headlamp INFINITI QX56 2010 Factory Repair Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 2103 of 4210

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

EXL-127

< ECU DIAGNOSIS >

C

D E

F

G H

I

J

K

M A

B

EXL

N

O P

26 P/L Headlamp aiming mo-

tors

Output —Lighting

switch 2nd

position or

AUTO, head-

lamp aiming

switch in po-

sition OFF

0V

ON Battery voltage

27 W/B Fuse 38

(With trailer tow)

Output —Ignition switch ON or START

Battery voltage

Ignition switch OFF or ACC 0V

30 W Fuse 53 Output —Ignition switch ON or START

Battery voltage

Ignition switch OFF or ACC 0V

32 L Wiper low speed sig-

nal

OutputON or

START Wiper switch OFF

Battery voltage

LO or INT 0V

35 L/B Wiper high speed sig-

nal

OutputON or

START Wiper switch OFF, LO, INT Battery voltage

HI 0V

37 Y Power generation

command signal Output —Ignition switch ON

6.3 V

40% is set on "Active test,"

"ALTERNATOR DUTY" of

"ENGINE" 3.8 V

40% is set on "Active test,"

"ALTERNATOR DUTY" of

"ENGINE" 1.4 V

38 B Ground Input ——0V

39 L CAN-H — ON— —

40 P CAN-L — ON— —

41 Y/B Hood switch Input —Hood closed OFF

0V

Hood open ON Battery voltage

42 GR Oil pressure switch Input — Engine running

Battery voltage

Engine stopped 0V

Te r m i n a l

Wire

color Signal name Signal

input/

output Measuring condition

Reference value(Approx.)

Igni-

tion

switch Operation or condition

JPMIA0001GB

JPMIA0002GB

JPMIA0003GB

Revision: April 20092010 QX56

Page 2110 of 4210

EXL-134

< ECU DIAGNOSIS >

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

If No CAN Communication Is Available With BCM

IGNITION RELAY MALFUNCTION DETECTION FUNCTION

• IPDM E/R monitors the voltage at the contact circuit and excitation coil circuit of the ignition relay inside it.

• IPDM E/R judges the ignition relay error if the voltage differs between the contact circuit and the excitation

coil circuit.

• If the ignition relay cannot turn OFF due to contact seizure, it activates the tail lamp relay for 10 minutes to alert the user to the ignition relay malfunction when the ignition switch is turned OFF.

NOTE:

The tail lamp turns OFF when the ignition switch is turned ON.

FRONT WIPER CONTROL

IPDM E/R detects front wiper stop posit ion by a front wiper auto stop signal.

When a front wiper auto stop signal is in the conditions listed below, IPDM E/R stops power supply to wiper

after repeating a front wiper 10 second activation and 20 second stop five times.

NOTE:

This operation status can be confirmed on the IPDM E/R “DATA MONITOR” that displays “Block” for the item

“WIP PROT” while the wiper is stopped.

STARTER MOTOR PROTECTION FUNCTION

IPDM E/R turns OFF the starter control relay to protect the starter motor when the starter control relay remains

active for 90 seconds.

Control part Fail-safe in operation

Cooling fan • Turns ON the cooling fan relay when the ignition switch is turned ON

• Turns OFF the cooling fan relay when the ignition switch is turned OFF

Control part

Fail-safe in operation

Headlamp • Turns ON the headlamp low relay when the ignition switch is turned ON

• Turns OFF the headlamp low relay when the ignition switch is turned OFF

• Headlamp high LH/RH relays OFF

•Parking lamps

• License plate lamps

• Tail lamps • Turns ON the tail lamp relay when the ignition switch is turned ON

• Turns OFF the tail lamp relay when the ignition switch is turned OFF

Front wiper • The status just before activation of fail-safe control is maintained until the ignition

switch is turned OFF while the front wiper is operating at LO or HI speed.

• The wiper is operated at LO speed until the ignition switch is turned OFF if the fail- safe control is activated while the front wipe r is set in the INT mode and the front wiper

motor is operating.

Rear window defogger Rear window defogger relay OFF

A/C compressor A/C relay OFF

Front fog lamps Front fog lamp relay OFF

Ignition switch Ignition relayTail lamp relay

ON ON —

OFF OFF —

Ignition switchFront wiper switch Auto stop signal

ON OFF

Front wiper stop position signal cannot be

input 10 seconds.

ON The signal does not change for 10 seconds.

Revision: April 20092010 QX56

Page 2112 of 4210

EXL-136

< SYMPTOM DIAGNOSIS >

EXTERIOR LIGHTING SYSTEM SYMPTOMS

SYMPTOM DIAGNOSIS

EXTERIOR LIGHTING SYSTEM SYMPTOMS

Symptom TableINFOID:0000000005146686

CAUTION:

Perform the self-diagnosis with CONSULT-III before the symptom diagnosis. Perform the trouble diag-

nosis if any DTC is detected.

Symptom Possible causeInspection item

Headlamp does not

switch to the high beam. One side•Fuse

• Harness between IPDM E/R

and the front combination lamp

• Front combination lamp

(High beam relay)

• IPDM E/R Headlamp (HI) circuit

Refer to EXL-30, "

Description".

Both sides Symptom diagnosis

"BOTH SIDE HEADLAMPS DO NOT SWITCH TO HIGH BEAM"

Refer to

EXL-139

.

High beam indicator lamp is not turned ON.

(Headlamp switches to the high beam.) • Combination meter

•BCM• Combination meter.

Data monitor "HI-BEAM IND".

• BCM (HEAD LAMP) Active test "HEADLAMP".

Headlamp does not

switch to the low beam. One side

Front combination lamp (Low

beam relay)

—

Both sides • Combination switch (lighting

and turn signal switch)

• Harness between the combina-

tion switch and BCM

•BCM Combination switch

Refer to BCS-38

.

High beam request signal

•BCM

• IPDM E/R IPDM E/R

Data monitor "HL HI REQ".

IPDM E/R —

Headlamp does not turn

ON. One side•Fuse

•Bulb

• Harness between IPDM E/R

and the front combination lamp

• Front combination lamp

• IPDM E/R Headlamp (L

O) circuit

Refer to EXL-33

.

Both sides Symptom diagnosis

"BOTH SIDE HEADLAMPS (LO) ARE NOT TURNED ON"

Refer to

EXL-140, "

Description".

Headlamp does not turn

OFF. When the ignition

switch is turned ON•BCM

• Combination switch (lighting

and turn signal switch) Combination switch (lighting and

turn signal switch)

Refer to BCS-38

.

Headlamp is not turned ON/OFF with the lighting

switch AUTO. • Combination switch (lighting

and turn signal switch)

• Harness between the combina-

tion switch and BCM

•BCM Combination switch (lighting and

turn signal switch)

Refer to BCS-38

.

• Optical sensor

• Harness between the optical sensor and BCM

•BCM Optical sensor

Refer to EXL-47

.

Revision: April 20092010 QX56

Page 2114 of 4210

EXL-138

< SYMPTOM DIAGNOSIS >

NORMAL OPERATING CONDITION

NORMAL OPERATING CONDITION

DescriptionINFOID:0000000005146687

XENON HEADLAMPS

The brightness and color of the light may vary slightly immediately after turning the headlamp ON. This condi-

tionwill remain until the xenon bulb becomes stable. This is normal.

• Illumination time lag may occur between right and left. This is normal.

AUTO LIGHT SYSTEM

The auto light system may not turn the headlamp ON/OF F immediately after passing a dark area or a bright

area (short tunnel, sky bridge, shadowed area etc.). This is normal.

Revision: April 20092010 QX56

Page 2115 of 4210

BOTH SIDE HEADLAMPS DO NOT SWITCH TO HIGH BEAM

EXL-139

< SYMPTOM DIAGNOSIS >

C

D E

F

G H

I

J

K

M A

B

EXL

N

O P

BOTH SIDE HEADLAMPS DO NOT SWITCH TO HIGH BEAM

DescriptionINFOID:0000000005146688

The headlamps (both sides) do not switch to high beam when the combination switch (lighting and turn signal

switch) is in the HI or PASS setting.

Diagnosis ProcedureINFOID:0000000005146689

1.COMBINATION SWITCH (LIGHTING AND TURN SIGNAL SWITCH) INSPECTION

Check the combination switch (lighting and turn signal switch). Refer to BCS-38, "

Diagnosis Procedure".

Is the combination switch (lighting and turn signal switch) normal?

YES >> GO TO 2.

NO >> Repair or replace the malfunctioning part.

2.CHECK HEADLAMP (HI) REQUEST SIGNAL INPUT

CONSULT-III DATA MONITOR

1. Select "HL HI REQ" of IPDM E/R DATA MONITOR item.

2. With operating the combination switch (lighting and turn signal switch), check the monitor status.

Is the item status normal?

YES >> GO TO 3.

NO >> Replace BCM. Refer to BCS-59, "

Removal and Installation" .

3.HEADLAMP (HI) CIRCUIT INSPECTION

Check the headlamp (HI) circuit. Refer to EXL-30, "

Description".

Is the headlamp (HI) circuit normal?

YES >> Replace IPDM E/R. Refer to PCS-35, "Removal and Installation of IPDM E/R" .

NO >> Repair or replace the malfunctioning part.

Monitor item ConditionMonitor status

HL HI REQ Combination switch (lighting and

turn signal switch)

(2ND) HI or PASS

ON

Except for HI or

PASS OFF

Revision: April 20092010 QX56

Page 2116 of 4210

EXL-140

< SYMPTOM DIAGNOSIS >

BOTH SIDE HEADLAMPS (LO) ARE NOT TURNED ON

BOTH SIDE HEADLAMPS (LO) ARE NOT TURNED ON

DescriptionINFOID:0000000005146690

The headlamps (both sides) do not turn ON in any combination switch (lighting and turn signal switch) setting.

Diagnosis ProcedureINFOID:0000000005146691

1.COMBINATION SWITCH (LIGHTING AND TURN SIGNAL SWITCH) INSPECTION

Check the combination switch (lighting and turn signal switch). Refer to BCS-38, "

Diagnosis Procedure".

Is the combination switch (lighting and turn signal switch) normal?

YES >> GO TO 2.

NO >> Repair or replace the malfunctioning part.

2.CHECK HEADLAMP (LO) REQUEST SIGNAL INPUT

CONSULT-III DATA MONITOR

1. Select "HL LO REQ" of IPDM E/R DATA MONITOR item.

2. With operating the combination switch (lighting and turn signal switch), check the monitor status.

Is the item status normal?

YES >> GO TO 3.

NO >> Replace BCM. Refer to BCS-59, "

Removal and Installation" .

3.HEADLAMP (LO) CIRCUIT INSPECTION

Check the headlamp (LO) circuit. Refer to EXL-33, "

Description".

Is the headlamp (LO) circuit normal?

YES >> Replace IPDM E/R. Refer to PCS-35, "Removal and Installation of IPDM E/R" .

NO >> Repair or replace the malfunctioning part.

Monitor item ConditionMonitor status

HL LO REQ Combination switch

(lighting and turn signal

switch) 2ND

ON

OFF OFF

Revision: April 20092010 QX56

Page 2121 of 4210

ADJUSTMENT AND INSPECTIONEXL-145

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

ON-VEHICLE REPAIR

ADJUSTMENT AND INSPECTION

HEADLAMP

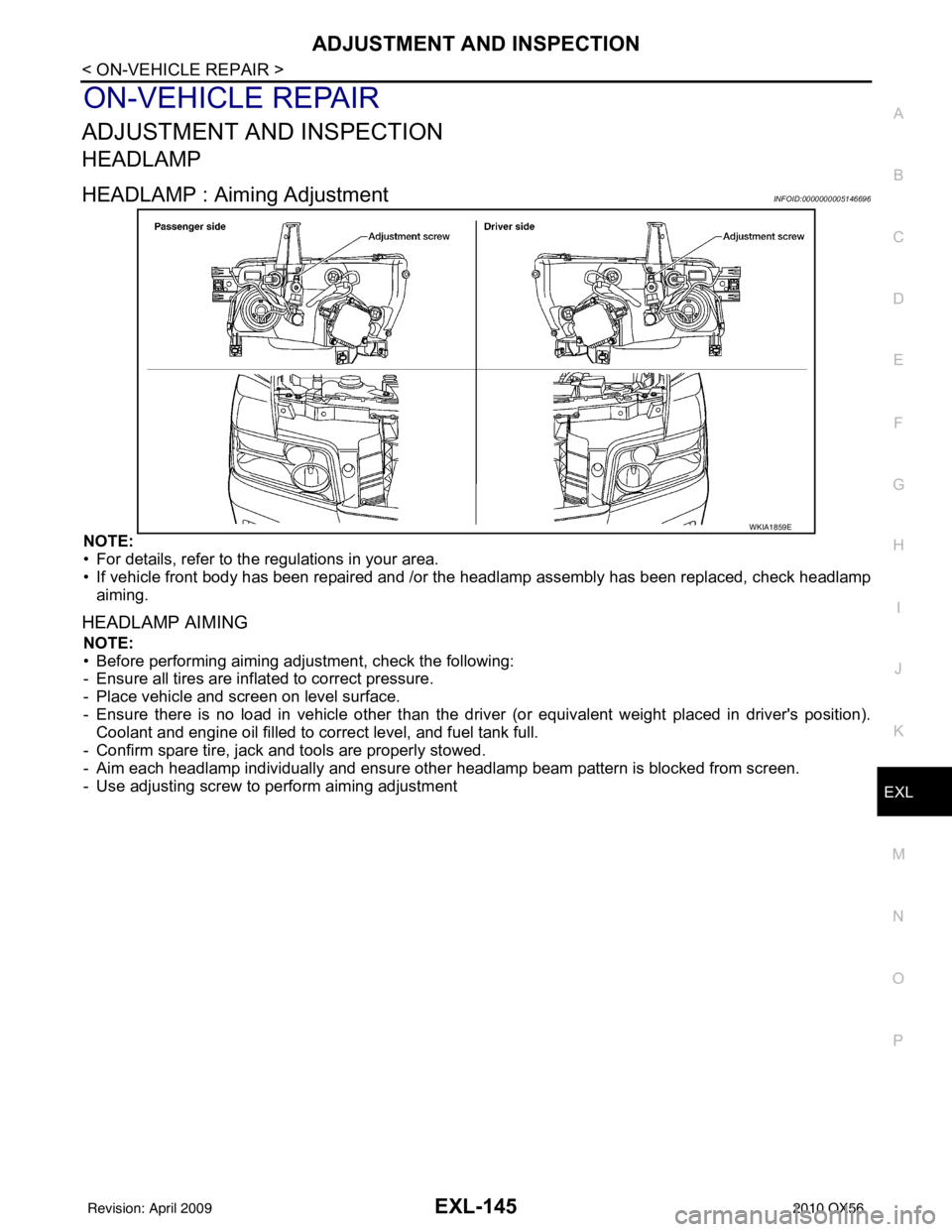

HEADLAMP : Aiming AdjustmentINFOID:0000000005146696

NOTE:

• For details, refer to the regulations in your area.

• If vehicle front body has been repaired and /or the headlamp assembly has been replaced, check headlamp

aiming.

HEADLAMP AIMING

NOTE:

• Before performing aiming adjustment, check the following:

- Ensure all tires are inflated to correct pressure.

- Place vehicle and screen on level surface.

- Ensure there is no load in vehicle other than the driver (or equivalent weight placed in driver's position). Coolant and engine oil filled to correct level, and fuel tank full.

- Confirm spare tire, jack and tools are properly stowed.

- Aim each headlamp individually and ensure other headlamp beam pattern is blocked from screen.

- Use adjusting screw to perform aiming adjustment

WKIA1859E

Revision: April 20092010 QX56

Page 2122 of 4210

EXL-146

< ON-VEHICLE REPAIR >

ADJUSTMENT AND INSPECTION

NOTE:

Basic illuminating area for adjustment should be within the range shown on the aiming chart. Adjust head-

lamps accordingly.

LOW BEAM AND HIGH BEAM

1. Turn headlamp low beam on.

2. Use adjusting screw to perform aiming adjustment.

FRONT FOG LAMP

FRONT FOG LAMP : Aiming AdjustmentINFOID:0000000005146697

The fog lamp is a semi-sealed beam type which uses a replaceable halogen bulb. Before performing aiming

adjustment, make sure of the following.

• Keep all tires inflated to correct pressure.

• Place vehicle on level ground.

A. RightB. Left C. Center of headlamp bulb (H-V point)

D. Cutoff line E. ScreenF. Aim evaluation segment

G. Step H. Horizontal center line of headlamp J. 103 mm (4.06 in.)

K. 37 mm (1.46 in.) L. 7.62 m (25 ft.) M. 399 mm (15.71 in.)

N. 133 mm (5.24 in.) P. 53.2 mm (2.09 in.)Q. 466 mm (18.35 in.)

R. 200 mm (7.87 in.) S. RH headlamp aiming screen T. LH headlamp aiming screen

V. Vertical center line

LKIA0809E

Revision: April 20092010 QX56

Page 2124 of 4210

EXL-148

< REMOVAL AND INSTALLATION >

HEADLAMP

REMOVAL AND INSTALLATION

HEADLAMP

Bulb ReplacementINFOID:0000000005146698

CAUTION:

• Disconnect battery negative terminal before touching xenon bulb or headlamp wiring harness

assembly.

• Turn headlamp switch OFF before disconnecting headlamp harness connector.

• Do not touch bulb by hand right after being turned off. Burning may result.

• Do not touch the glass of bulb directly by hand. Keep grease and other oily substances away from it.

• Do not turn xenon bulb ON wh en xenon bulb is removed from front combination lamp assembly.

• After installing the bulb, be sure to install the bulb socket securely to ensure watertightness.

• Do not leave bulb out of front combination lamp assembly for a long time because dust, moisture,

smoke, etc. may affect the performa nce of the lamp. When replacing bulb, be sure to replace it with a

new one.

HEADLAMP (OUTER SIDE), FOR LOW BEAM

Removal

1. Position fender protector aside.

2. Turn headlamp switch OFF.

3. Disconnect battery negative terminal.

4. Remove ballast.

5. Disconnect headlamp electrical connector.

6. Release bulb retaining spring and pull bulb straight out.

Installation

Installation is in the reverse order of removal.

HEADLAMP (INNER SIDE), FOR HIGH BEAM

Removal

1. Turn headlamp switch OFF.

2. Disconnect headlamp electrical connector.

3. Turn the bulb counterclockwise to remove it.

Installation

Installation is in the reverse order of removal.

FRONT PARKING LAMP (INNER OR OUTER)

Removal

1. Turn the bulb socket counterclockwise to unlock it.

2. Pull the bulb to remove it from the socket.

Installation

Installation is in the reverse order of removal.

SIDE MARKER LAMP (FRONT)

Removal

1. Position fender protector aside.

2. Turn the side marker lamp (front) bulb socket counterclockwise and remove side marker lamp (front) bulb socket.

3. Pull to remove side marker lamp (front) fr om the side marker lamp (front) bulb socket.

Installation

Installation is in the reverse order of removal.

Revision: April 20092010 QX56

Page 2125 of 4210

HEADLAMPEXL-149

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

Removal and InstallationINFOID:0000000005146699

FRONT COMBINATION LAMP ASSEMBLY

CAUTION:

• Disconnect battery negative terminal before touc hing xenon bulb or headlamp wiring harness

assembly.

• Turn headlamp switch OFF before di sconnecting headlamp harness connector.

• Do not touch bulb by hand right after being turned off. Burning may result.

• Do not touch the glass of bulb directly by hand. Keep grease and other oily substances away from it.

• Do not turn xenon bulb ON when xenon bulb is removed fr om front combination lamp assembly.

• After installing the bu lb, be sure to install the bulb socket securely to ensure watertightness.

• Do not leave bulb out of front combination lamp assembly for a lo ng time because dust, moisture,

smoke, etc. may affect the performance of the lamp. When replacing bulb, be sure to replace it with a

new one.

Removal

1. Disconnect battery negative terminal.

2. Disconnect front combination lamp assembly.

3. Remove front fascia. Refer to EXT-13, "

Removal and Installation".

4. Remove front combination lamp assembly bolts.

5. Remove front combination lamp assembly.

Installation

Installation is in the reverse order of removal.

Disassembly and AssemblyINFOID:0000000005146700

FRONT COMBINATION LAMP ASSEMBLY

WKIA1860E

1. Parking lamp bulb (outer) 2. Headlamp bulb (high beam) 3. Headlamp assembly

ALKIA1536GB

Revision: April 20092010 QX56