key INFINITI QX56 2010 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 1433 of 4210

![INFINITI QX56 2010 Factory Service Manual EC-80

< COMPONENT DIAGNOSIS >[VK56DE]

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

2. Disconnect mass air flow sensor harness connector. Check pin terminal and connector for damage and

then reconnect it ag INFINITI QX56 2010 Factory Service Manual EC-80

< COMPONENT DIAGNOSIS >[VK56DE]

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

2. Disconnect mass air flow sensor harness connector. Check pin terminal and connector for damage and

then reconnect it ag](/img/42/57032/w960_57032-1432.png)

EC-80

< COMPONENT DIAGNOSIS >[VK56DE]

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

2. Disconnect mass air flow sensor harness connector. Check pin terminal and connector for damage and

then reconnect it again.

>> GO TO 22.

22.CHECK “A/F ALPHA-B1”, “A/F ALPHA-B2”

1. Start engine.

2. Select “A/F ALPHA-B1”, “A/F AL PHA-B2” in “SPEC” of “DATA MONITOR” mode, and make sure that the

each indication is within the SP value.

OK or NG

OK >> 1. Detect malfunctioning part of mass air flow sensor circuit and repair it. Refer to EC-110.

2. GO TO 29.

NG >> GO TO 23.

23.CHECK “MAS A/F SE-B1”

Select “MAS A/F SE-B1” in “SPEC” of “DATA MONITOR” mode, and make sure that the indication is within the

SP value.

OK or NG

OK >> GO TO 24.

NG (More than the SP value)>>Replace mass air flow sensor, and then GO TO 29.

24.REPLACE ECM

1. Replace ECM.

2. Perform initialization of IVIS(NATS) system and registration of all IVIS(NATS) ignition key IDs. Refer to SEC-9, "

ECM RE-COMMUNICATING FUNCTION : Special Repair Requirement".

3. Perform EC-17, "

VIN Registration".

4. Perform EC-18, "

Accelerator Pedal Released Position Learning".

5. Perform EC-18, "

Throttle Valve Closed Position Learning".

6. Perform EC-18, "

Idle Air Volume Learning".

>> GO TO 29.

25.CHECK INTAKE SYSTEM

Check for the cause of uneven air flow through mass air flow sensor. Refer to the following.

• Crushed air ducts

• Malfunctioning seal of air cleaner element

• Uneven dirt of air cleaner element

• Improper specification of intake air system

OK or NG

OK >> GO TO 27.

NG >> Repair or replace malfunctioning part, and then GO TO 26.

26.CHECK “B/FUEL SCHDL”

Select “B/FUEL SCHDL” in “SPEC” of “DATA MONITOR” mode, and make sure that the indication is within the

SP value.

OK or NG

OK >> INSPECTION END

NG (Less than the SP value)>>GO TO 27.

27.CHECK “MAS A/F SE-B1”

Select “MAS A/F SE-B1” in “SPEC” of “DATA MONITOR” mode, and make sure that the indication is within the

SP value.

OK or NG

OK >> GO TO 28.

NG (Less than the SP value)>>Replace mass air flow sensor, and then GO TO 30.

28.CHECK INTAKE SYSTEM

Check for the cause of air leak after the mass air flow sensor. Refer to the following.

Revision: April 20092010 QX56

Page 1630 of 4210

![INFINITI QX56 2010 Factory Service Manual P0506 ISC SYSTEMEC-277

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0506 ISC SYSTEM

DescriptionINFOID:0000000005149303

NOTE:

If DTC P0506 is displayed with ot

her DTC, first perfo INFINITI QX56 2010 Factory Service Manual P0506 ISC SYSTEMEC-277

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0506 ISC SYSTEM

DescriptionINFOID:0000000005149303

NOTE:

If DTC P0506 is displayed with ot

her DTC, first perfo](/img/42/57032/w960_57032-1629.png)

P0506 ISC SYSTEMEC-277

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0506 ISC SYSTEM

DescriptionINFOID:0000000005149303

NOTE:

If DTC P0506 is displayed with ot

her DTC, first perform the trouble diagnosis for the other DTC.

The ECM controls the engine idle speed to a specified level through the fine adjustment of the air, which is let

into the intake manifold, by operating the electric thrott le control actuator. The operating of the throttle valve is

varied to allow for optimum control of the engine idli ng speed. The crankshaft position sensor (POS) detects

the actual engine speed and sends a signal to the ECM.

The ECM controls the electric throttle control actuator so that the engine speed coincides with the target value

memorized in the ECM. The target engine speed is the lowest speed at which the engine can operate steadily.

The optimum value stored in the ECM is determined by taking into consideration various engine conditions,

such as during warming up, deceleration, and engine load (air conditioner, power steering and cooling fan

operation, etc.).

On Board Diagnosis LogicINFOID:0000000005149304

DTC Confirmation ProcedureINFOID:0000000005149305

NOTE:

• If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next step.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

• If the target idle speed is ou t of the specified value, perform EC-18, "

Idle Air Volume Learning",

before conducting DTC Confirmation Procedure. For the target idle speed, refer to the EC-497, "

Idle

Speed and Ignition Timing".

TESTING CONDITION:

• Before performing the following procedure, confirm that battery voltage is more than 11V at idle.

• Always perform the test at a temperature above −10° C (14° F).

1. Open engine hood.

2. Start engine and warm it up to normal operating temperature.

3. Turn ignition switch OFF and wait at least 10 seconds.

4. Start engine and run it for at least 1 minute at idle speed.

5. Check 1st trip DTC.

6. If 1st trip DTC is detected, go to EC-277, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000005149306

1.CHECK INTAKE AIR LEAK

1. Start engine and let it idle.

2. Listen for an intake air leak after the mass air flow sensor.

OK or NG

OK >> GO TO 2.

NG >> Discover air leak location and repair.

2.REPLACE ECM

1. Stop engine.

2. Replace ECM.

3. Perform initialization of IVIS(NATS) system and registration of all IVIS(NATS) ignition key IDs. Refer to SEC-9, "

ECM RE-COMMUNICATING FUNCTION : Special Repair Requirement".

4. Perform EC-17, "

VIN Registration".

5. Perform EC-18, "

Accelerator Pedal Released Position Learning".

DTC No. Trouble diagnosis name DTC detecting conditionPossible cause

P0506

0506 Idle speed control system

RPM lower than expected The idle speed is less than the target idle speed

by 100 rpm or more. • Electric throttle control actuator

• Intake air leak

Revision: April 20092010 QX56

Page 1633 of 4210

![INFINITI QX56 2010 Factory Service Manual EC-280

< COMPONENT DIAGNOSIS >[VK56DE]

P0507 ISC SYSTEM

3.REPLACE ECM

1. Stop engine.

2. Replace ECM.

3. Perform initialization of IVIS(NATS) system and registration of all IVIS(NATS) ignition key IDs INFINITI QX56 2010 Factory Service Manual EC-280

< COMPONENT DIAGNOSIS >[VK56DE]

P0507 ISC SYSTEM

3.REPLACE ECM

1. Stop engine.

2. Replace ECM.

3. Perform initialization of IVIS(NATS) system and registration of all IVIS(NATS) ignition key IDs](/img/42/57032/w960_57032-1632.png)

EC-280

< COMPONENT DIAGNOSIS >[VK56DE]

P0507 ISC SYSTEM

3.REPLACE ECM

1. Stop engine.

2. Replace ECM.

3. Perform initialization of IVIS(NATS) system and registration of all IVIS(NATS) ignition key IDs. Refer to SEC-9, "

ECM RE-COMMUNICATING FUNCTION : Special Repair Requirement".

4. Perform EC-17, "

VIN Registration".

5. Perform EC-18, "

Accelerator Pedal Released Position Learning".

6. Perform EC-18, "

Throttle Valve Closed Position Learning".

7. Perform EC-18, "

Idle Air Volume Learning".

>> INSPECTION END

Revision: April 20092010 QX56

Page 1638 of 4210

![INFINITI QX56 2010 Factory Service Manual P0603 ECM POWER SUPPLYEC-285

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

• IPDM E/R connector E121

• 20A fuse (No. 53)

• Harness for open or short between ECM and battery

>> INFINITI QX56 2010 Factory Service Manual P0603 ECM POWER SUPPLYEC-285

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

• IPDM E/R connector E121

• 20A fuse (No. 53)

• Harness for open or short between ECM and battery

>>](/img/42/57032/w960_57032-1637.png)

P0603 ECM POWER SUPPLYEC-285

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

• IPDM E/R connector E121

• 20A fuse (No. 53)

• Harness for open or short between ECM and battery

>> Repair or replace harness or connectors.

3.CHECK INTERMITTENT INCIDENT

Refer to GI-35, "

How to Check Terminal" and GI-38, "Intermittent Incident".

OK or NG

OK >> GO TO 4.

NG >> Repair or replace harness or connectors.

4.PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT-III

1. Turn ignition switch ON.

2. Select “SELF DIAG RESULTS” mode with CONSULT-III.

3. Touch “ERASE”.

4. Perform DTC Confirmation Procedure.

See EC-284, "

DTC Confirmation Procedure".

5. Is the 1st trip DTC P0603 displayed again?

With GST

1. Turn ignition switch ON.

2. Select Service $04 with GST.

3. Perform DTC Confirmation Procedure.

See EC-284, "

DTC Confirmation Procedure".

4. Is the 1st trip DTC P0603 displayed again?

Ye s o r N o

Yes >> GO TO 5.

No >> INSPECTION END

5.REPLACE ECM

1. Replace ECM.

2. Perform initialization of IVIS(NATS) system and registration of all IVIS(NATS) ignition key IDs. Refer to SEC-9, "

ECM RE-COMMUNICATING FUNCTION : Special Repair Requirement".

3. Perform EC-17, "

VIN Registration".

4. Perform EC-18, "

Accelerator Pedal Released Position Learning".

5. Perform EC-18, "

Throttle Valve Closed Position Learning".

6. Perform EC-18, "

Idle Air Volume Learning".

>> INSPECTION END

Revision: April 20092010 QX56

Page 1640 of 4210

![INFINITI QX56 2010 Factory Service Manual P0605 ECMEC-287

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

3. Repeat step 2 for 32 times.

4. Check 1st trip DTC.

5. If 1st trip DTC is detected, go to

EC-287, "

Diagnosis Proced INFINITI QX56 2010 Factory Service Manual P0605 ECMEC-287

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

3. Repeat step 2 for 32 times.

4. Check 1st trip DTC.

5. If 1st trip DTC is detected, go to

EC-287, "

Diagnosis Proced](/img/42/57032/w960_57032-1639.png)

P0605 ECMEC-287

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

3. Repeat step 2 for 32 times.

4. Check 1st trip DTC.

5. If 1st trip DTC is detected, go to

EC-287, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000005149323

1.INSPECTION START

With CONSULT-III

1. Turn ignition switch ON.

2. Select “SELF DIAG RESULTS” mode with CONSULT-III.

3. Touch “ERASE”.

4. Perform DTC Confirmation Procedure.

See EC-286, "

DTC Confirmation Procedure".

5. Is the 1st trip DTC P0605 displayed again?

With GST

1. Turn ignition switch ON.

2. Select Service $04 with GST.

3. Perform DTC Confirmation Procedure.

See EC-286, "

DTC Confirmation Procedure".

4. Is the 1st trip DTC P0605 displayed again?

Ye s o r N o

Yes >> GO TO 2.

No >> INSPECTION END

2.REPLACE ECM

1. Replace ECM.

2. Perform initialization of IVIS(NATS) system and registration of all IVIS(NATS) ignition key IDs. Refer to SEC-9, "

ECM RE-COMMUNICATING FUNCTION : Special Repair Requirement".

3. Perform EC-17, "

VIN Registration".

4. Perform EC-18, "

Accelerator Pedal Released Position Learning".

5. Perform EC-18, "

Throttle Valve Closed Position Learning".

6. Perform EC-18, "

Idle Air Volume Learning".

>> INSPECTION END

Revision: April 20092010 QX56

Page 1641 of 4210

![INFINITI QX56 2010 Factory Service Manual EC-288

< COMPONENT DIAGNOSIS >[VK56DE]

P0607 ECM

P0607 ECM

DescriptionINFOID:0000000005149324

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicl INFINITI QX56 2010 Factory Service Manual EC-288

< COMPONENT DIAGNOSIS >[VK56DE]

P0607 ECM

P0607 ECM

DescriptionINFOID:0000000005149324

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicl](/img/42/57032/w960_57032-1640.png)

EC-288

< COMPONENT DIAGNOSIS >[VK56DE]

P0607 ECM

P0607 ECM

DescriptionINFOID:0000000005149324

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication s

peed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CA N communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

On Board Diagn osis LogicINFOID:0000000005149325

This self-diagnosis has the one trip detection logic.

DTC Confirmation ProcedureINFOID:0000000005149326

1. Turn ignition switch ON.

2. Check DTC.

3. If DTC is detected, go to EC-288, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000005149327

1.INSPECTION START

With CONSULT-III

1. Turn ignition switch ON.

2. Select “SELF-DIAG RESULTS” mode with CONSULT-III.

3. Touch “ERASE”.

4. Perform DTC Confirmation Procedure.

See EC-288, "

DTC Confirmation Procedure".

5. Is the DTC P0607 displayed again?

With GST

1. Turn ignition switch ON.

2. Select Service $04 with GST.

3. Perform DTC Confirmation Procedure.

See EC-288, "

DTC Confirmation Procedure".

4. Is the DTC P0607 displayed again?

Ye s o r N o

Ye s > > G O T O 2 .

No >> INSPECTION END

2.REPLACE ECM

1. Replace ECM.

2. Perform initialization of IVIS (NATS) system and regist ration of all IVIS (NATS) ignition key IDs. Refer to

SEC-9, "

ECM RE-COMMUNICATING FUNCTION : Special Repair Requirement".

3. Perform EC-17, "

VIN Registration".

4. Perform EC-18, "

Accelerator Pedal Released Position Learning".

5. Perform EC-18, "

Throttle Valve Closed Position Learning".

6. Perform EC-18, "

Idle Air Volume Learning".

>> INSPECTION END

DTC No. Trouble diagnosis name DTC detecting conditionPossible cause

P0607

0607 CAN communication bus When detecting error during the initial diagno-

sis of CAN controller of ECM.

•ECM

Revision: April 20092010 QX56

Page 1664 of 4210

![INFINITI QX56 2010 Factory Service Manual P1421 COLD START CONTROLEC-311

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

3.CHECK FUEL INJECTION SYSTEM FUNCTION

Perform EC-172, "

DTC Confirmation Procedure" in DTC P0171, P017 INFINITI QX56 2010 Factory Service Manual P1421 COLD START CONTROLEC-311

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

3.CHECK FUEL INJECTION SYSTEM FUNCTION

Perform EC-172, "

DTC Confirmation Procedure" in DTC P0171, P017](/img/42/57032/w960_57032-1663.png)

P1421 COLD START CONTROLEC-311

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

3.CHECK FUEL INJECTION SYSTEM FUNCTION

Perform EC-172, "

DTC Confirmation Procedure" in DTC P0171, P0174 FUEL INJECTION SYSTEM FUNC-

TION.

OK or NG

OK >> GO TO 4.

NG >> Go to EC-173, "

Diagnosis Procedure".

4.PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT-III

1. Turn ignition switch ON.

2. Select “SELF DIAG RESULTS” mode with CONSULT-III.

3. Touch “ERASE”.

4. Perform DTC Confirmation Procedure.

See EC-310, "

DTC Confirmation Procedure".

5. Is the 1st trip DTC P1421 displayed again?

With GST

1. Turn ignition switch ON.

2. Select Service $04 with GST.

3. Perform DTC Confirmation Procedure.

See EC-310, "

DTC Confirmation Procedure".

4. Is the 1st trip DTC P1421 displayed again?

Ye s o r N o

Yes >> GO TO 5.

No >> INSPECTION END

5.REPLACE ECM

1. Replace ECM.

2. Perform initialization of IVIS (NATS) system and registration of all IVIS (NATS) ignition key IDs.

Refer to SEC-9, "

ECM RE-COMMUNICATING FUNCTION : Special Repair Requirement".

3. Perform EC-17, "

VIN Registration".

4. Perform EC-18, "

Accelerator Pedal Released Position Learning".

5. Perform EC-18, "

Throttle Valve Closed Position Learning".

6. Perform EC-18, "

Idle Air Volume Learning".

>> INSPECTION END

Revision: April 20092010 QX56

Page 1815 of 4210

![INFINITI QX56 2010 Factory Service Manual EC-462

< ECU DIAGNOSIS >[VK56DE]

ECM

*1: 1st trip DTC No. is the same as DTC No.

*2: This number is prescribed by SAE J2012.BAT CURRENT SENSOR

P15541554—2—EC-324

ASCD SW P15641564—1—EC-328

( INFINITI QX56 2010 Factory Service Manual EC-462

< ECU DIAGNOSIS >[VK56DE]

ECM

*1: 1st trip DTC No. is the same as DTC No.

*2: This number is prescribed by SAE J2012.BAT CURRENT SENSOR

P15541554—2—EC-324

ASCD SW P15641564—1—EC-328

(](/img/42/57032/w960_57032-1814.png)

EC-462

< ECU DIAGNOSIS >[VK56DE]

ECM

*1: 1st trip DTC No. is the same as DTC No.

*2: This number is prescribed by SAE J2012.BAT CURRENT SENSOR

P15541554—2—EC-324

ASCD SW P15641564—1—EC-328

(Models

with ICC) EC-332

(Models

with ASCD)

ICC COMMAND VALUE*

9P1568 1568—1—EC-336

ASCD BRAKE SW P15721572—1—EC-337

(Models

with ICC) EC-344

(Models

with ASCD)

ASCD VHL SPD SEN*

8P1574 1574—1—EC-349

(Models

with ICC)

EC-351

(Models

with ASCD)

ID DISCARD IMM-ECM P16111611—2—SEC-41

CHAIN OF ECM-IMMU P16121612—2—SEC-37

CHAIN OF IMMU-KEY P16141614—2—SEC-31

DIFFERENCE OF KEY P16151615—2—SEC-34

INTERLOCK P17301730—1×TM-78

INPUT CLUTCH SOLENOID P17521752—1×TM-82

FR BRAKE SOLENOID P17571757—1×TM-84

DRCT CLUTCH SOLENOID P17621762—1×TM-86

HLR CLUTCH SOLENOID P17671767—1×TM-88

L C BRAKE SOLENOID P17721772—1×TM-90

L C BRAKE SOLENOID P17741774—1×TM-92

BRAKE SW/CIRCUIT P18051805—2—EC-353

ETC MOT PWR-B1 P21002100—1×EC-356

ETC FUNCTION/CIRC-B1 P21012101—1×EC-359

ETC MOT PWR P21032103—1×EC-356

ETC MOT-B1 P21182118—1×EC-363

ETC ACTR-B1 P21192119—1×EC-365

APP SEN 1/CIRC P21222122—1×EC-367

APP SEN 1/CIRC P21232123—1×EC-367

APP SEN 2/CIRC P21272127—1×EC-370

APP SEN 2/CIRC P21282128—1×EC-370

TP SENSOR-B1 P21352135—1×EC-374

APP SENSOR P21382138—1×EC-378

A/F SENSOR1 (B1) P2A002A00—2×EC-382

A/F SENSOR1 (B2) P2A032A03—2×EC-382

Items

(CONSULT-IIl screen terms) DTC*

1

SRT code Trip

MILReference

page

CONSULT-IIl

GST*

2ECM*3

Revision: April 20092010 QX56

Page 1854 of 4210

PRECAUTIONSEM-3

< PRECAUTION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

PRECAUTION

PRECAUTIONS

Precaution for Supplemental

Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005259661

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wheel Rotation After Battery Disconnect

INFOID:0000000005260133

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecti ng both battery cables with the ignition knob in the

″ LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS , an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

Revision: April 20092010 QX56

Page 1899 of 4210

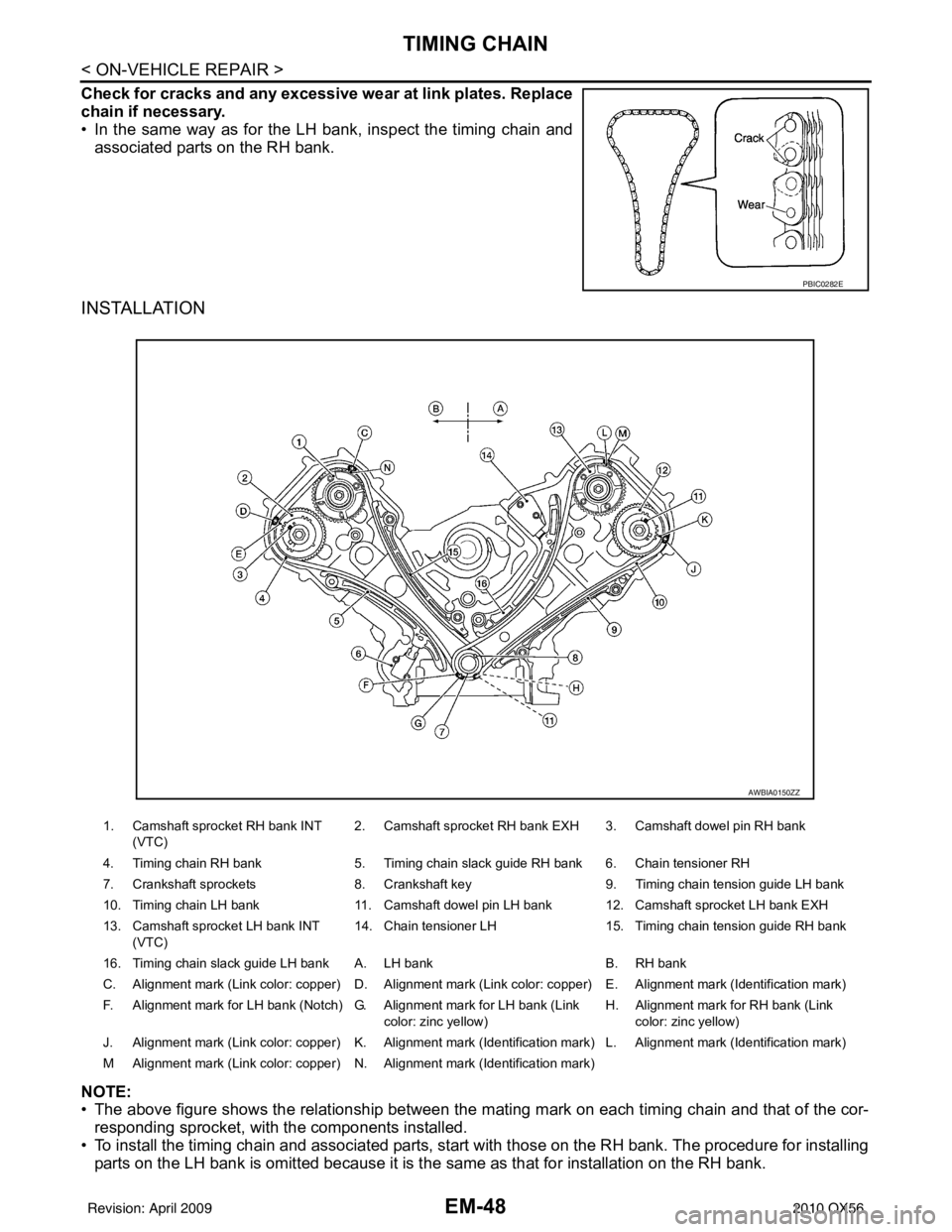

EM-48

< ON-VEHICLE REPAIR >

TIMING CHAIN

Check for cracks and any excessive wear at link plates. Replace

chain if necessary.

• In the same way as for the LH bank, inspect the timing chain andassociated parts on the RH bank.

INSTALLATION

NOTE:

• The above figure shows the relationship between the ma ting mark on each timing chain and that of the cor-

responding sprocket, with the components installed.

• To install the timing chain and associated parts, start with those on the RH bank. The procedure for installing parts on the LH bank is omitted because it is t he same as that for installation on the RH bank.

PBIC0282E

1. Camshaft sprocket RH bank INT

(VTC) 2. Camshaft sprocket RH bank EXH 3. Camshaft dowel pin RH bank

4. Timing chain RH bank 5. Timing chain slack guide RH bank 6. Chain tensioner RH

7. Crankshaft sprockets 8. Crankshaft key9. Timing chain tension guide LH bank

10. Timing chain LH bank 11. Camshaft dowel pin LH bank 12. Camshaft sprocket LH bank EXH

13. Camshaft sprocket LH bank INT (VTC) 14. Chain tensioner LH

15. Timing chain tension guide RH bank

16. Timing chain slack guide LH bank A. LH bank B. RH bank

C. Alignment mark (Link color: copper) D . Alignment mark (Link color: copper) E. Alignment mark (Identification mark)

F. Alignment mark for LH bank (Notch) G. Alignment mark for LH bank (Link color: zinc yellow)H. Alignment mark

for RH bank (Link

color: zinc yellow)

J. Alignment mark (Link color: copper) K. Alignment mark (Identification mark) L. Alignment mark (Identification mark)

M Alignment mark (Link color: copper) N. Alignment mark (Identification mark)

AWBIA0150ZZ

Revision: April 20092010 QX56