seat adjustment INFINITI QX56 2010 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 15 of 4210

ADP-1

BODY INTERIOR

C

DE

F

G H

I

K L

M

SECTION ADP

A

B

ADP

N

O P

CONTENTS

AUTOMATIC DRIVE POSITIONER

BASIC INSPECTION ....... .............................5

DIAGNOSIS AND REPAIR WORKFLOW ..... .....5

Work Flow ........................................................... ......5

INSPECTION AND ADJUSTMENT .....................8

Preliminary Check ............................................... ......8

Special Repair Requirement .....................................8

PRE-INSPECTION FOR DIAGNOSTIC ..............9

Basic Inspection .................................................. ......9

FUNCTION DIAGNOSIS ..............................11

AUTOMATIC DRIVE POSITIONER SYSTEM ....11

AUTOMATIC DRIVE POSITIONER SYSTEM ....... ....11

AUTOMATIC DRIVE POSITIONER SYSTEM :

System Diagram ......................................................

11

AUTOMATIC DRIVE POSITIONER SYSTEM :

System Description .................................................

12

AUTOMATIC DRIVE POSITIONER SYSTEM :

Component Parts Location ......................................

12

AUTOMATIC DRIVE POSITIONER SYSTEM :

Component Description ..........................................

13

MANUAL FUNCTION ............................................ ....14

MANUAL FUNCTION : System Diagram ................15

MANUAL FUNCTION : System Description ............15

MANUAL FUNCTION : Component Parts Loca-

tion ..........................................................................

17

MANUAL FUNCTION : Component Description ....17

MEMORY FUNCTION ........................................... ....18

MEMORY FUNCTION : System Diagram ...............19

MEMORY FUNCTION : System Description ..........19

MEMORY FUNCTION : Component Parts Loca-

tion ..........................................................................

20

MEMORY FUNCTION : Component Description ....21

EXIT ASSIST FUNCTION ...................................... ....22

EXIT ASSIST FUNCTION : System Diagram .........22

EXIT ASSIST FUNCTION : System Description . ....22

EXIT ASSIST FUNCTION : Component Parts Lo-

cation ................................................................... ....

23

EXIT ASSIST FUNCTION :

Component Description ...................................... ....

24

ENTRY ASSIST FUNCTION .................................. ....24

ENTRY ASSIST FUNCTION : System Diagram .....25

ENTRY ASSIST FUNCTION : System Description

....

25

ENTRY ASSIST FUNCTION : Component Parts

Location ...................................................................

26

ENTRY ASSIST FUNCTION :

Component Description ..........................................

27

DIAGNOSIS SYSTEM (DRIVER SEAT C/U) ....28

Diagnosis Description ..............................................28

CONSULT-III Function ............................................28

COMPONENT DIAGNOSIS .........................31

U1000 CAN COMM CIRCUIT ...........................31

Description ........................................................... ....31

DTC Logic ................................................................31

Special Repair Requirement ....................................31

B2112 SLIDING MOTOR ..................................32

Description ...............................................................32

DTC Logic ................................................................32

Diagnosis Procedure ..............................................32

B2113 RECLINING MOTOR .............................33

Description ...............................................................33

DTC Logic ................................................................33

Diagnosis Procedure ..............................................33

B2114 SEAT LIFTER FR ..................................34

Description ...............................................................34

DTC Logic ................................................................34

Diagnosis Procedure ..............................................34

B2115 SEAT LIFTER RR ..................................35

Description ...............................................................35

Revision: April 20092010 QX56

Page 22 of 4210

ADP-8

< BASIC INSPECTION >

INSPECTION AND ADJUSTMENT

INSPECTION AND ADJUSTMENT

Preliminary CheckINFOID:0000000005147422

1. FOREIGN OBJECTS

Check the following:

• objects on or behind the seats that could cause binding

• objects under the seats that may be interfering with the seat’s moving parts

• objects under pedals that may interfere with movement

Are there any foreign objects that could be causing interference?

YES >> Remove objects.

NO >> GO TO 2

2. WIRING CONNECTIONS

1. Disconnect harness connectors.

2. Check terminals for damage or loose connections.

3. Reconnect harness connectors.

Are any connectors damaged or loose?

YES >> Repair or replace damaged parts.

NO >> GO TO 3

3. POWER AND GROUND

Check power supply and ground circuits for control unit. Refer to ADP-47, "

DRIVER SEAT CONTROL UNIT :

DiagnosisProcedure".

Is the inspection result normal?

YES >> Refer to ADP-134, "DTCIndex".

NO >> Repair or replace as necessary.

Special Repair RequirementINFOID:0000000005147423

Refer to Owner’s Manual for Automatic Driv e Positioner system operating instructions.

Revision: April 20092010 QX56

Page 148 of 4210

ADP-134

< ECU DIAGNOSIS >

DRIVER SEAT CONTROL UNIT

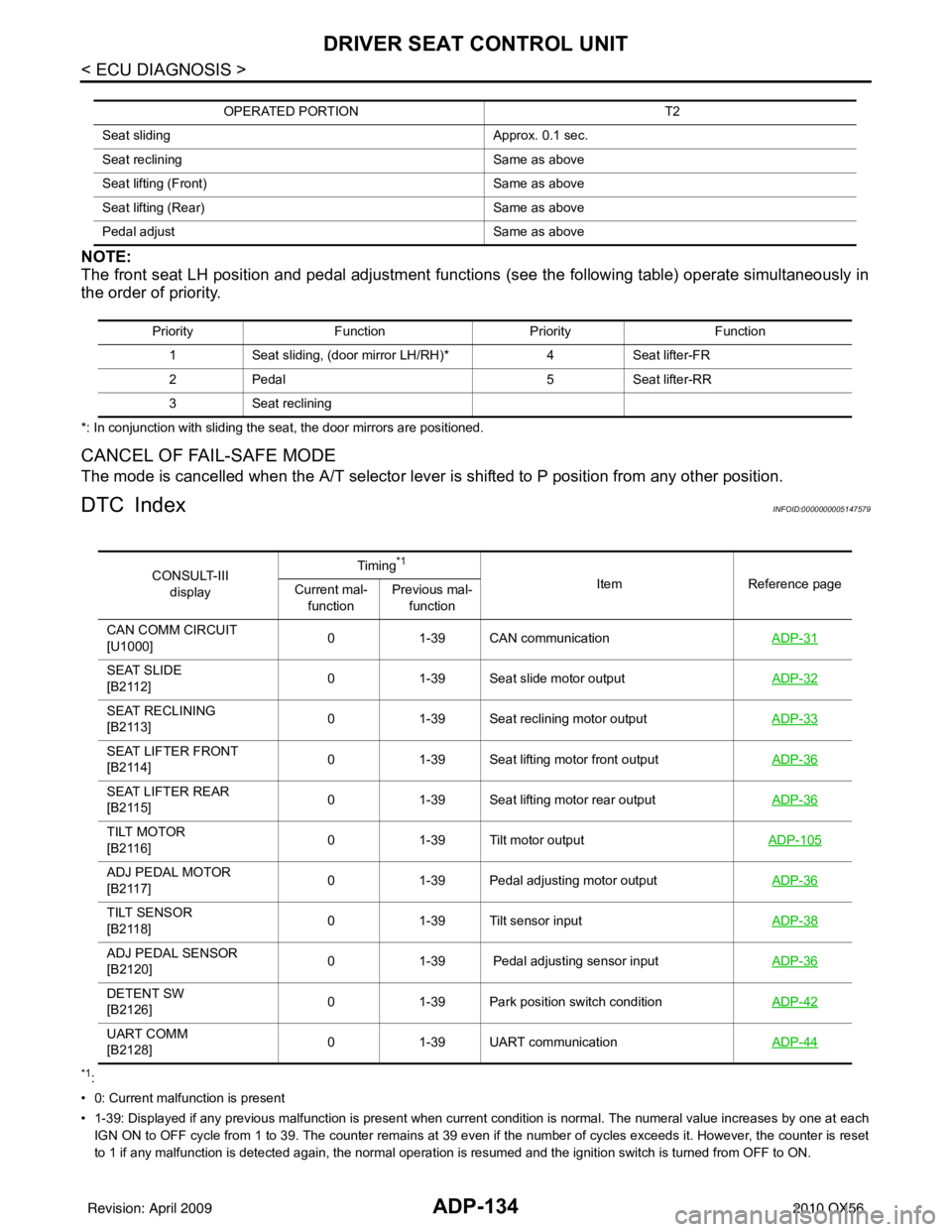

NOTE:

The front seat LH position and pedal adjustment functions (see the following table) operate simultaneously in

the order of priority.

*: In conjunction with sliding the seat, the door mirrors are positioned.

CANCEL OF FAIL-SAFE MODE

The mode is cancelled when the A/T selector lever is shifted to P position from any other position.

DTC IndexINFOID:0000000005147579

*1:

• 0: Current malfunction is present

• 1-39: Displayed if any previous malfunction is present when current condition is normal. The numeral value increases by one at each

IGN ON to OFF cycle from 1 to 39. The counter remains at 39 even if the number of cycles exceeds it. However, the counter is re set

to 1 if any malfunction is detected again, the normal operation is resumed and the ignition switch is turned from OFF to ON. OPERATED PORTION

T2

Seat sliding Approx. 0.1 sec.

Seat reclining Same as above

Seat lifting (Front) Same as above

Seat lifting (Rear) Same as above

Pedal adjust Same as above

Priority Function PriorityFunction

1 Seat sliding, (door mirro r LH/RH)* 4Seat lifter-FR

2 Pedal 5Seat lifter-RR

3 Seat reclining

CONSULT-III

display Timing

*1

Item

Reference page

Current mal-

function Previous mal-

function

CAN COMM CIRCUIT

[U1000] 0

1-39 CAN communication ADP-31

SEAT SLIDE

[B2112]0

1-39 Seat slide motor output ADP-32

SEAT RECLINING

[B2113]0

1-39 Seat reclin ing motor output ADP-33

SEAT LIFTER FRONT

[B2114] 0

1-39 Seat lifting motor front output ADP-36

SEAT LIFTER REAR

[B2115]0

1-39 Seat lifting motor rear output ADP-36

TILT MOTOR

[B2116]0

1-39 Tilt motor output ADP-105

ADJ PEDAL MOTOR

[B2117]0

1-39 Pedal adjusting motor output ADP-36

TILT SENSOR

[B2118]0

1-39 Tilt sensor input ADP-38

ADJ PEDAL SENSOR

[B2120]0

1-39 Pedal adjusting sensor input ADP-36

DETENT SW

[B2126]0

1-39 Park position switch condition ADP-42

UART COMM

[B2128]0

1-39 UART communication ADP-44

Revision: April 20092010 QX56

Page 446 of 4210

BR-1

BRAKES

C

DE

G H

I

J

K L

M

SECTION BR

A

B

BR

N

O P

CONTENTS

BRAKE SYSTEM

PRECAUTION ....... ........................................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

3

Precaution for Brake System ....................................4

PREPARATION ............................................5

PREPARATION .............................................. .....5

Special Service Tool ........................................... ......5

Commercial Service Tool ..........................................5

FUNCTION DIAGNOSIS ...............................6

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ........................ .....

6

NVH Troubleshooting Chart ................................ ......6

BASIC INSPECTION ....................................7

FRONT DISC B RAKE .................................... .....7

BRAKE PAD .......................................................... ......7

BRAKE PAD : Front Pad Inspection .........................7

DISC ROTOR ......................................................... ......7

DISC ROTOR : Front Rotor Inspection .....................7

REAR DISC BRAKE ...................................... .....9

BRAKE PAD .......................................................... ......9

BRAKE PAD : Rear Pad Inspection ..........................9

DISC ROTOR ......................................................... ......9

DISC ROTOR : Rear Rotor Inspection ......................9

BRAKE BOOSTER ........................................ ....10

Inspection ............................................................ ....10

VACUUM LINES ............................................. ....11

Inspection ............................................................ ....11

BRAKE MASTER CYLINDER ..........................12

On Board Inspection ................................................12

BRAKE TUBE AND HOSE ...............................13

Hydraulic Circuit ......................................................13

FRONT BRAKE ..................................................... ....13

FRONT BRAKE : Inspection ......................... ...........13

REAR BRAKE ........................................................ ....14

REAR BRAKE : Inspection ........................ ..............14

ON-VEHICLE MAINTEN ANCE ....................15

BRAKE PEDAL .................................................15

Inspection and Adjustment .................................. ....15

BRAKE FLUID ..................................................17

On Board Inspection ............................................ ....17

Drain and Refill ........................................................17

Bleeding Brake System ...........................................17

ON-VEHICLE REPAIR .................................19

BRAKE PEDAL .................................................19

Removal and Installation ..................................... ....19

BRAKE TUBE AND HOSE ...............................21

Hydraulic Circuit ......................................................21

Removal and Installation of Front Brake Piping

and Brake Hose .......................................................

21

Removal and Installation of Rear Brake Piping

and Brake Hose .......................................................

22

Inspection After Installation .....................................23

BRAKE MASTER CYLINDER ..........................25

Removal and Installation .........................................25

BRAKE BOOSTER ...........................................26

Removal and Installation ..................................... ....26

VACUUM LINES ...............................................28

Revision: April 20092010 QX56

Page 838 of 4210

DLK-4

Diagnosis Procedure .............................................138

BACK DOOR CLOSE SWITCH SYSTEM .......139

Diagnosis Procedure ........................................... ..139

BACK DOOR SWITCH ....................................140

Diagnosis Procedure ........................................... ..140

CINCH LATCH MOTOR SYSTEM ...................141

Diagnosis Procedure ........................................... ..141

INTELLIGENT KEY UNIT POWER BACK

DOOR INPUT SIGNAL ....................................

142

Description ........................................................... ..142

Diagnosis Procedure .............................................142

INTELLIGENT KEY UNIT POWER BACK

DOOR OUTPUT SIGNAL ................................

143

Description ........................................................... ..143

Diagnosis Procedure .............................................143

HOMELINK UNIVERSAL TRANSCEIVER ......144

Wiring Diagram .................................................... ..144

Description .............................................................145

Component Function Check ................................146

Diagnosis Procedure .............................................146

ECU DIAGNOSIS ..................................... ..148

BCM (BODY CONTROL MODULE) ............... .148

Reference Value .................................................. ..148

Terminal Layout .....................................................151

Physical Values .....................................................151

Wiring Diagram — POWER DOOR LOCK SYS-

TEM — ..................................................................

157

Fail Safe ................................................................170

DTC Inspection Priority Chart .............................171

DTC Index ........................................................... ..171

INTELLIGENT KEY UNIT ................................173

Reference Value .................................................. ..173

Terminal Layout - Intelligent Key Unit ....................174

Physical Values - Intelligent Key Unit ....................174

Terminal Layout - Steering Lock Solenoid ........... ..177

Physical Values - Steering Lock Solenoid .............177

Wiring Diagram — INTELLIGENT KEY SYSTEM

— ...........................................................................

178

Fail Safe ................................................................195

DTC Inspection Priority Chart .............................196

DTC Index ........................................................... ..196

BACK DOOR CONTROL UNIT .......................197

Reference Value .................................................. ..197

Wiring Diagram—AUTOMATIC BACK DOOR

SYSTEM— ............................................................

199

Fail Safe .............................................................. ..209

SYMPTOM DIAGNOSIS ............................210

INTELLIGENT KEY SYSTEM SYMPTOMS ... .210

Symptom Table ................................................... ..210

DOOR LOCK FUNCTION SYMPTOMS ...........211

DOOR LOCK AND UNLOCK SWITCH .................. .211

DOOR LOCK AND UNLOCK SWITCH : Symptom

Table .....................................................................

211

INTELLIGENT KEY ................................................ .212

INTELLIGENT KEY : Symptom Table ..................212

BACK DOOR OPENER FUNCTION ................214

BACK DOOR OPENER SWITCH .......................... .214

BACK DOOR OPENER SWITCH : Symptom Ta-

ble ........................................................................ .

214

BACK DOOR HANDLE .......................................... .214

BACK DOOR HANDLE : Symptom Table .............215

INTELLIGENT KEY ................................................ .215

INTELLIGENT KEY : Symptom Table ..................215

WARNING FUNCTION SYMPTOMS ...............216

Symptom Table .................................................... .216

KEY REMINDER FUNCTION SYMPTOMS .....219

Symptom Table .................................................... .219

HAZARD FUNCTION ..................................... ..220

Symptom Table .................................................... .220

HORN FUNCTION ............................................221

Symptom Table .................................................... .221

HOMELINK UNIVERSAL TRANSCEIVER ......222

Symptom Table .................................................... .222

SQUEAK AND RATTLE TROUBLE DIAG-

NOSES ..............................................................

223

Work Flow ............................................................ .223

Inspection Procedure ............................................225

Diagnostic Worksheet ...........................................227

PRECAUTION ...........................................229

PRECAUTIONS .............................................. ..229

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .............................................................. .

229

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ................................

229

Precaution for work ...............................................230

PREPARATION .........................................231

PREPARATION .............................................. ..231

Special Service Tool ............................................ .231

Commercial Service Tool ......................................232

ON-VEHICLE REPAIR ..............................233

HOOD ............................................................. ..233

Fitting Adjustment ................................................ .233

Removal and Installation of Hood Assembly ........234

Revision: April 20092010 QX56

Page 1060 of 4210

![INFINITI QX56 2010 Factory Service Manual DLK-226

< SYMPTOM DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Most of these incidents can be repaired by adjusting, se

curing or insulating the item(s) or component(s) INFINITI QX56 2010 Factory Service Manual DLK-226

< SYMPTOM DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Most of these incidents can be repaired by adjusting, se

curing or insulating the item(s) or component(s)](/img/42/57032/w960_57032-1059.png)

DLK-226

< SYMPTOM DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Most of these incidents can be repaired by adjusting, se

curing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area c an often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sunvisor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

SEATS

When isolating seat noise it's important to note the pos ition the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of thes e incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the \

vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Revision: April 20092010 QX56

Page 1085 of 4210

DLN-3

CEF

G H

I

J

K L

M A

B

DLN

N

O P

PRECAUTIONS .............................................. ..120

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ..

120

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ..

120

Precaution for Transfer Assembly and Transfer

Control Unit Replacement .....................................

121

Precaution .............................................................121

Service Notice .......................................................122

PREPARATION .........................................123

PREPARATION .............................................. ..123

Special Service Tool ........................................... ..123

Commercial Service Tool ......................................125

ON-VEHICLE MAINTENANCE ..................127

TRANSFER OIL FILTER ................................ ..127

Removal and Installation .......................................127

TRANSFER FLUID ......................................... ..129

Replacement ....................................................... ..129

Inspection ..............................................................129

ON-VEHICLE REPAIR ...............................130

TRANSFER CONTROL UNIT ........................ ..130

Removal and Installation .......................................130

FRONT OIL SEAL ............................................131

Removal and Installation .......................................131

REAR OIL SEAL ..............................................133

Removal and Installation .......................................133

SIDE OIL SEAL .............................................. ..135

Removal and Installation .......................................135

TRANSFER CONTROL DEVICE ................... ..136

Removal and Installation .......................................136

AIR BREATHER HOSE .................................. ..137

Removal and Installation .......................................137

TRANSFER MOTOR ...................................... ..140

Removal and Installation .......................................140

REMOVAL AND INSTALLA TION .............141

TRANSFER ASSEMBLY ............................... ..141

Removal and Installation .......................................141

DISASSEMBLY AND ASSEMBLY ........... .142

TRANSFER ASSEMBLY ............................... ..142

Disassembly and Assembly ................................ ..142

SERVICE DATA AND SPECIFICATIONS

(SDS) ......... ................................. ................

179

SERVICE DATA AND SPECIFICATIONS

(SDS) ...............................................................

179

General Specification .......................................... ..179

Inspection and Adjustment ....................................179

PROPELLER SHAFT: 2F1310

PRECAUTION ...... ......................................

181

PRECAUTIONS ...............................................181

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ..

181

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect .................................

181

PREPARATION .........................................183

PREPARATION ...............................................183

Commercial Service Tool .................................... ..183

SYMPTOM DIAGNOSIS ............................184

NOISE, VIBRATION, AND HARSHNESS

(NVH) TROUBLESHOOTING .........................

184

NVH Troubleshooting Chart ................................ ..184

ON-VEHICLE REPAIR ...............................185

PROPELLER SHAFT ......................................185

On-Vehicle Service .............................................. ..185

REMOVAL AND INSTALLATION .............186

PROPELLER SHAFT ......................................186

Removal and Installation ..................................... ..186

DISASSEMBLY AND ASSEMBLY ............188

PROPELLER SHAFT ......................................188

Disassembly and Assembly ................................. ..188

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... .

190

SERVICE DATA AND SPECIFICATIONS

(SDS) ...............................................................

190

General Specification .......................................... ..190

Snap Ring ..............................................................190

PROPELLER SHAFT: 2S1410

PRECAUTION ...... ......................................

191

PRECAUTIONS ...............................................191

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ..

191

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect .................................

191

PREPARATION .........................................193

PREPARATION ...............................................193

Revision: April 20092010 QX56

Page 1086 of 4210

DLN-4

Commercial Service Tool ......................................193

SYMPTOM DIAGNOSIS ............................194

NOISE, VIBRATION, AND HARSHNESS

(NVH) TROUBLESHOOTING ......................... .

194

NVH Troubleshooting Chart ................................ ..194

ON-VEHICLE REPAIR ...............................195

PROPELLER SHAFT ..................................... .195

On-Vehicle Service .............................................. ..195

REMOVAL AND INSTALLATION ..............196

PROPELLER SHAFT ..................................... .196

Removal and Installation ..................................... ..196

DISASSEMBLY AND ASSEMBLY ............199

PROPELLER SHAFT ..................................... .199

Disassembly and Assembly ................................. ..199

SERVICE DATA AND SPECIFICATIONS

(SDS) ........................................................ ..

201

SERVICE DATA AND SPECIFICATIONS

(SDS) ............................................................... .

201

General Specification .......................................... ..201

Snap Ring ..............................................................201

FRONT FINAL DRIVE: M205

PRECAUTION .............. ..............................

203

PRECAUTIONS .............................................. .203

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .............................................................. ..

203

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect .................................

203

Precaution for Servicing Front Final Drive .............204

PREPARATION ..........................................205

PREPARATION .............................................. .205

Special Service Tool ............................................ ..205

Commercial Service Tool ......................................207

SYMPTOM DIAGNOSIS ............................208

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ......................... .

208

NVH Troubleshooting Chart ................................ ..208

ON-VEHICLE MAINTENANCE ..................209

DIFFERENTIAL GEAR OIL ............................ .209

Changing Front Differential Gear Oil .....................209

Checking Front Differential Gear Oil .................... ..209

ON-VEHICLE REPAIR ...............................210

SIDE OIL SEAL .............................................. ..210

Removal and Installation .......................................210

FRONT OIL SEAL ............................................211

Removal and Installation .......................................211

CARRIER COVER .......................................... ..214

Removal and Installation .......................................214

REMOVAL AND INSTALLA TION .............215

FRONT FINAL DRIVE .................................... ..215

Removal and Installation .......................................215

DISASSEMBLY AND ASSEMBLY ...........217

FRONT FINAL DRIVE .................................... ..217

Disassembly and Assembly ................................. .217

SERVICE DATA AND SPECIFICATIONS

(SDS) ........ .................................................

234

SERVICE DATA AND SPECIFICATIONS

(SDS) .............................................................. ..

234

General Specification ........................................... .234

Inspection and Adjustment ....................................234

REAR FINAL DRIVE: R230

PRECAUTION ............... ............................

236

PRECAUTIONS .............................................. ..236

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .............................................................. .

236

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ................................

236

Precaution for Servicing Rear Final Drive .............237

PREPARATION .........................................238

PREPARATION .............................................. ..238

Special Service Tool ............................................ .238

Commercial Service Tool ......................................240

SYMPTOM DIAGNOSIS ...........................242

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ......................... ..

242

NVH Troubleshooting Chart ..................................242

DESCRIPTION ................................................ ..243

Cross-Sectional View ........................................... .243

ON-VEHICLE MAINTENANCE .................244

DIFFERENTIAL GEAR OIL ..............................244

Changing Rear Differential Gear Oil .................... .244

Checking Rear Differential Gear Oil ......................244

ON-VEHICLE REPAIR ..............................245

FRONT OIL SEAL ............................................245

Revision: April 20092010 QX56

Page 1294 of 4210

![INFINITI QX56 2010 Factory Service Manual DLN-212

< ON-VEHICLE REPAIR >[FRONT FINAL DRIVE: M205]

FRONT OIL SEAL

8. Remove the front oil seal using Tool as shown.

INSTALLATION

1. Apply multi-purpose grease to the lips of the new front oil seal INFINITI QX56 2010 Factory Service Manual DLN-212

< ON-VEHICLE REPAIR >[FRONT FINAL DRIVE: M205]

FRONT OIL SEAL

8. Remove the front oil seal using Tool as shown.

INSTALLATION

1. Apply multi-purpose grease to the lips of the new front oil seal](/img/42/57032/w960_57032-1293.png)

DLN-212

< ON-VEHICLE REPAIR >[FRONT FINAL DRIVE: M205]

FRONT OIL SEAL

8. Remove the front oil seal using Tool as shown.

INSTALLATION

1. Apply multi-purpose grease to the lips of the new front oil seal.

Then drive the new front oil seal in evenly to the gear carrier

using Tool.

CAUTION:

• Do not reuse front oil seal.

• Do not incline the new front oil seal when installing.

• Apply multi-purpose grease to the lips of the new front oilseal.

2. Install the companion flange to the drive pinion while aligning the matching marks.

3. Apply anti-corrosive oil to the threads of the drive pinion and the seating surface of the new drive pinion lock nut. Then adjust the

drive pinion lock nut tightening torque using suitable tool A, and

check the total preload torque using Tool B.

• The total preload torque should be within the total preload

torque specification. When not replacing the collapsible

spacer, it should also be equal to the measurement taken dur-

ing removal plus an additional 0.56 N·m (0.06 Kg-m, 5 in-lb).

• If the total preload torque is low, tighten the drive pinion lock nut in 6.8 N·m (0.69 Kg-m, 5ft-lb) increments until the total pre-

load torque is met.

CAUTION:

• Do not reuse drive pinion lock nut.

• Apply anti-corrosive oil to the threads of the drive pinion and the seating surface of the new drive pinion lock nut.

• Adjust the drive pinion lock nut tightening torque to the

lower limit first. Do not exceed the drive pinion lock nut

specified torque. Refer to DLN-217, "

Disassembly and

Assembly".

• Do not loosen drive pinion lock nu t to adjust the total preload torque. If the drive pinion lock nut

torque or the total preload torque exceeds the sp ecifications, replace the collapsible spacer and

tighten it again to adjust. Refer to DLN-217, "

Disassembly and Assembly".

• After adjustment, rotate drive pinion back and fo rth 2 to 3 times to check for unusual noise, rota-

tion malfunction, and other malfunctions.

4. Installation of the remaining components is in the reverse order of removal. CAUTION:Tool number : SP8P

LDIA0130E

Tool number : KV38100500 (J-25273)

: KV38102200 ( — )

BDIA0003E

Tool number B: ST3127S000 (J-25765-A)

Total preload torque: Refer to DLN-234, "

General

Specification".

WDIA0381E

Revision: April 20092010 QX56

Page 1312 of 4210

![INFINITI QX56 2010 Factory Service Manual DLN-230

< DISASSEMBLY AND ASSEMBLY >[FRONT FINAL DRIVE: M205]

FRONT FINAL DRIVE

10. Apply anti-corrosive oil to the threads of the drive pinion and the

seating surface of the new drive pinion lock nut INFINITI QX56 2010 Factory Service Manual DLN-230

< DISASSEMBLY AND ASSEMBLY >[FRONT FINAL DRIVE: M205]

FRONT FINAL DRIVE

10. Apply anti-corrosive oil to the threads of the drive pinion and the

seating surface of the new drive pinion lock nut](/img/42/57032/w960_57032-1311.png)

DLN-230

< DISASSEMBLY AND ASSEMBLY >[FRONT FINAL DRIVE: M205]

FRONT FINAL DRIVE

10. Apply anti-corrosive oil to the threads of the drive pinion and the

seating surface of the new drive pinion lock nut. Then adjust the

drive pinion lock nut tightening torque using suitable tool (A),

and check the drive pinion bearing preload torque using Tool

(B).

CAUTION:

• Do not reuse drive pinion lock nut.

• Apply anti-corrosive oil to the threads of the drive pinionand the seating surface of the new drive pinion lock nut.

• Adjust the drive pinion lock nut tightening torque to the lower limit first. Do not exceed the drive pinion lock nut

specified torque. Refer to DLN-217, "

Disassembly and

Assembly".

• If the drive pinion bearin g preload torque exceeds the

specified value, replace collap sible spacer and tighten it

again to adjust. Do not loosen drive pinion lock nut to

adjust the drive pinion bearing preload torque.

• After adjustment, rotate drive pinion back and fo rth 2 to 3 times to check for unusual noise, rota-

tion malfunction, and other malfunctions.

11. Check companion flange runout.

12. Install the differential case assembly.

Differential Assembly

1. Install side gear thrust washers with the same thickness as the ones installed prior to disassembly, or reinstall the old ones on

the side gears.

2. Install the side gears and side gear thrust washers into the dif- ferential case.

3. Install the pinion mate thrust washers to the two pinion mate gears. Then install the pinion mate gears with the pinion mate

thrust washers by aligning them in diagonally opposite positions

and rotating them into the differential case.Tool number B: ST3127S000 (J-25765-A)

Drive pinion bearing preload torque

: Refer to DLN-234, "

Inspection and Adjust-

ment"

WDIA0382E

SDIA0193J

SDIA2025E

Revision: April 20092010 QX56