light INFINITI QX56 2010 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 3606 of 4210

SRC-60

< COMPONENT DIAGNOSIS >

B1113 – B1115 SATELLITE SENSOR RH

2.IGNITION SWITCH

After air bag warning lamp lights for 7 seconds, turn ignition switch OFF within 1 second.

>> GO TO 3

3.WAIT TIME

Wait more than 3 seconds.

>> GO TO 4

4.REPEAT STEPS

Repeat steps 1 to 3 twice.

>> GO TO 5

5.IGNITION SWITCH

Turn ignition switch ON.

>> GO TO 6

6.DIAGNOSTIC MODE

SRS system is now in diagnostic mode and AIR BAG warning lamp flashes. Refer to SRC-84, "

Trouble Diag-

nosis without CONSULT-III".

>> END

Diagnosis Procedure (C omponent Diagnosis)INFOID:0000000005147833

Recheck SRS after each replacement.

1.HARNESS CONNECTOR

Is there any visible damage to the connector?

YES or NO

YES >> Replace the harness.

NO >> GO TO 2

2.WIRING HARNESS

Is there any visible damage to the harness?

YES or NO

YES >> Replace the harness.

NO >> GO TO 3

3.RH SIDE AIR BAG SATELLITE SENSOR

Replace the RH side air bag satellite sensor. Refer to SR-15, "

Removal and Installation".

>> GO TO 4

4.AIR BAG DIAGNOSIS SENSOR UNIT

Replace the air bag diagnosis sensor unit. Refer to SR-17, "

Removal and Installation".

>> GO TO 5

5.RELATED HARNESS

Replace the related harness.

Revision: April 20092010 QX56

Page 3609 of 4210

B1XXX AIR BAG DIAGNOSIS SENSOR UNITSRC-63

< COMPONENT DIAGNOSIS >

C

DE

F

G

I

J

K L

M A

B

SRC

N

O P

2.IGNITION SWITCH

After air bag warning lamp lights for 7 seconds, turn ignition switch OFF within 1 second.

>> GO TO 3

3.WAIT TIME

Wait more than 3 seconds.

>> GO TO 4

4.REPEAT STEPS

Repeat steps 1 to 3 twice.

>> GO TO 5

5.IGNITION SWITCH

Turn ignition switch ON.

>> GO TO 6

6.DIAGNOSTIC MODE

SRS system is now in diagnostic mode and AIR BAG warning lamp flashes. Refer to SRC-84, "

Trouble Diag-

nosis without CONSULT-III".

>> END

Diagnosis Procedure (C omponent Diagnosis)INFOID:0000000005147836

Recheck SRS after each replacement.

1.HARNESS CONNECTOR

Is there any visible damage to the connector?

YES or NO

YES >> Replace the harness.

NO >> GO TO 2

2.WIRING HARNESS

Is there any visible damage to the harness?

YES or NO

YES >> Replace the harness.

NO >> GO TO 3

3.AIR BAG DIAGNOSIS SENSOR UNIT

Replace the air bag diagnosis sensor unit. Refer to SR-17, "

Removal and Installation".

>> GO TO 4

4.RELATED HARNESS

Replace the related harness.

>>END

Revision: April 20092010 QX56

Page 3611 of 4210

B1023 PASSENGER AIR BAG OFF INDICATORSRC-65

< COMPONENT DIAGNOSIS >

C

DE

F

G

I

J

K L

M A

B

SRC

N

O P

>> GO TO 2

2.IGNITION SWITCH

After air bag warning lamp lights for 7 seconds, turn ignition switch OFF within 1 second.

>> GO TO 3

3.WAIT TIME

Wait more than 3 seconds.

>> GO TO 4

4.REPEAT STEPS

Repeat steps 1 to 3 twice.

>> GO TO 5

5.IGNITION SWITCH

Turn ignition switch ON.

>> GO TO 6

6.DIAGNOSTIC MODE

SRS system is now in diagnostic mode and AIR BAG warning lamp flashes. Refer to SRC-84, "

Trouble Diag-

nosis without CONSULT-III".

>> END

Diagnosis Procedure (C omponent Diagnosis)INFOID:0000000005147839

Recheck SRS after each replacement.

1.HARNESS CONNECTOR

Is there any visible damage to the connector?

YES or NO

YES >> Replace the harness.

NO >> GO TO 2

2.WIRING HARNESS

Is there any visible damage to the harness?

YES or NO

YES >> Replace the harness.

NO >> GO TO 3

3.FRONT PASSENGER AIR BAG OFF INDICATOR

Replace the front passenger air bag off indicator. Refer to IP-15, "

Removal and Installation".

>> GO TO 4

4.AIR BAG DIAGNOSIS SENSOR UNIT

Replace the air bag diagnosis sensor unit. Refer to SR-17, "

Removal and Installation".

>> GO TO 5

5.RELATED HARNESS

Replace the related harness.

Revision: April 20092010 QX56

Page 3614 of 4210

SRC-68

< COMPONENT DIAGNOSIS >

B1017 – B1022 OCCUPANT CLASSIFICATION SYSTEM

2.CHECK SELF-DIAG RESULT

Check for the DTC on CONSULT-lll.

Is the DTC detected?

YES >> Refer to SRC-68, "Diagnosis Procedure (Component Diagnosis)".

NO >> Inspection End.

DTC CONFIRMATION PROCEDURE (Without CONSULT-lll)

NOTE:

SRS will not enter diagnosis mode if no malfunction is detected in user mode.

1.IGNITION SWITCH

Turn ignition switch ON.

>> GO TO 2

2.IGNITION SWITCH

After air bag warning lamp lights for 7 seconds, turn ignition switch OFF within 1 second.

>> GO TO 3

3.WAIT TIME

Wait more than 3 seconds.

>> GO TO 4

4.REPEAT STEPS

Repeat steps 1 to 3 twice.

>> GO TO 5

5.IGNITION SWITCH

Turn ignition switch ON.

>> GO TO 6

6.DIAGNOSTIC MODE

SRS system is now in diagnostic mode and AIR BAG warning lamp flashes. Refer to SRC-84, "

Trouble Diag-

nosis without CONSULT-III".

>> END

Diagnosis Procedure (C omponent Diagnosis)INFOID:0000000005147842

Recheck SRS after each replacement.

1.DTC

Does CONSULT-III indicate B1019 or B1022?

YES or NO

YES >> GO TO 2

NO >> GO TO 6

2.HARNESS CONNECTOR

Is there any visible damage to the connector?

YES or NO

YES >> Replace the harness.

NO >> GO TO 3

Revision: April 20092010 QX56

Page 3637 of 4210

PASSENGER SEAT BELT WARNING SYSTEMSRC-91

< SYMPTOM DIAGNOSIS >

C

DE

F

G

I

J

K L

M A

B

SRC

N

O P

PASSENGER SEAT BELT WARNING SYSTEM

Seat Belt Warning Syst em Does Not FunctionINFOID:0000000005147851

1.SEAT BELT WARNING LIGHT

Turn ignition switch ON.

Does the seat belt warning lamp come ON?

YES >> GO TO 2

NO >> • Check 10A fuse [No. 14, loca ted in the fuse block (J/B)].

• Check seat belt buckle switch LH.

• Check harness between combination meter and seat belt buckle switch LH.

• Check combination meter. Refer to MWI-23, "

CONSULT-III Function (METER/M&A)".

2.SEAT BELT BUCKLE LH

Fasten the seat belt buckle LH.

Does the seat belt warning lamp go OFF?

YES >> GO TO 3

NO >> • Check seat belt buckle switch LH. • Check harness between combination meter and seat belt buckle switch LH.

3.OCCUPANT CLASSIFICATION SYSTEM

Have a helper sit in the passenger seat.

Does the seat belt warning lamp go ON?

YES >> GO TO 4

NO >> • Check occupant classification system. Refer to SRC-10, "

Occupant Classification System

(OCS)".

• Check harness between occupant classification control unit and air bag diagnosis sensor unit.

4.SEAT BELT BUCKLE RH

Fasten the seat belt buckle RH.

Does the seat belt warning lamp go OFF?

YES >> System OK.

NO >> • Check seat belt buckle switch RH. • Check harness between seat belt buckle switch RH and air bag diagnosis sensor unit.

• Replace air bag diagnosis sensor unit. Refer to SR-17, "

Removal and Installation".

Revision: April 20092010 QX56

Page 3645 of 4210

HEATED STEERING WHEELST-7

< FUNCTION DIAGNOSIS >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

FUNCTION DIAGNOSIS

HEATED STEERING WHEEL

System DiagramINFOID:0000000005147859

System DescriptionINFOID:0000000005147860

The heated steering wheel switch controls the heated steeri ng relay. When the switch is turned on, the relay is

energized and the heated steering system will operate. T he heated steering system will turn off when the

steering wheel temperature reaches approximately 86 ° F (30 ° C). Heated steering system operation can also

be canceled by pressing the heated steering wheel switch again.

NOTE:

If the surface temperature of the steering wheel is below 68 ° F (20 ° C), the system will heat the steering wheel

to approximately 86 ° F (30 ° C), and cycle off and on to maintain a temperature above 68 ° F (20 ° C). The indi-

cator light will remain on as long as the system is on. Push the switch again to turn the heated steering wheel

system off manually. The indicator light will go off.

Component Parts LocationINFOID:0000000005147861

AWGIA0022GB

1. Heated steering relay M71 2. Combination switch (spiral cable) M52 3. Heated steering wheel M114

4. Heated steering wheel switch M260

ALGIA0030ZZ

Revision: April 20092010 QX56

Page 3653 of 4210

STEERING WHEELST-15

< ON-VEHICLE REPAIR >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

ON-VEHICLE REPAIR

STEERING WHEEL

On-Vehicle Inspection and ServiceINFOID:0000000005147868

CHECKING CONDITION OF INSTALLATION

• Check installation condition of steering gear assembly, front suspension, axle and steering column.

• Check if movement exists when steering wheel is mo ved up and down, to the left and right and to the axial

direction.

• Check if the nuts for steering gear assembly are loose. Refer to ST-23, "

Removal and Installation".

CHECKING STEERING WHEEL PLAY

1. Turn tires straight ahead, start engine, then turn steer ing wheel to the left and right lightly, and measure

steering wheel movement on the outer circumference when steering wheel is turned up to the point where

tires start moving.

CHECKING NEUTRAL POSITION ON STEERING WHEEL

• Check neutral position on steering wheel after confirming that front wheel alignment is correct. Refer to FSU-

6, "Front Wheel Alignment".

1. Turn tires straight ahead, check if steering wheel is in the neutral position.

2. If it is not in the neutral position, remo ve steering wheel and reinstall it correctly.

3. If the neutral position cannot be attained by repositi oning the steering wheel two teeth or less on steering

stem, loosen tie-rod lock nuts of steering outer socket s, then adjust tie-rods by the same amount in the

opposite direction.

CHECKING STEERING WHEEL TURNING FORCE

1. Park vehicle on a level, dry surface and set parking brake.

2. Start engine.

3. Bring power steering fluid up to operating temperature of 60 °– 80° C (140° – 176°F).

4. Tires need to be inflated to specified pressure. Refer to WT-52, "

Tire".

5. Check steering wheel turning force using Tool when steering wheel has been turned 360 ° from the neutral position.

End play of the axial direction for steering wheel : Refer to

ST-35, "

Steering Wheel".

LGIA0024E

Steering wheel play on the outer circumference : Refer to ST-35, "Steering Wheel".

Tool number — (J-44372)

Steering wheel

turning force : Refer to

ST-35, "

Steering

Wheel".

WGIA0035E

Revision: April 20092010 QX56

Page 3726 of 4210

ON BOARD DIAGNOSTIC (OBD) SYSTEMTM-31

< FUNCTION DIAGNOSIS >

CEF

G H

I

J

K L

M A

B

TM

N

O P

longer stored. Remember, only one set of freeze frame data can be stored in the ECM. The ECM has the fol-

lowing priorities to update the data.

Both 1st trip freeze frame data and freeze frame data (along with the DTC) are cleared when the ECM mem-

ory is erased.

HOW TO ERASE DTC

The diagnostic trouble code can be erased by CONSULT- III, GST or ECM DIAGNOSTIC TEST MODE as

described following.

• If the battery cable is disconnected, the diagnostic trouble code will be lost within 24 hours.

• When you erase the DTC, using CONSULT-III or GS T is easier and quicker than switching the mode

selector on the ECM.

The following emission-related diagnostic information is cleared from the ECM memory when erasing DTC

related to OBD-II. For details, refer to EC-42, "

Emission-related Diagnostic Information".

• Diagnostic trouble codes (DTC)

• 1st trip diagnostic trouble codes (1st trip DTC)

• Freeze frame data

• 1st trip freeze frame data

• System readiness test (SRT) codes

• Test values

HOW TO ERASE DTC (WITH CONSULT-III)

1. The emission related diagnostic information in the TCM and ECM can be er\

ased by selectioning "ALL

ERASE" in the "Description" of "F INAL CHECK" mode with CONSULT-III.

HOW TO ERASE DTC (WITH GST)

1. If the ignition switch stays “ON” after repair work, be sure to turn ignition switch “OFF” once. Wait at least

10 seconds and then turn it “ON” (engine stopped) again.

2. Select Mode 4 with the Generic Scan Tool (GST). For details refer to EC-72, "

Generic Scan Tool (GST)

Function".

HOW TO ERASE DTC (NO TOOLS)

1. Disconnect battery for 24 hours.

2. Reconnect battery.

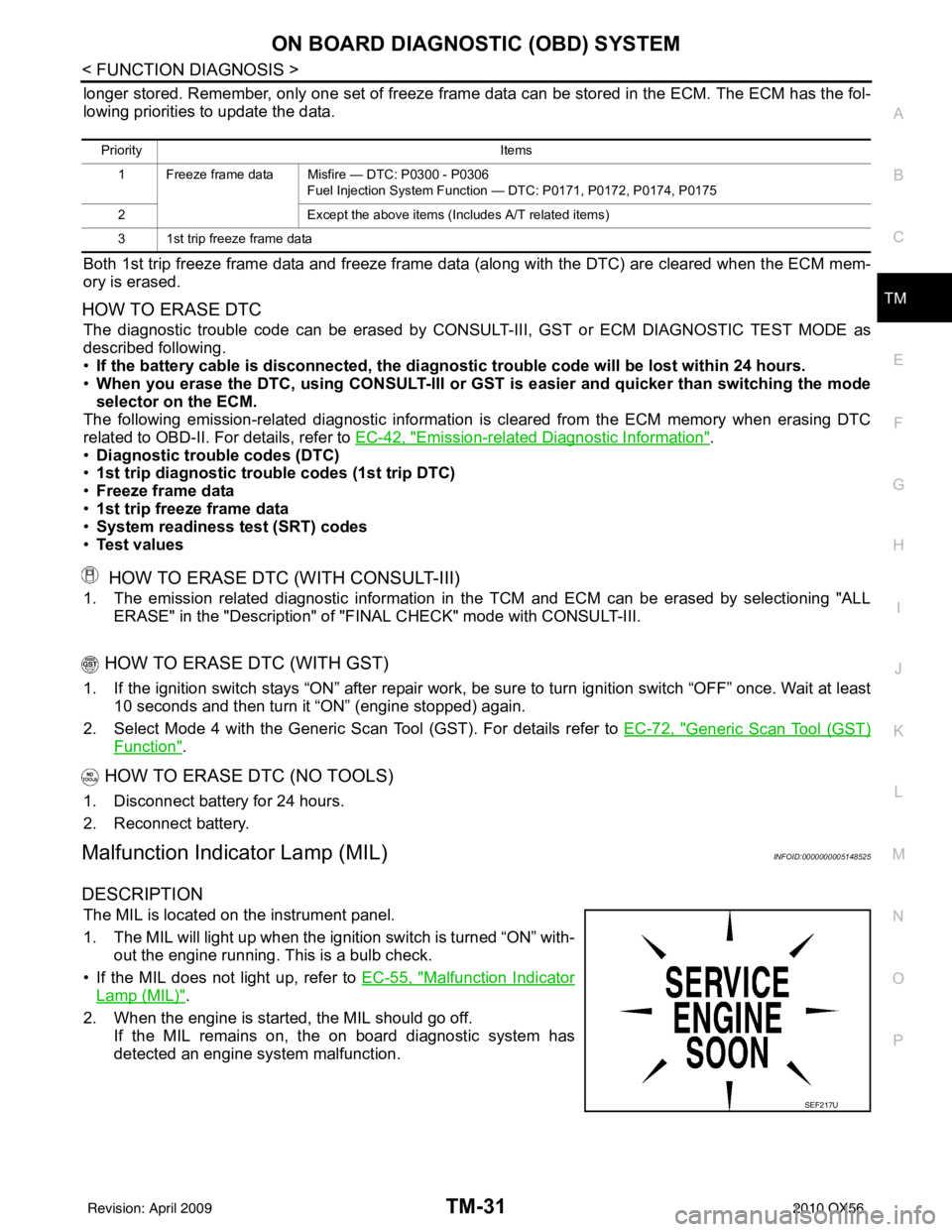

Malfunction Indicator Lamp (MIL)INFOID:0000000005148525

DESCRIPTION

The MIL is located on the instrument panel.

1. The MIL will light up when the ignition switch is turned “ON” with-

out the engine running. This is a bulb check.

• If the MIL does not light up, refer to EC-55, "

Malfunction Indicator

Lamp (MIL)".

2. When the engine is start ed, the MIL should go off.

If the MIL remains on, the on board diagnostic system has

detected an engine system malfunction.

Priority Items

1 Freeze frame data Misfire — DTC: P0300 - P0306 Fuel Injection System Function — DTC: P0171, P0172, P0174, P0175

2 Except the above items (Includes A/T related items)

3 1st trip freeze frame data

SEF217U

Revision: April 20092010 QX56

Page 3732 of 4210

DIAGNOSIS SYSTEM (TCM)TM-37

< FUNCTION DIAGNOSIS >

CEF

G H

I

J

K L

M A

B

TM

N

O P

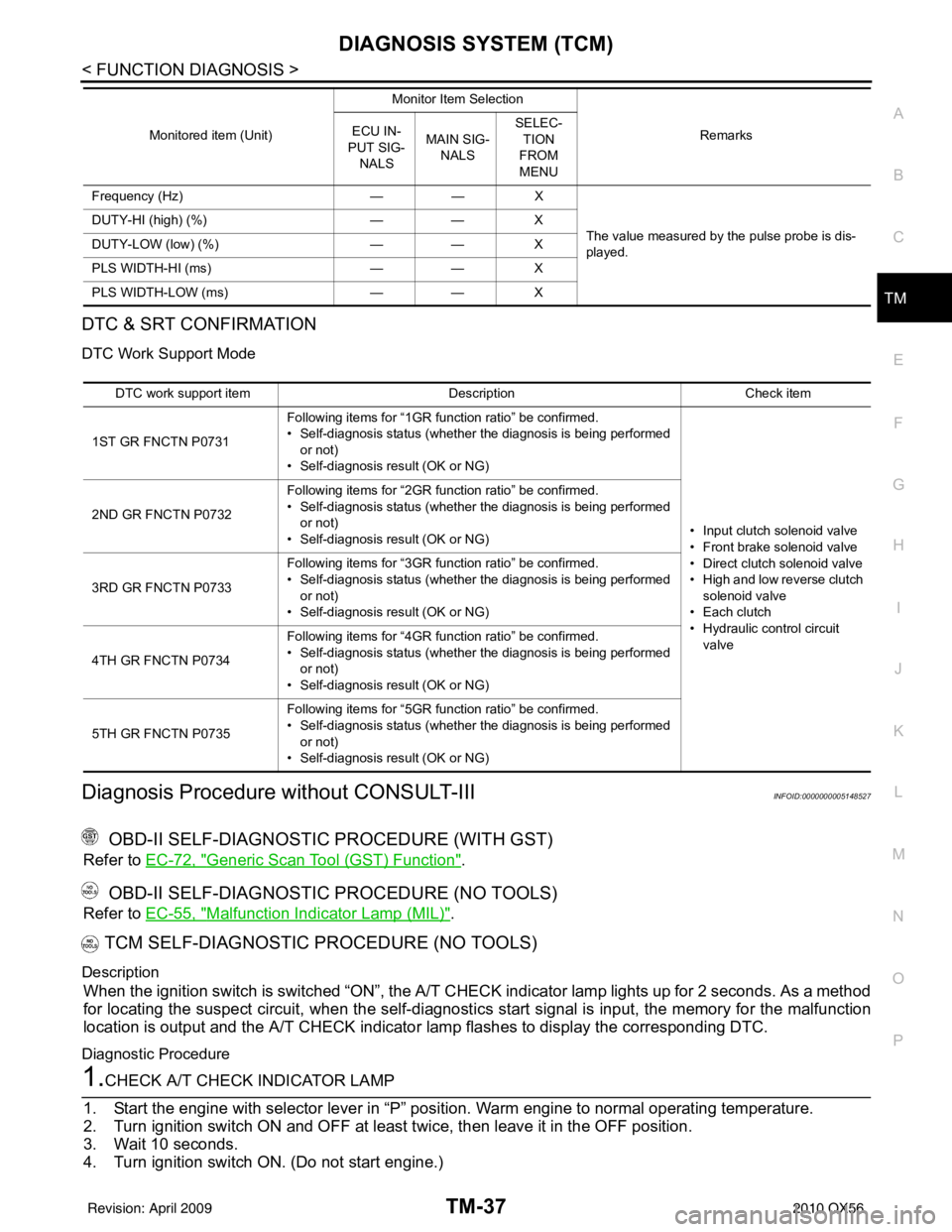

DTC & SRT CONFIRMATION

DTC Work Support Mode

Diagnosis Procedure without CONSULT-IIIINFOID:0000000005148527

OBD-II SELF-DIAGNOSTIC PROCEDURE (WITH GST)

Refer to EC-72, "Generic Scan Tool (GST) Function".

OBD-II SELF-DIAGNOSTIC PROCEDURE (NO TOOLS)

Refer to EC-55, "Malfunction Indicator Lamp (MIL)".

TCM SELF-DIAGNOSTIC PROCEDURE (NO TOOLS)

Description

When the ignition switch is switched “ON”, the A/T CHECK indicator lamp lights up for 2 seconds. As a method

for locating the suspect circuit, when the self-diagnosti cs start signal is input, the memory for the malfunction

location is output and the A/T CHECK indicator lamp flashes to display the corresponding DTC.

Diagnostic Procedure

1.CHECK A/T CHECK INDICATOR LAMP

1. Start the engine with selector lever in “P” pos ition. Warm engine to normal operating temperature.

2. Turn ignition switch ON and OFF at least twice, then leave it in the OFF position.

3. Wait 10 seconds.

4. Turn ignition switch ON. (Do not start engine.)

Frequency (Hz) —— X

The value measured by the pulse probe is dis-

played.

DUTY-HI (high) (%)

—— X

DUTY-LOW (low) (%) —— X

PLS WIDTH-HI (ms) —— X

PLS WIDTH-LOW (ms) —— X

Monitored item (Unit)

Monitor Item Selection

Remarks

ECU IN-

PUT SIG- NALS MAIN SIG-

NALS SELEC-

TION

FROM

MENU

DTC work support item DescriptionCheck item

1ST GR FNCTN P0731 Following items for “1GR function ratio” be confirmed.

• Self-diagnosis status (whether the diagnosis is being performed

or not)

• Self-diagnosis result (OK or NG)

• Input clutch solenoid valve

• Front brake solenoid valve

• Direct clutch solenoid valve

• High and low reverse clutch solenoid valve

• Each clutch

• Hydraulic co ntrol circuit

valve

2ND GR FNCTN P0732

Following items for “2GR function ratio” be confirmed.

• Self-diagnosis status (whether the diagnosis is being performed

or not)

• Self-diagnosis result (OK or NG)

3RD GR FNCTN P0733 Following items for “3GR function ratio” be confirmed.

• Self-diagnosis status (whether the diagnosis is being performed

or not)

• Self-diagnosis result (OK or NG)

4TH GR FNCTN P0734 Following items for “4GR function ratio” be confirmed.

• Self-diagnosis status (whether the diagnosis is being performed

or not)

• Self-diagnosis result (OK or NG)

5TH GR FNCTN P0735 Following items for “5GR function ratio” be confirmed.

• Self-diagnosis status (whether the diagnosis is being performed

or not)

• Self-diagnosis result (OK or NG)

Revision: April 20092010 QX56

Page 3733 of 4210

TM-38

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (TCM)

Does A/T CHECK indicator lamp come on for about 2 seconds?

YES >> GO TO 2.

NO >> GO TO TM-121, "

Symptom Table".

2.JUDGMENT PROCEDURE STEP 1

1. Turn ignition switch OFF.

2. Keep pressing shift lock release button.

3. Move selector lever from “P” to “D” position.

4. Release accelerator pedal. (Set the closed throttle position signal “ON”.)

5. Depress brake pedal. (Stop lamp switch signal “ON”.)

6. Turn ignition switch ON. (Do not start engine.)

7. Wait 3 seconds.

8. Move the selector lever from “D” to “3” position.

9. Release brake pedal. (Stop lamp switch signal “OFF”.)

10. Move the selector lever from “3” to “2” position.

11. Depress brake pedal. (Stop lamp switch signal “ON”.)

12. Depress accelerator pedal fully and release it.

>> GO TO 3.

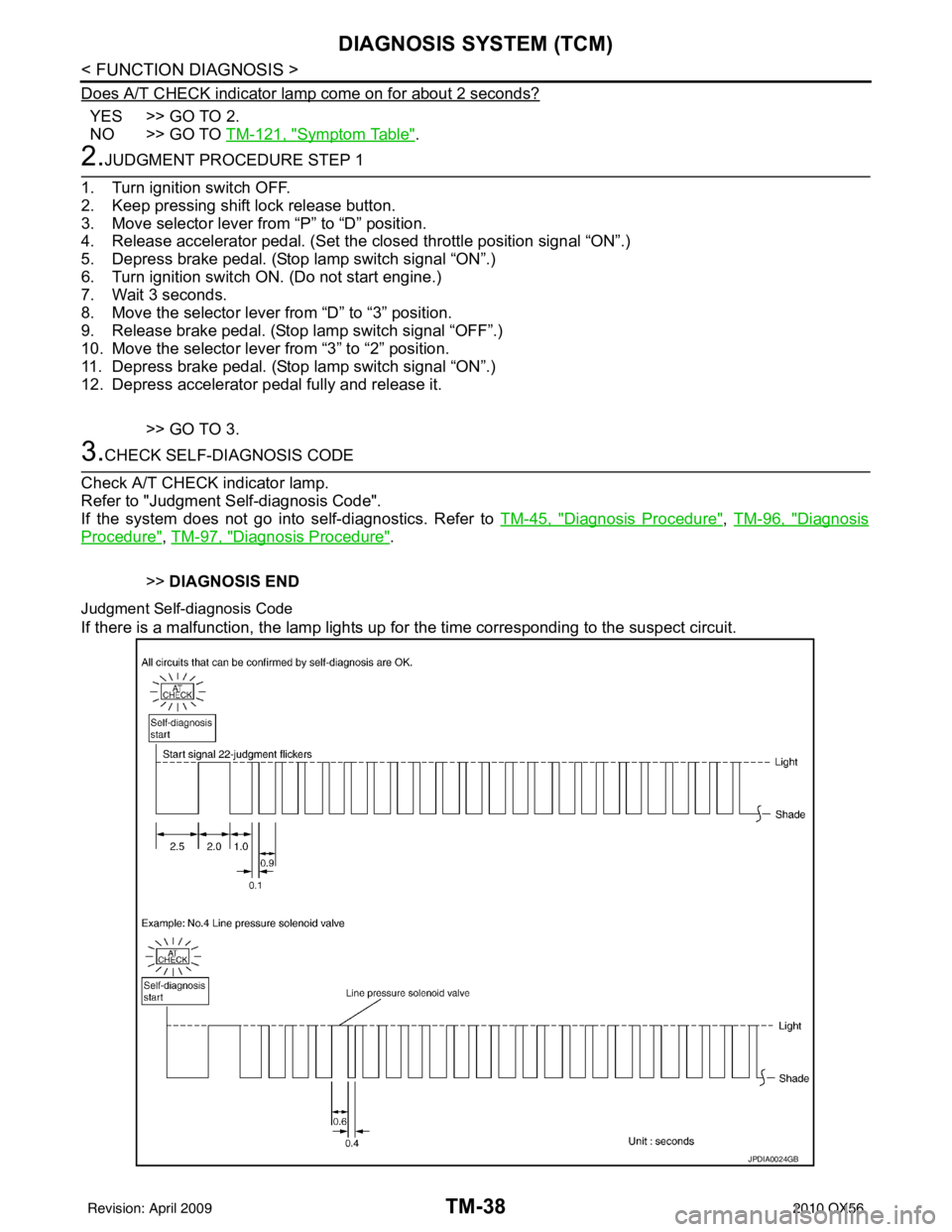

3.CHECK SELF-DIAGNOSIS CODE

Check A/T CHECK indicator lamp.

Refer to "Judgment Self-diagnosis Code".

If the system does not go into self-diagnostics. Refer to TM-45, "

Diagnosis Procedure", TM-96, "Diagnosis

Procedure", TM-97, "Diagnosis Procedure".

>> DIAGNOSIS END

Judgment Self-diagnosis Code

If there is a malfunction, the lamp lights up for the time corresponding to the suspect circuit.

JPDIA0024GB

Revision: April 20092010 QX56