air filter INFINITI QX56 2010 Factory Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 2717 of 4210

RECOMMENDED FLUIDS AND LUBRICANTSMA-13

< ON-VEHICLE MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

RECOMMENDED FLUIDS AND LUBRICANTS

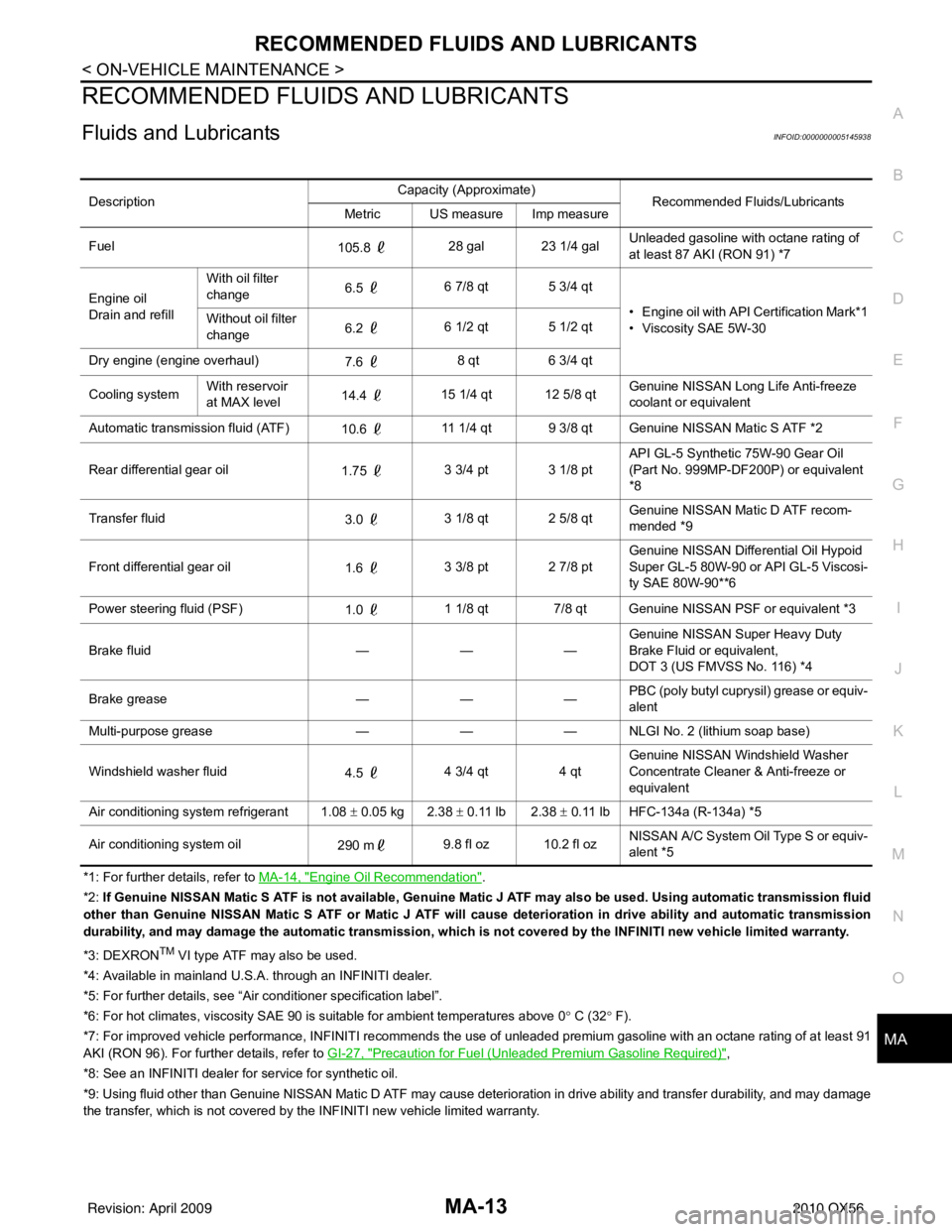

Fluids and LubricantsINFOID:0000000005145938

*1: For further details, refer to

MA-14, "Engine Oil Recommendation".

*2: If Genuine NISSAN Matic S ATF is not ava ilable, Genuine Matic J ATF may also be used. Using automatic transmission fluid

other than Genuine NISSAN Matic S ATF or Matic J ATF will cause deterioration in drive ability and automatic transmission

durability, and may damage the automatic transmission, which is not covered by the INFINITI new vehicle limited warranty.

*3: DEXRON

TM VI type ATF may also be used.

*4: Available in mainland U.S.A. through an INFINITI dealer.

*5: For further details, see “Air conditioner specification label”.

*6: For hot climates, viscosity SAE 90 is suitable for ambient temperatures above 0° C (32° F).

*7: For improved vehicle performance, INFINITI recommends the use of unleaded premium gasoline with an octane rating of at leas t 91

AKI (RON 96). For furt her details, refer to GI-27, "

Precaution for Fuel (Unleaded Premium Gasoline Required)",

*8: See an INFINITI dealer for service for synthetic oil.

*9: Using fluid other than Genuin e NISSAN Matic D ATF may cause deterioration in drive ability and transfer durability, and may damage

the transfer, which is not covered by the INFINITI new vehicle limited warranty. Description

Capacity (Approximate)

Recommended Fluids/Lubricants

Metric US measure Imp measure

Fuel 105.8 28 gal 23 1/4 gal Unleaded gasoline with octane rating of

at least 87 AKI (RON 91) *7

Engine oil

Drain and refill With oil filter

change

6.5

6 7/8 qt 5 3/4 qt

• Engine oil with API Certification Mark*1

• Viscosity SAE 5W-30

Without oil filter

change

6.2

6 1/2 qt 5 1/2 qt

Dry engine (engine overhaul) 7.6 8 qt

6 3/4 qt

Cooling system With reservoir

at MAX level

14.4

15 1/4 qt 12 5/8 qt Genuine NISSAN Long

Life Anti-freeze

coolant or equivalent

Automatic transmission fluid (ATF) 10.6 11 1/4 qt 9 3/8 qt Genuine NISSAN Matic S ATF *2

Rear differential gear oil 1.75 3 3/4 pt 3 1/8 pt API GL-5 Synthetic 75W-90 Gear Oil

(Part No. 999MP-DF200P) or equivalent

*8

Transfer fluid 3.0 3 1/8 qt 2 5/8 qt Genuine NISSAN Matic D ATF recom-

mended *9

Front differential gear oil 1.6 3 3/8 pt 2 7/8 pt Genuine NISSAN Differ

ential Oil Hypoid

Super GL-5 80W-90 or API GL-5 Viscosi-

ty SAE 80W-90**6

Power steering fluid (PSF) 1.0 1 1/8 qt 7/8 qt Genuine NISSAN PSF or equivalent *3

Brake fluid ———Genuine NISSAN S

uper Heavy Duty

Brake Fluid or equivalent,

DOT 3 (US FMVSS No. 116) *4

Brake grease ———PBC (poly butyl cuprysil) grease or equiv-

alent

Multi-purpose grease ——— NLGI No. 2 (lithium soap base)

Windshield washer fluid 4.5 4 3/4 qt

4 qtGenuine NISSAN Wind

shield Washer

Concentrate Cleaner & Anti-freeze or

equivalent

Air conditioning system refrigerant 1.08 ± 0.05 kg 2.38 ± 0.11 lb 2.38 ± 0.11 lb HFC-134a (R-134a) *5

Air conditioning system oil 290 m9.8 fl oz 10.2 fl oz NISSAN A/C System Oil Type S or equiv-

alent *5

Revision: April 20092010 QX56

Page 2723 of 4210

ENGINE MAINTENANCEMA-19

< ON-VEHICLE MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

9. When the vacuum gauge has reached the specified

amount, disconnect the air hose and wait 20 seconds

to see if the system loses any vacuum. If the vacuum level drops, perform any necessary repairs to the

system and repeat steps 6 - 8 to br ing the vacuum to the specified amount. Recheck for any leaks.

10. Place the coolant container (with the refill hose inserted) at the same level as the top of the radiator. Then

open the ball valve on the refill hose so the coolant will be drawn up to fill the cooling system. The cooling

system is full when the vacuum gauge reads zero.

CAUTION:

Do not allow the coolant container to get too low when filling, to avoid air from being drawn into

the cooling system.

11. Remove the Tool from the radiator neck opening and install the radiator cap.

12. Remove the non-vented reservoir cap.

13. Fill the cooling system reservoir tank to the specified level. Run the engine to warm up the cooling system and top up the system as necessary befor e installing the vented reservoir cap.

FLUSHING COOLING SYSTEM

1. Drain the water from the engine cooling system. Refer to MA-17, "ENGINE COOLANT : Changing Engine

Coolant".

2. Fill the radiator and the reservoir tank (to the “MAX” line), with water. Reinstall the radiator cap and leave

the vented reservoir cap off.

3. Run the engine until it reaches normal operating temperature.

4. Press the engine accelerator two or three times under no-load.

5. Stop the engine and wait until it cools down.

6. Drain the water from the engine cooling system. Refer to MA-17, "

ENGINE COOLANT : Changing Engine

Coolant".

7. Repeat steps 2 through 6 until clear water begins to drain from the radiator.

FUEL LINES

FUEL LINES : Checking Fuel LineINFOID:0000000005403135

Inspect fuel lines, fuel filler cap and fuel tank for improper attach-

ment, leaks, cracks, damage, loos e connections, chafing or deterio-

ration.

If necessary, repair or replace damaged parts.

FUEL FILTER

FUEL FILTER : Changing Fuel FilterINFOID:0000000005259654

The fuel filter is part of the fuel level sensor unit, fuel filter and fuel pump assembly and cannot be replaced

separately. Refer to FL-7, "

Removal and Installation".

WARNING:

Before replacing the fuel filter, release the fuel pressure from the fuel system. Refer to EC-489, "

Fuel

Pressure Check".

AIR CLEANER FILTER

500 m (1,641 ft): 26 inches of vacuum

1,000 m (3,281 ft) : 24 - 25 inches of vacuum

SMA803A

Revision: April 20092010 QX56

Page 2724 of 4210

MA-20

< ON-VEHICLE MAINTENANCE >

ENGINE MAINTENANCE

AIR CLEANER FILTER : Exploded View

INFOID:0000000005403138

AIR CLEANER FILTER : Removal and Installation (Viscous paper type)INFOID:0000000005403139

REMOVAL

NOTE:

• The viscous paper type filter does not need cleaning between replacement intervals.

• Replace the air filter as necessary for periodic maintenance. Refer to MA-9, "

Introduction of Periodic Mainte-

nance".

1. Remove the air cleaner case (upper).

2. Remove the air cleaner filter from the air cleaner case (lower).

INSTALLATION

1. Install the new air cleaner filter in the air cleaner case (lower).

2. Install the air cleaner case (upper).

ENGINE OIL

ENGINE OIL : InspectionINFOID:0000000005403140

OIL LEVEL

• Before starting the engine make sure the vehicle is parked on a flat and level surface, then check the oil level. If the engine is already

running, turn it off and allow 10 minutes before checking.

• Check that the oil level is within the low (L) to high (H) range as indicated on the dipstick.

• If the engine oil level is out of range, add oil as necessary. Refer to

MA-13, "

Fluids and Lubricants".

OIL APPEARANCE

• Check the engine oil for a white milky appearance or excessive contamination.

1. Air cleaner case (lower) 2. Air cleaner filter 3. Air cleaner case (upper)

4. Air duct and resonator assembly Front

ALBIA0413GB

SMA954C

Revision: April 20092010 QX56

Page 2725 of 4210

ENGINE MAINTENANCEMA-21

< ON-VEHICLE MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

• If the engine oil is milky, it is highly probable that it is contaminated with engine coolant. Repair the broken

parts.

OIL LEAKAGE

Check for oil leakage around the following areas:

•Oil pan

• Oil pan drain plug

• Oil pressure switch

• Oil filter

• Oil cooler

• Intake valve timing control cover

• Intake valve timing control solenoid valve

• Front cover

• Mating surface between cylinder block and cylinder head

• Mating surface between cylinder head and rocker cover

• Crankshaft oil seal (front and rear)

OIL PRESSURE CHECK

WARNING:

• Be careful not to burn yoursel f, as engine oil may be hot.

• Put the selector lever in the Park “P” position.

1. Check the engine oil level. Refer to MA-20, "

ENGINE OIL : Inspection".

2. Remove engine front undercover using power tool.

3. Disconnect the oil pressure switch harness connector.

4. Remove the oil pressure switch (A).

5. Install Tools.

6. Start the engine and warm it up to normal operating temperature.

7. Check the engine oil pressure with engine running under no-load.

Engine oil pressure [Engine oil temperature at 80 °C (175 °F)]

Unit: kPa (kg/cm2, psi)

CAUTION:

If the difference is extreme, check the oil passages and oil pump for leaks and blockages.

WBIA0791E

Tool number : ST25051001 (J-25695-1)

: ST25052000 (J-25695-2)

WBIA0571E

Engine Speed Approximate Discharge Oil Pressure

Idle speed More than 98 (1.0, 14)

2,000 rpm More than 294 (3.0, 43)

Revision: April 20092010 QX56

Page 2730 of 4210

MA-26

< ON-VEHICLE MAINTENANCE >

CHASSIS AND BODY MAINTENANCE

CHASSIS AND BODY MAINTENANCE

IN-CABIN MICROFILTER

IN-CABIN MICROFILTER : Removal and InstallationINFOID:0000000005403149

REPLACEMENT PROCEDURE

1. Remove the glove box assembly from the instrument panel. Refer to IP-17, "Removal and Installation".

2. Remove the screw and remove the in-cabin microfilter cover as shown.

3. Remove the two in-cabin microf ilters from the front heater and

cooling unit assembly housing.

4. Insert the first new in-cabin micr ofilter into the front heater and

cooling unit assembly housing and slide it over to the right.

Insert the second new in-cabin mi crofilter into the front heater

and cooling unit assembly housing as shown.

NOTE:

The in-cabin microfilters are marked with air flow arrows. The

end of the microfilter with the arro w should face the rear of the

vehicle. The arrows should point downward.

5. Install the in-cabin microfilter cover.

6. Install the glove box assembly in the instrument panel. Refer to IP-17, "

Removal and Installation".

7. Fill out the date information on the small replac ement label and attach it to the glove box lid.

EXHAUST SYSTEM

EXHAUST SYSTEM : Checking Exhaust SystemINFOID:0000000005403150

Check exhaust pipes, muffler and mounting for improper attachment, leaks, cracks, damage or deterioration.

LJIA0134E

LJIA0148E

LJIA0134E

Revision: April 20092010 QX56

Page 3848 of 4210

A/T FLUID COOLERTM-153

< ON-VEHICLE MAINTENANCE >

CEF

G H

I

J

K L

M A

B

TM

N

O P

13. Flush each steel line from the cooler side back toward the A/T by spraying Transmission Cooler Cleaner in a continuous stream for 5 seconds.

14. Blow compressed air regulated to 490 - 883 kPa (5 - 9 kg/cm

2, 71 - 128 psi) through each steel line from

the cooler side back toward the A/T for 10 seconds to force out any remaining fluid.

15. Ensure all debris is removed from the steel cooler lines.

16. Ensure all debris is removed from the banjo bolts and fittings.

17. Perform A/T fluid cooler diagnosis procedure.

A/T FLUID COOLER DIAGNOSIS PROCEDURE

NOTE:

Insufficient cleaning of the cooler inlet hose exte rior may lead to inaccurate debris identification.

1. Position a drain pan under the A/T inlet and outlet fluid cooler tube to cooler hose connection.

2. Clean the exterior and tip of the cooler inlet hose.

3. Put a different color matching mark on each cooler tube to cooler hose connection to aid in assembly. CAUTION:

Use paint to make the matching mark. Do not damage the tubes or hose.

4. Disconnect the fluid cooler inle t and outlet rubber hoses from the

steel cooler tubes.

NOTE:

Replace the cooler hoses if rubber material from the hose

remains on the tube fitting.

5. Insert the extension adapter hose of a can of Transmission Cooler Cleaner (Nissan P/N 999MP-AM006) into the cooler out-

let hose.

CAUTION:

• Wear safety glasses and rubber gloves when spraying the

Transmission Cooler Cleaner.

• Spray cooler cleaner only with adequate ventilation.

• Avoid contact with eyes and skin.

• Do not breath vapors or spray mist.

6. Hold the hose and can as high as possible and spray Transmis- sion Cooler Cleaner in a continuous stream into the cooler outlet

hose until fluid flows out of the cooler inlet hose for 5 seconds.

7. Tie a common white, basket-type coffee filter to the end of the cooler inlet hose.

SCIA3830E

SCIA3831E

SCIA3833E

Revision: April 20092010 QX56

Page 3849 of 4210

TM-154

< ON-VEHICLE MAINTENANCE >

A/T FLUID COOLER

8. Insert the tip of an air gun into the end of the cooler outlet hose.

9. Wrap a shop rag around the air gun tip and end of cooler outlethose.

10. Blow compressed air regulated to 490 - 883 kPa (5 - 9 kg/cm

2,

71 - 128 psi) through the cooler outlet hose to force any remain-

ing A/T fluid into the coffee filter.

11. Remove the coffee filter from the end of the cooler inlet hose.

12. Perform A/T fluid cooler inspection. Refer to TM-152, "

A/T Fluid

Cooler Cleaning".

A/T FLUID COOLER INSPECTION PROCEDURE

1. Inspect the coffee filter for debris.

a. If small metal debris less than 1mm (0.040 in) in size or metal

powder is found in the coffee filter, this is normal. If normal

debris is found, the A/T fluid cooler/radiator can be re-used and

the procedure is ended.

b. If one or more pieces of debris are found that are over 1mm (0.040 in) in size and/or peeled clutch facing material is found in

the coffee filter, the fluid cooler is not serviceable. The A/T fluid

cooler/radiator must be replaced and the inspection procedure is

ended. Refer to CO-15, "

Removal and Installation".

A/T FLUID COOLER FINAL INSPECTION

After performing all procedures, ensure that all remaining oil is cleaned from all components.

InspectionINFOID:0000000005148725

After performing all procedures, ensure that all remaining oil is cleaned from all components.

SCIA3834E

SCIA2967E

SCIA5659E

Revision: April 20092010 QX56

Page 3963 of 4210

VTL-1

VENTILATION, HEATER & AIR CONDITIONER

C

DE

F

G H

J

K L

M

SECTION VTL

A

B

VTL

N

O P

CONTENTS

VENTILATION SYSTEM

PRECAUTION ....... ........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

Precaution for Working with HFC-134a (R-134a) ......3

Precaution for Procedure without Cowl Top Cover ......3

PREPARATION ............................................4

PREPARATION .............................................. .....4

Commercial Service Tool .................................... ......4

FUNCTION DIAGNOSIS ...............................5

IN-CABIN MICROFILTER .............................. .....5

Description .......................................................... ......5

ON-VEHICLE MAINTENANCE .....................6

IN-CABIN MICROFILTER .............................. .....6

Removal and Installation ...........................................6

ON-VEHICLE REPAIR .... ..............................7

CONTROL UNIT ..................................................7

Removal and Installation ...........................................7

IN-VEHICLE SENSOR ................................... .....9

Removal and Installation ...........................................9

OPTICAL SENSOR ........................................ ....10

Removal and Installation .........................................10

INTAKE SENSOR ..............................................11

Removal and Installation .........................................11

BLOWER MOTOR .......................................... ....12

Component .......................................................... ....12

Removal and Installation .........................................12

VARIABLE BLOWER CONTROL .....................14

Components ............................................................14

Removal and Installation .........................................15

HEATER & COOLING UNIT ASSEMBLY ........16

Component ..............................................................16

Removal and Installation .........................................17

EVAPORATOR .................................................19

Removal and Installation for Front Evaporator ........19

Removal and Installation for Rear Evaporator .........20

EXPANSION VALVE .........................................22

Removal and Installation for Rear Expansion

Valve .................................................................... ....

22

HEATER CORE .................................................23

Component ..............................................................23

Removal and Installation .........................................24

DEFROSTER DOOR MOTOR ..........................26

Removal and Installation .........................................26

INTAKE DOOR MOTOR ...................................27

Removal and Installation .........................................27

MODE DOOR MOTOR ......................................28

Components ............................................................28

Removal and Installation .........................................29

AIR MIX DOOR MOTOR ...................................30

Component ..............................................................30

Removal and Installation .........................................31

DUCTS AND GRILLES .....................................33

Component ..............................................................33

Removal and Installation .........................................36

Revision: April 20092010 QX56

Page 3967 of 4210

IN-CABIN MICROFILTERVTL-5

< FUNCTION DIAGNOSIS >

C

DE

F

G H

J

K L

M A

B

VTL

N

O P

FUNCTION DIAGNOSIS

IN-CABIN MICROFILTER

DescriptionINFOID:0000000005147603

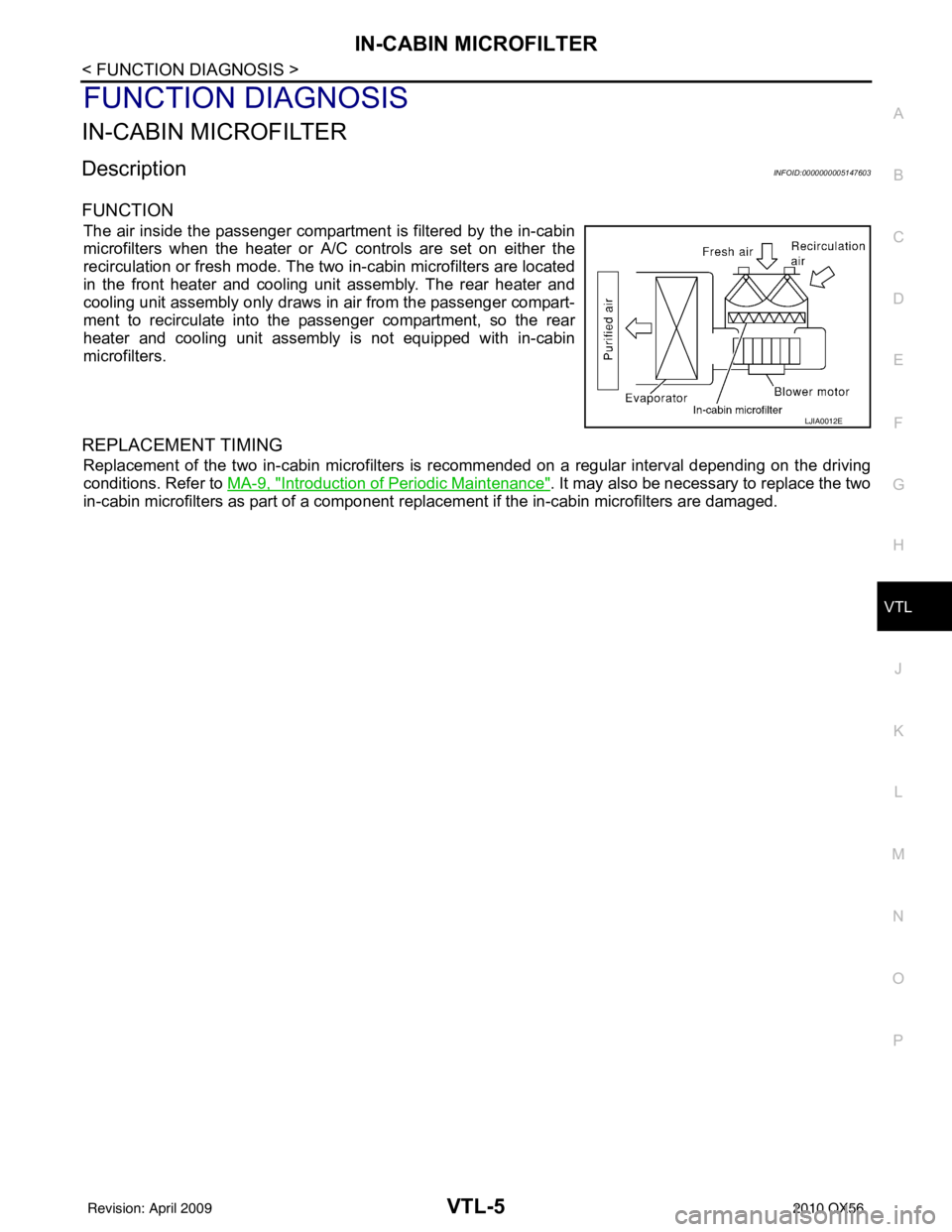

FUNCTION

The air inside the passenger compartment is filtered by the in-cabin

microfilters when the heater or A/C controls are set on either the

recirculation or fresh mode. The two in-cabin microfilters are located

in the front heater and cooling unit assembly. The rear heater and

cooling unit assembly only draws in air from the passenger compart-

ment to recirculate into the passenger compartment, so the rear

heater and cooling unit assembly is not equipped with in-cabin

microfilters.

REPLACEMENT TIMING

Replacement of the two in-cabin microfilters is recommended on a regular interval depending on the driving

conditions. Refer to MA-9, "

Introduction of Periodic Maintenance". It may also be necessary to replace the two

in-cabin microfilters as part of a component r eplacement if the in-cabin microfilters are damaged.

LJIA0012E

Revision: April 20092010 QX56

Page 3968 of 4210

VTL-6

< ON-VEHICLE MAINTENANCE >

IN-CABIN MICROFILTER

ON-VEHICLE MAINTENANCE

IN-CABIN MICROFILTER

Removal and InstallationINFOID:0000000005147604

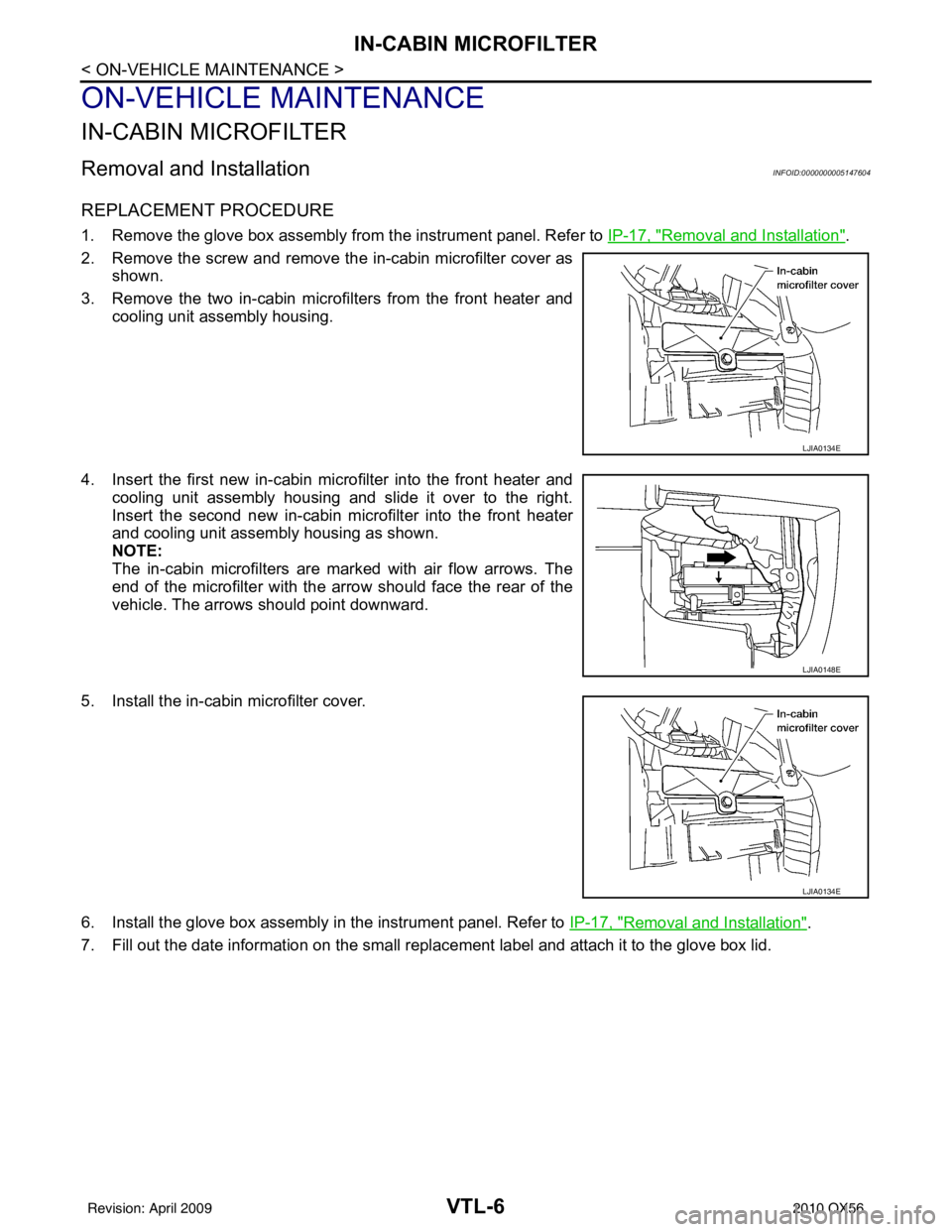

REPLACEMENT PROCEDURE

1. Remove the glove box assembly from the instrument panel. Refer to IP-17, "Removal and Installation".

2. Remove the screw and remove the in-cabin microfilter cover as shown.

3. Remove the two in-cabin microf ilters from the front heater and

cooling unit assembly housing.

4. Insert the first new in-cabin micr ofilter into the front heater and

cooling unit assembly housing and slide it over to the right.

Insert the second new in-cabin mi crofilter into the front heater

and cooling unit assembly housing as shown.

NOTE:

The in-cabin microfilters are marked with air flow arrows. The

end of the microfilter with the arro w should face the rear of the

vehicle. The arrows should point downward.

5. Install the in-cabin microfilter cover.

6. Install the glove box assembly in the instrument panel. Refer to IP-17, "

Removal and Installation".

7. Fill out the date information on the small replac ement label and attach it to the glove box lid.

LJIA0134E

LJIA0148E

LJIA0134E

Revision: April 20092010 QX56