engine INFINITI QX56 2010 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 3655 of 4210

POWER STEERING OIL PUMPST-17

< ON-VEHICLE REPAIR >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

POWER STEERING OIL PUMP

On-Vehicle Inspection and ServiceINFOID:0000000005147869

CHECKING RELIEF OIL PRESSURE

CAUTION:

Before starting work, confirm belt tension is proper.

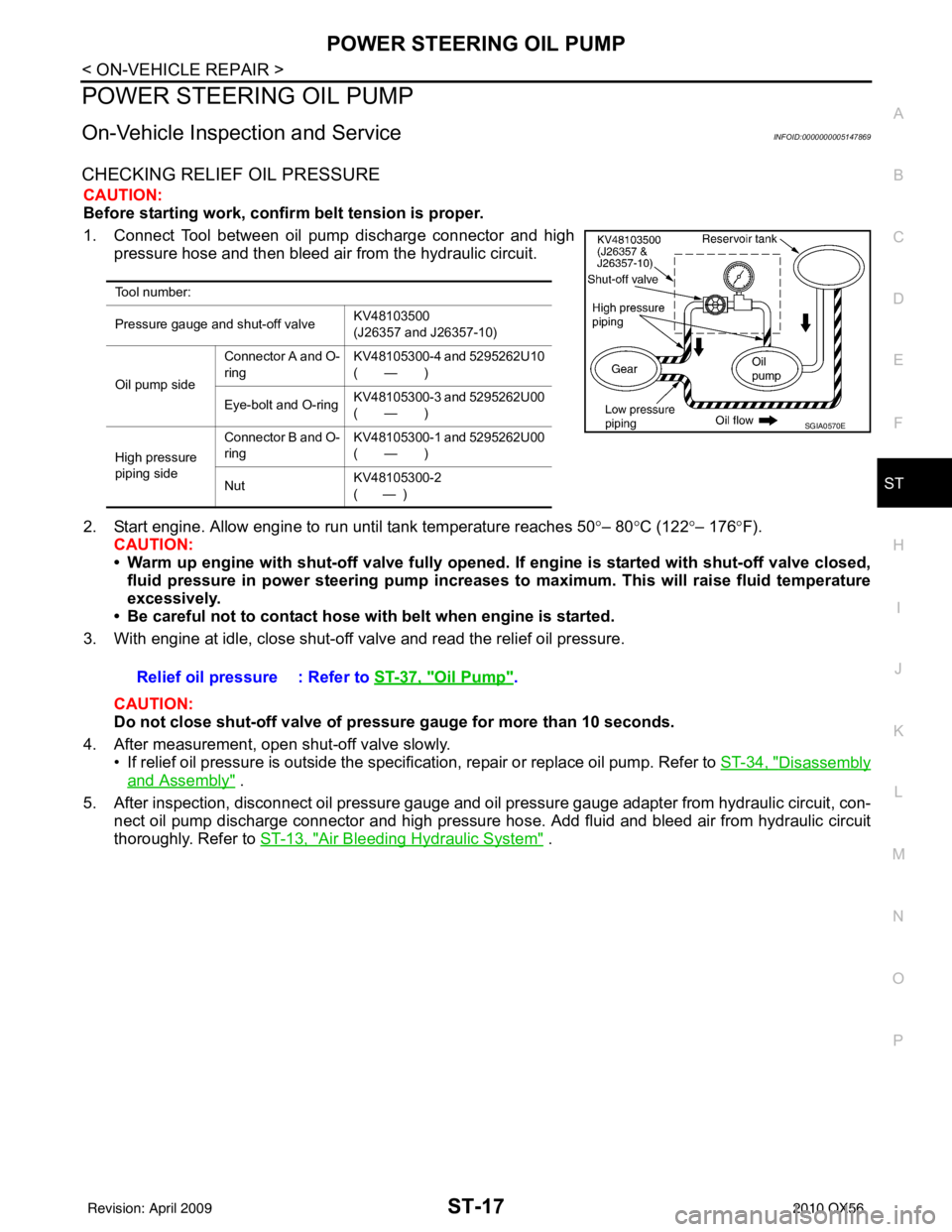

1. Connect Tool between oil pump discharge connector and high pressure hose and then bleed air from the hydraulic circuit.

2. Start engine. Allow engine to run until tank temperature reaches 50 °– 80° C (122° – 176°F).

CAUTION:

• Warm up engine with shut-off valve fully opened. If engine is started with shut-off valve closed,

fluid pressure in power steering pump increases to maximum. This will raise fluid temperature

excessively.

• Be careful not to contact hose with belt when engine is started.

3. With engine at idle, close shut-off valve and read the relief oil pressure.

CAUTION:

Do not close shut-off valve of pressure gauge for more than 10 seconds.

4. After measurement, open shut-off valve slowly. • If relief oil pressure is outside the specification, repair or replace oil pump. Refer to ST-34, "

Disassembly

and Assembly" .

5. After inspection, disconnect oil pressure gauge and oil pressure gauge adapter from hydraulic circuit, con-

nect oil pump discharge connector and high pressure hose. Add fluid and bleed air from hydraulic circuit

thoroughly. Refer to ST-13, "

Air Bleeding Hydraulic System" .

Tool number:

Pressure gauge and shut-off valve KV48103500

(J26357 and J26357-10)

Oil pump side Connector A and O-

ring

KV48105300-4 and 5295262U10

(—)

Eye-bolt and O-ring KV48105300-3 and 5295262U00

(—)

High pressure

piping side Connector B and O-

ring

KV48105300-1 and 5295262U00

(—)

Nut KV48105300-2

( — )

SGIA0570E

Relief oil pressure : Refer to

ST-37, "Oil Pump".

Revision: April 20092010 QX56

Page 3664 of 4210

ST-26

< REMOVAL AND INSTALLATION >

POWER STEERING OIL PUMP

POWER STEERING OIL PUMP

Removal and InstallationINFOID:0000000005147874

REMOVAL

1. Drain power steering fluid from reservoir tank.

2. Remove engine room cover. Refer to EM-24, "

Removal and Installation".

3. Remove air duct assembly. Refer to EM-25, "

Removal and Installation".

4. Remove power steering reservoir tank.

5. Remove serpentine drive belt belt from auto tensioner and power steering pump. Refer to EM-13,

"Removal and Installation".

6. Disconnect pressure sensor electrical connector.

7. Remove high pressure and low pressure piping from power steering oil pump. Refer to ST-27

.

8. Remove bolts, then remove power steering pump.

INSTALLATION

Installation is in the reverse order of removal. Refer to ST-27 for tightening torque.

• After installation, bleed air. Refer to ST-13, "

Air Bleeding Hydraulic System".

NOTE:

Belt tension is automatic and requires no adjustment.

Revision: April 20092010 QX56

Page 3676 of 4210

STR-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION STR

A

STR

N

O P

CONTENTS

STARTING SYSTEM

PRECAUTION ....... ........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

Precaution for Power Generation Variable Voltage

Control System ..........................................................

3

PREPARATION ............................................4

PREPARATION .............................................. .....4

Special Service Tool ........................................... ......4

Commercial Service Tool ..........................................4

BASIC INSPECTION ....................................5

DIAGNOSIS AND REPAIR WORKFLOW ..... .....5

Work Flow ........................................................... ......5

FUNCTION DIAGNOSIS ...............................8

STARTING SYSTEM ...................................... .....8

System Diagram .................................................. ......8

System Description ...................................................8

Component Parts Location ........................................8

Component Description ............................................9

COMPONENT DIAGNOSIS .........................10

B TERMINAL CIRCUIT .....................................10

Description ........................................................... ....10

Diagnosis Procedure ...............................................10

S CONNECTOR CIRCUIT .................................12

Description ...............................................................12

Diagnosis Procedure ...............................................12

STARTING SYSTEM .........................................14

Wiring Diagram .................................................... ....14

SYMPTOM DIAGNOSIS ..............................18

STARTING SYSTEM .........................................18

Symptom Table ................................................... ....18

ON-VEHICLE REPAIR .................................19

STARTER MOTOR ...........................................19

Removal and Installation ..................................... ....19

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... ...

20

STARTER MOTOR ...........................................20

Starter .................................................................. ....20

Revision: April 20092010 QX56

Page 3677 of 4210

STR-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005315461

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005315460

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: April 20092010 QX56

Page 3678 of 4210

PRECAUTIONSSTR-3

< PRECAUTION >

C

DE

F

G H

I

J

K L

M A

STR

NP

O

5. When the repair work is completed, return the ignition switch to the

″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Precaution for Power Generation Variable Voltage Control SystemINFOID:0000000005149546

CAUTION:

For this model, the battery current sensor that is installed to the negative battery cable measures the

charging/discharging current of the battery and performs various engine controls. If an electrical com-

ponent is connected directly to the negative battery terminal, the current flowing through that compo-

nent will not be measured by the battery current sensor. This condition may cause a malfunction of

the engine control system and battery discharge m ay occur. Do not connect an electrical component

or ground wire directly to the battery terminal.

Revision: April 20092010 QX56

Page 3681 of 4210

STR-6

< BASIC INSPECTION >

DIAGNOSIS AND REPAIR WORKFLOW

NOTE:

To ensure a complete and thorough diagnosis, the battery, starter motor and generator test segments must be

done as a set from start to finish.

1.DIAGNOSIS WITH MULTITASKING BATTERY DIAGNOSTIC STATION

Perform the starting system test with multitasking batte ry diagnostic station. For details and operating instruc-

tions, refer to diagnostic station instruction manual.

Te s t r e s u l t

CRANKING NORMAL>>GO TO 2.

LOW VOLTAGE>>GO TO 5.

CHARGE BATTERY>>Perform the slow battery charging procedure. (Initial rate of charge is 10A for 12

hours.) Perform battery test again. Refer to diagnostic station instruction manual.

REPLACE BATTERY>>Before replacing battery, clean t he battery cable clamps and battery posts. Perform

battery test again. Refer to diagnostic station instruction manual. If second test result is

“REPLACE BATTERY”, then do so. Perform battery test again to confirm repair.

2.CRANKING CHECK

Check that the starter motor operates properly.

Does the engine crank normally?

YES >> GO TO 3.

NO >> GO TO 4.

3.ENGINE START CHECK

Check that the engine starts.

Does the engine start?

YES >> Starter motor is OK. Inspection End.

NO >> Perform further diagnosis of engine mechanical or engine control system. Refer to EM and EC sections. Once resolved, perform battery test again.

4.STARTER MOTOR ACTIVATION

Check that the starter motor operates.

Does the starter motor turn?

YES >> Check ring gear and starter motor drive pinion. Once resolved, perform battery test again.

NO >> GO TO 7.

5.COMPARISON BETWEEN ENGINE COOLANT AND CRANKING VOLTAGE

Compare the engine coolant temperature and verify the cranking voltage is within specification.

Minimum Specification of Cranking Voltage Referencing Coolant Temperature

Is the voltage less than the specified value?

YES >> GO TO 7.

NO >> GO TO 6.

6.STARTER OPERATION

Check the starter operation.

Does the starter motor turn smoothly?

YES >> Starter motor is OK. Inspection End.

NO >> GO TO 7.

7.“B” TERMINAL CIRCUIT INSPECTION

Check “B” terminal circuit. Refer to STR-10, "

Diagnosis Procedure".

Is

“B” terminal circuit normal?

Engine coolant temperature [ °C ( °F)] Voltage [V]

− 30 to − 20 (−22 to − 4) 8.6

− 19 to −10 ( −2 to 14) 9.1

− 9 to 0 (16 to 32) 9.5

More than 1 (More than 34) 9.9

Revision: April 20092010 QX56

Page 3682 of 4210

DIAGNOSIS AND REPAIR WORKFLOWSTR-7

< BASIC INSPECTION >

C

DE

F

G H

I

J

K L

M A

STR

NP

O

YES >> GO TO 8.

NO >> Repair as needed.

8.“S” CONNECTOR CIRCUIT INSPECTION

Check “S” connector circuit. Refer to STR-12, "

Diagnosis Procedure".

Is

“S” connector circuit normal?

YES >> GO TO 9.

NO >> Repair as needed.

9.ENGINE ROTATION STATUS

Check that the engine can be rotated by hand.

Does the engine turn freely by hand?

YES >> Replace starter motor.

NO >> Perform further diagnosis of engine mechanical or powertrain mechanism. Refer to EM or TM

sections. Once resolved, perform battery test agai n. Refer to diagnostic station instruction man-

ual.

Revision: April 20092010 QX56

Page 3684 of 4210

STARTING SYSTEMSTR-9

< FUNCTION DIAGNOSIS >

C

DE

F

G H

I

J

K L

M A

STR

NP

O

Component DescriptionINFOID:0000000005149553

Component part

Description

TCM TCM supplies power to the starter relay inside the IPDM E/R when

the selector lever is shifted to the P or N position.

BCM BCM sends a starter request signal to the CPU of the IPDM E/R

over the CAN communication lines.

IPDM E/R CPU inside IPDM E/R operates the starter relay at the request of

the BCM over the CAN communication lines.

Starter motor The starter motor plunger closes and the motor is supplied with

battery power, which in turn cranks the engine, when the “S” ter-

minal is supplied with electric power.

Revision: April 20092010 QX56

Page 3685 of 4210

STR-10

< COMPONENT DIAGNOSIS >

B TERMINAL CIRCUIT

COMPONENT DIAGNOSIS

B TERMINAL CIRCUIT

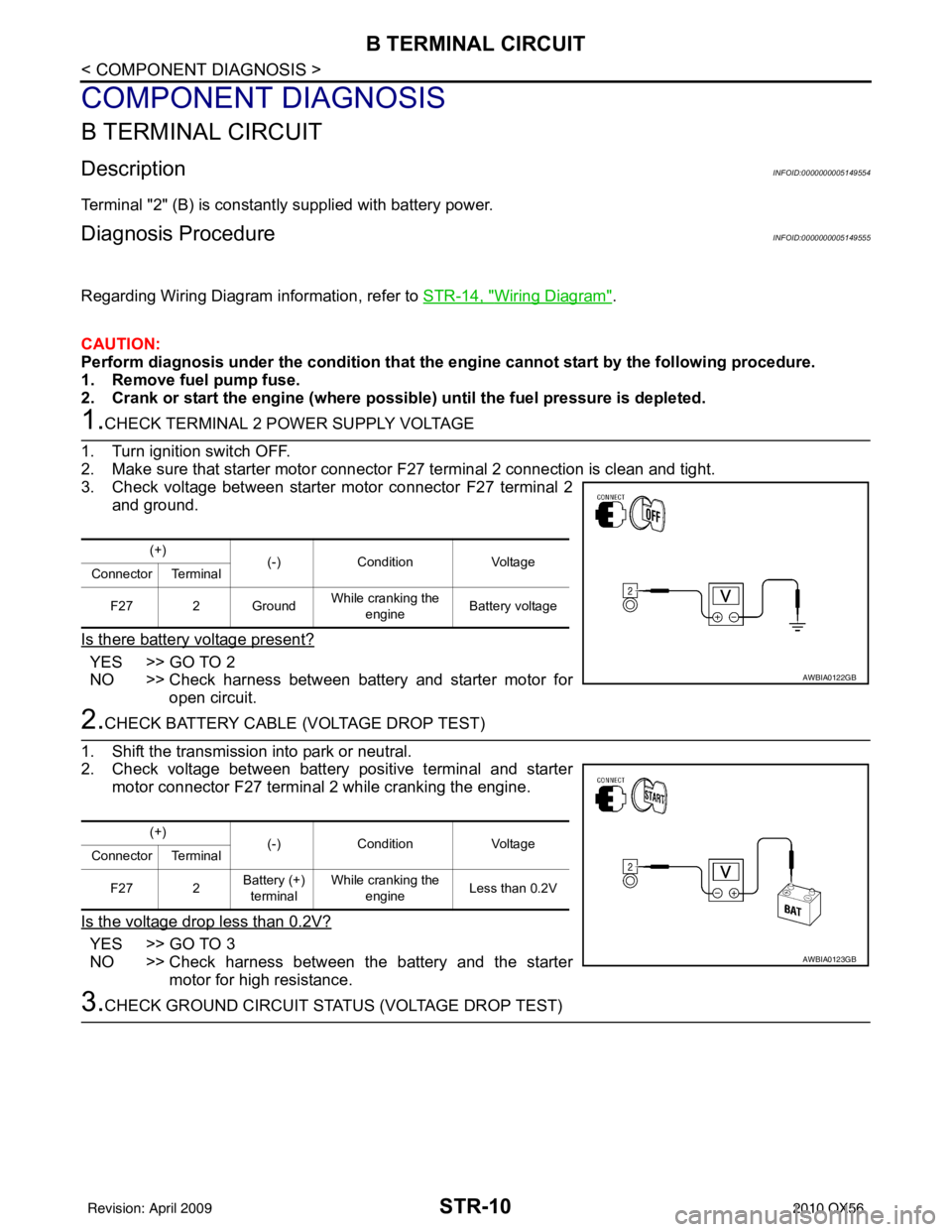

DescriptionINFOID:0000000005149554

Terminal "2" (B) is constantly supplied with battery power.

Diagnosis ProcedureINFOID:0000000005149555

Regarding Wiring Diagram information, refer to STR-14, "Wiring Diagram".

CAUTION:

Perform diagnosis under the condi tion that the engine cannot start by the following procedure.

1. Remove fuel pump fuse.

2. Crank or start the engine (where possible) until the fuel pressure is depleted.

1.CHECK TERMINAL 2 POWER SUPPLY VOLTAGE

1. Turn ignition switch OFF.

2. Make sure that starter motor connector F27 terminal 2 connection is clean and tight.

3. Check voltage between starter motor connector F27 terminal 2

and ground.

Is there battery voltage present?

YES >> GO TO 2

NO >> Check harness between battery and starter motor for open circuit.

2.CHECK BATTERY CABLE (VOLTAGE DROP TEST)

1. Shift the transmission into park or neutral.

2. Check voltage between battery positive terminal and starter motor connector F27 terminal 2 while cranking the engine.

Is the voltage drop less than 0.2V?

YES >> GO TO 3

NO >> Check harness between the battery and the starter motor for high resistance.

3.CHECK GROUND CIRCUIT STATUS (VOLTAGE DROP TEST)

(+) (-)Condition Voltage

Connector Terminal

F27 2 Ground While cranking the

engine Battery voltage

AWBIA0122GB

(+)

(-)Condition Voltage

Connector Terminal

F27 2 Battery (+)

terminal While cranking the

engine Less than 0.2V

AWBIA0123GB

Revision: April 20092010 QX56

Page 3686 of 4210

B TERMINAL CIRCUITSTR-11

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K L

M A

STR

NP

O

Check voltage between starter motor case and battery negative ter-

minal while cranking the engine.

Is the voltage drop less than 0.2V?

YES >> Terminal 2 circuit is OK. Further inspection necessary.

Refer to STR-5, "

Work Flow".

NO >> Check the starter motor case to engine mounting for

high resistance.

(+) (-)Condition Voltage

Starter motor case Battery (-) terminal While cranking the

engine Less than 0.2V

AWBIA0124GB

Revision: April 20092010 QX56