Oil INFINITI QX56 2010 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 2455 of 4210

![INFINITI QX56 2010 Factory Service Manual INSUFFICIENT COOLINGHAC-115

< SYMPTOM DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

Low-pressure Side Becomes Negative

Gauge indication

Refrigerant cycleProbable causeCorre INFINITI QX56 2010 Factory Service Manual INSUFFICIENT COOLINGHAC-115

< SYMPTOM DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

Low-pressure Side Becomes Negative

Gauge indication

Refrigerant cycleProbable causeCorre](/img/42/57032/w960_57032-2454.png)

INSUFFICIENT COOLINGHAC-115

< SYMPTOM DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

Low-pressure Side Becomes Negative

Gauge indication

Refrigerant cycleProbable causeCorrective action

Low-pressure side sometimes be-

comes negative. • Air conditioning system does

not function and does not cy-

clically cool the compart-

ment air.

• The system constantly func- tions for a certain period of

time after compressor is

stopped and restarted. Refrigerant does not discharge

cyclically.

↓

Moisture is frozen at expan-

sion valve outlet and inlet.

↓

Water is mixed with refrigerant.

• Drain water from refrigerant

or replace refrigerant.

• Replace liquid tank.

AC354A

Gauge indication Refrigerant cycleProbable causeCorrective action

Low-pressure side becomes nega-

tive. Liquid tank or front/rear side of

expansion valve′s pipe is frost-

ed or dewed. High-pressure side is closed

and refrigerant does not flow.

↓

Expansion valve or liquid tank

is frosted.Leave the system at rest until

no frost is present. Start it

again to check whether or not

the malfunction is caused by

water or foreign particles.

• If water is the cause, initially

cooling is okay. Then the wa-

ter freezes causing a block-

age. Drain water from

refrigerant or replace refrig-

erant.

• If due to foreign particles, re- move expansion valve and

remove the particles with dry

and compressed air (not

shop air).

• If either of the above meth- ods cannot correct the mal-

function, replace expansion

valve.

• Replace liquid tank.

• Check oil for contamination.

AC362A

Revision: April 20092010 QX56

Page 2459 of 4210

![INFINITI QX56 2010 Factory Service Manual NOISE

HAC-119

< SYMPTOM DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

*4 HA-47, "Removal and Installation for

Front Expansion Valve"

*5HA-32, "Removal and Installation for INFINITI QX56 2010 Factory Service Manual NOISE

HAC-119

< SYMPTOM DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

*4 HA-47, "Removal and Installation for

Front Expansion Valve"

*5HA-32, "Removal and Installation for](/img/42/57032/w960_57032-2458.png)

NOISE

HAC-119

< SYMPTOM DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

*4 HA-47, "Removal and Installation for

Front Expansion Valve"

*5HA-32, "Removal and Installation for

Compressor Clutch"

*6 HA-32, "Removal and Installation for

Compressor Clutch"

*7HA-31, "Removal and Installation for

Compressor"

*8HA-22, "Maintenance of Oil Quantity

in Compressor"

*9 HA-44, "Removal and Installation for

Condenser"

Revision: April 20092010 QX56

Page 2461 of 4210

![INFINITI QX56 2010 Factory Service Manual PRECAUTIONSHAC-121

< PRECAUTION > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE INFINITI QX56 2010 Factory Service Manual PRECAUTIONSHAC-121

< PRECAUTION > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE](/img/42/57032/w960_57032-2460.png)

PRECAUTIONSHAC-121

< PRECAUTION > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005197361

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the battery, and wait at least 3 minutes before performing any service.

Working with HFC-134a (R-134a)INFOID:0000000005147743

WARNING:

• CFC-12 (R-12) refrigerant and HFC-134a (R-134a) refr igerant are not compatible. If the refrigerants

are mixed compressor failure is likely to occur. Refer to HA-4, "

Contaminated Refrigerant". To deter-

mine the purity of HFC-134a (R-134a) in the vehic le and recovery tank, use Refrigerant Recovery/

Recycling Recharging equipment and Refrigerant Identifier.

• Use only specified oil for the HFC-134a (R-134a) A/C system and HFC-134a (R-134a) components. If oil other than that specified is used, compressor fa ilure is likely to occur.

• The specified HFC-134a (R-134a) oil rapidly absorb s moisture from the atmosphere. The following

handling precautions must be observed:

- When removing refrigerant components from a vehicle, immediately cap (seal) the component to

minimize the entry of mois ture from the atmosphere.

- When installing refrigerant components to a vehicle, do not remove the caps (unseal) until just

before connecting the co mponents. Connect all refrigerant lo op components as quickly as possible

to minimize the entry of moisture into system.

- Only use the specified oil from a sealed container. Immediately r eseal containers of oil. Without

proper sealing, oil will become moisture saturat ed and should not be used.

- Avoid breathing A/C refrigerant and oil vapor or mist. Exposure may irritate eyes, nose and throat.

Remove HFC-134a (R-134a) from the A/C system usi ng certified service equipment meeting require-

ments of SAE J2210 [HFC-134a (R-134a) recycling equipment], or J2209 [HFC-134a (R-134a) recy-

cling equipment], If accidental system discharge occurs, ventilate work area before resuming

service. Additional health and safety information may be obtained from refrigerant and oil manufac-

turers.

- Do not allow A/C oil to come in contact with styrofoam parts. Damage may result.

CONTAMINATED REFRIGERANT

Revision: April 20092010 QX56

Page 2462 of 4210

![INFINITI QX56 2010 Factory Service Manual HAC-122

< PRECAUTION >[AUTOMATIC AIR CONDITIONER]

PRECAUTIONS

If a refrigerant other than pure HFC-134a (R-134a)

is identified in a vehicle, your options are:

• Explain to the customer that environ INFINITI QX56 2010 Factory Service Manual HAC-122

< PRECAUTION >[AUTOMATIC AIR CONDITIONER]

PRECAUTIONS

If a refrigerant other than pure HFC-134a (R-134a)

is identified in a vehicle, your options are:

• Explain to the customer that environ](/img/42/57032/w960_57032-2461.png)

HAC-122

< PRECAUTION >[AUTOMATIC AIR CONDITIONER]

PRECAUTIONS

If a refrigerant other than pure HFC-134a (R-134a)

is identified in a vehicle, your options are:

• Explain to the customer that environmental regulations prohibit the release of contaminated refrigerant into

the atmosphere.

• Explain that recovery of the contaminated refri gerant could damage your service equipment and refrigerant

supply.

• Suggest the customer return the vehicle to the location of previous service where the contamination may

have occurred.

• If you choose to perform the repair, recover the refrigerant using only dedicated equipment and contain- ers. Do not recover contamin ated refrigerant into your existing service equipment. If your facility does

not have dedicated recovery equipment, you may contact a local refrigerant product retailer for available ser-

vice. This refrigerant must be disposed of in acco rdance with all federal and local regulations. In addition,

replacement of all refrigerant system components on the vehicle is recommended.

• If the vehicle is within the warranty period, the air conditioner warranty is void. Please contact NISSAN Cus-

tomer Affairs for further assistance.

Precaution for Service EquipmentINFOID:0000000005147744

MANIFOLD GAUGE SET

Be certain that the gauge face indicates R-134a or 134a. Make sure

the gauge set has 1/2 ″-16 ACME threaded connections for service

hoses. Confirm the set has been used only with refrigerant HFC-

134a (R-134a) along with specified oil.

SERVICE HOSES

Be certain that the service hoses display the markings described

(colored hose with black stripe). All hoses must include positive shut-

off devices (either manual or aut omatic) near the end of the hoses

opposite the manifold gauge.

SERVICE COUPLERS

Never attempt to connect HFC-134a (R-134a) service couplers to a

CFC-12 (R-12) A/C system. The HFC-134a (R-134a) couplers will

not properly connect to the CFC-12 (R-12) system. However, if an

improper connection is attempted, discharging and contamination

may occur.

SHA533D

RHA272D

Shut-off valve rotati on A/C service valve

Clockwise Open

Counterclockwise Close

RHA273D

Revision: April 20092010 QX56

Page 2478 of 4210

ILLUMINATION CONTROL SYSTEMINL-9

< FUNCTION DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

INL

N

O P

ILLUMINATION CONTROL SYSTEM

System DiagramINFOID:0000000005358668

System DescriptionINFOID:0000000005358669

The illumination lamps operation is dependent upon the posit ion of the combination switch (lighting and turn

signal switch). When the combination switch (lighting and turn signal switch) is placed in the 1ST or 2ND posi-

tion (or if the auto light system is activated) the BCM (body control modul e) receives input requesting the park-

ing lamps to illuminate. This input is communicated to the IPDM E/R (intelligent power distribution module

engine room) via the CAN communication lines. The CPU (central processing unit) of the IPDM E/R controls

the tail lamp relay coil. When energized, this relay directs power to the parking and illumination lamps, which

then illuminate.

BATTERY SAVER CONTROL

When the combination switch (lighting and turn signal s witch) is in the 1ST or 2ND position and the ignition

switch is turned from ON or ACC to OFF, the battery saver control feature is activated. Under this condition,

the illumination lamps remain illuminated for 30 minutes unless the combination switch (lighting and turn signal

switch) position is changed. If the combination switch (lighting and turn signal switch) position is changed, then

the illumination lamps are turned off after a 30 second delay. When the combination switch (lighting and turn

signal switch) is turned from OFF to 1ST or 2ND position (or if auto light system is activated) after illumination

lamps have been turned off by the battery saver c ontrol, the illumination lamps illuminate again.

Component Parts LocationINFOID:0000000005146721

AWLIA1754GB

AWLIA0398ZZ

Revision: April 20092010 QX56

Page 2528 of 4210

BCM (BODY CONTROL MODULE)INL-59

< ECU DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

INL

N

O P

LIGHT SW 1ST Lighting switch OFF OFF

Lighting switch 1st

ON

HEAD LAMP SW1 Headlamp switch OFF

OFF

Headlamp switch 1st ON

HEAD LAMP SW2 Headlamp switch OFF

OFF

Headlamp switch 1st ON

HI BEAM SW High beam switch OFF

OFF

High beam switch HI ON

IGN ON SW Ignition switch OFF or ACC

OFF

Ignition switch ON ON

IGN SW CAN Ignition switch OFF or ACC

OFF

Ignition switch ON ON

INT VOLUME Wiper intermittent dial is in a dial position 1 - 7 1 - 7

I-KEY LOCK LOCK button of Intelligent Key is not pressed

OFF

LOCK button of Intelligent Key is pressed ON

I-KEY UNLOCK UNLOCK button of Intelligent Key is not pressed

OFF

UNLOCK button of Intelligent Key is pressed ON

KEY CYL LK-SW Door key cylinder LOCK position

ON

Door key cylinder other than LOCK position OF

KEY CYL UN-SW Door key cylinder UNLOCK position

ON

Door key cylinder other than UNLOCK position ON

KEY ON SW Mechanical key is removed from key cylinder

OFF

Mechanical key is inserted to key cylinder ON

OIL PRESS SW • Ignition switch OFF or ACC

• Engine running

OFF

Ignition switch ON ON

OPTICAL SENSOR Bright outside of the vehicle

Close to 5V

Dark outside of the vehicle Close to 0V

PASSING SW Other than lighting switch PASS

OFF

Lighting switch PASS ON

PUSH SW Return to ignition switch to LOCK position

OFF

Press ignition switch ON

REAR DEF SW Rear window defogger switch OFF

OFF

Rear window defogger switch ON ON

RR WASHER SW Rear washer switch OFF

OFF

Rear washer switch ON ON

RR WIPER INT Rear wiper switch OFF

OFF

Rear wiper switch INT ON

RR WIPER ON Rear wiper switch OFF

OFF

Rear wiper switch ON ON

RR WIPER STOP Rear wiper stop position

OFF

Other than rear wiper stop position ON

RR WIPER STP2 Rear wiper stop position

OFF

Other than rear wiper stop position ON

Monitor Item

Condition Value/Status

Revision: April 20092010 QX56

Page 2561 of 4210

PRECAUTIONSINT-9

< PRECAUTION >

C

DE

F

G H

I

K L

M A

B

INT

N

O P

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Service NoticeINFOID:0000000005147346

• When removing or installing various parts, place a cloth or padding on the vehicle body to prevent scratches.

• Handle trim, molding, instruments, grille, etc. carefully during removing or installing. Be careful not to soil or

damage them.

• Apply sealing compound where necessary when installing parts.

• When applying sealing compound, be careful that the sealing compound does not protrude from parts.

• When replacing any metal parts (for example body outer panel, members, etc.), be sure to take rust preven-

tion measures.

Revision: April 20092010 QX56

Page 2687 of 4210

LU-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION LU

A

LU

N

O P

CONTENTS

ENGINE LUBRICATION SYSTEM

PRECAUTION ....... ........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

Precaution for Liquid Gasket .....................................3

PREPARATION ............................................4

PREPARATION .............................................. .....4

Special Service Tool ........................................... ......4

Commercial Service Tool ..........................................4

FUNCTION DIAGNOSIS ...............................6

LUBRICATION SYSTEM ............................... .....6

Lubrication Circuit ............................................... ......6

Schematic .................................................................7

ON-VEHICLE MAINTENANCE .....................8

ENGINE OIL ................................................... .....8

Inspection ............................................................ ......8

Changing Engine Oil ............................................ .....9

OIL FILTER .......................................................11

Removal and Installation .........................................11

ON-VEHICLE REPAIR .................................12

OIL COOLER ....................................................12

Exploded View ..................................................... ....12

Removal and Installation .........................................12

OIL PUMP .........................................................14

Exploded View .........................................................14

Removal and Installation .........................................14

DISASSEMBLY AND ASSEMBLY ..............16

OIL PUMP .........................................................16

Disassembly and Assembly ................................. ....16

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... ...

18

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

18

Standard and Limit .............................................. ....18

Revision: April 20092010 QX56

Page 2689 of 4210

PRECAUTIONSLU-3

< PRECAUTION >

C

DE

F

G H

I

J

K L

M A

LU

NP

O

5. When the repair work is completed, return the ignition switch to the

″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

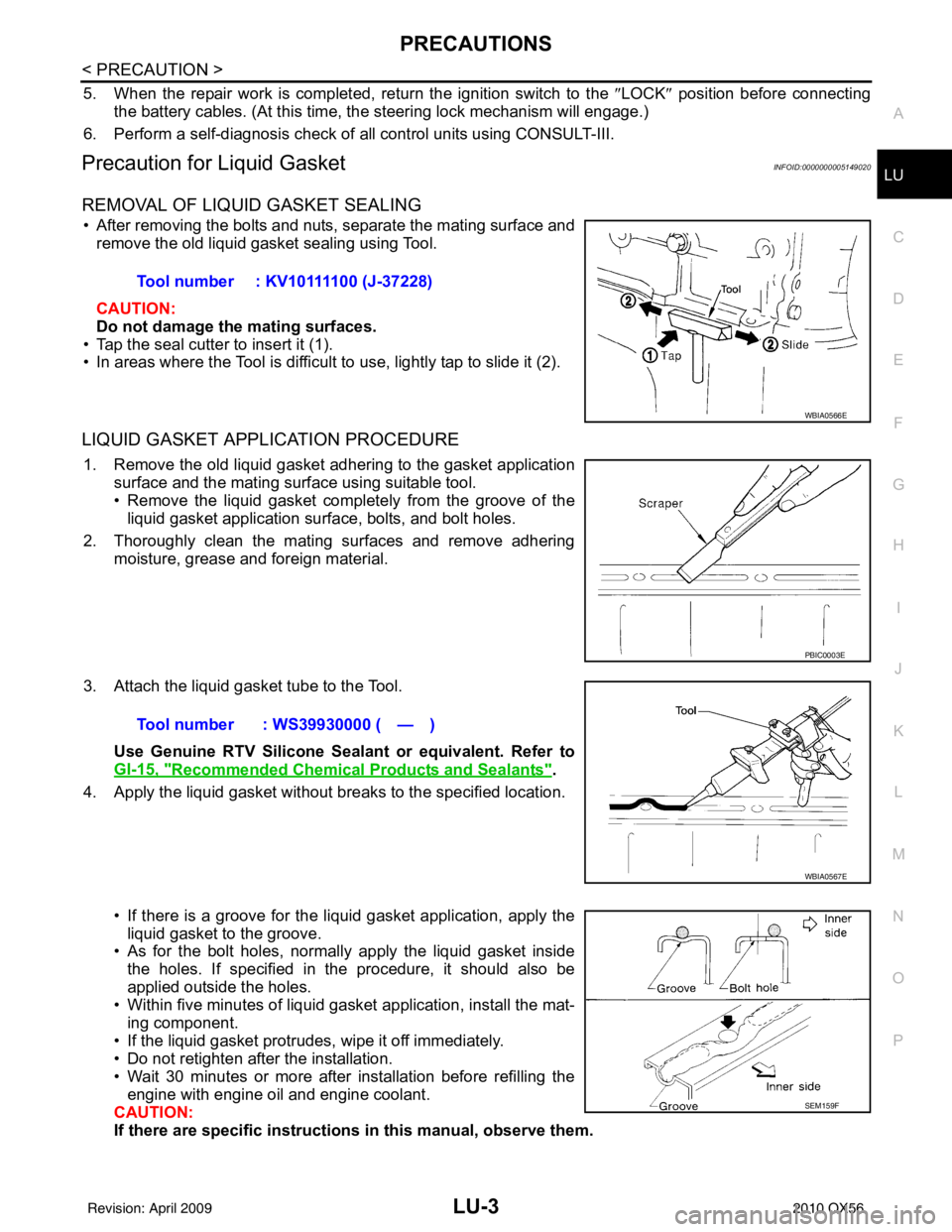

Precaution for Liquid GasketINFOID:0000000005149020

REMOVAL OF LIQUID GASKET SEALING

• After removing the bolts and nuts, separate the mating surface and

remove the old liquid gasket sealing using Tool.

CAUTION:

Do not damage the mating surfaces.

• Tap the seal cutter to insert it (1).

• In areas where the Tool is difficult to use, lightly tap to slide it (2).

LIQUID GASKET APPLICATION PROCEDURE

1. Remove the old liquid gasket adhering to the gasket application surface and the mating surface using suitable tool.

• Remove the liquid gasket completely from the groove of the

liquid gasket application surface, bolts, and bolt holes.

2. Thoroughly clean the mating surfaces and remove adhering moisture, grease and foreign material.

3. Attach the liquid gasket tube to the Tool. Use Genuine RTV Silicone Sealant or equivalent. Refer to

GI-15, "

Recommended Chemical Products and Sealants".

4. Apply the liquid gasket without breaks to the specified location.

• If there is a groove for the liquid gasket application, apply theliquid gasket to the groove.

• As for the bolt holes, normally apply the liquid gasket inside

the holes. If specified in the procedure, it should also be

applied outside the holes.

• Within five minutes of liquid gasket application, install the mat-

ing component.

• If the liquid gasket protrudes, wipe it off immediately.

• Do not retighten after the installation.

• Wait 30 minutes or more after installation before refilling the engine with engine oil and engine coolant.

CAUTION:

If there are specific instructions in this manual, observe them.

Tool number : KV10111100 (J-37228)

WBIA0566E

PBIC0003E

Tool number : WS39930000 ( — )

WBIA0567E

SEM159F

Revision: April 20092010 QX56

Page 2690 of 4210

LU-4

< PREPARATION >

PREPARATION

PREPARATION

PREPARATION

Special Service ToolINFOID:0000000005149021

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Commercial Service ToolINFOID:0000000005149022

Tool number

(Kent-Moore No.)

Tool name Description

ST25051001

(J-25695-1)

Oil pressure gauge Measuring oil pressure

Maximum measuring range:

2,452 kPa (25 kg/cm

2, 356 psi)

ST25052000

(J-25695-2)

Hose Adapting oil pressure gauge to cylinder block

K V 1 0 1111 0 0

(J-37228)

Seal cutter Removing steel oil pan and rear timing chain

case

KV10115801

(J-38956)

Oil filter wrench Removing and installing oil filter

a: 64.3 mm (2.531 in)

WS39930000

(—)

Tube presser Pressing the tube of liquid gasket

S-NT050

S-NT559

NT046

S-NT375

S-NT052

Revision: April 20092010 QX56