boot INFINITI QX56 2010 Factory Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 2218 of 4210

KNUCKLEFSU-19

< REMOVAL AND INSTALLATION >

C

DF

G H

I

J

K L

M A

B

FSU

N

O P

KNUCKLE

Removal and InstallationINFOID:0000000005148118

REMOVAL

1. Remove wheel hub and bearing assembly. Refer to FAX-7, "Removal and Installation" .

• Disconnect wheel sensor harness connector. Do not remove wheel sensor from wheel hub and bearing

assembly for this procedure.

2. Remove steering outer socket from steering knuckle using Tool. CAUTION:

• Be careful not to damage ball joint boot.

• Temporarily tighten nut to prevent damage to threads andto prevent Tool from coming off.

3. Remove the coil spring and shock absorber assembly using power tool. Refer to FSU-14, "

Removal and

Installation" .

4. Support lower link using a suitable jack.

5. Remove cotter pin and nut from upper link ball joint and discard the cotter pin.

6. Separate upper link ball joint from steering knuckle using Tool.

1. Disc rotor 2. Wheel hub and bearing assembly 3. Wheel stud

4. Splash guard 5. Steering knuckle Front

AWDIA0423GB

Tool number : HT72520000 (J-25730-A)

WGIA0130E

Tool number : ST29020001 (J-24319-01)

LEIA0095E

Revision: April 20092010 QX56

Page 2228 of 4210

HOW TO USE THIS MANUALGI-5

< HOW TO USE THIS MANUAL >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

SYMBOLS

1. Union bolt 2. Copper washer3. Brake hose

4. Cap 5. Bleed valve6. Sliding pin bolt

7. Piston seal 8. Piston9. Piston boot

10. Cylinder body 11. Sliding pin12. Torque member mounting bolt

13. Washer 14. Sliding pin boot15. Bushing

16. Torque member 17. Inner shim cover18. Inner shim

19. Inner pad 20. Pad retainer21. Pad wear sensor

22. Outer pad 23. Outer shim24. Outer shim cover

1: PBC (Poly Butyl Cuprysil) grease

or silicone-based grease 2: Rubber grease

: Brake fluid

Refer to GI section for additional symbol definitions.

SFIA2959E

SAIA0749E

Revision: April 20092010 QX56

Page 2714 of 4210

MA-10

< ON-VEHICLE MAINTENANCE >

PERIODIC MAINTENANCE

(1) After 60,000 miles (96,000 km) or 48 months, inspect every 15,000 miles (24,000 km) or 12 months. Replace the drive belts if found

damaged or if the auto belt tensioner reading reaches the maximum limit.

(2) If operating mainly in dusty conditions, more frequent maintenance may be required.

(3) Maintenance-free item. For service procedures, go to the FL section.

(4) After 60,000 miles (96,000 km) or 48 months, replace every 30,000 miles (48,000 km) or 24 months.

(5) Periodic maintenance is not required. However, if valve noise increases, inspect valve clearance.

* Maintenance items and intervals with “*” are recommended by NISSAN for reliable vehicle operation. The owner need not perform

such maintenance in order to maintain the emission warranty or manufacturer recall liability. Other maintenance items and intervals are

required.

CHASSIS AND BODY MAINTENANCE

Abbreviations: R = Replace. I = Inspec t. Correct or replace if necessary.

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Reference

Section -

Page or -

Content Title

Perform at number of miles, kilo-

meters or months, whichever

comes first. Miles x 1,000

(km x 1,000) Months 33.75

(54)27 37.5

(60) 30 41.25

(66)33 45

(72) 36 48.75

(78)39 52.5

(84) 42 56.25

(90)45 60

(96) 48

Drive belts NOTE (1) I*MA-15

Air cleaner filter NOTE (2) [R]MA-20

EVAP vapor lines I*MA-25

Fuel lines I*MA-19

Fuel filter NOTE (3) MA-19

Engine coolantNOTE (4) R*MA-17

Engine oil R R R R R R R R MA-22

Engine oil filter (Use genuine

NISSAN oil filter or equivalent.)R R RRRRRR

MA-22

Spark plugs (Iridium-tipped type)Replace every 105,000 miles (169,000 km).MA-24

Intake and exhaust valve clear-

ance*NOTE (5)

EM-18

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

Section- Page or

- Content Title

Perform at number of miles, kilometers or

months, whichever comes first. Miles x

1,000

(km x

1,000)

Months 3.75

(6)3 7.5

(12) 6 11 . 2 5

(18) 9 15

(24) 12 18.75

(30)15 22.5

(36) 18 26.25

(42)21 30

(48) 24

Brake lines and cables IIMA-34

Brake pads and rotors II I IMA-35

Automatic transmission fluid, transfer fluid and

differential gear oil NOTE (1)

IIMA-29,

MA-30

,

MA-32

Steering gear and linkage, axle and suspension

parts II I I

MA-36,

MA-37

Tire Rotation NOTE (2) MA-34

Drive shaft boots and propeller shaft (4WD)II I IMA-31

Exhaust system II I IMA-26

In-cabin microfilter RRMA-26

Revision: April 20092010 QX56

Page 2715 of 4210

PERIODIC MAINTENANCEMA-11

< ON-VEHICLE MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

(1) If towing a trailer, or using a car-top carrier, or driving on rough or muddy roads, change (not just inspect) oil at every

30,000 miles

(48,000 km) or 24 months. Using automatic transmission fluid other than Ge nuine NISSAN Matic S ATF or Matic J ATF will cause

deterioration in drive ability and automatic transmission durability, and may damage the automatic transmission, which is not

covered by the INFINITI new vehicle limited warranty.

(2) Refer to “Tire rotation” under the “General maintenance” heading earlier in this section.

Schedule 2INFOID:0000000005145937

EMISSION CONTROL SYSTEM MAINTENANCE

Abbreviations: R = Replace. I = Ins pect. Correct or replace if necessary. [ ]: At the mileage intervals only

(1) After 60,000 miles (96,000 km) or 48 months, inspect every 15,000 miles (24,000 km) or 12 months. Replace the drive belts i f found

damaged or if the auto belt tensioner reading reaches the maximum limit.

(2) Maintenance-free item. For service procedures, go to FL section.

(3) After 60,000 miles (96,000 km) or 48 months, replace every 30,000 miles (48,000 km) or 24 months.

(4) Periodic maintenance is not required. However, if valve noise increases, inspect valve clearance.

* Maintenance items and inte rvals with “*” are recommended by NISSAN for reliable vehicle operation. The owner need not perform

such maintenance in order to maintain the emission warranty or manufacturer recall liability. Other maintenance items and inter vals are

required.

CHASSIS AND BODY MAINTENANCE

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Reference

Section

- Page or

- Content

Title

Perform at number of miles, kilometers or

months, whichever comes first. Miles x

1,000(km x

1,000)

Months 33.75

(54)

27 37.5

(60)

30 41.25

(66)

33 45

(72)

36 48.75

(78)

39 52.5

(84)

42 56.25

(90)

45 60

(96)

48

Brake lines and cables IIMA-34

Brake pads and rotors IIIIMA-35

Automatic transmission fluid, transfer fluid and

differential gear oil NOTE (1)

IIMA-29,

MA-30

,

MA-32

Steering gear and linkage, axle and suspen-

sion parts IIII

MA-36,

MA-37

Tire Rotation NOTE (2) MA-34

Drive shaft boots and propeller shaft (4WD)IIIIMA-31

Exhaust system IIIIMA-26

In-cabin microfilter RRMA-26

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Reference

Section - Page

or - Content Ti- tle

Perform at number of miles, kilometers

or months, whichever comes first. Miles x 1,000

(km x 1,000) Months 7.5

(12) 6 15

(24) 12 22.5

(36) 18 30

(48) 24 37.5

(60) 30 45

(72) 36 52.5

(84) 42 60

(96) 48

Drive belts NOTE (1) I*MA-15

Air cleaner filter [R][R]MA-20

EVAP vapor lines I*I*MA-25

Fuel lines I*I*MA-19

Fuel filter NOTE (2) MA-19

Engine coolantNOTE (3) R*MA-17

Engine oil R R R R R R R R MA-22

Engine oil filter (Use Genuine NISSAN

oil filter or equivalent)RRRR RRR R

MA-22

Spark plug (Iridium - tipped type) Replace every 105,000 miles (169,000 km).MA-24

Intake and exhaust valve clearance* NOTE (4) EM-18

Revision: April 20092010 QX56

Page 2716 of 4210

MA-12

< ON-VEHICLE MAINTENANCE >

PERIODIC MAINTENANCE

Abbreviations: R = Replace. I = Inspect. Correct or replace if necessary.

(1) Using automatic transmission fluid other than Genuine NISSAN Matic S ATF or Matic J ATF will cause deterioration in drive

ability and automatic transmission durability, and may damage the automatic transmission, which is not covered by the

INFINITI new vehicle limited warranty.

(2) Refer to “Tire rotation” unde r the “General maintenance” heading earlier in this section.

MAINTENANCE OPERATION

MAINTENANCE INTERVALReference

Section

- Page or

- Content

Title

Perform at number of miles, kilometers or

months, whichever comes first.

Miles x 1,000

(km x 1,000)

Months 7.5

(12)

6 15

(24)

12 22.5

(36)

18 30

(48)

24 37.5

(60)

30 45

(72)

36 52.

5

(84) 42 60

(96)

48

Brake lines and cables IIIIMA-34

Brake pads and rotors IIIIMA-35

Automatic transmission fluid, transfer fluid

and differential gear oil N

O TE (1)IIII MA-27,

MA-30

,

MA-32

Steering gear and linkage, axle and suspen-

sion parts IIMA-36,

MA-37

Tire rotation NOTE (2) MA-34

Drive shaft boots and propeller shaft

(4WD)IIII

MA-31

Exhaust system IIMA-26

In-cabin microfilter RRRRMA-26

Revision: April 20092010 QX56

Page 2741 of 4210

CHASSIS AND BODY MAINTENANCEMA-37

< ON-VEHICLE MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

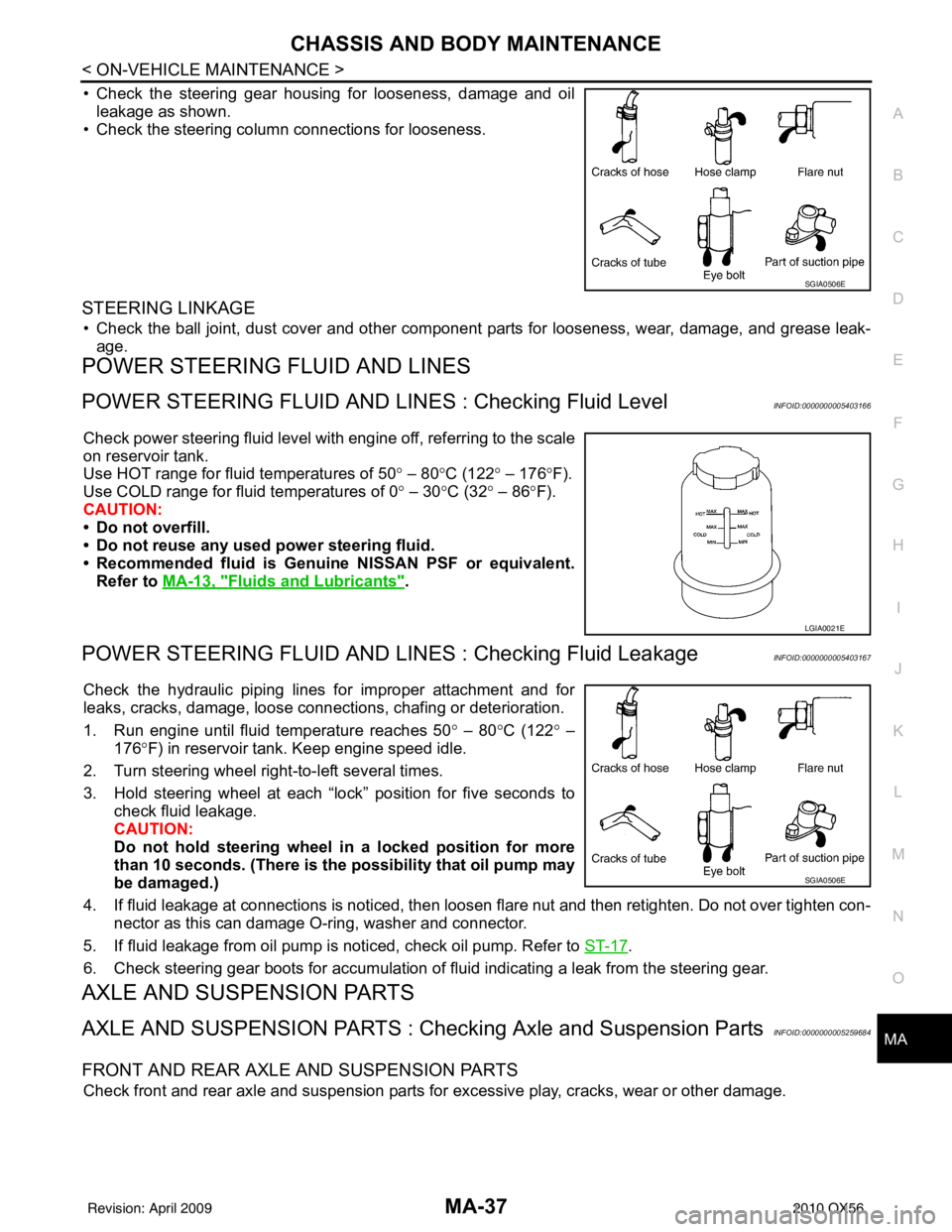

• Check the steering gear housing for looseness, damage and oil

leakage as shown.

• Check the steering column connections for looseness.

STEERING LINKAGE

• Check the ball joint, dust cover and other component parts for looseness, wear, damage, and grease leak-

age.

POWER STEERING FLUID AND LINES

POWER STEERING FLUID AND LINE S : Checking Fluid LevelINFOID:0000000005403166

Check power steering fluid level with engine off, referring to the scale

on reservoir tank.

Use HOT range for fluid temperatures of 50 ° – 80 °C (122 ° – 176 °F).

Use COLD range for fluid temperatures of 0 ° – 30 °C (32° – 86°F).

CAUTION:

• Do not overfill.

• Do not reuse any used power steering fluid.

• Recommended fluid is Genuine NISSAN PSF or equivalent.

Refer to MA-13, "

Fluids and Lubricants".

POWER STEERING FLUID AND LINES : Checking Fluid LeakageINFOID:0000000005403167

Check the hydraulic piping lines for improper attachment and for

leaks, cracks, damage, loose connec tions, chafing or deterioration.

1. Run engine until fluid temperature reaches 50 ° – 80° C (122° –

176° F) in reservoir tank. Keep engine speed idle.

2. Turn steering wheel right-to-left several times.

3. Hold steering wheel at each “lock” position for five seconds to check fluid leakage.

CAUTION:

Do not hold steering wheel in a locked position for more

than 10 seconds. (There is the possibility that oil pump may

be damaged.)

4. If fluid leakage at connections is noticed, then loosen flare nut and then retighten. Do not over tighten con- nector as this can damage O-ring, washer and connector.

5. If fluid leakage from oil pump is noticed, check oil pump. Refer to ST-17

.

6. Check steering gear boots for accumulation of fluid indicating a leak from the steering gear.

AXLE AND SUSPENSION PARTS

AXLE AND SUSPENSION PARTS : Chec king Axle and Suspension PartsINFOID:0000000005259684

FRONT AND REAR AXLE AND SUSPENSION PARTS

Check front and rear axle and suspension parts for excessive play, cracks, wear or other damage.

SGIA0506E

LGIA0021E

SGIA0506E

Revision: April 20092010 QX56

Page 3113 of 4210

RAX-1

TRANSMISSION & DRIVELINE

CEF

G H

I

J

K L

M

SECTION RAX

A

B

RAX

N

O P

CONTENTS

REAR AXLE

PRECAUTION ....... ........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

Precaution .................................................................3

PREPARATION ............................................4

PREPARATION .............................................. .....4

Special Service Tool ........................................... ......4

Commercial Service Tool ..........................................4

SYMPTOM DIAGNOSIS ...............................5

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ........................ .....

5

NVH Troubleshooting Chart ................................ ......5

ON-VEHICLE MAINTENANCE .....................6

WHEEL HUB .................................................. .....6

On-Vehicle Inspection and Service ..................... ......6

ON-VEHICLE REPAIR ..................................7

REAR DRIVE SHAFT .........................................7

Component .......................................................... .....7

REMOVAL AND INSTALLATION ................8

WHEEL HUB ......................................................8

Removal and Installation ..................................... .....8

REAR DRIVE SHAFT ........................................10

Removal and Installation .........................................10

DISASSEMBLY AND ASSEMBLY ..............11

REAR DRIVE SHAFT ........................................11

Disassembly and Assembly ................................. ....11

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... ...

16

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

16

Wheel Bearing ..................................................... ....16

Drive Shaft ...............................................................16

Boot Bands ..............................................................16

Revision: April 20092010 QX56

Page 3116 of 4210

RAX-4

< PREPARATION >

PREPARATION

PREPARATION

PREPARATION

Special Service ToolINFOID:0000000005148951

The actual shapes of the Kent-Moore tools may differ from those of the special service tools illustrated here.

Commercial Service ToolINFOID:0000000005148952

Tool number

(Kent-Moore No.)

Tool name Description

KV38100500

(—)

Drift Installing drive shaft plug

a: 80 mm (3.15 in) dia.

b: 60 mm (2.36 in) dia.

KV38102200

(—)

Drift Installing drive shaft plug

a: 90 mm (3.54 in) dia.

b: 31 mm (1.22 in) dia.

KV40107300

(—)

Boot band crimping tool Installing boot bands

ZZA0701D

ZZA0920D

ZZA1229D

Tool name

Description

Power tools Removing bolts and nuts

PBIC0190E

Revision: April 20092010 QX56

Page 3122 of 4210

RAX-10

< REMOVAL AND INSTALLATION >

REAR DRIVE SHAFT

REAR DRIVE SHAFT

Removal and InstallationINFOID:0000000005148957

REMOVAL

1. Remove the wheel and tire using power tool.

2. Remove the stabilizer bar clamp. Refer to RSU-9, "

Component".

3. Remove the cotter pin and discard, then remove the drive shaft nut from the drive shaft.

• Do not reuse the cotter pin, discard after removal and use anew cotter pin for installation.

4. Remove the six bolts from the inside flange of the drive shaft using power tool. • Do not reuse the drive shaft inside flange bolts, discard after removal and use new bolts for installation.

5. Separate the drive shaft from the wheel hub and bearing assembly by lightly tapping the end with a suit- able hammer and wood block. If it is difficult to separate, use a suitable puller.

6. Remove the drive shaft. CAUTION:

When removing the drive shaft, do not bend at an excessive angle to the drive shaft joint. Do not

excessively extend the slide joint.

INSPECTION AFTER REMOVAL

• Move the joint up and down, left and right, and in the axial direc- tion. Check for any rough movement or significant looseness.

• Check the boot for cracks or other damage, and for any grease leakage.

• If necessary, disassemble the drive shaft, and repair as necessary.

INSTALLATION

Installation is in the reverse order of removal.

• Do not reuse the drive shaft inside flange bolts, discard after removal and use new bolts for installation.

• Do not reuse the cotter pin, discard after removal and use a new cotter pin for installation.

LDIA0050E

RAA0030D

Drive shaft lock nut : Refer to RAX-7, "Component".

Drive shaft inside flange bolts : Refer to RAX-7, "

Component".

Revision: April 20092010 QX56

Page 3123 of 4210

REAR DRIVE SHAFTRAX-11

< DISASSEMBLY AND ASSEMBLY >

CEF

G H

I

J

K L

M A

B

RAX

N

O P

DISASSEMBLY AND ASSEMBLY

REAR DRIVE SHAFT

Disassembly and AssemblyINFOID:0000000005274245

DISASSEMBLY

Final Drive Side

1. Secure the drive shaft in a vise. CAUTION:

When securing the drive shaft in a vise, use copper or aluminum plates between the vise and the

drive shaft.

2. Remove the boot bands.

3. If the plug needs to be removed, move the boot to t he wheel side, then drive the plug out using a suitable

tool.

4. Remove the stopper ring using a suitable tool as shown, and pull the housing out.

1. Plug 2. Housing3. Snap ring

4. Ball cage, steel ball, inner race assembly 5. Stopper ring 6. Boot band

7. Boot 8. Shaft9. Circlip

10. Joint sub-assembly

SDIA1488E

SRA249A

Revision: April 20092010 QX56