air filter INFINITI QX56 2010 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 7 of 4210

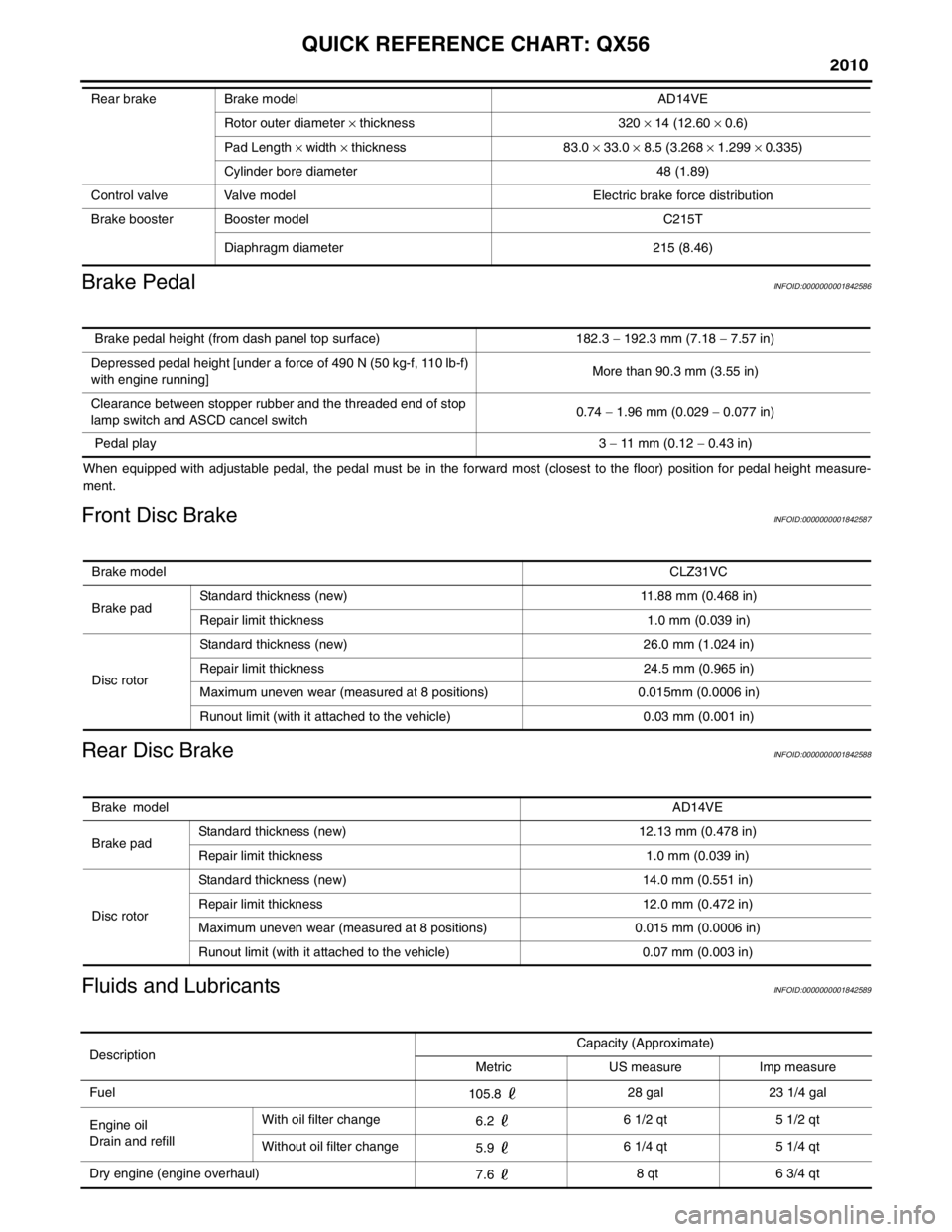

QUICK REFERENCE CHART: QX56

2010

Brake PedalINFOID:0000000001842586

When equipped with adjustable pedal, the pedal must be in the forward most (closest to the floor) position for pedal height measure-

ment.

Front Disc BrakeINFOID:0000000001842587

Rear Disc BrakeINFOID:0000000001842588

Fluids and LubricantsINFOID:0000000001842589

Rear brake Brake model AD14VE

Rotor outer diameter × thickness 320 × 14 (12.60 × 0.6)

Pad Length × width × thickness 83.0 × 33.0 × 8.5 (3.268 × 1.299 × 0.335)

Cylinder bore diameter 48 (1.89)

Control valve Valve model Electric brake force distribution

Brake booster Booster model C215T

Diaphragm diameter 215 (8.46)

Brake pedal height (from dash panel top surface) 182.3 − 192.3 mm (7.18 − 7.57 in)

Depressed pedal height [under a force of 490 N (50 kg-f, 110 lb-f)

with engine running] More than 90.3 mm (3.55 in)

Clearance between stopper rubber and the threaded end of stop

lamp switch and ASCD cancel switch 0.74

− 1.96 mm (0.029 − 0.077 in)

Pedal play 3 − 11 mm (0.12 − 0.43 in)

Brake model CLZ31VC

Brake pad Standard thickness (new) 11.88 mm (0.468 in)

Repair limit thickness 1.0 mm (0.039 in)

Disc rotor Standard thickness (new) 26.0 mm (1.024 in)

Repair limit thickness 24.5 mm (0.965 in)

Maximum uneven wear (measured at 8 positions) 0.015mm (0.0006 in)

Runout limit (with it attached to the vehicle) 0.03 mm (0.001 in)

Brake model

AD14VE

Brake pad Standard thickness (new) 12.13 mm (0.478 in)

Repair limit thickness 1.0 mm (0.039 in)

Disc rotor Standard thickness (new) 14.0 mm (0.551 in)

Repair limit thickness 12.0 mm (0.472 in)

Maximum uneven wear (measured at 8 positions) 0.015 mm (0.0006 in)

Runout limit (with it attached to the vehicle) 0.07 mm (0.003 in)

Description

Capacity (Approximate)

Metric US measure Imp measure

Fuel 105.8 28 gal 23 1/4 gal

Engine oil

Drain and refill With oil filter change

6.2 6 1/2 qt 5 1/2 qt

Without oil filter change 5.9 6 1/4 qt 5 1/4 qt

Dry engine (engine overhaul) 7.6 8 qt 6 3/4 qt

Page 1085 of 4210

DLN-3

CEF

G H

I

J

K L

M A

B

DLN

N

O P

PRECAUTIONS .............................................. ..120

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ..

120

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ..

120

Precaution for Transfer Assembly and Transfer

Control Unit Replacement .....................................

121

Precaution .............................................................121

Service Notice .......................................................122

PREPARATION .........................................123

PREPARATION .............................................. ..123

Special Service Tool ........................................... ..123

Commercial Service Tool ......................................125

ON-VEHICLE MAINTENANCE ..................127

TRANSFER OIL FILTER ................................ ..127

Removal and Installation .......................................127

TRANSFER FLUID ......................................... ..129

Replacement ....................................................... ..129

Inspection ..............................................................129

ON-VEHICLE REPAIR ...............................130

TRANSFER CONTROL UNIT ........................ ..130

Removal and Installation .......................................130

FRONT OIL SEAL ............................................131

Removal and Installation .......................................131

REAR OIL SEAL ..............................................133

Removal and Installation .......................................133

SIDE OIL SEAL .............................................. ..135

Removal and Installation .......................................135

TRANSFER CONTROL DEVICE ................... ..136

Removal and Installation .......................................136

AIR BREATHER HOSE .................................. ..137

Removal and Installation .......................................137

TRANSFER MOTOR ...................................... ..140

Removal and Installation .......................................140

REMOVAL AND INSTALLA TION .............141

TRANSFER ASSEMBLY ............................... ..141

Removal and Installation .......................................141

DISASSEMBLY AND ASSEMBLY ........... .142

TRANSFER ASSEMBLY ............................... ..142

Disassembly and Assembly ................................ ..142

SERVICE DATA AND SPECIFICATIONS

(SDS) ......... ................................. ................

179

SERVICE DATA AND SPECIFICATIONS

(SDS) ...............................................................

179

General Specification .......................................... ..179

Inspection and Adjustment ....................................179

PROPELLER SHAFT: 2F1310

PRECAUTION ...... ......................................

181

PRECAUTIONS ...............................................181

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ..

181

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect .................................

181

PREPARATION .........................................183

PREPARATION ...............................................183

Commercial Service Tool .................................... ..183

SYMPTOM DIAGNOSIS ............................184

NOISE, VIBRATION, AND HARSHNESS

(NVH) TROUBLESHOOTING .........................

184

NVH Troubleshooting Chart ................................ ..184

ON-VEHICLE REPAIR ...............................185

PROPELLER SHAFT ......................................185

On-Vehicle Service .............................................. ..185

REMOVAL AND INSTALLATION .............186

PROPELLER SHAFT ......................................186

Removal and Installation ..................................... ..186

DISASSEMBLY AND ASSEMBLY ............188

PROPELLER SHAFT ......................................188

Disassembly and Assembly ................................. ..188

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... .

190

SERVICE DATA AND SPECIFICATIONS

(SDS) ...............................................................

190

General Specification .......................................... ..190

Snap Ring ..............................................................190

PROPELLER SHAFT: 2S1410

PRECAUTION ...... ......................................

191

PRECAUTIONS ...............................................191

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ..

191

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect .................................

191

PREPARATION .........................................193

PREPARATION ...............................................193

Revision: April 20092010 QX56

Page 1225 of 4210

![INFINITI QX56 2010 Factory Service Manual TRANSFER ASSEMBLYDLN-143

< DISASSEMBLY AND ASSEMBLY > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

40. Retaining plate 41. Driven plate (10 sheet) 42. Drive plate (10 sheet)

43. Return spring assembly 44 INFINITI QX56 2010 Factory Service Manual TRANSFER ASSEMBLYDLN-143

< DISASSEMBLY AND ASSEMBLY > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

40. Retaining plate 41. Driven plate (10 sheet) 42. Drive plate (10 sheet)

43. Return spring assembly 44](/img/42/57032/w960_57032-1224.png)

TRANSFER ASSEMBLYDLN-143

< DISASSEMBLY AND ASSEMBLY > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

40. Retaining plate 41. Driven plate (10 sheet) 42. Drive plate (10 sheet)

43. Return spring assembly 44. Press flange 45. Thrust needle bearing

46. Snap ring 47. Retaining pin 48. L-H fork

49. 2-4 fork 50. Shift fork spring 51. Fork guide

52. Retainer pin 53. Shift rod

1. Dust cover 2. Rear oil seal 3. Rear case

4. Breather tube 5. Seal ring 6. Main oil pump cover

7. Inner gear 8. Outer gear 9. Main oil pump housing

10. D-ring 11. D-ring 12. Clutch piston

13. Thrust needle bearing race 14. Oil strainer 15. O-ring

16. Snap ring 17. Control valve assembly 18. Lip seal (large 5 pieces)

19. Lip seal (small 2 pieces) 20. Gasket 21. Filler plug

22. Oil filter stud 23. O-ring 24. Oil filter

25 ATP switch 26. Neutral-4LO switch 27. Oil pressure check plug

28. Harness bracket 29. Air breather hose clamp 30. Stem bleeder

31. Harness bracket 32. Center case 33. Mainshaft rear bearing

34. C-ring 35. Washer holder 36. Snap ring

37. Sub oil pump housing 38. Outer gear 39. Inner gear

WDIA0302E

Revision: April 20092010 QX56

Page 1430 of 4210

![INFINITI QX56 2010 Factory Service Manual TROUBLE DIAGNOSIS - SPECIFICATION VALUEEC-77

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Check “A/F ALPHA-B1”, “A/F ALPHA-B2” for approximat

ely 1 minute because they may INFINITI QX56 2010 Factory Service Manual TROUBLE DIAGNOSIS - SPECIFICATION VALUEEC-77

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Check “A/F ALPHA-B1”, “A/F ALPHA-B2” for approximat

ely 1 minute because they may](/img/42/57032/w960_57032-1429.png)

TROUBLE DIAGNOSIS - SPECIFICATION VALUEEC-77

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Check “A/F ALPHA-B1”, “A/F ALPHA-B2” for approximat

ely 1 minute because they may fluctuate. It is NG

if the indication is out of the SP value even a little.

OK or NG

OK >> GO TO 17.

NG (Less than the SP value)>>GO TO 2.

NG (More than the SP value)>>GO TO 3.

2.CHECK “B/FUEL SCHDL”

Select “B/FUEL SCHDL” in “SPEC” of “DATA MONITOR” m ode, and make sure that the indication is within the

SP value.

OK or NG

OK >> GO TO 4.

NG (More than the SP value)>>GO TO 19.

3.CHECK “B/FUEL SCHDL”

Select “B/FUEL SCHDL” in “SPEC” of “DATA MONITOR” m ode, and make sure that the indication is within the

SP value.

OK or NG

OK >> GO TO 6.

NG (More than the SP value)>>GO TO 6.

NG (Less than the SP value)>>GO TO 25.

4.CHECK “A/F ALPHA-B1”, “A/F ALPHA-B2”

1. Stop the engine.

2. Disconnect PCV hose, and then plug it.

3. Start engine.

4. Select “A/F ALPHA-B1”, “A/F ALPHA-B2” in “SPEC” of “DATA MONITOR” mode, and make sure that the each indication is within the SP value.

OK or NG

OK >> GO TO 5.

NG >> GO TO 6.

5.CHANGE ENGINE OIL

1. Stop the engine.

2. Change engine oil. NOTE:

This symptom may occur when a large amount of gas oline is mixed with engine oil because of driving

conditions (such as when engine oil temperature does not rise enough since a journey distance is too

short during winter). The symptom will not be detect ed after changing engine oil or changing driving con-

dition.

>>INSPECTION END

6.CHECK FUEL PRESSURE

Check fuel pressure. (Refer to EC-489, "

Fuel Pressure Check".)

OK or NG

OK >> GO TO 9.

NG (Fuel pressure is too high)>>Replace fuel pressure regulator, refer to EC-489, "

Fuel Pressure Check".

GO TO 8.

NG (Fuel pressure is too low)>>GO TO 7.

7.DETECT MALFUNCTIONING PART

1. Check the following.

- Clogged and bent fuel hose and fuel tube

- Clogged fuel filter

- Fuel pump and its circuit (Refer to EC-489, "

Fuel Pressure Check".)

2. If NG, repair or replace the malfunctioning part. (Refer to EC-489, "

Fuel Pressure Check".)

If OK, replace fuel pressure regulator.

Revision: April 20092010 QX56

Page 1528 of 4210

![INFINITI QX56 2010 Factory Service Manual P0171, P0174 FUEL INJECTION SYSTEM FUNCTION

EC-175

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

6. Also check harness for short to power.

OK or NG

OK >> GO TO 4.

NG >> Repair open INFINITI QX56 2010 Factory Service Manual P0171, P0174 FUEL INJECTION SYSTEM FUNCTION

EC-175

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

6. Also check harness for short to power.

OK or NG

OK >> GO TO 4.

NG >> Repair open](/img/42/57032/w960_57032-1527.png)

P0171, P0174 FUEL INJECTION SYSTEM FUNCTION

EC-175

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

6. Also check harness for short to power.

OK or NG

OK >> GO TO 4.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

4.CHECK FUEL PRESSURE

1. Release fuel pressure to zero. Refer to EC-489, "

Fuel Pressure Check".

2. Install fuel pressure gauge kit [SST (J-44321)] and check fuel pressure. Refer to EC-489, "

Fuel Pressure

Check".

OK or NG

OK >> GO TO 6.

NG >> GO TO 5.

5.DETECT MALFUNCTIONING PART

Check the following.

• Fuel pump and circuit (Refer to EC-399, "

Diagnosis Procedure".)

• Fuel pressure regulator (Refer to EC-489, "

Fuel Pressure Check".)

• Fuel lines

• Fuel filter for clogging

>> Repair or replace.

6.CHECK MASS AIR FLOW SENSOR

With CONSULT-III

1. Install all removed parts.

2. Check “MASS AIR FLOW” in “DATA MONITOR” mode with CONSULT-III.

With GST

1. Install all removed parts.

2. Check mass air flow sensor signal in Service $01 with GST.

OK or NG

OK >> GO TO 7.

NG >> Check connectors for rusted terminals or loose c onnections in the mass air flow sensor circuit or

grounds. Refer to EC-104

.

7.CHECK FUNCTION OF FUEL INJECTOR

With CONSULT-III

1. Start engine.

2. Perform “POWER BALANCE” in “A CTIVE TEST” mode with CONSULT-III.

3. Make sure that each circuit produces a momentary engine speed drop.

Without CONSULT-III

1. Start engine. Continuity should not exist.

At idling: Approximately 350 kPa (3.57 kg/cm

2, 51 psi)

3.0 - 9.0 g·m/sec: at idling

9.0 - 28.0 g·m/sec: at 2,500 rpm

3.0 - 9.0 g·m/sec: at idling

9.0 - 28.0 g·m/sec: at 2,500 rpm

Revision: April 20092010 QX56

Page 1549 of 4210

![INFINITI QX56 2010 Factory Service Manual EC-196

< COMPONENT DIAGNOSIS >[VK56DE]

P0300, P0301, P0302, P

0303, P0304, P0305, P0306, P0307, P0308 MISFIRE

OK or NG

OK >> GO TO 12.

NG >> GO TO 11.

11 .DETECT MALFUNCTIONING PART

Check the followi INFINITI QX56 2010 Factory Service Manual EC-196

< COMPONENT DIAGNOSIS >[VK56DE]

P0300, P0301, P0302, P

0303, P0304, P0305, P0306, P0307, P0308 MISFIRE

OK or NG

OK >> GO TO 12.

NG >> GO TO 11.

11 .DETECT MALFUNCTIONING PART

Check the followi](/img/42/57032/w960_57032-1548.png)

EC-196

< COMPONENT DIAGNOSIS >[VK56DE]

P0300, P0301, P0302, P

0303, P0304, P0305, P0306, P0307, P0308 MISFIRE

OK or NG

OK >> GO TO 12.

NG >> GO TO 11.

11 .DETECT MALFUNCTIONING PART

Check the following.

• Fuel pump and circuit (Refer to EC-399, "

Diagnosis Procedure".)

• Fuel pressure regulator (Refer to EC-489, "

Fuel Pressure Check".)

• Fuel lines

• Fuel filter for clogging

>> Repair or replace.

12.CHECK IGNITION TIMING

Check the following items. Refer to EC-13, "

Basic Inspection".

OK or NG

OK >> GO TO 13.

NG >> Follow the EC-13, "

Basic Inspection".

13.CHECK A/F SENSOR 1 INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect A/F sensor 1 harness connector.

3. Disconnect ECM harness connector.

4. Check harness continuity between the following terminals. Refer to Wiring Diagram.

5. Check harness continuity between the following terminals and ground. Refer to Wiring Diagram.

Items Specifications

Target idle speed 650 ± 50 rpm (in P or N position)

Ignition timing 15 ± 5 ° BTDC (in P or N position)

A/F sensor 1 terminal ECM terminal

Bank 1 13

5

25 6

Bank 2 11

6

27 5

Continuity should exist.

Bank 1 Bank 2

A/F sensor 1 terminal ECM terminal A/F sensor 1 terminal ECM terminal 13 511 6

25 627 5

BBIA0376E

Revision: April 20092010 QX56

Page 1843 of 4210

![INFINITI QX56 2010 Factory Service Manual EC-490

< ON-VEHICLE MAINTENANCE >[VK56DE]

FUEL PRESSURE

8. If result is unsatisfactory, go to next step.

9. Check the following.

• Fuel hoses and fuel tubes for clogging

• Fuel filter for clogging INFINITI QX56 2010 Factory Service Manual EC-490

< ON-VEHICLE MAINTENANCE >[VK56DE]

FUEL PRESSURE

8. If result is unsatisfactory, go to next step.

9. Check the following.

• Fuel hoses and fuel tubes for clogging

• Fuel filter for clogging](/img/42/57032/w960_57032-1842.png)

EC-490

< ON-VEHICLE MAINTENANCE >[VK56DE]

FUEL PRESSURE

8. If result is unsatisfactory, go to next step.

9. Check the following.

• Fuel hoses and fuel tubes for clogging

• Fuel filter for clogging

• Fuel pump

• Fuel pressure regulator for clogging

If OK, replace fuel pressure regulator.

If NG, repair or replace.

10. Before disconnecting Fuel Pressure Gauge and Fuel Pressure Adapter J-44321-6, release fuel pressure to zero. Refer to "FUEL PRESSURE RELEASE".At idling:

Approximately 350 kPa (3.57 kg/cm

2, 51 psi)

Revision: April 20092010 QX56

Page 1852 of 4210

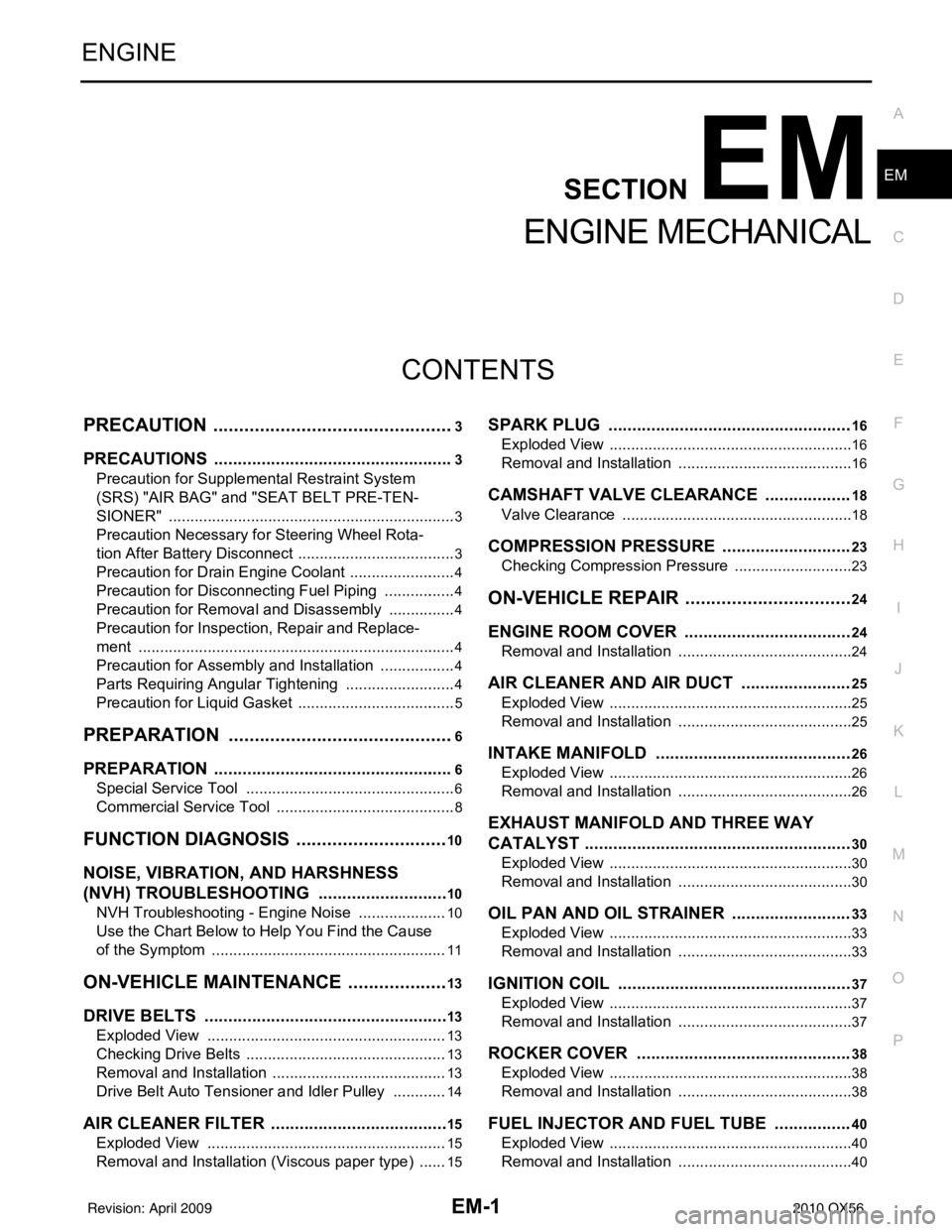

EM-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION EM

A

EM

N

O P

CONTENTS

ENGINE MECHANICAL

PRECAUTION ....... ........................................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

3

Precaution for Drain Engine Coolant .........................4

Precaution for Disconnecting Fuel Piping .................4

Precaution for Removal and Disassembly ................4

Precaution for Inspection, Repair and Replace-

ment .................................................................... ......

4

Precaution for Assembly and Installation ..................4

Parts Requiring Angular Tightening ..........................4

Precaution for Liquid Gasket ............................... ......5

PREPARATION ............................................6

PREPARATION .............................................. .....6

Special Service Tool ........................................... ......6

Commercial Service Tool ..........................................8

FUNCTION DIAGNOSIS ..............................10

NOISE, VIBRATION, AND HARSHNESS

(NVH) TROUBLESHOOTING ........................ ....

10

NVH Troubleshooting - Engine Noise ................. ....10

Use the Chart Below to Help You Find the Cause

of the Symptom .......................................................

11

ON-VEHICLE MAINTENANCE ....................13

DRIVE BELTS ................................................ ....13

Exploded View .................................................... ....13

Checking Drive Belts ...............................................13

Removal and Installation .........................................13

Drive Belt Auto Tensioner and Idler Pulley ......... ....14

AIR CLEANER FILTER ......................................15

Exploded View .................................................... ....15

Removal and Installation (Viscous paper type) .......15

SPARK PLUG ...................................................16

Exploded View ..................................................... ....16

Removal and Installation .........................................16

CAMSHAFT VALVE CLEARANCE ..................18

Valve Clearance ......................................................18

COMPRESSION PRESSURE ...........................23

Checking Compression Pressure ............................23

ON-VEHICLE REPAIR .................................24

ENGINE ROOM COVER ...................................24

Removal and Installation ..................................... ....24

AIR CLEANER AND AIR DUCT .......................25

Exploded View .........................................................25

Removal and Installation .........................................25

INTAKE MANIFOLD .........................................26

Exploded View .........................................................26

Removal and Installation .........................................26

EXHAUST MANIFOLD AND THREE WAY

CATALYST ........................................................

30

Exploded View .........................................................30

Removal and Installation .........................................30

OIL PAN AND OIL STRAINER .........................33

Exploded View .........................................................33

Removal and Installation .........................................33

IGNITION COIL .................................................37

Exploded View .........................................................37

Removal and Installation .........................................37

ROCKER COVER .............................................38

Exploded View .........................................................38

Removal and Installation .........................................38

FUEL INJECTOR AND FUEL TUBE ................40

Exploded View .........................................................40

Removal and Installation .........................................40

Revision: April 20092010 QX56

Page 1866 of 4210

AIR CLEANER FILTEREM-15

< ON-VEHICLE MAINTENANCE >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

AIR CLEANER FILTER

Exploded ViewINFOID:0000000005148978

Removal and Installation (Viscous paper type)INFOID:0000000005148979

REMOVAL

NOTE:

• The viscous paper type filter does not

need cleaning between replacement intervals.

• Replace the air filter as necessary for periodic maintenance. Refer to MA-9, "

Introduction of Periodic Mainte-

nance".

1. Remove the air cleaner case (upper).

2. Remove the air cleaner filter from the air cleaner case (lower).

INSTALLATION

1. Install the new air cleaner filter in the air cleaner case (lower).

2. Install the air cleaner case (upper).

1. Air cleaner case (lower) 2. Air cleaner filter3. Air cleaner case (upper)

4. Air duct and resonator assembly Front

ALBIA0413GB

Revision: April 20092010 QX56

Page 1876 of 4210

AIR CLEANER AND AIR DUCTEM-25

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

AIR CLEANER AND AIR DUCT

Exploded ViewINFOID:0000000005148985

Removal and InstallationINFOID:0000000005148986

REMOVAL

1. Remove the engine room cover using power tool. Refer to

EM-24, "Removal and Installation".

2. Disconnect the harness connector from air cleaner case (upper).

3. Remove the air duct and resonator assembly and air cleaner case.

4. Remove air cleaner filter and air cleaner case (lower)

• Add marks as necessary for easier installation.

INSTALLATION

Installation is in the reverse order of removal.

1. Air cleaner case (lower) 2. Air cleaner filter 3. Air cleaner case (upper)

4. Air duct and resonator assembly Front

ALBIA0413GB

Revision: April 20092010 QX56