check transmission fluid INFINITI QX56 2010 Factory Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 3760 of 4210

P0740 TORQUE CONVERTERTM-65

< COMPONENT DIAGNOSIS >

CEF

G H

I

J

K L

M A

B

TM

N

O P

P0740 TORQUE CONVERTER

DescriptionINFOID:0000000005148593

• The torque converter clutch solenoid valve is activated, with the gear in D4, D5 by the TCM in response to

signals sent from the output speed sensor and accele rator pedal position sensor. Torque converter clutch

piston operation will then be controlled.

• Lock-up operation, however, is prohibited when A/T fluid temperature is too low.

• When the accelerator pedal is depressed (less than 1/8) in lock-up condition, the engine speed should not change abruptly. If there is a big jump in engine speed, there is no lock-up.

CONSULT-III Reference Val ue in Data Monitor ModeINFOID:0000000005148594

On Board Diagnosis LogicINFOID:0000000005148595

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0740 TORQUE CONVERTER” wi th CONSULT-III is detected under the following

conditions.

- When TCM detects an improper voltage drop when it tries to operate the solenoid valve.

- When TCM detects as irregular by comparing target value with monitor value.

Possible CauseINFOID:0000000005148596

• Torque converter clutch solenoid valve

• Harness or connectors (The solenoid circuit is open or shorted.)

DTC Confirmation ProcedureINFOID:0000000005148597

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch “OFF”

and wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch “ON”. (Do not start engine.)

2. Select “DATA MONITOR” mode for “ENGINE” with CONSULT-III.

3. Start engine and maintain the following conditions for at least 5 consecutive seconds.

VHCL/S SE-A/T: 80 km/h (50 MPH) or more

ACCELE POSI: 0.5/8 - 1.0/8

SLCT LVR POSI: “D” position

Driving location: Driving the vehic le uphill (increased engine load) will help maintain the driving

conditions required for this test.

4. If DTC is detected go to TM-65, "

Diagnosis Procedure".

WITH GST

Follow the procedure “With CONSULT-III”.

Diagnosis ProcedureINFOID:0000000005148598

1.CHECK INPUT SIGNAL

With CONSULT-III

1. Turn ignition switch “ON”.

2. Select “MAIN SIGNALS” in “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

Item name Condition Display value (Approx.)

TCC SOLENOID When performing slip lock-up.

0.2 - 0.4 A

When performing lock-up. 0.4 - 0.6 A

Revision: April 20092010 QX56

Page 3763 of 4210

TM-68

< COMPONENT DIAGNOSIS >

P0744 TORQUE CONVERTER

Diagnosis Procedure

INFOID:0000000005148604

1.CHECK INPUT SIGNAL

With CONSULT-III

1. Turn ignition switch “ON”.

2. Select “MAIN SIGNALS” in “DATA MONITO R” mode for “TRANSMISSION” with CONSULT-III.

3. Start the engine.

4. Read out the value of “TCC SOLENOID” while driving.

OK or NG

OK >> GO TO 4.

NG >> GO TO 2.

2.CHECK TCM POWER SUPPLY AND GROUND CIRCUIT

Check TCM power supply and ground circuit. Refer to TM-94, "

Diagnosis Procedure".

OK or NG

OK >> GO TO 3.

NG >> Repair or replace damaged parts.

3.DETECT MALFUNCTIONING ITEM

Check the following items:

• The A/T assembly harness connector pin terminals for damage or loose connection with harness connector.

OK or NG

OK >> Replace the control valve with TCM. Refer to TM-172, "Control Valve with TCM and A/T Fluid

Temperature Sensor 2 and Plug".

NG >> Repair or replace damaged parts.

4.CHECK DTC

Perform “DTC Confirmation Procedure”.

• Refer to TM-67, "

DTC Confirmation Procedure".

OK or NG

OK >> INSPECTION END

NG >> GO TO 2.

Item name Condition Display value (Approx.)

TCC SOLENOID When performing slip lock-up.

0.2 - 0.4 A

When performing lock-up. 0.4 - 0.6 A

Revision: April 20092010 QX56

Page 3767 of 4210

TM-72

< COMPONENT DIAGNOSIS >

P1705 TP SENSOR

OK >> GO TO 4.

NG >> GO TO 3.

3.CHECK DTC WITH ECM

With CONSULT-III

1. Turn ignition switch “ON”. (Do not start engine.)

2. Select “SELF-DIAG RESULTS” mode for “ENGINE” with CONSULT-III. Refer to TM-32, "

CONSULT-III

Function (TRANSMISSION)".

OK or NG

OK >> GO TO 4.

NG >> Check the DTC detected item. Refer to TM-119, "

DTC No. Index".

• If CAN communication line is detected, go to TM-40, "

Description".

4.CHECK DTC

Perform “DTC Confirmation Procedure”.

• Refer to TM-71, "

DTC Confirmation Procedure".

OK or NG

OK >> INSPECTION END

NG >> GO TO 5.

5.CHECK TCM POWER SUPPLY AND GROUND CIRCUIT

Check TCM power supply and ground circuit. Refer to TM-94, "

Diagnosis Procedure".

OK or NG

OK >> GO TO 6.

NG >> Repair or replace damaged parts.

6.DETECT MALFUNCTIONING ITEM

Check the following items:

• The A/T assembly harness connector pin terminals for damage or loose connection with harness connector.

OK or NG

OK >> Replace the control valve with TCM. Refer to TM-172, "Control Valve with TCM and A/T Fluid

Temperature Sensor 2 and Plug".

NG >> Repair or replace damaged parts.

Revision: April 20092010 QX56

Page 3768 of 4210

P1710 TRANSMISSION FLUID TEMPERATURE SENSOR

TM-73

< COMPONENT DIAGNOSIS >

C EF

G H

I

J

K L

M A

B

TM

N

O P

P1710 TRANSMISSION FLUI D TEMPERATURE SENSOR

DescriptionINFOID:0000000005148617

The A/T fluid temperature sensor 1 detects the A/ T fluid temperature and sends a signal to the TCM.

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000005148618

On Board Diagnosis LogicINFOID:0000000005148619

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P1710 FLUID TEMP SENSOR, P0710 FLUID TEMP SENSOR A” with CONSULT-

III is detected when TCM receives an excess ively low or high voltage from the sensor.

Possible CauseINFOID:0000000005148620

• Harness or connectors

(The sensor circuit is open or shorted.)

• A/T fluid temperature sensors 1

DTC Confirmation ProcedureINFOID:0000000005148621

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch “OFF”

and wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch “ON”. (Do not start engine.)

2. Select “DATA MONITOR” mode for “ENGINE” with CONSULT-III.

3. Start engine and maintain the following conditions for at least 10 minutes (Total). (It is not necessary to maintain continuously.)

VHCL/S SE-A/T: 10 km/h (6 MPH) or more

ACCELE POSI: More than 1.0/8

SLCT LVR POSI: “D” position

4. If DTC is detected, go to TM-73, "

Diagnosis Procedure".

WITH GST

Follow the procedure “With CONSULT-III”.

Diagnosis ProcedureINFOID:0000000005148622

1.CHECK A/T FLUID TEMPERATURE SENSOR 1 SIGNAL

With CONSULT-III

1. Start engine.

2. Select “ECU INPUT SIGNALS” in “DATA MONITO R” mode for “TRANSMISSION” with CONSULT-III.

3. Read out the value of “ATF TEMP SE 1”.

OK or NG

OK >> GO TO 5.

NG >> GO TO 2.

Item name Condition °C ( °F) Display value (Approx.)

ATF TEMP SE 1 0 (32) - 20 (68) - 80 (176) 3.3 - 2.7 - 0.9 V

Item nameCondition °C ( °F) Display value (Approx.)

ATF TEMP SE 1 0 (32) - 20 (68) - 80 (176) 3.3 - 2.7 - 0.9 V

Revision: April 20092010 QX56

Page 3769 of 4210

TM-74

< COMPONENT DIAGNOSIS >

P1710 TRANSMISSION FLUID TEMPERATURE SENSOR

2.CHECK A/T FLUID TEMPERATURE SENSOR 1

Check A/T fluid temperature sensor 1. Refer to TM-74, "

Component Inspection".

OK or NG

OK >> GO TO 3.

NG >> Replace the control valve with TCM. Refer to TM-172, "

Control Valve with TCM and A/T Fluid

Temperature Sensor 2 and Plug".

3.CHECK SUB-HARNESS

1. Disconnect transmission range switch connector and TCM connector.

2. Check continuity between transmission range switch connector (A) terminals and TCM connector (B) terminals.

3. If OK, check harness for short to ground and short to power.

OK or NG

OK >> GO TO 4.

NG >> Replace open circuit or short to ground and short to power in harness or connectors.

4.CHECK TCM POWER SUPPLY AND GROUND CIRCUIT

1. Check TCM power supply and ground circuit. Refer to TM-94, "

Diagnosis Procedure".

2. Reinstall any part removed.

OK or NG

OK >> Replace the control valve with TCM. Refer to TM-172, "Control Valve with TCM and A/T Fluid

Temperature Sensor 2 and Plug".

NG >> Repair or replace damaged parts.

5.CHECK DTC

Perform “DTC Confirmation Procedure”.

• Refer to TM-73, "

DTC Confirmation Procedure".

OK or NG

OK >> INSPECTION END

NG >> GO TO 1.

Component InspectionINFOID:0000000005148623

A/T FLUID TEMPERATURE SENSOR 1

1. Remove control valve with TCM. Refer to TM-172, "Control Valve with TCM and A/T Fluid Temperature

Sensor 2 and Plug".

2. Check resistance between transmission range switch connector (A) terminals.

Item Connector Terminal Continuity

Transmission range switch con-

nector F505

6

Ye s

TCM connector F50319

Transmission range switch con-

nector F505

7

Ye s

TCM connector F50318

JSDIA1330ZZ

Item TerminalTemperature

°C

(° F) Resistance (Ap-

prox.) (k Ω)

0 (32) 15

A/T fluid temperature sensor 1 6-7 20 (68)6.5

80 (176) 0.9

JSDIA1331ZZ

Revision: April 20092010 QX56

Page 3788 of 4210

P1774 LOW COAST BRAKE SOLENOIDTM-93

< COMPONENT DIAGNOSIS >

CEF

G H

I

J

K L

M A

B

TM

N

O P

Diagnosis ProcedureINFOID:0000000005148677

1.CHECK INPUT SIGNALS

With CONSULT-III

1. Start the engine.

2. Select “SELECTION FROM MENU” in “DATA MONI TOR” mode for “TRANSMISSION” with CONSULT-III.

3. Drive vehicle in the “1” or “2” position (“1

1” or “22” gear) and confirm the ON/OFF actuation of the “ATF

PRES SW 2” and “ON OFF SOL”.

OK or NG

OK >> GO TO 4.

NG >> GO TO 2.

2.CHECK TCM POWER SUPPLY AND GROUND CIRCUIT

Check TCM power supply and ground circuit. Refer to TM-94, "

Diagnosis Procedure".

OK or NG

OK >> GO TO 3.

NG >> Repair or replace damaged parts.

3.DETECT MALFUNCTIONING ITEM

Check the following items:

• The A/T assembly harness connector pin terminals for damage or loose connection with harness connector.

OK or NG

OK >> Replace the control valve with TCM. Refer to TM-172, "Control Valve with TCM and A/T Fluid

Temperature Sensor 2 and Plug".

NG >> Repair or replace damaged parts.

4.CHECK DTC

Perform “DTC Confirmation Procedure”.

• Refer to TM-92, "

DTC Confirmation Procedure".

OK or NG

OK >> INSPECTION END

NG >> GO TO 2.

Item name Condition Display value

ON OFF SOL Low coast brake engaged. Refer to

TM-9

.O N

Low coast brake disengaged. Refer to TM-9

.O FF

ATF PRES SW 2 Low coast brake engaged. Refer to

TM-9

.O N

Low coast brake disengaged. Refer to TM-9

.O FF

Revision: April 20092010 QX56

Page 3790 of 4210

MAIN POWER SUPPLY AND GROUND CIRCUITTM-95

< COMPONENT DIAGNOSIS >

CEF

G H

I

J

K L

M A

B

TM

N

O P

5.DETECT MALFUNCTIONING ITEM

Check the following items:

• The A/T assembly harness connector terminals for damage or loose connection with harness connector.

OK or NG

OK >> GO TO 6.

NG >> Repair or replace damaged parts.

6.PERFORM SELF-DIAGNOSIS

Perform self-diagnosis. Refer to TM-32, "

CONSULT-III Function (TRANSMISSION)".

OK or NG

OK >> INSPECTION END

NG-1 >> Self-diagnosis does not activate: GO TO 7.

NG-2 >> DTC is displayed: Check t he malfunctioning system. Refer to TM-32, "

CONSULT-III Function

(TRANSMISSION)".

7.CHECK TERMINAL CORD ASSEMBLY

1. Remove control valve with TCM. Refer to TM-172, "

Control Valve with TCM and A/T Fluid Temperature

Sensor 2 and Plug".

2. Disconnect A/T assembly harness connector and TCM connector.

3. Check continuity between A/T assembly harness connector ter- minals and TCM connector terminals.

4. Check continuity between A/T assembly harness connector ter- minals and TCM connector terminals.

5. If OK, check harness for short to ground and short to power.

OK or NG

OK >> Replace the control valve with TCM. Refer to TM-172, "Control Valve with TCM and A/T Fluid

Temperature Sensor 2 and Plug".

NG >> Replace open circuit or short to ground and short to power in harness or connectors.

Item Connector Terminal Continuity

A/T assembly harness con-

nector F9

1

Ye s

TCM connector F5029

A/T assembly harness con-

nector F9

2

Ye s

TCM connector F50210

A/T assembly harness con-

nector F9

6

Ye s

TCM connector F5024

SCIA5464E

Item Connector Terminal Continuity

A/T assembly harness con-

nector F9

5

Ye s

TCM connector F50421

A/T assembly harness con-

nector F9

10

Ye s

TCM connector F50422

SCIA5465E

Revision: April 20092010 QX56

Page 3839 of 4210

TM-144

< PRECAUTION >

PRECAUTIONS

•After performing each TROUBLE DIAGNOSIS, perform “DTC

(Diagnostic Trouble Code) CONFIRMATION PROCEDURE”.

If the repair is completed the DTC should not be displayed in the

“DTC CONFIRMATION PROCEDURE”.

• Always use the specified brand of ATF. Refer to MA-13, "

Fluids and Lubricants".

• Use paper rags not cloth rags during work.

• After replacing the ATF, dispose of the waste oil using the methods prescribed by law, ordinance, etc.

• Before proceeding with disassembly, thoroughly clean the outside of the transmission. It is important to pre- vent the internal parts from becoming cont aminated by dirt or other foreign matter.

• Disassembly should be done in a clean work area.

• Use lint-free cloth or towels for wiping parts clean. Common shop rags can leave fibers that could interfere

with the operation of the transmission.

• Place disassembled parts in order for easier and proper assembly.

• All parts should be carefully cleaned with a general purpose, non-flammable solvent before inspection or

reassembly.

• Gaskets, seals and O-rings should be replaced any time the transmission is disassembled.

• It is very important to perform functional tests whenever they are indicated.

• The valve body contains precision parts and requires extreme care when parts are removed and serviced. Place disassembled valve body parts in order for easier and proper assembly. Care will also prevent springs

and small parts from becoming scattered or lost.

• Properly installed valves, sleeves, plugs, etc. will slide along bores in valve body under their own weight.

• Before assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings and

seals, or hold bearings and washers in place during assembly. Do not use grease.

• Extreme care should be taken to avoid damage to O-rings, seals and gaskets when assembling.

• Clean or replace ATF cooler if excessive foreign material is found in oil pan or clogging strainer. Refer to TM-

152, "A/T Fluid Cooler Cleaning".

• After overhaul, refill the transmission with new ATF.

• When the A/T drain plug is removed, only some of the fluid is drained. Old A/T fluid will remain in torque con- verter and ATF cooling system.

Always follow the procedures under “Changing A/T Fluid” in the AT section when changing A/T fluid. Refer to

TM-150, "

Changing the A/T Fluid (ATF)", TM-148, "Checking the A/T Fluid (ATF)".

Service Notice or PrecautionINFOID:0000000005148719

ATF COOLER SERVICE

• If A/T fluid contains fictional material (clutches, bands, etc.), or if an A/T is repaired, overhauled, or replaced,

inspect and clean the A/T fluid cooler mounted in the radiator or replace the radiator. Flush cooler lines with

cleaning solvent and compressed air after repair. For A/T fluid cooler cleaning procedure, refer to TM-152,

"A/T Fluid Cooler Cleaning". For radiator replacement, refer to CO-15, "Removal and Installation".

CHECKING AND CHANGING A/T FLUID

• Increase ATF oil temperature to 80 °C (176° F) first, then check and adjust oil level at 65 °C (149° F).

NOTE:

The A/T has both water cooling and air cooling systems . The air cooling system has a bypass valve. When

ATF oil temperature is at or below 50 °C (122° F), it does not flow through the air cooled system. If A/T oil

level is adjusted without flow throughout the entire system, the level will be 10mm lower than required.

Therefore, all piping should be filled with oil when adjusting level.

OBD-II SELF-DIAGNOSIS

• A/T self-diagnosis is performed by the TCM in combination with the ECM. Refer to the table on TM-32,

"CONSULT-III Function (TRANSMISSION)" for the indicator used to display each self-diagnostic result.

• The self-diagnostic results indicated by the MIL ar e automatically stored in both the ECM and TCM memo-

ries.

SEF217U

Revision: April 20092010 QX56

Page 3843 of 4210

TM-148

< ON-VEHICLE MAINTENANCE >

A/T FLUID

ON-VEHICLE MAINTENANCE

A/T FLUID

Checking the A/T Fluid (ATF)INFOID:0000000005148722

CAUTION:

If using the vehicle for towing, the A/T fluid must be replaced as specified. Refer to MA-9, "

Introduc-

tion of Periodic Maintenance".

1. Before driving, the A/T fluid level can be checked at A/T fluid temperatures of 30 ° to 50° C (86° to 122° F) using the “COLD”

range on the A/T fluid level gauge as follows:

a. Park the vehicle on a level surface and set the parking brake.

b. Start the engine and move the selector lever through each gear position. Shift the selector lever into the “P” position.

c. Check the A/T fluid level with the engine idling.

d. Remove the A/T fluid level gauge and wipe it clean with a lint- free paper.

CAUTION:

When wiping the A/T fluid from the A/ T fluid level gauge,

always use a lint-free paper, not a cloth.

e. Re-insert the A/T fluid level gauge into the A/T fluid charging pipe until the cap contacts the t op of the A/T fluid charging pipe

as shown.

CAUTION:

To check A/T fluid level, insert th e A/T fluid level gauge until

the cap contacts the top of the A/T fluid charging pipe, with

the gauge reversed from th e normal inserted position.

f. Remove the A/T fluid level gauge and note the A/T fluid level. If the A/T fluid level is at low si de of range, add A/T fluid to the

transmission through the A/T fluid charging pipe.

CAUTION:

Do not overfill the transmission with A/T fluid.

g. Install the A/T fluid level gauge and the A/T fluid level gauge bolt.

2. Warm up the engine and transmission.

3. Check for any A/T fluid leaks.

4. Drive the vehicle to increase the A/T fluid temperature to 80 ° C (176 ° F).

LLIA0071E

A/T fluid level

gauge bolt : Refer to

TM-186, "Removal and Installation (2WD)" or TM-188, "Removal

and Installation (4WD)"

SCIA2899E

Revision: April 20092010 QX56

Page 3844 of 4210

A/T FLUIDTM-149

< ON-VEHICLE MAINTENANCE >

CEF

G H

I

J

K L

M A

B

TM

N

O P

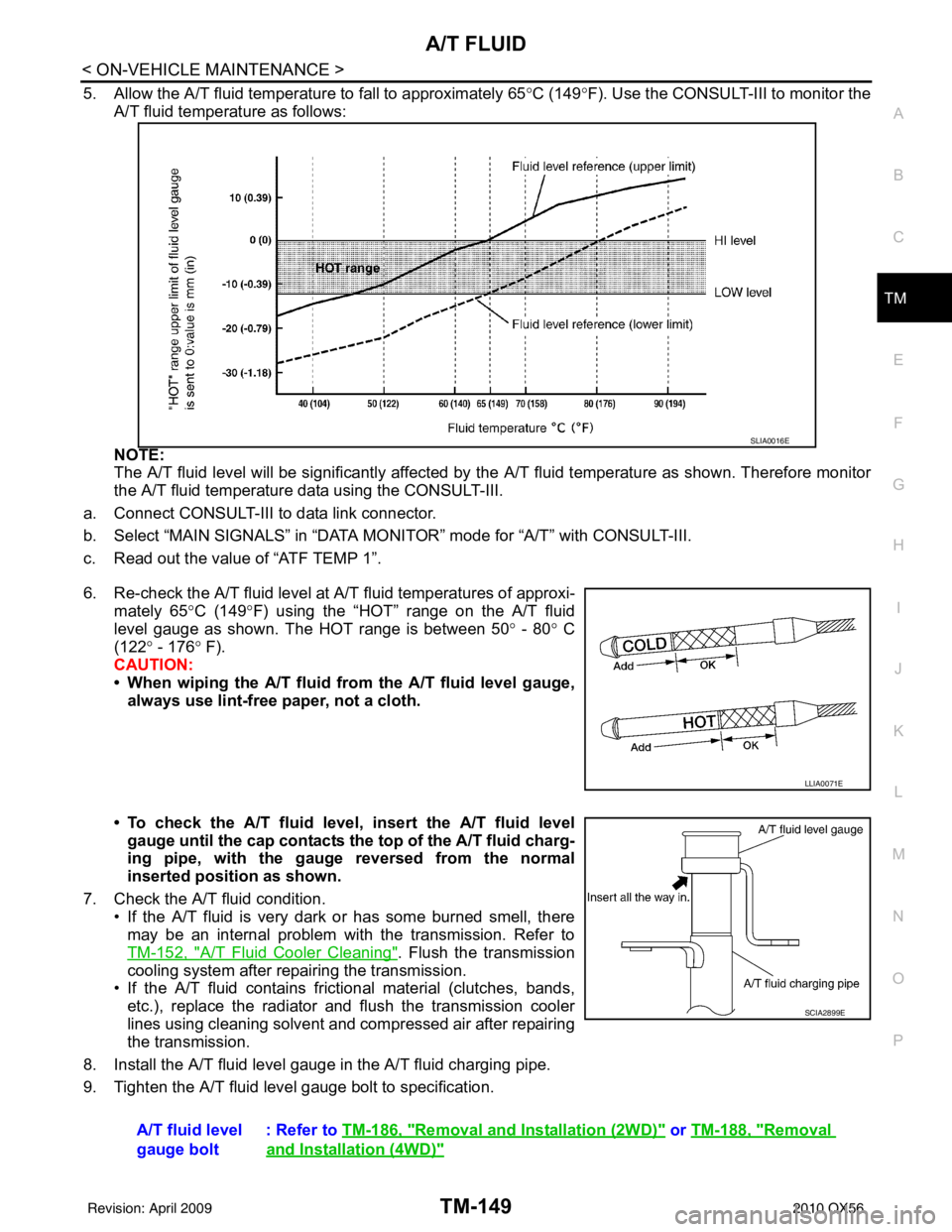

5. Allow the A/T fluid temperature to fall to approximately 65 °C (149° F). Use the CONSULT-III to monitor the

A/T fluid temperature as follows:

NOTE:

The A/T fluid level will be significantly affected by the A/T fluid temperature as shown. Therefore monitor

the A/T fluid temperature data using the CONSULT-III.

a. Connect CONSULT-III to data link connector.

b. Select “MAIN SIGNALS” in “DATA MO NITOR” mode for “A/T” with CONSULT-III.

c. Read out the value of “ATF TEMP 1”.

6. Re-check the A/T fluid level at A/T fluid temperatures of approxi-

mately 65° C (149°F) using the “HOT” range on the A/T fluid

level gauge as shown. The HOT range is between 50 ° - 80° C

(122° - 176 ° F).

CAUTION:

• When wiping the A/T fluid from the A/T fluid level gauge, always use lint-free paper, not a cloth.

• To check the A/T fluid level, insert the A/T fluid level gauge until the cap contacts the top of the A/T fluid charg-

ing pipe, with the gauge reversed from the normal

inserted position as shown.

7. Check the A/T fluid condition. • If the A/T fluid is very dark or has some burned smell, there

may be an internal problem with the transmission. Refer to

TM-152, "

A/T Fluid Cooler Cleaning". Flush the transmission

cooling system after repairing the transmission.

• If the A/T fluid contains frictional material (clutches, bands, etc.), replace the radiator and flush the transmission cooler

lines using cleaning solvent and compressed air after repairing

the transmission.

8. Install the A/T fluid level gauge in the A/T fluid charging pipe.

9. Tighten the A/T fluid level gauge bolt to specification.

SLIA0016E

LLIA0071E

A/T fluid level

gauge bolt : Refer to

TM-186, "Removal and Installation (2WD)" or TM-188, "Removal

and Installation (4WD)"

SCIA2899E

Revision: April 20092010 QX56