INFINITI QX56 2010 Factory Service Manual

Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 3201 of 4210

RSU-14

< REMOVAL AND INSTALLATION >

REAR SUSPENSION MEMBER

• When installing the upper and lower rubber seats for the rear coilsprings, the arrow embossed on the rubber seats must point out

toward the wheel and tire assembly.

• To connect the rear load leveling air suspension hoses, the lock ring must be fully seated in the fitt ing. Insert the hose (B) into the

lock ring (A) until the lock ring (A) is touching the hose (B) as

shown. Pull on the hose to check that it is securely inserted.

• Perform the final tightening of the nuts and bolts for the links (rubber bushing) under unladen condition (unladen condition means that the fuel tank, engine cool ant and lubricants are at the full specification, and

the spare tire, jack, hand tools, and mats are in t heir designated positions) with the tires on level ground.

• Check the wheel alignment. Refer to RSU-6, "

Wheel Alignment Inspection" .

LEIA0076E

LEIA0078E

Revision: April 20092010 QX56

Page 3202 of 4210

SHOCK ABSORBERRSU-15

< REMOVAL AND INSTALLATION >

C

DF

G H

I

J

K L

M A

B

RSU

N

O P

SHOCK ABSORBER

Removal and InstallationINFOID:0000000005148133

REMOVAL

1. Remove the wheel and tire assembly using power tool. Refer to WT-49, "Rotation".

2. Use CONSULT-III “EXHAUST SOLENOID ” active test to release the air pressure from the rear load level-

ing air suspension system.

3. Remove the four clips and remove the rear fender protector, front.

4. Disconnect the rear load leveling air suspension hose from the shock absorber.

• To disconnect the hose, push in on the lock ring using a suit-

able tool and pull the air hose out.

5. Remove the shock absorber upper and lower end bolts using power tool.

6. Remove the shock absorber. CAUTION:

Do not damage the rubber boot on the shock absorber.

INSTALLATION

Installation is in the reverse order of removal.

• Tighten the shock absorber bolts to specification. Refer to RSU-9, "

Component".

INSPECTION AFTER INSTALLATION

• Check the shock absorber for any air leaks or damage to the rubber boot.

• Check the shock absorber for smooth operation through a full stroke, both compression and extension.

• Check piston rod for cracks, deformation or other damage and replace if necessary.

DisposalINFOID:0000000005369243

1. Set shock absorber horizontally with the piston rod fully extended.

LEIA0081E

LEIA0082E

Revision: April 20092010 QX56

Page 3203 of 4210

RSU-16

< REMOVAL AND INSTALLATION >

SHOCK ABSORBER

2. Drill 2 – 3 mm (0.08 – 0.12 in) hole at the position ( ) from topas shown in the figure to release gas gradually.

CAUTION:

• Wear eye protection (safety glasses).

• Wear gloves.

• Be careful with metal chips or oil blown out by the com-pressed gas.

NOTE:

• Drill vertically in this direction ( ).

• Directly to the outer tube avoiding brackets.

• The gas is clear, colorless, odorless, and harmless.

3. Position the drilled hole downward and drain oil by moving the piston rod several times. CAUTION:

Dispose of drained oil according to the law and local regulations.

A : 20 – 30 mm (0.79 – 1.18 in)

JPEIA0161ZZ

Revision: April 20092010 QX56

Page 3204 of 4210

SUSPENSION ARMRSU-17

< REMOVAL AND INSTALLATION >

C

DF

G H

I

J

K L

M A

B

RSU

N

O P

SUSPENSION ARM

Removal and InstallationINFOID:0000000005148134

REMOVAL

1. Remove the rear suspension member assembly using power tool. Refer to RSU-11, "Removal and Instal-

lation" .

NOTE:

It is necessary to remove the rear suspension member to remove the front upper bolt from the suspension

arm.

2. Remove the shock absorber upper end bolt.

3. Remove the suspension arm upper nuts and bolts on the sus- pension member side using power tool.

4. Remove the suspension arm pinch bolt and nut on the knuckle side using power tool.

5. Disconnect the suspension arm from the knuckle using a soft hammer.

CAUTION:

Do not damage the ball joint with the soft hammer.

6. Remove the suspension arm.

INSPECTION AFTER REMOVAL

• Check the suspension arm for damage, cracks, deformation and replace if necessary.

• Check the rubber bushing for damage, cracks and deformati on. Replace suspension arm assembly if neces-

sary.

• Before checking, turn the ball joint at least 10 revo lutions so that the ball joint is properly broken in.

LEIA0082E

LEIA0087E

Revision: April 20092010 QX56

Page 3205 of 4210

RSU-18

< REMOVAL AND INSTALLATION >

SUSPENSION ARM

• Check the ball joint. Replace the suspension arm assembly if anyof the following conditions exist:

- Ball stud is worn.

- Joint is hard to swing.

- Play in axial direction is excessive.

INSTALLATION

Installation is in the reverse order of removal.

• Tighten the nuts and bolts to specification. Refer to RSU-9, "

Component" .

• Perform the final tightening of the nuts and bolts for the links (rubber bushing) under unladen condition (unladen condition means that the fuel tank, engine cool ant and lubricants are at the full specification, and

the spare tire, jack, hand tools, and mats are in t heir designated positions) with the tires on level ground.

• Check the wheel alignment. Refer to RSU-6, "

Wheel Alignment Inspection" .

Swinging force (A) : Refer to

RSU-29, "

Ball Joint" .

Turning force (B) : Refer to RSU-29, "

Ball Joint" .

Vertical end play (C) : Refer to RSU-29, "

Ball Joint" .

SFA858A

Revision: April 20092010 QX56

Page 3206 of 4210

FRONT LOWER LINKRSU-19

< REMOVAL AND INSTALLATION >

C

DF

G H

I

J

K L

M A

B

RSU

N

O P

FRONT LOWER LINK

Removal and InstallationINFOID:0000000005148135

REMOVAL

1. Remove the wheel and tire assembly using power tool.

2. Use CONSULT-III "EXHAUST SOLENOID" active test to release the air pressure from the rear load level-

ing air suspension system.

3. Remove the shock absorber lower end bolt.

4. Remove the adjusting bolt and nut, and the bolt and nut, from the front lower link and rear suspension member using power

tool.

5. Remove the front lower link pinch bolt and nut on the knuckle side using power tool.

6. Disconnect the front lower link from the knuckle using a soft hammer.

CAUTION:

Do not damage the ball joint with the soft hammer.

7. Remove the front lower link.

INSPECTION AFTER REMOVAL

• Check the front lower link and bushing for any deforma tion, crack, or damage. Replace if necessary.

• Check the rubber bushing for damage, cracks and deforma tion. Replace the front lower link and bushing if

necessary.

• Before checking, turn the ball joint at least 10 revo lutions so that the ball joint is properly broken in.

LEIA0082E

LEIA0086E

Revision: April 20092010 QX56

Page 3207 of 4210

RSU-20

< REMOVAL AND INSTALLATION >

FRONT LOWER LINK

• Check the ball joint. Replace the front lower link if any of the follow-

ing conditions exist:

- Ball stud is worn.

- Joint is hard to swing.

- Play in axial direction is excessive.

INSTALLATION

Installation is in the reverse order of removal.

• Tighten the nuts and bolts to specification. Refer to RSU-9, "

Component" .

• Perform the final tightening of the nuts and bolts for the links (rubber bushing) under unladen condition (unladen condition means that the fuel tank, engine cool ant and lubricants are at the full specification, and

the spare tire, jack, hand tools, and mats are in t heir designated positions) with the tires on level ground.

• Check the wheel alignment. Refer to RSU-6, "

Wheel Alignment Inspection"

Swinging force (A) : Refer to RSU-29, "Ball Joint" .

Turning force (B) : Refer to RSU-29, "

Ball Joint".

Vertical end play (C) : Refer to RSU-29, "

Ball Joint" .

SFA858A

Revision: April 20092010 QX56

Page 3208 of 4210

REAR LOWER LINK & COIL SPRINGRSU-21

< REMOVAL AND INSTALLATION >

C

DF

G H

I

J

K L

M A

B

RSU

N

O P

REAR LOWER LINK & COIL SPRING

Removal and InstallationINFOID:0000000005148136

REMOVAL

1. Remove the wheel and tire assembly using power tool. Refer to WT-49, "Rotation" .

2. Use CONSULT-III "EXHAUST SOLENOID" active test to release the air pressure from the rear load level-

ing air suspension system.

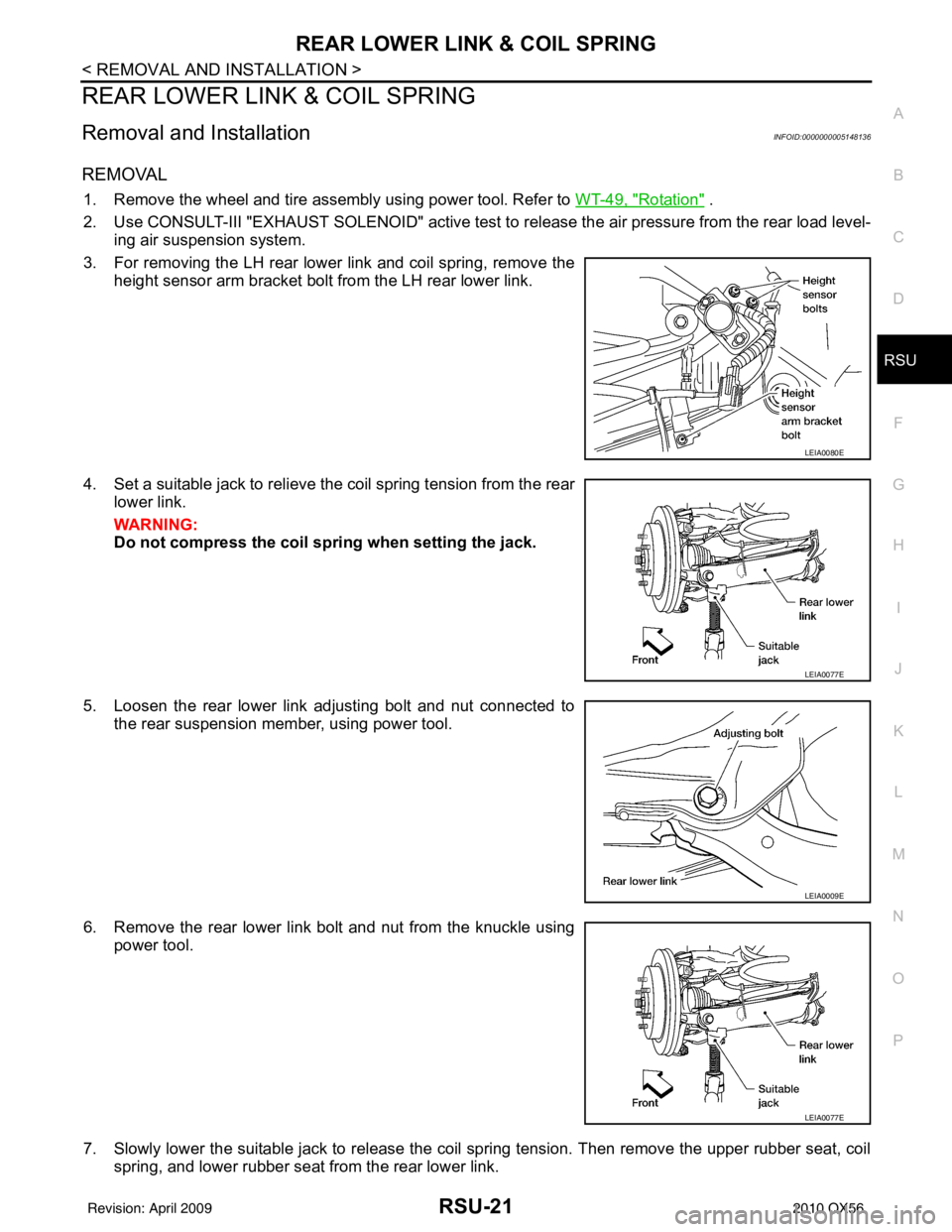

3. For removing the LH rear lower link and coil spring, remove the height sensor arm bracket bolt from the LH rear lower link.

4. Set a suitable jack to relieve the coil spring tension from the rear lower link.

WARNING:

Do not compress the coil sp ring when setting the jack.

5. Loosen the rear lower link adjusting bolt and nut connected to the rear suspension member, using power tool.

6. Remove the rear lower link bolt and nut from the knuckle using power tool.

7. Slowly lower the suitable jack to release the coil spring tension. Then remove the upper rubber seat, coil spring, and lower rubber seat from the rear lower link.

LEIA0080E

LEIA0077E

LEIA0009E

LEIA0077E

Revision: April 20092010 QX56

Page 3209 of 4210

RSU-22

< REMOVAL AND INSTALLATION >

REAR LOWER LINK & COIL SPRING

8. Remove the rear lower link adjusting bolt and nut from the rearsuspension member using power tool, then remove the rear

lower link.

INSPECTION AFTER REMOVAL

Check the coil spring and rubber seats for deformation, cracks, or other damage and replace if necessary.

INSTALLATION

Installation is in the reverse order of removal.

• Tighten the nuts and bolts to specification. Refer to RSU-9, "

Component" .

• When installing the upper and lower rubber seats for the rear coil springs, the arrow embossed on the rubber seats must point out

toward the wheel and tire assembly.

• After installing the rear lower link and coil spring, check the wheel alignment and adjust if necessary. Refer to RSU-6, "

Wheel Align-

ment Inspection"

LEIA0009E

LEIA0076E

Revision: April 20092010 QX56

Page 3210 of 4210

STABILIZER BARRSU-23

< REMOVAL AND INSTALLATION >

C

DF

G H

I

J

K L

M A

B

RSU

N

O P

STABILIZER BAR

Removal and InstallationINFOID:0000000005148137

REMOVAL

1. Disconnect the stabilizer bar ends from the connecting rods using power tool.

2. Remove the stabilizer bar clamps using power tool, and remove the stabilizer bar bushings.

3. Remove the stabilizer bar.

INSPECTION AFTER REMOVAL

• Check the stabilizer bar for any deformation, cracks, or damage and replace if necessary.

• Check the rubber bushings for deterioration, or cracks and replace if necessary.

INSTALLATION

Installation is in the reverse order of removal.

• Tighten the nuts and bolts to specification. Refer to RSU-9, "

Component" .

• Install the stabilizer bar with the ball joint sockets properly aligned.

• Install the stabilizer bar bushing and clamp so they are positioned inside of the sideslip prevention clamp on the stabilizer bar.

LEIA0088E

LEIA0089E

SFA449BB

Revision: April 20092010 QX56