190E

Revision: April 20092010 QX56

Page 2188 of 4210

FL-6

< BASIC INSPECTION >

FUEL SYSTEM

BASIC INSPECTION

FUEL SYSTEM

Checking Fuel LineINFOID:0000000005149533

Inspect fuel lines, fuel filler cap and fuel tank for improper attach-

ment, leaks, cracks, damage, loose connections, chafing or deterio-

ration.

If necessary, repair or replace damaged parts.

SMA803A

Revision: April 20092010 QX56

Page 2189 of 4210

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLYFL-7

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

FL

NP

O

REMOVAL AND INSTALLATION

FUEL LEVEL SENSOR UNIT, FUEL FI

LTER AND FUEL PUMP ASSEMBLY

Removal and InstallationINFOID:0000000005149534

REMOVAL

WARNING:

Follow the “General Precautions” before working on the fuel system. Refer to FL-4, "

General Precau-

tion" .

1. Remove the fuel filler cap to release the pressure from inside the fuel tank.

2. Release the fuel pressure from the fuel lines. Refer to EC-489, "

Fuel Pressure Check" .

3. Disconnect the battery negative terminal Refer to PG-74, "

Removal and Installation" .

4. Remove the second row seat and the third row LH seat. Refer to SE-56, "

Removal and Installation" (sec-

ond row), SE-59, "

LH Side Seat" (third row).

5. Remove the second and third row rear seat belt buckles mounted on the floor. Refer to SB-7, "

Removal

and Installation of Second Row Seat Belt", SB-8, "Removal and Installation of Third Row Seat Belt".

6. Remove the LH center pillar trim, the LH rear trim panel, and the LH rear side door kick plate and weather stripping. Refer to INT-14, "

Removal and Installation" .

7. Remove the second row rear center console and base, (if equipped). Refer to IP-21, "

Removal and Instal-

lation" .

8. Reposition the floor carpet out of the way to access the inspection hole cover, located under the center LH rear seat.

1. Inspection hole cover 2. Inspection hole cover O-ring 3. Lock ring

4. Fuel level sensor, fuel filter, and fuel pump assembly 5. Fuel tank

6. Fuel level sensor, fuel filter, and fuel

pump assembly O-ring

LBIA0381E

Revision: April 20092010 QX56

Page 2190 of 4210

FL-8

< REMOVAL AND INSTALLATION >

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

9. Remove the inspection hole cover by turning the retainers 90 °

degrees clockwise.

• Remove the O-ring.

10. Disconnect the fuel level sensor, fuel filter, and fuel pump assembly electrical connector, the EVAP hose, and the fuel feed

hose.

Disconnect the quick connector as follows:

• Hold the sides of the connector, push in tabs and pull out the

tube.

• If the connector and the tube are stuck together, push and pull several times until they start to move. Then disconnect them

by pulling.

CAUTION:

LBIA0382E

LBIA0383E

SFE562A

Revision: April 20092010 QX56