Oil INFINITI QX56 2010 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 2336 of 4210

HA-44

< ON-VEHICLE REPAIR >

CONDENSER

CONDENSER

Removal and Installation for CondenserINFOID:0000000005147663

REMOVAL

1. Discharge the refrigerant. Refer to HA-20, "HFC-134a (R-134a) Service Procedure".

2. Remove the radiator. Refer to CO-15, "

Removal and Installation".

CAUTION:

Be careful not to damage the core su rface of the condenser and the radiator.

3. Disconnect the high-pressure flexible hose and the high-pressure pipe from the condenser. CAUTION:

Cap or wrap the joint of the pipe with suitable ma terial such as vinyl tape to avoid the entry of air.

4. Disconnect the refrigerant pressure sensor connector. • Remove the refrigerant pressure sensor from the condenseras necessary.

5. Lift the condenser out of the mounting grommets to remove the condenser.

INSTALLATION

Installation is in the reverse order of removal.

Refer to HA-29, "

Component".

CAUTION:

• Replace the O-rings of the high-pressure pipe, refrigerant pressure sensor, and high-pressure flexi- ble hose with new ones, then apply compr essor oil to them when installing them.

• After charging refrigerant, check for leaks.

• Replace the grommets as necessary.

LJIA0145E

Revision: April 20092010 QX56

Page 2338 of 4210

HA-46

< ON-VEHICLE REPAIR >

REFRIGERANT PRESSURE SENSOR

REFRIGERANT PRESSURE SENSOR

Removal and Installation for Refrigerant Pressure SensorINFOID:0000000005147665

REMOVAL

1. Discharge the refrigerant. Refer to HA-20, "HFC-134a (R-134a) Service Procedure".

2. Disconnect the refrigerant pressure sensor electrical connector and remove the refrigerant pressure sensor from the condenser.

CAUTION:

Be careful not to damage the condenser fins.

INSTALLATION

Installation is in the reverse order of removal.

Refer to HA-29, "

Component".

CAUTION:

• Be careful not to damage the condenser fins.

• Replace the O-ring of the refriger ant pressure sensor with a new one, then apply compressor oil to it

when installing it.

• After charging refrigerant, check for leaks.

LJIA0145E

Revision: April 20092010 QX56

Page 2339 of 4210

EXPANSION VALVEHA-47

< ON-VEHICLE REPAIR >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

EXPANSION VALVE

Removal and Installation for Front Expansion ValveINFOID:0000000005147666

REMOVAL

1. Discharge the refrigerant. Refer to HA-20, "HFC-134a (R-134a) Service Procedure".

2. Remove the front evaporator. Refer to VTL-19, "

Removal and Installation for Front Evaporator".

3. Remove the cooler grommet.

4. Remove the expansion valve.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Replace the O-rings on the A/C refrigerant pipes with new ones, th en apply compressor oil to them

when installing them.

• After charging refrigerant, check for leaks.

WJIA0582E

Expansion valve bolts : 4 N·m (0.41 kg-m, 35 in-lb)

A/C refrigerant pipe to expansion valve bolt : Refer to HA-29, "

Component".

Revision: April 20092010 QX56

Page 2340 of 4210

HA-48

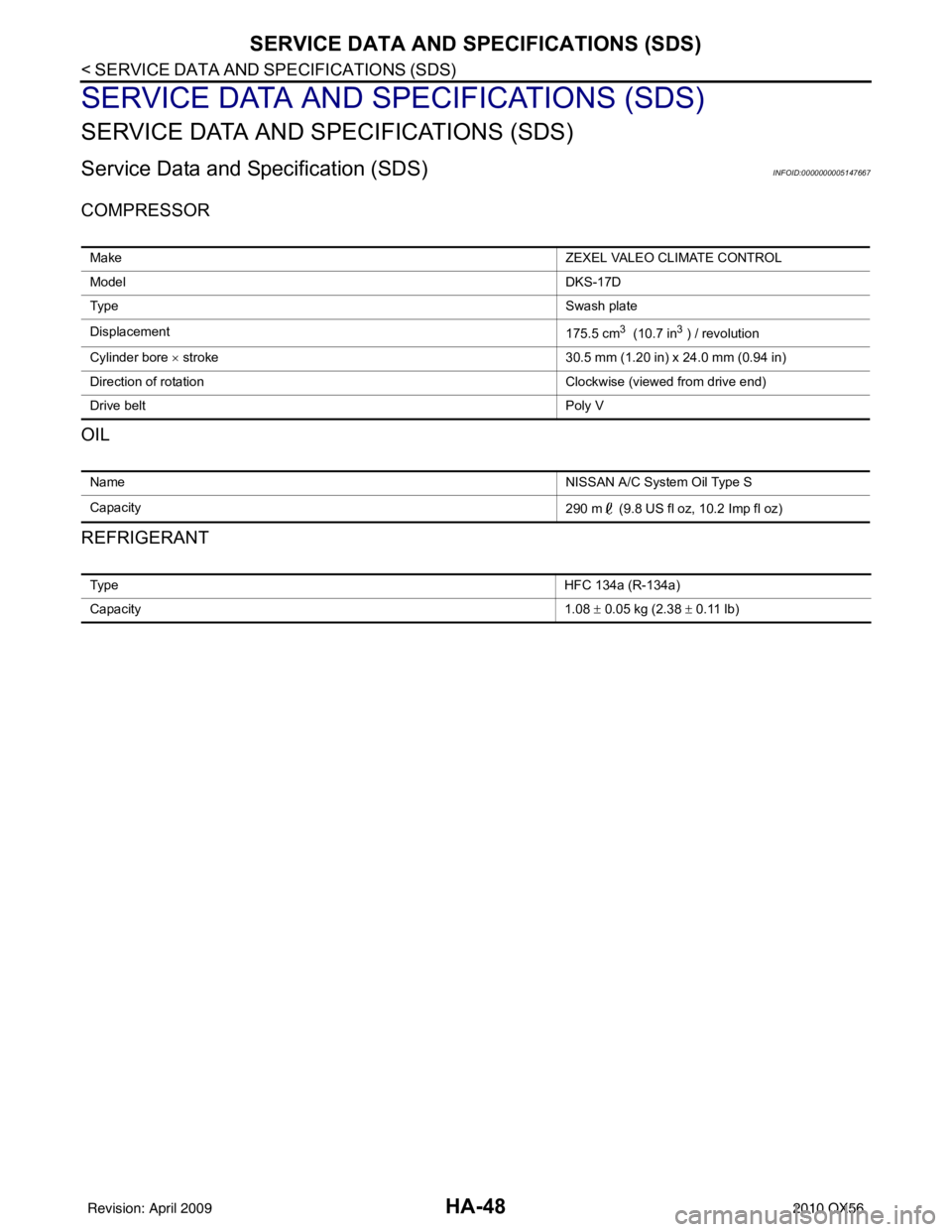

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Service Data and Specification (SDS)INFOID:0000000005147667

COMPRESSOR

OIL

REFRIGERANT

Make ZEXEL VALEO CLIMATE CONTROL

Model DKS-17D

Ty p e Swash plate

Displacement 175.5 cm

3 (10.7 in3 ) / revolution

Cylinder bore × stroke 30.5 mm (1.20 in) x 24.0 mm (0.94 in)

Direction of rotation Clockwise (viewed from drive end)

Drive belt Poly V

Name NISSAN A/C System Oil Type S

Capacity 290 m (9.8 US fl oz, 10.2 Imp fl oz)

Ty p eHFC 134a (R-134a)

Capacity 1.08 ± 0.05 kg (2.38 ± 0.11 lb)

Revision: April 20092010 QX56

Page 2351 of 4210

![INFINITI QX56 2010 Factory Service Manual REFRIGERATION SYSTEMHAC-11

< FUNCTION DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

REFRIGERATION SYSTEM

Refrigerant CycleINFOID:0000000005197357

REFRIGERANT FLOW

The refri INFINITI QX56 2010 Factory Service Manual REFRIGERATION SYSTEMHAC-11

< FUNCTION DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

REFRIGERATION SYSTEM

Refrigerant CycleINFOID:0000000005197357

REFRIGERANT FLOW

The refri](/img/42/57032/w960_57032-2350.png)

REFRIGERATION SYSTEMHAC-11

< FUNCTION DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

REFRIGERATION SYSTEM

Refrigerant CycleINFOID:0000000005197357

REFRIGERANT FLOW

The refrigerant flows in the standard pattern, that is, through the compressor, the condenser with liquid tank,

through the front and rear evaporators, and back to the compressor. The refrigerant evaporation through the

evaporator coils are controlled by front and rear externally equalized expansion valves, located inside the front

and rear evaporator cases.

Refrigerant System ProtectionINFOID:0000000005197358

REFRIGERANT PRESSURE SENSOR

The refrigerant system is protected against excessively hi gh or low pressures by the refrigerant pressure sen-

sor, located on the condenser. If the system pressure rises above or falls below the specifications, the refriger-

ant pressure sensor detects the pressure inside the refrigerant line and sends a voltage signal to the ECM.

The ECM de-energizes the A/C relay to disengage the magnetic compressor clutch when pressure on the high

pressure side detected by refrigerant pressu re sensor is over about 2,746 kPa (28 kg/cm

2, 398 psi), or below

about 120 kPa (1.22 kg/cm

2, 17.4 psi).

WJIA1342E

Revision: April 20092010 QX56

Page 2390 of 4210

![INFINITI QX56 2010 Factory Service Manual HAC-50

< COMPONENT DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

BLOWER MOTOR CONTROL SYSTEM

4.CHECK FRONT BLOWER MOTOR RELAY

Turn ignition switch OFF.

Check front blower motor relay. Refer to HAC-52, "

Fro INFINITI QX56 2010 Factory Service Manual HAC-50

< COMPONENT DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

BLOWER MOTOR CONTROL SYSTEM

4.CHECK FRONT BLOWER MOTOR RELAY

Turn ignition switch OFF.

Check front blower motor relay. Refer to HAC-52, "

Fro](/img/42/57032/w960_57032-2389.png)

HAC-50

< COMPONENT DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

BLOWER MOTOR CONTROL SYSTEM

4.CHECK FRONT BLOWER MOTOR RELAY

Turn ignition switch OFF.

Check front blower motor relay. Refer to HAC-52, "

Front Blower Motor Component Inspection".

Is the inspection result normal?

YES >> GO TO 5.

NO >> Replace front blower motor relay.

5.CHECK FRONT BLOWER MOTOR RELA Y (SWITCH SIDE) CIRCUIT FOR OPEN

Check continuity between front blower motor relay harness connec-

tor M107 terminal 3 and front blower motor harness connector M62

terminal 2.

Is the inspection result normal?

YES >> GO TO 6.

NO >> Repair harness or connector.

6.CHECK FRONT BLOWER MOTOR RE LAY (COIL SIDE) POWER SUPPLY

1. Turn ignition switch ON.

2. Check voltage between front blower motor relay harness con- nector M107 terminal 2 and ground.

Is the inspection result normal?

YES >> Repair front blower motor ground circuit or connector.

NO >> Repair harness or connector.

7.REPLACE FUSES

Replace fuses.

Does the fuse blow?

YES >> • If fuse blows without activating the front blower motor, repair short between fuse and front blower motor relay.

• If fuse blows activating the front blower motor, GO TO 8.

NO >> Inspection End.

8.CHECK FRONT BLOWER MOTOR POWER SUPPLY CIRCUIT FOR SHORT

1. Turn ignition switch OFF.

2. Disconnect front blower motor connector, front blower motor relay and variable blower control connector.

3. Check continuity between variable blower control harness con- nector M122 terminal 4 and ground.

Is the inspection result normal?

YES >> GO TO 9.

NO >> Repair harness or connector.

9.CHECK FRONT BLOWER MOTOR

Check front blower motor. Refer to HAC-52, "

Front Blower Motor Component Inspection".

Is the inspection result normal?

3 - 2 : Continuity should exist.

WJIA1360E

2 - Ground: Battery voltage

WJIA1363E

4 - Ground: Continuity should not exist.

AWIIA0177ZZ

Revision: April 20092010 QX56

Page 2392 of 4210

![INFINITI QX56 2010 Factory Service Manual HAC-52

< COMPONENT DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

BLOWER MOTOR CONTROL SYSTEM

1. Reconnect all disconnected component connectors.

2. Disconnect A/C auto amp. connector.

3. Turn ignition switch INFINITI QX56 2010 Factory Service Manual HAC-52

< COMPONENT DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

BLOWER MOTOR CONTROL SYSTEM

1. Reconnect all disconnected component connectors.

2. Disconnect A/C auto amp. connector.

3. Turn ignition switch](/img/42/57032/w960_57032-2391.png)

HAC-52

< COMPONENT DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

BLOWER MOTOR CONTROL SYSTEM

1. Reconnect all disconnected component connectors.

2. Disconnect A/C auto amp. connector.

3. Turn ignition switch ON.

4. Press the blower (+) switch to maximum speed.

5. Check voltage between A/C auto amp. harness connector M49

terminal 13 and ground.

Is the inspection result normal?

YES >> Replace A/C auto amp. Refer to VTL-7, "Removal and

Installation".

NO >> GO TO 15.

15.CHECK VARIABLE BLOWER CONT ROL SIGNAL CIRCUIT FOR OPEN

1. Disconnect variable blower control connector.

2. Check continuity between A/C auto amp. harness connector M49 (B) terminal 13 and variable blower control harness con-

nector M122 (A) terminal 3.

Is the inspection result normal?

YES >> Replace variable blower control. Refer to VTL-15,

"Removal and Installation".

NO >> Repair harness or connector.

Front Blower Motor Component InspectionINFOID:0000000005147703

COMPONENT INSPECTION

Check continuity between terminals by supplying 12 volts and

ground to coil side terminals of relay.

Front Blower Motor

13 - Ground : Approx. 4.5V

AWIIA1129ZZ

13 - 3: Continuity should exist.

AWIIA0178ZZ

WJIA1401E

Revision: April 20092010 QX56

Page 2397 of 4210

![INFINITI QX56 2010 Factory Service Manual BLOWER MOTOR CONTROL SYSTEMHAC-57

< COMPONENT DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

1. Disconnect A/C auto amp. connector.

2. Check continuity between A/C auto amp. INFINITI QX56 2010 Factory Service Manual BLOWER MOTOR CONTROL SYSTEMHAC-57

< COMPONENT DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

1. Disconnect A/C auto amp. connector.

2. Check continuity between A/C auto amp.](/img/42/57032/w960_57032-2396.png)

BLOWER MOTOR CONTROL SYSTEMHAC-57

< COMPONENT DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

1. Disconnect A/C auto amp. connector.

2. Check continuity between A/C auto amp. harness connector M50 (A) terminal 47 and rear air control (rear) harness connec-

tor R209 (B) terminal 5.

Is the inspection results normal?

YES >> Replace A/C auto amp. Refer to VTL-7, "Removal and

Installation".

NO >> Repair harness or connector.

Rear Blower Motor Component Inspection INFOID:0000000005147708

COMPONENT INSPECTION

Rear Blower Motor Relay

Check circuit continuity between terminals by supplying 12 volts and

ground to coil side terminals of relays.

Rear Blower Motor

Check that there are no foreign particles inside the intake unit.

Apply 12 volts to terminal 2 and ground to terminal 1 and ensure that

the blower motor rotates freely and quietly. Continuity should exist.

AWIIA0187ZZ

WJIA0973E

AWIIA1086ZZ

Revision: April 20092010 QX56

Page 2453 of 4210

![INFINITI QX56 2010 Factory Service Manual INSUFFICIENT COOLINGHAC-113

< SYMPTOM DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

dard (usual) pressure, however, differs from vehicle to vehicle, refer to above table (A INFINITI QX56 2010 Factory Service Manual INSUFFICIENT COOLINGHAC-113

< SYMPTOM DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

dard (usual) pressure, however, differs from vehicle to vehicle, refer to above table (A](/img/42/57032/w960_57032-2452.png)

INSUFFICIENT COOLINGHAC-113

< SYMPTOM DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

dard (usual) pressure, however, differs from vehicle to vehicle, refer to above table (Ambient air temperature-

to-operating pressure table).

Both High- and Low-pressure Sides are Too High

High-pressure Side is Too High and Low-pressure Side is Too Low

High-pressure Side is Too Low and Low-pressure Side is Too High

Gauge indication Refrigerant cycleProbable causeCorrective action

Both high- and low-pressure sides

are too high. Pressure is reduced soon af-

ter water is splashed on con-

denser.

Excessive refrigerant charge in

refrigeration cycle

Reduce refrigerant until speci-

fied pressure is obtained.

Air suction by cooling fan is in-

sufficient. Insufficient condenser cooling

performance

↓

1. Condenser fins are

clogged.

2. Improper fan rotation of

cooling fan • Clean condenser.

• Check and repair cooling fan

if necessary.

• Low-pressure pipe is not cold.

• When compressor is

stopped high-pressure val-

ue quickly drops by approx-

imately 196 kPa (2 kg/cm

2 ,

28 psi). It then decreases

gradually thereafter. Poor heat exchange in con-

denser

(After compressor operation

stops, high-pressure decreas-

es too slowly.)

↓

Air in refrigeration cycle

Evacuate and recharge system.

Engine tends to overheat. Engine cooling systems mal-

function. Check and repair engine cool-

ing system.

• An area of the low-pressure pipe is colder than areas

near the evaporator outlet.

• Plates are sometimes cov- ered with frost. • Excessive liquid refrigerant

on low-pressure side

• Excessive refrigerant dis-

charge flow

• Expansion valve is open a lit- tle compared with the speci-

fication.

↓

Improper expansion valve ad-

justment Replace expansion valve.

AC359A

Gauge indication

Refrigerant cycleProbable causeCorrective action

High-pressure side is too high and

low-pressure side is too low. Upper side of condenser and

high-pressure side are hot,

however, liquid tank is not so

hot.High-pressure tube or parts lo-

cated between compressor

and condenser are clogged or

crushed.

• Check and repair or replace

malfunctioning parts.

• Check oil for contamination.

AC360A

Revision: April 20092010 QX56

Page 2454 of 4210

![INFINITI QX56 2010 Factory Service Manual HAC-114

< SYMPTOM DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

INSUFFICIENT COOLING

Both High- and Low-pressure Sides are Too Low

Low-pressure Side Sometimes Becomes Negative

Gauge indication

Refrigerant cy INFINITI QX56 2010 Factory Service Manual HAC-114

< SYMPTOM DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

INSUFFICIENT COOLING

Both High- and Low-pressure Sides are Too Low

Low-pressure Side Sometimes Becomes Negative

Gauge indication

Refrigerant cy](/img/42/57032/w960_57032-2453.png)

HAC-114

< SYMPTOM DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

INSUFFICIENT COOLING

Both High- and Low-pressure Sides are Too Low

Low-pressure Side Sometimes Becomes Negative

Gauge indication

Refrigerant cycleProbable causeCorrective action

High-pressure side is too low and

low-pressure side is too high. High- and low-pressure sides

become equal soon after com-

pressor operation stops.Compressor pressure opera-

tion is improper.

↓

Damaged inside compressor

packings.

Replace compressor.

No temperature difference be-

tween high- and low-pressure

sides. Compressor pressure opera-

tion is improper.

↓

Damaged inside compressor

packings.

Replace compressor.

AC356A

Gauge indication

Refrigerant cycleProbable causeCorrective action

Both high- and low-pressure sides

are too low. • There is a big temperature

difference between liquid

tank outlet and inlet. Outlet

temperature is extremely

low.

• Liquid tank inlet and expan- sion valve are frosted. Liquid tank inside is slightly

clogged.

• Replace liquid tank.

• Check oil for contamination.

• Temperature of expansion valve inlet is extremely low

as compared with areas

near liquid tank.

• Expansion valve inlet may be frosted.

• Temperature difference oc-

curs somewhere in high-

pressure side. High-pressure pipe located be-

tween liquid tank and expan-

sion valve is clogged.

• Check and repair malfunc-

tioning parts.

• Check oil for contamination.

Expansion valve and liquid

tank are warm or only cool

when touched. Low refrigerant charge.

↓

Leaking fittings or compo-

nents. Check refrigerant system for

leaks. Refer to

HA-24, "

Check-

ing of Refrigerant Leaks".

There is a big temperature dif-

ference between expansion

valve inlet and outlet while the

valve itself is frosted. Expansion valve closes a little

compared with the specifica-

tion.

↓

1. Improper expansion

valve adjustment.

2. Malfunctioning expansion valve.

3. Outlet and inlet may be clogged. • Remove foreign particles by

using compressed air.

• Check oil for contamination.

An area of the low-pressure

pipe is colder than areas near

the evaporator outlet. Low-pressure pipe is clogged

or crushed. • Check and repair malfunc-

tioning parts.

• Check oil for contamination.

Air flow volume is too low. Evaporator is frozen. • Check intake sensor circuit.

Refer to HAC-83, "

Intake

Sensor Diagnosis Proce-

dure".

• Repair evaporator fins.

• Replace evaporator.

•Refer to HAC-48, "

Front

Blower Motor Component

Function Check".

AC353A

Revision: April 20092010 QX56