Ignition switch replacement INFINITI QX56 2010 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 1203 of 4210

![INFINITI QX56 2010 Factory Service Manual PRECAUTIONSDLN-121

< PRECAUTION > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery INFINITI QX56 2010 Factory Service Manual PRECAUTIONSDLN-121

< PRECAUTION > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery](/img/42/57032/w960_57032-1202.png)

PRECAUTIONSDLN-121

< PRECAUTION > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Precaution for Transfer Assembly and Transfer Control Unit ReplacementINFOID:0000000005148879

When replacing transfer assembly or transfer control uni t, check the 4WD shift indicator lamp as follows.

1. Turn ignition switch ON.

2. Check 4WD shift indicator lamp is turned ON for approximately 1 second.

• If OK, the position between transfer assembly and transfer control unit is correct.

• If NG, the position is different between transfer assembly and transfer control unit. Adjust the position between transfer assembly and transfer control unit. See METHOD FOR POSITION

ADJUSTMENT that follows.

METHOD FOR POSITION ADJUSTMENT

1. Start engine. Run the engine for at least 10 seconds.

2. Stop vehicle and move A/T selector lever to N position with brake pedal depressed. Stay in N for at least 2

seconds.

3. Turn 4WD shift switch to 2WD position. Stay in 2WD for at least 2 seconds.

4. Turn ignition switch OFF.

5. Start engine.

6. Erase self-diagnosis. Refer to DLN-18, "

CONSULT-III Function (ALL MODE AWD/4WD)".

7. Check 4WD shift indicator lamp. Refer to DLN-7, "

Preliminary Check".

If 4WD shift indicator lamp does not indicate 2WD, install new transfer control unit and retry the above

check.

PrecautionINFOID:0000000005148880

• Before connecting or disconnect ing the transfer control unit

harness connector, turn ignition switch “OFF” and disconnect

battery cables. Failure to do so may damage the transfer con-

trol unit. Battery voltage is ap plied to transfer control unit

even if ignition swit ch is turned “OFF”.

• When connecting or disconnecting pin connectors into or

from transfer control unit, take care not to damage pin termi-

nals (bend or break).

When connecting pin connectors make sure that there are not

any bends or breaks on transfer control unit pin terminals.

SEF289H

SEF291H

Revision: April 20092010 QX56

Page 1212 of 4210

![INFINITI QX56 2010 Factory Service Manual DLN-130

< ON-VEHICLE REPAIR >[ATX14B]

TRANSFER CONTROL UNIT

ON-VEHICLE REPAIR

TRANSFER CONTROL UNIT

Removal and InstallationINFOID:0000000005148887

REMOVAL

1. Set transfer state as 2WD when 4WD shift INFINITI QX56 2010 Factory Service Manual DLN-130

< ON-VEHICLE REPAIR >[ATX14B]

TRANSFER CONTROL UNIT

ON-VEHICLE REPAIR

TRANSFER CONTROL UNIT

Removal and InstallationINFOID:0000000005148887

REMOVAL

1. Set transfer state as 2WD when 4WD shift](/img/42/57032/w960_57032-1211.png)

DLN-130

< ON-VEHICLE REPAIR >[ATX14B]

TRANSFER CONTROL UNIT

ON-VEHICLE REPAIR

TRANSFER CONTROL UNIT

Removal and InstallationINFOID:0000000005148887

REMOVAL

1. Set transfer state as 2WD when 4WD shift switch is at 2WD, or as AUTO when 4WD shift switch is at

AUTO.

CAUTION:

When removing transfer co ntrol unit, transfer state must be at 2WD or AUTO.

2. Turn the ignition switch OFF and disconnect negative battery terminal.

3. Remove the lower instrument panel RH. Refer to IP-17, "

Exploded View".

4. Disconnect the two transfer control unit connectors.

5. Remove the transfer control unit bolts.

6. Remove the transfer control unit.

INSTALLATION

Installation is in the reverse order of removal.

• When installing the transfer control unit, tighten bolts to the specified torque.

CAUTION:

Do not connect harness connector to transfer control unit when 4WD shift switch is at 4LO.

• After the installation, check perform self-diagnosis. Refer to DLN-6, "

Work Flow". If NG, adjust position

between transfer assembly and transfer control unit. Refer to DLN-121, "

Precaution for Transfer Assembly

and Transfer Control Unit Replacement".

BDIA0014E

Transfer control unit bolts : 3.4 N·m (0.35 kg-m, 30 in-lb)

Revision: April 20092010 QX56

Page 1855 of 4210

EM-4

< PRECAUTION >

PRECAUTIONS

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of a ll control units using CONSULT-III.

Precaution for Drain Engine CoolantINFOID:0000000005148963

Drain engine coolant when engine is cooled.

Precaution for Disconnecting Fuel PipingINFOID:0000000005148964

• Before starting work, make sure no fire or spark producing items are in the work area.

• Release fuel pressure before disconnecting and disassembly.

• After disconnecting pipes, plug openings to stop fuel leakage.

Precaution for Removal and DisassemblyINFOID:0000000005148965

• When instructed to use special service tools, use the s pecified tools. Always be careful to work safely, avoid

forceful or uninstructed operations.

• Exercise maximum care to avoid damage to mating or sliding surfaces.

• Cover openings of engine system with tape or the equivalent, if necessary, to seal out foreign materials.

• Mark and arrange disassembly parts in an organi zed way for easy troubleshooting and assembly.

• When loosening nuts and bolts, as a basic rule, start with the one furthest outside, then the one diagonally opposite, and so on. If the order of loosening is specified, do exactly as specified. Power tools may be used

where noted in the step.

Precaution for Inspection, Repair and ReplacementINFOID:0000000005148966

Before repairing or replacing, thoroughly inspect parts. Inspect new replacement parts in the same way, and

replace if necessary.

Precaution for Assembly and InstallationINFOID:0000000005148967

• Use torque wrench to tighten bolts or nuts to specification.

• When tightening nuts and bolts, as a basic rule, equally tighten in several different steps starting with theones in center, then ones on inside and outside diagonally in this order. If the order of tightening is specified,

do exactly as specified.

• Replace with new gasket, packing, oil seal or O-ring.

• Thoroughly wash, clean, and air-blow each part. Carefully check engine oil or engine coolant passages for any restriction and blockage.

• Avoid damaging sliding or mating surfaces. Completely remove foreign materials such as cloth lint or dust. Before assembly, oil sliding surfaces well.

• Release air within route when refilling after draining engine coolant.

• Before starting engine, apply fuel pressure to fuel lines with turning ignition switch ON (with engine stopped). Then make sure that there are no leaks at fuel line connections.

• After repairing, start engine and increase engine s peed to check engine coolant, fuel, oil, and exhaust sys-

tems for leakage.

Parts Requiring Angular TighteningINFOID:0000000005148968

• For final tightening of the following engine parts use Tool:

- Cylinder head bolts

- Main bearing cap bolts

- Connecting rod cap bolts

- Crankshaft pulley bolt (No angle wrench is required as the bolt flange is provided with notches for angle tightening)

• Do not use a torque value for final tightening.

• The torque value for these parts are for a preliminary step.

• Ensure thread and seat surfaces are clean and lightly coated with engine oil. Tool number : KV10112100 (BT-8653-A)

Revision: April 20092010 QX56

Page 2186 of 4210

FL-4

< PRECAUTION >

FUEL SYSTEM

FUEL SYSTEM

General PrecautionINFOID:0000000005149530

WARNING:

When replacing fuel line parts, be sure to observe the following.

• Put a “CAUTION: FLAMMABLE” sign in the workshop.

• Be sure to work in a well ventilate d area and furnish workshop with a CO

2 fire extinguisher.

• Do not smoke while servicing fuel system. Keep open flames and sparks away from the work area.

CAUTION:

• Before removing fuel line parts, carry out the following procedures:

- Put drained fuel in an explosi on-proof container and put the lid on securely. Keep the container in

safe area.

- Release fuel pressure from the fuel lines. Refer to EC-489, "

Fuel Pressure Check" .

- Disconnect the battery negative terminal.

• Always replace O-rings and clamps with new ones.

• Do not kink or twist hoses when they are being installed.

• After connecting the fuel t ube quick connectors, make sure

the quick connectors are secure.

Ensure that the connector and resin tube do not contact any

adjacent parts.

• After installing tubes, make su re there is no fuel leakage at

connections in the following steps.

- Apply fuel pressure to fuel lines with turning ignition switch

ON (with engine stopped). Th en check for fuel leaks at con-

nections.

- Start the engine and rev it up and check for fuel leaks at con-

nections.

• Use only a Genuine NISSAN fuel filler cap as a replacement. If an incorrect fuel filler cap is used, the MIL may come on.

• For servicing “Evaporative Emission System” parts, refer to EC-493, "

Removal and Installation" .

• For servicing “On Board Refueling Vapor Recovery (ORVR)”

parts, refer to EC-491, "

How to Detect Fuel Vapor Leakage" .

PBIC1268E

Revision: April 20092010 QX56

Page 2296 of 4210

HA-4

< PRECAUTION >

PRECAUTIONS

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of a ll control units using CONSULT-III.

Precaution for Working with HFC-134a (R-134a)INFOID:0000000005147630

WARNING:

• CFC-12 (R-12) refrigerant and HFC-134a (R-134a) refr igerant are not compatible. If the refrigerants

are mixed compressor failure is likely to occur. Refer to HA-4, "

Contaminated Refrigerant". To deter-

mine the purity of HFC-134a (R-134a) in the vehicle and recovery tank, use recovery/recycling equip-

ment and refrigerant identifier.

• Use only specified oil for the HFC-134a (R-134a) A/C system and HFC-134a (R-134a) components. If

oil other than that specified is used, compressor failure is likely to occur.

• The specified HFC-134a (R-134a) oi l rapidly absorbs moisture from the atmosphere. The following

handling precautions must be observed:

- When removing refrigerant components from a vehicle, immediately cap (seal) the component to

minimize the entry of moisture from the atmosphere.

- When installing refrigerant co mponents to a vehicle, do not remove the caps (unseal) until just

before connecting the components. Connect all refrigerant loop components as quickly as possible

to minimize the entry of moisture into system.

- Only use the specified oil from a sealed container. Immediately reseal containers of oil. Without

proper sealing, oil will become moisture saturat ed and should not be used.

- Avoid breathing A/C refrigerant and oil vapor or mist. Exposure may irrita te eyes, nose and throat.

Remove HFC-134a (R-134a) from the A/C system usin g certified service equipment meeting require-

ments of SAE J2210 [HFC-134a (R-134a) recycling equipment], or J2209 [HFC-134a (R-134a) recovery

equipment]. If accidental system discharge occurs, ventilate work area before resuming service.

Additional health and safety in formation may be obtained from refrigerant and oil manufacturers.

- Do not allow A/C oil to come in contact with styrofoam parts. Damage may result.

Precaution for Procedure without Cowl Top CoverINFOID:0000000005147631

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Contaminated RefrigerantINFOID:0000000005147632

If a refrigerant other than pure HFC-134a (R-134a) is identified in a vehicle, your options are:

• Explain to the customer that environmental regulations prohibit the release of contaminated refrigerant into

the atmosphere.

• Explain that recovery of the contaminated refri gerant could damage your service equipment and refrigerant

supply.

• Suggest the customer return the vehicle to the location of previous service where the contamination may have occurred.

• If you choose to perform the repair, recover the refrigerant using only dedicated equipment and contain- ers. Do not recover contamin ated refrigerant into your existing service equipment. If your facility does

not have dedicated recovery equipment, you may contact a local refrigerant product retailer for available ser-

vice. This refrigerant must be disposed of in acco rdance with all federal and local regulations. In addition,

replacement of all refrigerant system components on the vehicle is recommended.

• If the vehicle is within the warranty period, the air conditioner warranty is void. Please contact NISSAN Cus- tomer Affairs for further assistance.

PIIB3706J

Revision: April 20092010 QX56

Page 3360 of 4210

![INFINITI QX56 2010 Factory Service Manual INSPECTION AND ADJUSTMENTSEC-9

< BASIC INSPECTION > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

INSPECTION AND ADJUSTMENT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT

ADDITIONAL INFINITI QX56 2010 Factory Service Manual INSPECTION AND ADJUSTMENTSEC-9

< BASIC INSPECTION > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

INSPECTION AND ADJUSTMENT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT

ADDITIONAL](/img/42/57032/w960_57032-3359.png)

INSPECTION AND ADJUSTMENTSEC-9

< BASIC INSPECTION > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

INSPECTION AND ADJUSTMENT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Special Repair Re-

quirement

INFOID:0000000005147064

Refer to the CONSULT-III Operation Manual.

ECM RE-COMMUNICATING FUNCTION

ECM RE-COMMUNICATING FUNCTION : DescriptionINFOID:0000000005147065

Performing following procedure can automatically perform re-communication of ECM and BCM, but only when

the ECM has been replaced with a new one (*1).

*1: New one means an ECM which has never been energized on-board.

(In this step, initialization procedur e by CONSULT-III is not necessary)

NOTE:

• When registering new Key IDs or replacing the ECM that is not brand new, refer to CONSULT-III Oper-

ation Manual.

• If multiple keys are attached to the key holder, separate them before work.

• Distinguish keys with unregistered key ID from those with registered ID.

ECM RE-COMMUNICATING FUNCTION : Special Repair RequirementINFOID:0000000005147066

1.PERFORM ECM RE-COMMUNICATING FUNCTION

1. Install ECM.

2. Using a registered key (*2), turn ignition switch to “ON”. *2: To perform this step, use the key that has been used before performing ECM replacement.

3. Maintain ignition switch in “ON” position for at least 5 seconds.

4. Turn ignition switch to “OFF”.

5. Start engine.

Can engine be started?

YES >> Procedure is completed.

NO >> Initialize control unit. Refer to CONSULT-III Operation Manual.

Revision: April 20092010 QX56

Page 3366 of 4210

![INFINITI QX56 2010 Factory Service Manual INFINITI VEHICLE IMMOBILIZER SYSTEM-NATSSEC-15

< FUNCTION DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

- Mechanical key

- Intelligent Key unit

- Remote keyless entry rec INFINITI QX56 2010 Factory Service Manual INFINITI VEHICLE IMMOBILIZER SYSTEM-NATSSEC-15

< FUNCTION DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

- Mechanical key

- Intelligent Key unit

- Remote keyless entry rec](/img/42/57032/w960_57032-3365.png)

INFINITI VEHICLE IMMOBILIZER SYSTEM-NATSSEC-15

< FUNCTION DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

- Mechanical key

- Intelligent Key unit

- Remote keyless entry receiver

- Steering lock solenoid

• NATS trouble diagnosis, system initialization and additional registration of other mechanical key IDs must be

carried out using CONSULT-III.

When NATS initialization has been completed, the ID of the inserted mechanical key or mechanical key IDs

can be carried out.

• Possible symptom of NATS malfunction is “Engine cannot start”. Identify the possible causes according to

“Work Flow”, Refer to SEC-4, "

Work Flow".

• If ECM other than Genuine NISSAN is installed, the engine cannot be started. For ECM replacement proce- dure, refer to SEC-9, "

ECM RE-COMMUNICATING FUNCTION : Description".

PRECAUTIONS FOR KEY REGISTRATION

• The key registration is a procedure that erases the current NATS ID once, and then re-registers a new ID.

Therefore the registered Intelligent Key is necessary for this procedure. Before starting the registration oper-

ation collect all registered Inte lligent Keys from the customer.

• The NATS ID registration is the procedure that regi sters the ID stored into the transponder (integrated in

mechanical key) to BCM.

The Intelligent Key ID registration is the procedure that registers the ID to Intelligent Key unit.

• When performing the Intelligent Key system registration only, the engine cannot be started by inserting the

key into the key cylinder. When performing the NATS r egistration only, the engine cannot be started by using

the mechanical key.

SECURITY INDICATOR

• Always flashes with ignition knob released (igniti on knob switch: LOCK) condition on ignition knob LOCK

position.

• Always flashes with ignition knob released (ignition knob switch: LOCK) c\

ondition on mechanical key removed position.

MAINTENANCE INFORMATION

CAUTION:

It is necessary to perform NATS ID registrati on when replacing any of the following part.

If it's not (or fail to do so), the electrical system may not operate properly.

• Intelligent Key unit

• BCM

•ECM

• Mechanical key

• Steering lock solenoid

• NATS antenna amp.

Revision: April 20092010 QX56

Page 3536 of 4210

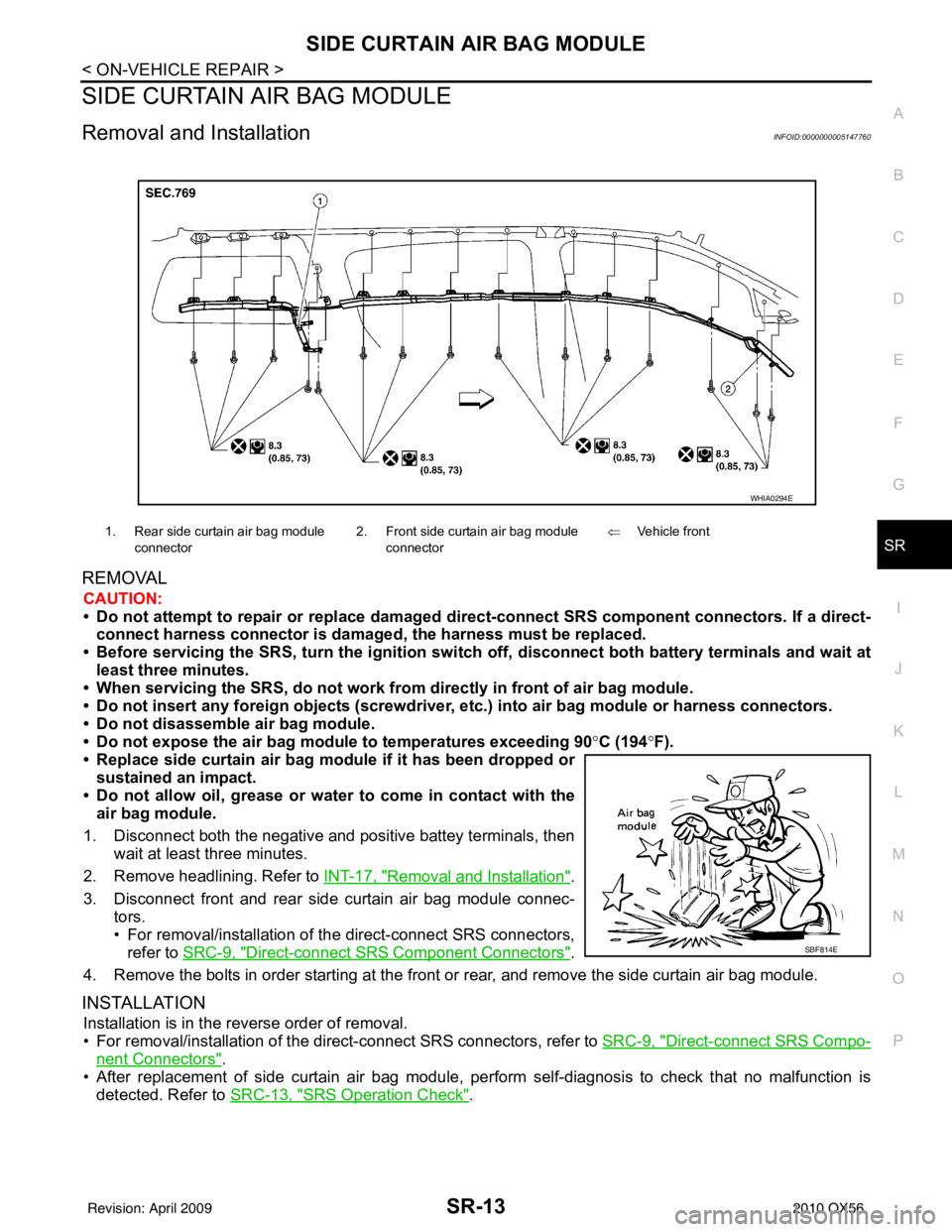

SIDE CURTAIN AIR BAG MODULESR-13

< ON-VEHICLE REPAIR >

C

DE

F

G

I

J

K L

M A

B

SR

N

O P

SIDE CURTAIN AIR BAG MODULE

Removal and InstallationINFOID:0000000005147760

REMOVAL

CAUTION:

• Do not attempt to repair or replace damaged direct-connect SRS component connectors. If a direct- connect harness connector is damage d, the harness must be replaced.

• Before servicing the SRS, turn the ignition switch off, disconnect both battery terminals and wait at

least three minutes.

• When servicing the SRS, do not work from directly in front of air bag module.

• Do not insert any foreign objects (screwdriver, etc.) into air bag module or harness connectors.

• Do not disassemble air bag module.

• Do not expose the air bag modu le to temperatures exceeding 90°C (194 °F).

• Replace side curtain air bag modu le if it has been dropped or

sustained an impact.

• Do not allow oil, grease or water to come in contact with the

air bag module.

1. Disconnect both the negative and positive battey terminals, then wait at least three minutes.

2. Remove headlining. Refer to INT-17, "

Removal and Installation".

3. Disconnect front and rear side curtain air bag module connec- tors.

• For removal/installation of the direct-connect SRS connectors,

refer to SRC-9, "

Direct-connect SRS Component Connectors".

4. Remove the bolts in order starting at the front or rear, and remove the side curtain air bag module.

INSTALLATION

Installation is in the reverse order of removal.

• For removal/installation of the direct-connect SRS connectors, refer to SRC-9, "

Direct-connect SRS Compo-

nent Connectors".

• After replacement of side curtain air bag module, per form self-diagnosis to check that no malfunction is

detected. Refer to SRC-13, "

SRS Operation Check".

1. Rear side curtain air bag module

connector 2. Front side curtain air bag module

connector ⇐

Vehicle front

WHIA0294E

SBF814E

Revision: April 20092010 QX56

Page 3540 of 4210

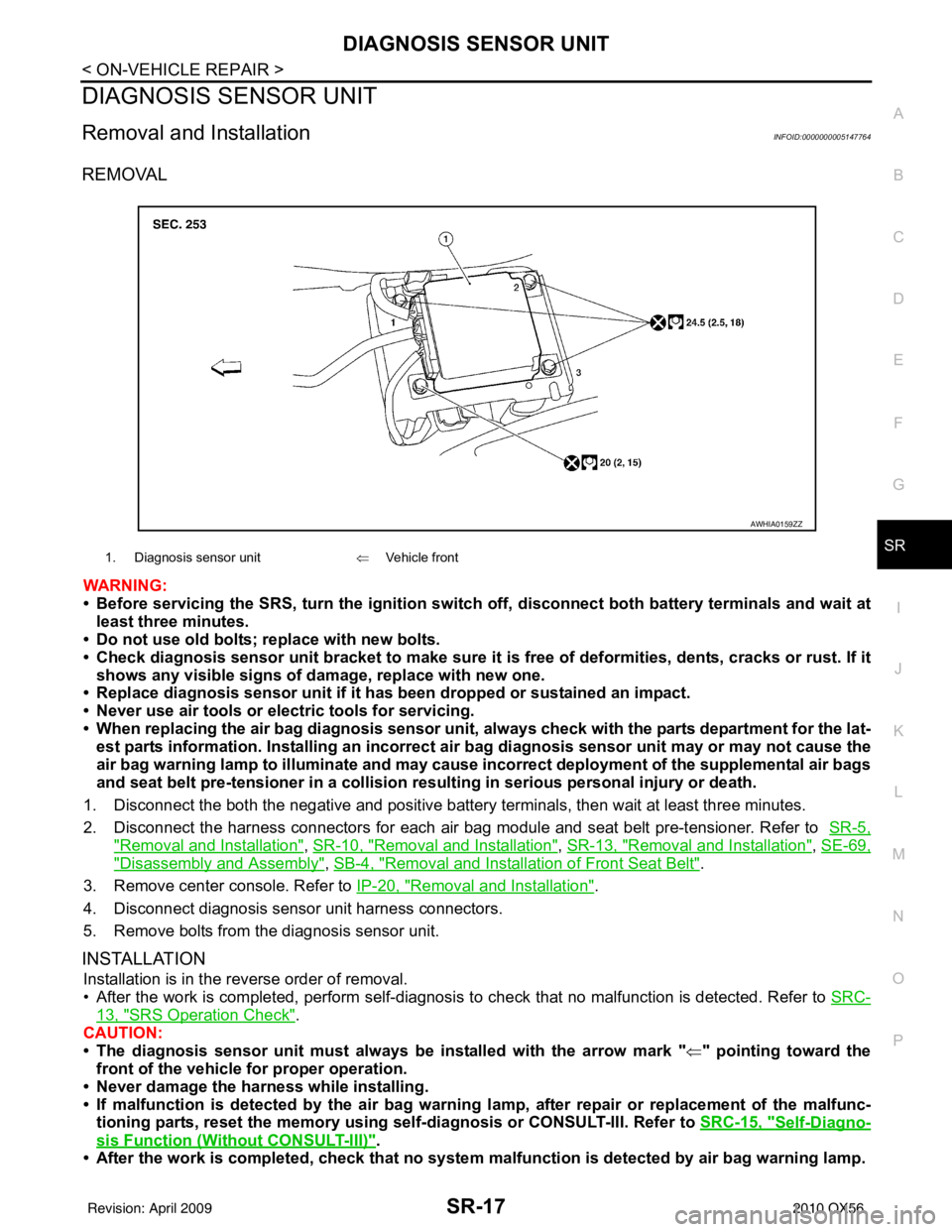

DIAGNOSIS SENSOR UNITSR-17

< ON-VEHICLE REPAIR >

C

DE

F

G

I

J

K L

M A

B

SR

N

O P

DIAGNOSIS SENSOR UNIT

Removal and InstallationINFOID:0000000005147764

REMOVAL

WARNING:

• Before servicing the SRS, turn the ignition switch off, disconnect both battery terminals and wait at

least three minutes.

• Do not use old bolts; replace with new bolts.

• Check diagnosis sensor unit bracket to make sure it is free of deformities, dents, cracks or rust. If it

shows any visible signs of damage, replace with new one.

• Replace diagnosis sensor unit if it has been dropped or sustained an impact.

• Never use air tools or el ectric tools for servicing.

• When replacing the air bag diagnosis sensor unit, always check with the parts department for the lat-

est parts information. Installing an incorrect air bag diagnosis sensor unit may or may not cause the

air bag warning lamp to illuminate and may cause incorrect deployment of the supplemental air bags

and seat belt pre-tensioner in a collision r esulting in serious personal injury or death.

1. Disconnect the both the negative and positive battery terminals, then wait at least three minutes.

2. Disconnect the harness connectors for each air bag module and seat belt pre-tensioner. Refer to SR-5,

"Removal and Installation", SR-10, "Removal and Installation", SR-13, "Removal and Installation", SE-69,

"Disassembly and Assembly", SB-4, "Removal and Installation of Front Seat Belt".

3. Remove center console. Refer to IP-20, "

Removal and Installation".

4. Disconnect diagnosis sensor unit harness connectors.

5. Remove bolts from the diagnosis sensor unit.

INSTALLATION

Installation is in the reverse order of removal.

• After the work is completed, perform self-diagnosis to check that no malfunction is detected. Refer to SRC-

13, "SRS Operation Check".

CAUTION:

• The diagnosis sensor unit must always be installed with the arrow mark " ⇐" pointing toward the

front of the vehicle for proper operation.

• Never damage the harness while installing.

• If malfunction is detected by the air bag warnin g lamp, after repair or replacement of the malfunc-

tioning parts, reset the memory using sel f-diagnosis or CONSULT-III. Refer to SRC-15, "

Self-Diagno-

sis Function (Without CONSULT-III)".

• After the work is completed, check that no system malfunction is detected by air bag warning lamp.

1. Diagnosis sensor unit⇐Vehicle front

AWHIA0159ZZ

Revision: April 20092010 QX56

Page 3564 of 4210

SRC-18

< COMPONENT DIAGNOSIS >

B1049 – B1052, B1054 – B1057 DRIVER AIRBAG MODULE

1.INSPECTION START

Turn ignition switch ON.

>> GO TO 2.

2.CHECK SELF-DIAG RESULT

Check for the DTC on CONSULT-lll.

Is the DTC detected?

YES >> Refer to SRC-18, "Diagnosis Procedure (Component Diagnosis)".

NO >> Inspection End.

DTC CONFIRMATION PROCEDURE (Without CONSULT-lll)

NOTE:

SRS will not enter diagnosis mode if no malfunction is detected in user mode.

1.IGNITION SWITCH

Turn ignition switch ON.

>> GO TO 2

2.IGNITION SWITCH

After air bag warning lamp lights for 7 seconds, turn ignition switch OFF within 1 second.

>> GO TO 3

3.WAIT TIME

Wait more than 3 seconds.

>> GO TO 4

4.REPEAT STEPS

Repeat steps 1 to 3 twice.

>> GO TO 5.

5.IGNITION SWITCH

Turn ignition switch ON.

>> GO TO 6.

6.DIAGNOSTIC MODE

SRS system is now in diagnostic mode and AIR BAG warning lamp flashes. Refer to SRC-84, "

Trouble Diag-

nosis without CONSULT-III".

>> END

Diagnosis Procedure (C omponent Diagnosis)INFOID:0000000005147791

Recheck SRS after each replacement.

1.HARNESS CONNECTOR

Is there any visible damage to the connector?

YES or NO

YES >> Replace the harness.

NO >> GO TO 2

Revision: April 20092010 QX56