oil pressure INFINITI QX56 2010 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 398 of 4210

![INFINITI QX56 2010 Factory Service Manual BCS-12

< FUNCTION DIAGNOSIS >[BCM]

SIGNAL BUFFER SYSTEM

SIGNAL BUFFER SYSTEM

System DiagramINFOID:0000000005146389

System DescriptionINFOID:0000000005146390

OUTLINE

BCM has the signal transmission fun INFINITI QX56 2010 Factory Service Manual BCS-12

< FUNCTION DIAGNOSIS >[BCM]

SIGNAL BUFFER SYSTEM

SIGNAL BUFFER SYSTEM

System DiagramINFOID:0000000005146389

System DescriptionINFOID:0000000005146390

OUTLINE

BCM has the signal transmission fun](/img/42/57032/w960_57032-397.png)

BCS-12

< FUNCTION DIAGNOSIS >[BCM]

SIGNAL BUFFER SYSTEM

SIGNAL BUFFER SYSTEM

System DiagramINFOID:0000000005146389

System DescriptionINFOID:0000000005146390

OUTLINE

BCM has the signal transmission function that output

s/transmits each input/received signal to each unit.

Signal transmission function list

ALMIA0263GB

Signal nameInputOutputDescription

Oil pressure switch signal IPDM E/R (CAN) Combination meter (CAN)Transmits the received oil pres-

sure switch signal via CAN

communication.

Revision: April 20092010 QX56

Page 414 of 4210

![INFINITI QX56 2010 Factory Service Manual BCS-28

< FUNCTION DIAGNOSIS >[BCM]

DIAGNOSIS SYSTEM (BCM)

SIGNAL BUFFER : CONSULT-III Fu nction (BCM - SIGNAL BUFFER)

INFOID:0000000005146411

DATA MONITOR

ACTIVE TEST

AIR PRESSURE MONITOR

AIR PRESSURE INFINITI QX56 2010 Factory Service Manual BCS-28

< FUNCTION DIAGNOSIS >[BCM]

DIAGNOSIS SYSTEM (BCM)

SIGNAL BUFFER : CONSULT-III Fu nction (BCM - SIGNAL BUFFER)

INFOID:0000000005146411

DATA MONITOR

ACTIVE TEST

AIR PRESSURE MONITOR

AIR PRESSURE](/img/42/57032/w960_57032-413.png)

BCS-28

< FUNCTION DIAGNOSIS >[BCM]

DIAGNOSIS SYSTEM (BCM)

SIGNAL BUFFER : CONSULT-III Fu nction (BCM - SIGNAL BUFFER)

INFOID:0000000005146411

DATA MONITOR

ACTIVE TEST

AIR PRESSURE MONITOR

AIR PRESSURE MONITOR : Diagnosis DescriptionINFOID:0000000005146412

DESCRIPTION

During driving, the TPMS receives the signal transmitt ed from the transmitter installed in each wheel, when

the tire pressure becomes low. The control unit (BCM ) of this system has pressure judgment and trouble diag-

nosis functions.

When the TPMS detects low inflation pressure or another unusual symptom, the warning lamps in the combi-

nation meter comes on.

SELF DIAGNOSIS (WITH CONSULT-III)

With CONSULT-III

• Touch “SELF-DIAG RESULTS” display to show malfunction experienced since the last erasing operation. Refer to WT-11, "

CONSULT-III Function (BCM)".

SELF DIAGNOSIS (WITHOUT CONSULT-III)

Without CONSULT-III

To start the self-diagnostic results mode, ground terminal of the tire pressure warning check connector. The

malfunction location is indicated by the warning lamp flashing.

NOTE:

When the low tire warning lamp flashes 5 Hz and continues repeating it, the system is normal.

Monitor Item

[Unit] Description

OIL PRESS SW [ON/OFF] Displays the status of oil pressure switch received from IPDM E/R via CAN communication.

Test ItemOperation Description

OIL PRESSURE SW OFF OFF

ON

BCM transmits the oil pressure switch signal to the combination meter via CAN communica-

tion, which operates the oil pressure gauge in the combination meter.

SEIA0745E

Flickering

pattern Items

Diagnostic items detected when··· Check item

15 Tire pressure value (Front LH) Front LH tire pressure drops to 181 kPa (1.8 kg/cm, 25.25 psi) or less.

–

16 Tire pressure value (Front RH) Front RH tire pressure drops to 181 kPa (1.8 kg/cm, 25.25 psi) or less.

17 Tire pressure value (Rear RH) Rear RH tire pressure drops to 181 kPa (1.8 kg/cm, 25.25 psi) or less.

18 Tire pressure value (Rear LH) Rear LH tire pressure drops to 181 kPa (1.8 kg/cm, 25.25 psi) or less.

Revision: April 20092010 QX56

Page 482 of 4210

BRAKE MASTER CYLINDERBR-37

< DISASSEMBLY AND ASSEMBLY >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

DISASSEMBLY AND ASSEMBLY

BRAKE MASTER CYLINDER

Disassembly and AssemblyINFOID:0000000005147922

DISASSEMBLY

CAUTION:

• Master cylinder assembly cannot be disassembled.

• Do not drop parts. If a part is dropped, do not use it.

1. Pull the reservoir tank off the master cylinder assembly.

2. Remove the grommets from master cylinder assembly and discard the grommets. CAUTION:

Discard the grommets, do not reuse.

3. Remove the fluid level sensor from the reservoir tank.

4. Remove the front and rear pressure sensors and discard. CAUTION:

Discard the front and rear pressure sensors, do not reuse.

ASSEMBLY

CAUTION:

• Never use mineral oil such as kerosene, g asoline during the cleaning and assembly process.

• Do not drop parts. If a part is dropped, do not use it.

1. Reservoir cap 2. Fluid level sensor 3. Grommet

4. Master cylinder assembly 5. Front pressure sensor6. Rear pressure sensor

7. Seal 8. Reservoir tankB. Brake fluid

R. Rubber grease

AWFIA0415GB

Revision: April 20092010 QX56

Page 674 of 4210

CCS

INSPECTION AND ADJUSTMENTCCS-5

< BASIC INSPECTION >

C

DE

F

G H

I

J

K L

M B

N P A

INSPECTION AND ADJUSTMENT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT

ADDITIONAL SERVICE WHEN REPL ACING CONTROL UNIT : Description

INFOID:0000000005145971

Always perform the laser beam aiming adjustment after repl acing the ICC unit. In addition, test the ICC sys-

tem operations to see if it functions normally.

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Special Repair Re-

quirement

INFOID:0000000005145972

1.LASER BEAM AIMING ADJUSTMENT

Adjust laser beam aiming. Refer to CCS-5, "

LASER BEAM AIMING ADJUSTMENT : Outline of Laser Beam

Aiming Adjustment Procedure".

>> GO TO 2

2.ICC SYSTEM ACTION TEST

1. Perform the ICC system operation test. Refer to CCS-8, "

ACTION TEST : ICC System Running Test".

2. Check that the ICC system operates normally.

>> INSPECTION END.

LASER BEAM AIMI NG ADJUSTMENT

LASER BEAM AIMING ADJUSTMENT : Outlin e of Laser Beam Aiming Adjustment

Procedure

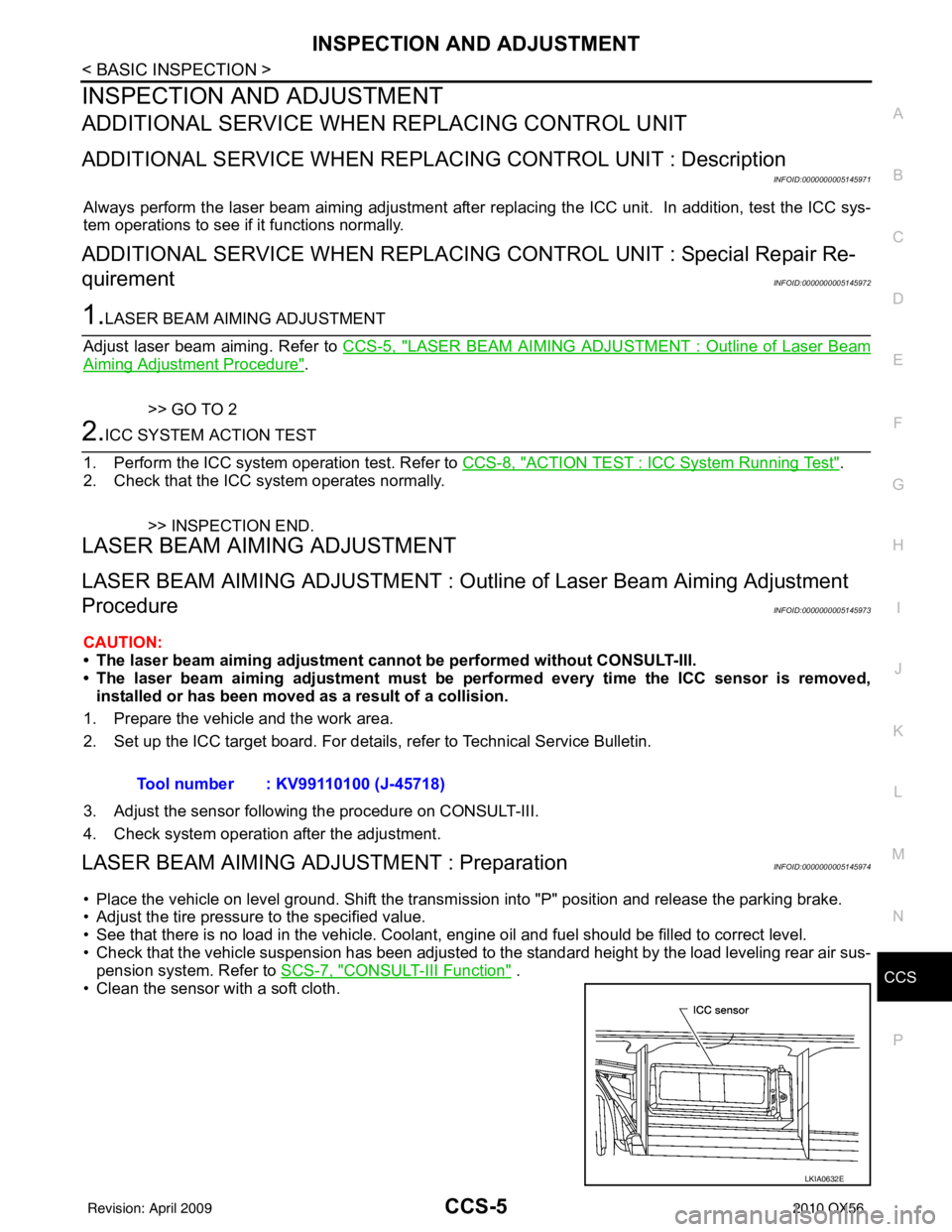

INFOID:0000000005145973

CAUTION:

• The laser beam aiming adjustment can not be performed without CONSULT-III.

• The laser beam aiming adjustment must be performed every time the ICC sensor is removed,

installed or has been moved as a result of a collision.

1. Prepare the vehicle and the work area.

2. Set up the ICC target board. For details, refer to Technical Service Bulletin.

3. Adjust the sensor following the procedure on CONSULT-III.

4. Check system operation after the adjustment.

LASER BEAM AIMING ADJU STMENT : PreparationINFOID:0000000005145974

• Place the vehicle on level ground. Shift the transmi ssion into "P" position and release the parking brake.

• Adjust the tire pressure to the specified value.

• See that there is no load in the vehicle. Coolant , engine oil and fuel should be filled to correct level.

• Check that the vehicle suspension has been adjusted to the standard height by the load leveling rear air sus-

pension system. Refer to SCS-7, "

CONSULT-III Function" .

• Clean the sensor with a soft cloth. Tool number : KV99110100 (J-45718)

LKIA0632E

Revision: April 20092010 QX56

Page 768 of 4210

CO-4

< PREPARATION >

PREPARATION

PREPARATION

PREPARATION

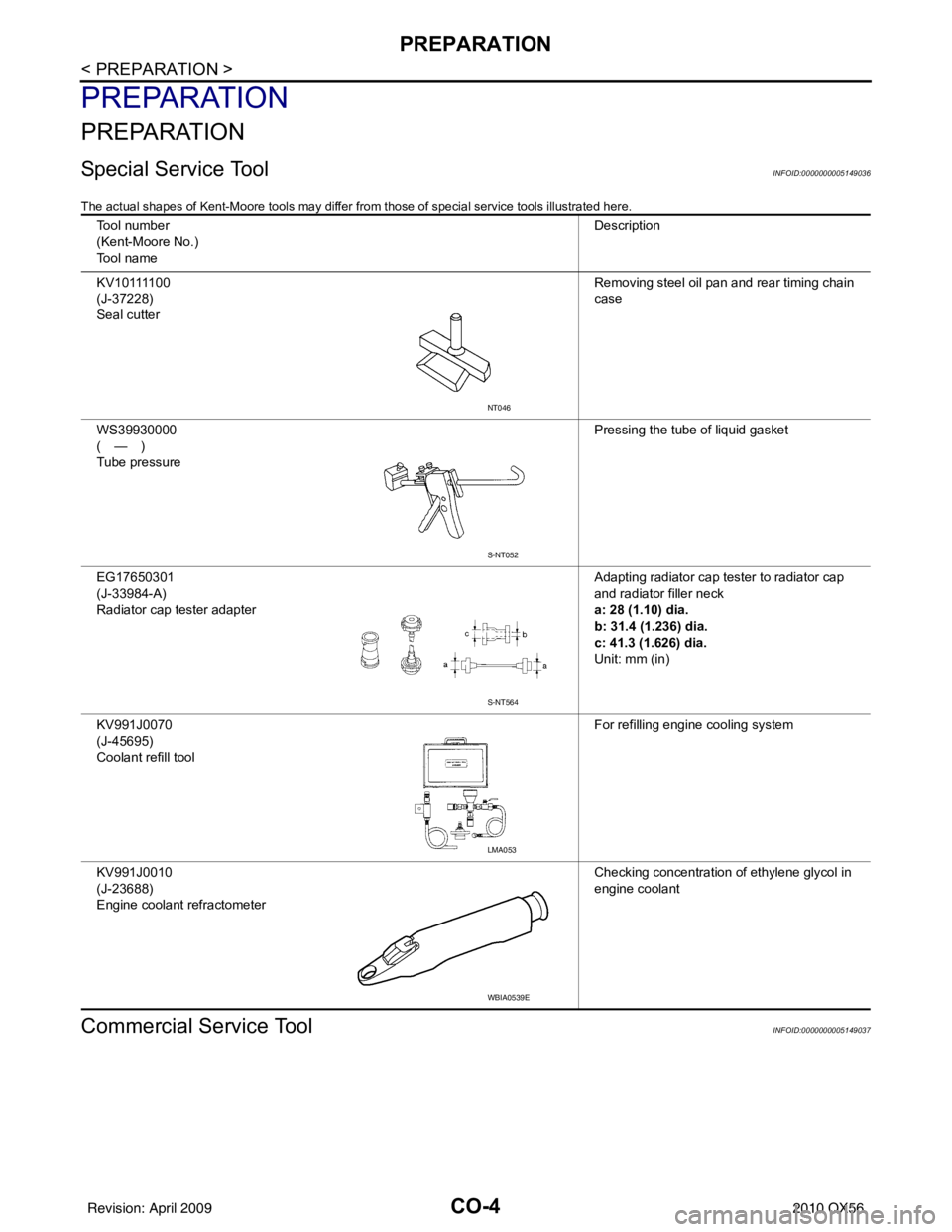

Special Service ToolINFOID:0000000005149036

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Commercial Service ToolINFOID:0000000005149037

Tool number

(Kent-Moore No.)

Tool name Description

K V 1 0 1111 0 0

(J-37228)

Seal cutter Removing steel oil pan and rear timing chain

case

WS39930000

(—)

Tube pressure Pressing the tube of liquid gasket

EG17650301

(J-33984-A)

Radiator cap tester adapter Adapting radiator cap tester to radiator cap

and radiator filler neck

a: 28 (1.10) dia.

b: 31.4 (1.236) dia.

c: 41.3 (1.626) dia.

Unit: mm (in)

KV991J0070

(J-45695)

Coolant refill tool For refilling engine cooling system

KV991J0010

(J-23688)

Engine coolant refractometer Checking concentration of ethylene glycol in

engine coolant

NT046

S-NT052

S-NT564

LMA053

WBIA0539E

Revision: April 20092010 QX56

Page 775 of 4210

ENGINE COOLANTCO-11

< ON-VEHICLE MAINTENANCE >

C

DE

F

G H

I

J

K L

M A

CO

NP

O

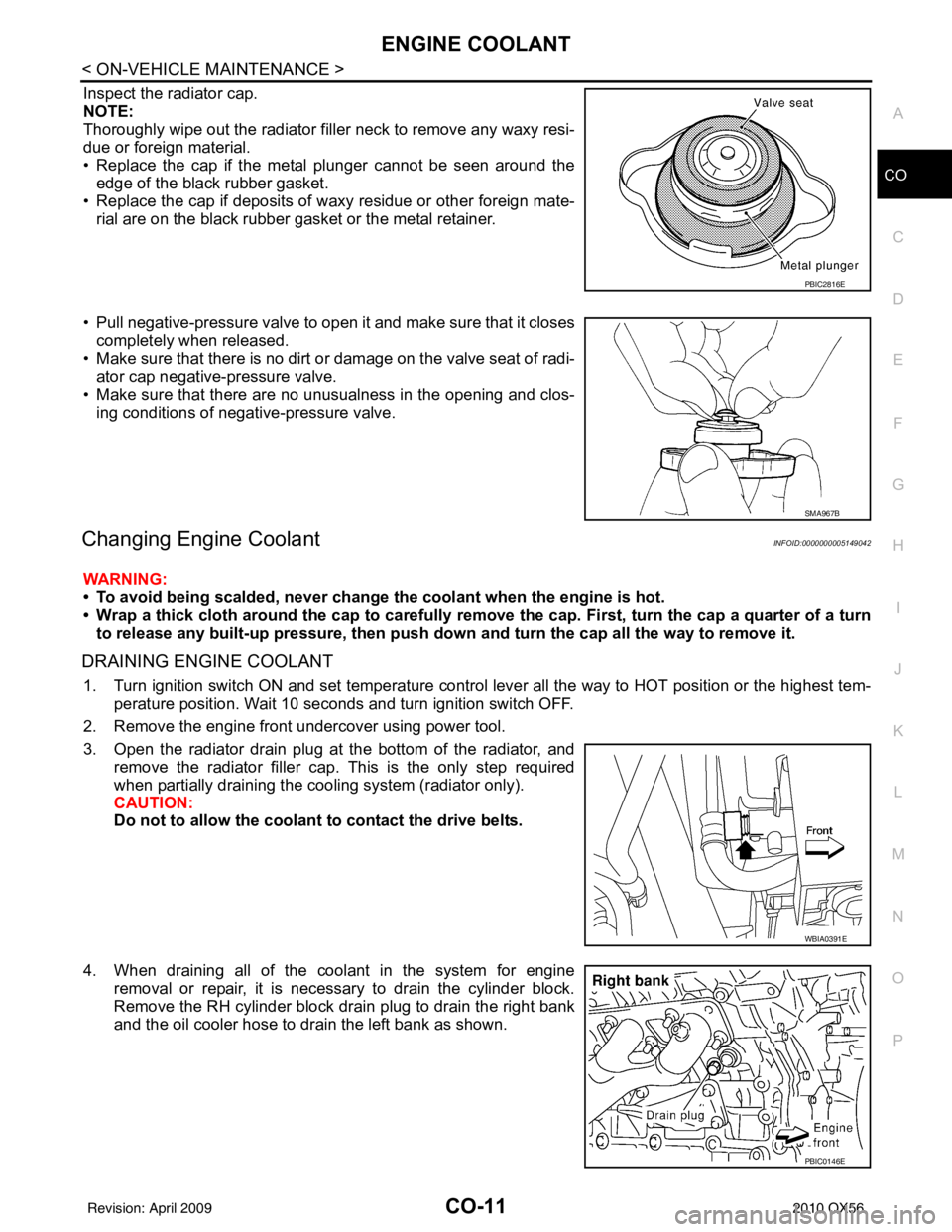

Inspect the radiator cap.

NOTE:

Thoroughly wipe out the radiator filler

neck to remove any waxy resi-

due or foreign material.

• Replace the cap if the metal plunger cannot be seen around the edge of the black rubber gasket.

• Replace the cap if deposits of waxy residue or other foreign mate- rial are on the black rubber gasket or the metal retainer.

• Pull negative-pressure valve to open it and make sure that it closes completely when released.

• Make sure that there is no dirt or damage on the valve seat of radi-

ator cap negative-pressure valve.

• Make sure that there are no unusualness in the opening and clos- ing conditions of negative-pressure valve.

Changing Engine CoolantINFOID:0000000005149042

WARNING:

• To avoid being scalded, never change the coolant when the engine is hot.

• Wrap a thick cloth around the cap to carefully remo ve the cap. First, turn the cap a quarter of a turn

to release any built-up pressure, then push down and turn the cap all the way to remove it.

DRAINING ENGINE COOLANT

1. Turn ignition switch ON and set temperature control lever all the way to HOT position or the highest tem-

perature position. Wait 10 seconds and turn ignition switch OFF.

2. Remove the engine front undercover using power tool.

3. Open the radiator drain plug at the bottom of the radiator, and remove the radiator filler cap. This is the only step required

when partially draining the cooling system (radiator only).

CAUTION:

Do not to allow the coolant to contact the drive belts.

4. When draining all of the coolant in the system for engine removal or repair, it is necessary to drain the cylinder block.

Remove the RH cylinder block drain plug to drain the right bank

and the oil cooler hose to drain the left bank as shown.

PBIC2816E

SMA967B

WBIA0391E

PBIC0146E

Revision: April 20092010 QX56

Page 776 of 4210

CO-12

< ON-VEHICLE MAINTENANCE >

ENGINE COOLANT

5. Remove the reservoir tank to drain the engine coolant, then clean the reservoir tank before installing it.

6. Check the drained coolant for contaminants such as rust, corrosion or discoloration.

If the coolant is contaminated, flus h the engine cooling system. Refer to CO-11, "

Changing Engine Cool-

ant".

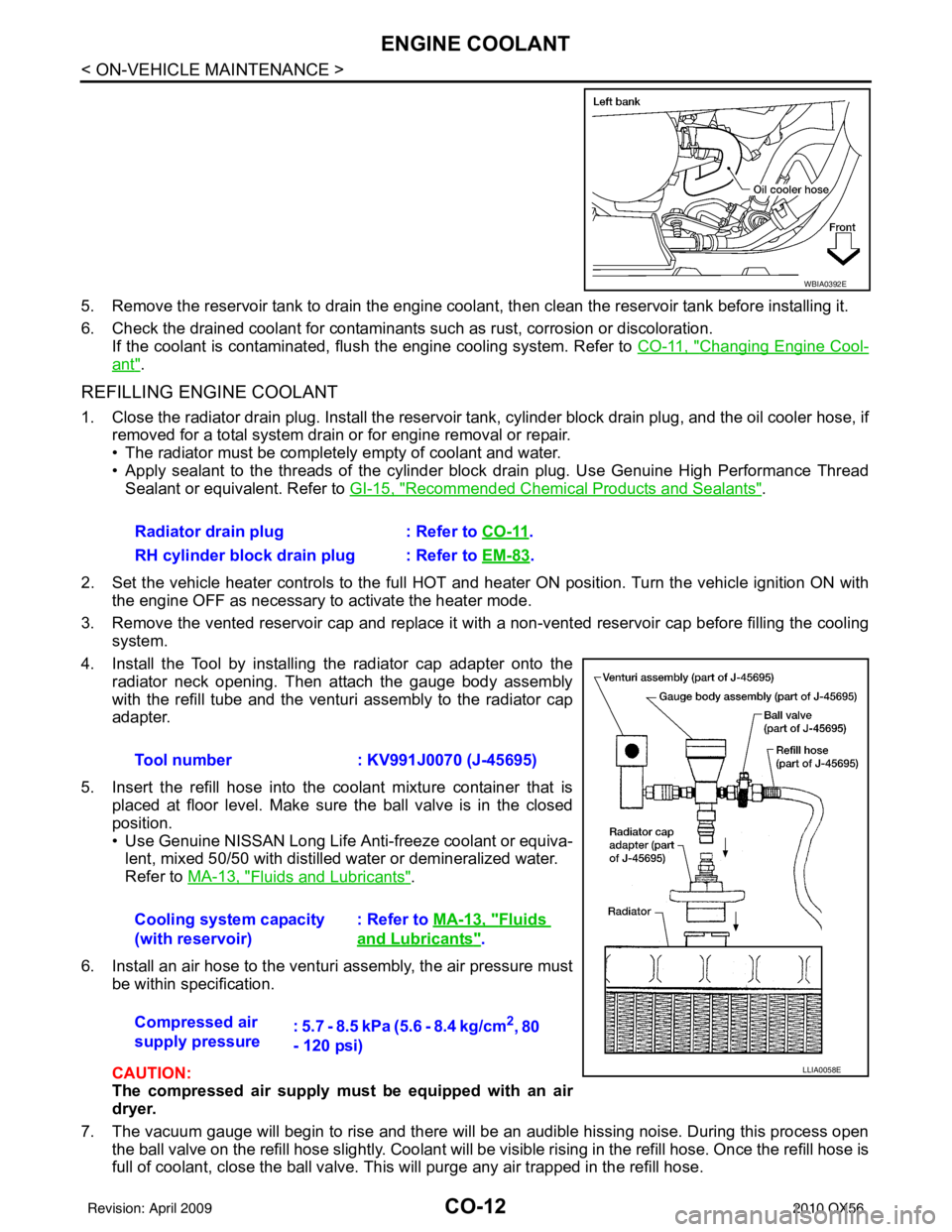

REFILLING ENGINE COOLANT

1. Close the radiator drain plug. Install the reservoir t ank, cylinder block drain plug, and the oil cooler hose, if

removed for a total system drain or for engine removal or repair.

• The radiator must be completely empty of coolant and water.

• Apply sealant to the threads of the cylinder bl ock drain plug. Use Genuine High Performance Thread

Sealant or equivalent. Refer to GI-15, "

Recommended Chemical Products and Sealants".

2. Set the vehicle heater controls to the full HOT and heat er ON position. Turn the vehicle ignition ON with

the engine OFF as necessary to activate the heater mode.

3. Remove the vented reservoir cap and replace it with a non-vented reservoir cap before filling the cooling

system.

4. Install the Tool by installing the radiator cap adapter onto the radiator neck opening. Then attach the gauge body assembly

with the refill tube and the venturi assembly to the radiator cap

adapter.

5. Insert the refill hose into the coolant mixture container that is placed at floor level. Make sure the ball valve is in the closed

position.

• Use Genuine NISSAN Long Life Anti-freeze coolant or equiva-lent, mixed 50/50 with distilled water or demineralized water.

Refer to MA-13, "

Fluids and Lubricants".

6. Install an air hose to the venturi assembly, the air pressure must be within specification.

CAUTION:

The compressed air supply must be equipped with an air

dryer.

7. The vacuum gauge will begin to rise and there will be an audible hissing noise. During this process open the ball valve on the refill hose slightly. Coolant will be vi sible rising in the refill hose. Once the refill hose is

full of coolant, close the ball valve. This will purge any air trapped in the refill hose.

WBIA0392E

Radiator drain plug : Refer to CO-11.

RH cylinder block drain plug : Refer to EM-83

.

Tool number : KV991J0070 (J-45695)

Cooling system capacity

(with reservoir) : Refer to

MA-13, "

Fluids

and Lubricants".

Compressed air

supply pressure : 5.7 - 8.5 kPa (5.6 - 8.4 kg/cm

2, 80

- 120 psi)

LLIA0058E

Revision: April 20092010 QX56

Page 1092 of 4210

![INFINITI QX56 2010 Factory Service Manual DLN-10

< FUNCTION DIAGNOSIS >[ATX14B]

4WD SYSTEM

FUNCTION DIAGNOSIS

4WD SYSTEM

System DiagramINFOID:0000000005148770

COMPONENT DESCRIPTION

WDIA0164E

Components

Function

Transfer control unit Controls INFINITI QX56 2010 Factory Service Manual DLN-10

< FUNCTION DIAGNOSIS >[ATX14B]

4WD SYSTEM

FUNCTION DIAGNOSIS

4WD SYSTEM

System DiagramINFOID:0000000005148770

COMPONENT DESCRIPTION

WDIA0164E

Components

Function

Transfer control unit Controls](/img/42/57032/w960_57032-1091.png)

DLN-10

< FUNCTION DIAGNOSIS >[ATX14B]

4WD SYSTEM

FUNCTION DIAGNOSIS

4WD SYSTEM

System DiagramINFOID:0000000005148770

COMPONENT DESCRIPTION

WDIA0164E

Components

Function

Transfer control unit Controls transfer control device, control valves and shifts between 2WD/4WD and 4H/4LO.

Transfer control device Integrates actuator motor and actuator position switch.

2-4WD shift solenoid valve Controls oil pressure and allows shifting between 2WD and 4WD.

Clutch pressure solenoid valve Controls oil pressure and distributes torque between front and rear tires.

Line pressure switch Detects line pressure.

Clutch pressure switch Detects clutch pressure.

Transfer fluid temperature sensor Detects transfer fluid temperature.

Actuator motor Moves shift rods when signaled by transfer control unit.

Actuator position switch Detects actuator motor position.

Wait detection switch Detects whether or not 4WD lock gear is locked.

4LO switch Detects if transfer case is in 4LO.

ATP switch Detects if transfer case is in neutral.

4WD shift switch Allows driver to select from 2WD/4WD, 4H/4LO and AUTO.

4WD warning lamp • Illuminates if malfunction is detected in 4WD system.

• Flashes (1 flash / 2 seconds) if large difference in diameter of front and rear tires.

• Flashes (2 flashes / 1 second) if high transfer fluid temperature is detected.

AT P w a r n i n g l a m p Indicates that A/T parking mechanism does not operate when A/T selector lever is in P position

because transfer case is in neutral.

4WD shift indicator lamp Displays driving range selected by 4WD shift switch.

4LO indicator lamp Displays 4LO range.

Revision: April 20092010 QX56

Page 1096 of 4210

![INFINITI QX56 2010 Factory Service Manual DLN-14

< FUNCTION DIAGNOSIS >[ATX14B]

4WD SYSTEM

• Displays 4LO condition while engine is running. 4LO indicator lamp flashes if transfer gear does not shift

completely under 2WD, AUTO, 4H ⇔4LO. ( INFINITI QX56 2010 Factory Service Manual DLN-14

< FUNCTION DIAGNOSIS >[ATX14B]

4WD SYSTEM

• Displays 4LO condition while engine is running. 4LO indicator lamp flashes if transfer gear does not shift

completely under 2WD, AUTO, 4H ⇔4LO. (](/img/42/57032/w960_57032-1095.png)

DLN-14

< FUNCTION DIAGNOSIS >[ATX14B]

4WD SYSTEM

• Displays 4LO condition while engine is running. 4LO indicator lamp flashes if transfer gear does not shift

completely under 2WD, AUTO, 4H ⇔4LO. (When 4WD warning lamp is turned on, 4LO indicator lamp is

turned off.)

• Turns ON for approximately 1 second when ignition switch is turned ON, for purpose of lamp check.

4WD WARNING LAMP

Turns on or flashes when there is a malfunction in 4WD system.

Also turns on when ignition switch is turned ON, for purpose of lamp che\

ck. Turns OFF approximately 1 sec-

ond after the engine starts if system is normal.

4WD Warning Lamp Indication

ATP WARNING LAMP

When the A/T selector lever is in P position, the vehicle may move if the transfer case is in neutral. ATP warn-

ing lamp is turned on to indicate this condition to the driver.

LINE PRESSURE SWITCH

• With the transfer system design, control of the oil pressure provides the transmission of drive torque to the

front wheels. The main pressure to control the oil pressure is referred to as the line pressure.

• The line pressure switch determines whether or not adequate line pressure has built up under different oper- ating conditions.

• The line pressure switch closes when line pressure is produced.

• The line pressure switch senses line pressure abnormalities and turns the 4WD warning lamp ON.

CLUTCH PRESSURE SWITCH

• The clutch pressure switch determines whether or not adequate clutch pressure has built up under different

operating conditions.

• The clutch pressure switch closes when clutch pressure is produced.

• The clutch pressure switch senses clutch pressure abnormalities and turns the 4WD warning lamp ON.

WAIT DETECTION SWITCH

• The wait detection switch operates when there is circulating torque produced in the propeller shaft (L→H) or

when there is a phase difference between 2-4 sleeve and clutch drum (H →L). After the release of the circu-

lating torque, the wait detection switch helps provi de the 4WD lock gear (clutch drum) shifts. A difference

may occur between the operation of the 4WD shift swit ch and actual drive mode. At this point, the wait

detection switch senses an actual drive mode.

• The wait detection switch operates as follows.

- 4WD lock gear (clutch drum) locked: ON

- 4WD lock gear (clutch drum) released: OFF

• The wait detection switch senses an actual drive mode and the 4WD shift indicator lamp indicates the vehi-

cle drive mode.

ATP SWITCH

ATP switch detects if transfer case is in neutral by the position of the L-H shift fork.

NOTE:

Transfer case may be in neutral when shifting between 4H-4LO.

NEUTRAL-4LO SWITCH

The neutral-4LO switch detects that transfer gear is in neutral or 4LO (or shifting from neutral to 4LO) condi-

tion by L-H shift fork position.

Condition 4WD warning lamp

System normal OFF

Lamp check Turns ON when ignition switch is turned ON.

Turns OFF after engine start.

4WD system malfunction ON

During self-diagnosis Flashes malfunction mode.

Large difference in diameter of front/

rear tires Flashes slow (1 flash / 2 seconds)

(Continues to flash until the ignition switch is turned OFF)

High fluid temperature in transfer case Flashes rapidly (2 flashes / 1 second)

(Continues to flash until fluid temperature returns to normal)

Revision: April 20092010 QX56

Page 1097 of 4210

![INFINITI QX56 2010 Factory Service Manual 4WD SYSTEMDLN-15

< FUNCTION DIAGNOSIS > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

TRANSFER FLUID TEMPERATURE SENSOR

The transfer fluid temperature sensor detects the trans fer fluid temperature and se INFINITI QX56 2010 Factory Service Manual 4WD SYSTEMDLN-15

< FUNCTION DIAGNOSIS > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

TRANSFER FLUID TEMPERATURE SENSOR

The transfer fluid temperature sensor detects the trans fer fluid temperature and se](/img/42/57032/w960_57032-1096.png)

4WD SYSTEMDLN-15

< FUNCTION DIAGNOSIS > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

TRANSFER FLUID TEMPERATURE SENSOR

The transfer fluid temperature sensor detects the trans fer fluid temperature and sends a signal to the transfer

control unit.

TRANSFER MOTOR

• The transfer motor drives the sub-oil pump to provi de proper lubrication and oil pressure control when the

vehicle is at standstill, during low-speed operations or is being driven in reverse.

• The main oil pump is operated by the driving force of t he mainshaft. In other words, sufficient oil pressure

buildup does not occur when the vehicle is at standsti ll or during low-speed operations. While the vehicle is

being driven in reverse, the main oil pump rotates in the reverse direction. Therefore the main oil pump does

not discharge oil pressure. During any of the above vehi cle operations, the transfer motor drives the sub-oil

pump to compensate for insufficient oil pressure.

• The transfer motor operates as follows:

- The motor relay turns OFF in the 2WD mode.

- The motor relay operates as described in the table below in modes other than the 2WD mode.

• 4WD shift switch, transmission range switch, Neutral-4LO switch, vehicle speed sensor and throttle position

sensor are used in conjunction with the transfer motor.

Transfer Motor Relay Operation

*: After 2.5 seconds have elapsed.

CLUTCH PRESSURE SOLENOID VALVE

The clutch pressure solenoid valve distributes front and rear torque in AUTO mode.

2-4WD SHIFT SOLENOID VALVE

The 2-4WD shift solenoid valve operates to apply oil pressure to the wet-multiplate clutch, depending on the

drive mode. The driving force is transmitted to the front wheels through the clutch so the vehicle is set in the

4WD mode. Setting the vehicle in the 2WD mode requires no pressure buildup. In other words, pressure force

applied to the wet-multiplate clutch becomes zero.

TRANSFER CONTROL DEVICE

Integrates actuator motor and actuator position switch.

4WD shift switch A/T selector lever position Vehicle speed

(VSS) Accelerator pedal position Motor relay drive

command

2WD ———OFF

4H (LOCK) and 4LO N position

0— ON

P position 00 - 0.07/8

OFF*

0.07/8 - 1/8 HOLD

1/8 - MAX ON

Other than R position 0 < VSS ≤

50 km/h (31 MPH)

— ON

50 km/h (31 MPH) < VSS < 55 km/h (34 MPH) HOLD

55 km/h (34 MPH) ≤ VSS OFF

R position —— ON

R position —— ON

AUTO P or N position 0

0 - 0.07/8

OFF*

0.07/8 - 1/8 HOLD

1/8 - MAX ON

0 < VSS ≤ 50 km/h (31 MPH)

— ON

50 km/h (31 MPH) < VSS < 55 km/h (34 MPH) HOLD

55 km/h (34 MPH) ≤ VSS OFF

Other than R, P and N posi-

tion 0 < VSS ≤

50 km/h (31 MPH)

— ON

50 km/h (31 MPH) < VSS < 55 km/h (34 MPH) HOLD

55 km/h (34 MPH) ≤ VSS OFF

Revision: April 20092010 QX56