service indicator INFINITI QX56 2010 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 1 of 4210

A

B

C

D

E

F

G

H

I

J

K

L

M

N

P

O

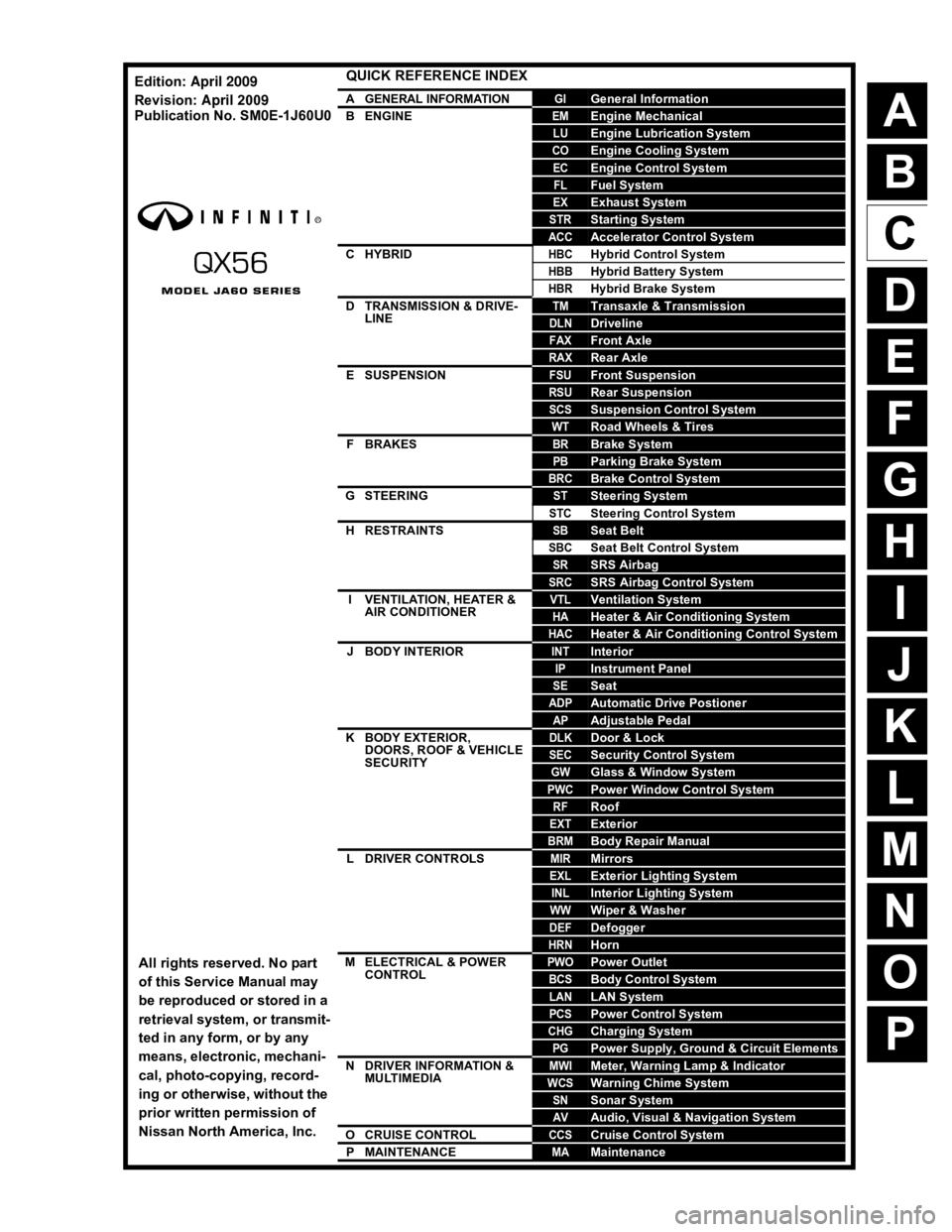

QUICK REFERENCE INDEX

AGENERAL INFORMATIONGIGeneral Information

BENGINEEMEngine Mechanical

LUEngine Lubrication System

COEngine Cooling System

ECEngine Control System

FLFuel System

EXExhaust System

STRStarting System

ACCAccelerator Control System

CHYBRIDHBCHybrid Control System

HBBHybrid Battery System

HBRHybrid Brake System

DTRANSMISSION & DRIVE-

LINETMTransaxle & Transmission

DLNDriveline

FAXFront Axle

RAXRear Axle

ESUSPENSIONFSUFront Suspension

RSURear Suspension

SCSSuspension Control System

WTRoad Wheels & Tires

FBRAKESBRBrake System

PBParking Brake System

BRCBrake Control System

GSTEERINGSTSteering System

STCSteering Control System

HRESTRAINTSSBSeat Belt

SBCSeat Belt Control System

SRSRS Airbag

SRCSRS Airbag Control System

IVENTILATION, HEATER &

AIR CONDITIONERVTLVentilation System

HAHeater & Air Conditioning System

HACHeater & Air Conditioning Control System

JBODY INTERIORINTInterior

IPInstrument Panel

SESeat

ADPAutomatic Drive Postioner

APAdjustable Pedal

KBODY EXTERIOR,

DOORS, ROOF & VEHICLE

SECURITYDLKDoor & Lock

SECSecurity Control System

GWGlass & Window System

PWCPower Window Control System

RFRoof

EXTExterior

BRMBody Repair Manual

LDRIVER CONTROLSMIRMirrors

EXLExterior Lighting System

INLInterior Lighting System

WWWiper & Washer

DEFDefogger

HRNHorn

MELECTRICAL & POWER

CONTROLPWOPower Outlet

BCSBody Control System

LANLAN System

PCSPower Control System

CHGCharging System

PGPower Supply, Ground & Circuit Elements

NDRIVER INFORMATION &

MULTIMEDIAMWIMeter, Warning Lamp & Indicator

WCSWarning Chime System

SNSonar System

AVAudio, Visual & Navigation System

OCRUISE CONTROLCCSCruise Control System

PMAINTENANCEMAMaintenance

All rights reserved. No part

of this Service Manual may

be reproduced or stored in a

retrieval system, or transmit-

ted in any form, or by any

means, electronic, mechani-

cal, photo-copying, record-

ing or otherwise, without the

prior written permission of

Nissan North America, Inc.

Edition: April 2009

Revision: April 2009

Publication No. SM0

E-1J60U0

Page 495 of 4210

BRC-3

C

DE

G H

I

J

K L

M A

B

BRC

N

O P

C1185 ICC UNIT .................................................77

Description .......................................................... ....77

DTC Logic ...............................................................77

Diagnosis Procedure ...............................................77

Special Repair Requirement ...................................78

U1000 CAN COMM CIRCUIT .............................79

Description .......................................................... ....79

DTC Logic ...............................................................79

Diagnosis Procedure ...............................................79

VDC OFF SWITCH .............................................80

Description .......................................................... ....80

Component Function Check ....................................80

Diagnosis Procedure ...............................................80

Component Inspection ............................................81

Special Repair Requirement ...................................81

ABS WARNING LAMP ................................... ....82

Description .......................................................... ....82

Component Function Check ....................................82

Diagnosis Procedure ...............................................82

Special Repair Requirement ...................................82

BRAKE WARNING LAMP ............................. ....83

Description .......................................................... ....83

Component Function Check ....................................83

Diagnosis Procedure ...............................................83

Special Repair Requirement ...................................83

VDC OFF INDICATOR LAMP ........................ ....84

Description .......................................................... ....84

Component Function Check ....................................84

Diagnosis Procedure ...............................................84

Special Repair Requirement ...................................85

SLIP INDICATOR LAMP ................................ ....86

Description .......................................................... ....86

Component Function Check ....................................86

Diagnosis Procedure ...............................................86

Special Repair Requirement ...................................86

ECU DIAGNOSIS ........... ..............................87

ABS ACTUATOR AND ELECTRIC UNIT

(CONTROL UNIT) .......................................... ....

87

Reference Value ................................................. ....87

Wiring Diagram - BRAKE CONTROL SYSTEM - ....92

Fail-Safe ..................................................................99

DTC No. Index ......................................................100

SYMPTOM DIAGNOSIS ............................102

VDC/TCS/ABS ................................................ ..102

Symptom Table ................................................... ..102

EXCESSIVE ABS FUNCTION OPERATION

FREQUENCY ...................................................

103

Diagnosis Procedure ........................................... ..103

UNEXPECTED PEDAL REACTION ...............104

Diagnosis Procedure .............................................104

THE BRAKING DISTANCE IS LONG .............105

Diagnosis Procedure .............................................105

ABS FUNCTION DOES NOT OPERATE .......106

Diagnosis Procedure .............................................106

PEDAL VIBRATION OR ABS OPERATION

SOUND OCCURS ...........................................

107

Diagnosis Procedure ........................................... ..107

VEHICLE JERKS DURING VDC/TCS/ABS

CONTROL .......................................................

108

Diagnosis Procedure .............................................108

NORMAL OPERATING CONDITION .............109

Description .............................................................109

PRECAUTION ............................................110

PRECAUTIONS ...............................................110

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ..

110

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect .................................

110

Precaution for Brake System .................................111

Precaution for Brake Control .................................111

Precaution for CAN System ...................................112

PREPARATION .........................................113

PREPARATION ...............................................113

Special Service Tool ............................................ ..113

Commercial Service Tool ......................................113

REMOVAL AND INSTALLATION .............114

WHEEL SENSORS .........................................114

Removal and Installation ..................................... ..114

SENSOR ROTOR ............................................115

Removal and Installation .......................................115

ACTUATOR AND ELECTRIC UNIT (ASSEM-

BLY) ................................................................

116

Removal and Installation .......................................116

STEERING ANGLE SENSOR .........................118

Removal and Installation .......................................118

G SENSOR ......................................................119

Removal and Installation .......................................119

Revision: April 20092010 QX56

Page 521 of 4210

![INFINITI QX56 2010 Factory Service Manual C1101, C1102, C1103, C1104 WHEEL SENSOR-1

BRC-29

< COMPONENT DIAGNOSIS > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

NOTE:

The green POWER indicator should illuminate. If the POWER indicator does INFINITI QX56 2010 Factory Service Manual C1101, C1102, C1103, C1104 WHEEL SENSOR-1

BRC-29

< COMPONENT DIAGNOSIS > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

NOTE:

The green POWER indicator should illuminate. If the POWER indicator does](/img/42/57032/w960_57032-520.png)

C1101, C1102, C1103, C1104 WHEEL SENSOR-1

BRC-29

< COMPONENT DIAGNOSIS > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

NOTE:

The green POWER indicator should illuminate. If the POWER indicator does not illuminate, replace the

battery in the ABS active wheel sensor tester before proceeding.

3. Spin the wheel of the vehicle by hand and observe the red SENSOR indicator on the ABS active wheel

sensor tester. The red SENSOR indicator should flash on and off to indicate an output signal.

NOTE:

If the red SENSOR indicator illuminates but does not flash, reverse the polarity of the tester leads and

retest.

Does the ABS active wheel s ensor tester detect a signal?

YES >> GO TO 3

NO >> Replace the wheel sensor. Refer to BRC-114, "

Removal and Installation".

3.CHECK TIRES

Check the inflation pressure, wear and size of each tire.

Is the inspection result normal?

YES >> GO TO 4

NO >> Adjust tire pressure or replace tire(s).

4.CHECK WHEEL BEARINGS

Check wheel bearing axial end play. Refer to FA X - 6 , "

On-Vehicle Inspection and Service" (front) or RAX-6,

"On-Vehicle Inspection and Service" (rear).

Is the inspection result normal?

YES >> GO TO 5

NO >> Repair or replace as necessary. Refer to FAX-7, "

Removal and Installation" (front) or RAX-8,

"Removal and Installation" (rear).

5.CHECK WIRING HARNESS FOR SHORT CIRCUIT

1. Disconnect ABS actuator and electric unit (control unit) connec- tor and wheel sensor connector of malfunction code.

2. Check continuity between wheel sensor connector terminals

and ground.

Is the inspection result normal?

YES >> GO TO 6

NO >> Repair the circuit.

6.CHECK WIRING HARNESS FOR OPEN CIRCUIT

Check continuity between ABS actuator and electric unit (control unit) connector and the malfunctioning wheel

sensor connector.

Is the inspection result normal?

Continuity should not exist.

AWFIA0188ZZ

Wheel sensor ABS actuator and

electric unit (control unit) Wheel sensor

Continuity

Connector Terminal Connector Terminal

Front LH

E12545

E18 1

Ye s

46

2

Front RH 34

E117 1

33 2

Rear LH 37

C11 2

36 1

Rear RH 42

C10 2

43 1

Revision: April 20092010 QX56

Page 524 of 4210

![INFINITI QX56 2010 Factory Service Manual BRC-32

< COMPONENT DIAGNOSIS >[VDC/TCS/ABS]

C1105, C1106, C1107,

C1108 WHEEL SENSOR-2

NO >> Repair or replace as necessary.

2.CHECK WHEEL SENSOR OUTPUT SIGNAL

1. Connect ABS active wheel sensor teste INFINITI QX56 2010 Factory Service Manual BRC-32

< COMPONENT DIAGNOSIS >[VDC/TCS/ABS]

C1105, C1106, C1107,

C1108 WHEEL SENSOR-2

NO >> Repair or replace as necessary.

2.CHECK WHEEL SENSOR OUTPUT SIGNAL

1. Connect ABS active wheel sensor teste](/img/42/57032/w960_57032-523.png)

BRC-32

< COMPONENT DIAGNOSIS >[VDC/TCS/ABS]

C1105, C1106, C1107,

C1108 WHEEL SENSOR-2

NO >> Repair or replace as necessary.

2.CHECK WHEEL SENSOR OUTPUT SIGNAL

1. Connect ABS active wheel sensor tester (J-45741) to wheel sensor using appropriate adapter.

2. Turn on the ABS active wheel sensor tester power switch. NOTE:

The green POWER indicator should illuminate. If the POWER indicator does not illuminate, replace the

battery in the ABS active wheel sensor tester before proceeding.

3. Spin the wheel of the vehicle by hand and observe the red SENSOR indicator on the ABS active wheel

sensor tester. The red SENSOR indicator should flash on and off to indicate an output signal.

NOTE:

If the red SENSOR indicator illuminates but does not flash, reverse the polarity of the tester leads and

retest.

Does the ABS active wheel sensor tester detect a signal?

YES >> GO TO 3

NO >> Replace the wheel sensor. Refer to BRC-114, "

Removal and Installation".

3.CHECK TIRES

Check the inflation pressure, wear and size of each tire.

Is the inspection result normal?

YES >> GO TO 4

NO >> Adjust tire pressure or replace tire(s).

4.CHECK WHEEL BEARINGS

Check wheel bearing axial end play. Refer to FAX-6, "

On-Vehicle Inspection and Service" (front) or RAX-6,

"On-Vehicle Inspection and Service" (rear).

Is the inspection result normal?

YES >> GO TO 5

NO >> Repair or replace as necessary. Refer to FA X - 7 , "

Removal and Installation" (front) or RAX-8,

"Removal and Installation" (rear).

5.CHECK WIRING HARNESS FOR SHORT CIRCUIT

1. Disconnect ABS actuator and elec tric unit (control unit) connec-

tor and wheel sensor connector of malfunction code.

2. Check continuity between wheel sensor connector terminals and ground.

Is the inspection result normal?

YES >> GO TO 6

NO >> Repair the circuit.

6.CHECK WIRING HARNESS FOR OPEN CIRCUIT

Check continuity between ABS actuator and electric unit (control unit) connecto r and the malfunctioning wheel

sensor connector. Continuity should not exist.

AWFIA0188ZZ

Revision: April 20092010 QX56

Page 1366 of 4210

![INFINITI QX56 2010 Factory Service Manual INSPECTION AND ADJUSTMENTEC-13

< BASIC INSPECTION > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

INSPECTION AND ADJUSTMENT

Basic InspectionINFOID:0000000005149055

1.INSPECTION START

1. Check service recor INFINITI QX56 2010 Factory Service Manual INSPECTION AND ADJUSTMENTEC-13

< BASIC INSPECTION > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

INSPECTION AND ADJUSTMENT

Basic InspectionINFOID:0000000005149055

1.INSPECTION START

1. Check service recor](/img/42/57032/w960_57032-1365.png)

INSPECTION AND ADJUSTMENTEC-13

< BASIC INSPECTION > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

INSPECTION AND ADJUSTMENT

Basic InspectionINFOID:0000000005149055

1.INSPECTION START

1. Check service records for any recent repairs that may indicate a related malfunction, or a current need for scheduled maintenance.

2. Open engine hood and check the following:

- Harness connectors for improper connections

- Wiring harness for improper connections, pinches and cut

- Vacuum hoses for splits, kinks and improper connections

- Hoses and ducts for leaks

- Air cleaner clogging

- Gasket

3. Confirm that electrical or mechanical loads are not applied.

- Headlamp switch is OFF.

- Air conditioner switch is OFF.

- Rear window defogger switch is OFF.

- Steering wheel is in the straight-ahead position, etc.

4. Start engine and warm it up until engine coolant temperature indicator points the middle of gauge.

Ensure engine stays below 1,000 rpm.

5. Run engine at about 2,000 rpm for about 2 minutes under no load.

6. Make sure that no DTC is displayed with CONSULT-III or GST.

OK or NG

OK >> GO TO 3.

NG >> GO TO 2.

2.REPAIR OR REPLACE

Repair or replace components as necessary according to corresponding Diagnostic Procedure.

>> GO TO 3.

3.CHECK TARGET IDLE SPEED

With CONSULT-III

1. Run engine at about 2,000 rpm for about 2 minutes under no load.

SEF983U

SEF976U

SEF977U

Revision: April 20092010 QX56

Page 1394 of 4210

![INFINITI QX56 2010 Factory Service Manual ON BOARD DIAGNOSTIC (OBD) SYSTEMEC-41

< FUNCTION DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

ON BOARD DIAGNOSTIC (OBD) SYSTEM

IntroductionINFOID:0000000005149074

The ECM has an on board diagn INFINITI QX56 2010 Factory Service Manual ON BOARD DIAGNOSTIC (OBD) SYSTEMEC-41

< FUNCTION DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

ON BOARD DIAGNOSTIC (OBD) SYSTEM

IntroductionINFOID:0000000005149074

The ECM has an on board diagn](/img/42/57032/w960_57032-1393.png)

ON BOARD DIAGNOSTIC (OBD) SYSTEMEC-41

< FUNCTION DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

ON BOARD DIAGNOSTIC (OBD) SYSTEM

IntroductionINFOID:0000000005149074

The ECM has an on board diagnostic system, which detects malfunctions related to engine sensors or actua-

tors. The ECM also records various emission-related diagnostic information including:

The above information can be checked using procedures listed in the table below.

×

: Applicable —: Not applicable

*: When DTC and 1st trip DTC simultaneously appear on the display, they cannot be clearly distinguished from each other.

The malfunction indicator lamp (MIL) on the instrument panel lights up when the same malfunction is detected

in two consecutive trips (Two trip detection logic) , or when the ECM enters fail-safe mode. (Refer to EC-456,

"Fail-Safe Chart".)

Two Trip Detection LogicINFOID:0000000005149075

When a malfunction is detected for the first time, 1st tr ip DTC and 1st trip Freeze Frame data are stored in the

ECM memory. The MIL will not light up at this stage. <1st trip>

If the same malfunction is detected again during the next drive, the DTC and Freeze Frame data are stored in

the ECM memory, and the MIL lights up. The MIL lights up at the same time when the DTC is stored. <2nd

trip> The “trip” in the “Two Trip Detection Logic” m eans a driving mode in which self-diagnosis is performed

during vehicle operation. Specific on board diagnostic item s will cause the ECM to light up or blink the MIL,

and store DTC and Freeze Frame data, even in the 1st trip, as shown below.

× : Applicable —: Not applicable

When there is an open circuit on MIL circuit, the ECM c annot warn the driver by lighting up MIL when there is

malfunction on engine control system.

Emission-related diagnostic information Diagnostic service

Diagnostic Trouble Code (DTC) Service $03 of SAE J1979

Freeze Frame data Service $02 of SAE J1979

System Readiness Test (SRT) code Service $01 of SAE J1979

1st Trip Diagnostic Trou ble Code (1st Trip DTC) Service $07 of SAE J1979

1st Trip Freeze Frame data

Test values and Test limits Service $06 of SAE J1979

Calibration ID Service $09 of SAE J1979

DTC 1st trip DTC Freeze

Frame data 1st trip Freeze

Frame data SRT code SRT status Test value

CONSULT-III ×× × × × × —

GST ×× × —×××

ECM ××*— — — ×—

Items MIL

DTC1st trip DTC

1st trip 2nd trip

1st trip

displaying 2nd trip

displaying 1st trip

displaying 2nd trip

display- ing

Blinking Lighting

up Blinking Lighting

up

Misfire (Possible three way catalyst

damage) — DTC: P0300 - P0308 is

being detected ×

———— — ×—

Misfire (Possible three way catalyst

damage) — DTC: P0300 - P0308 is

being detected ——

×—— ×——

One trip detection diagnoses (Re-

fer to EC-459, "

DTC Index".) —

×—— ×———

Except above — — —×— ×× —

Revision: April 20092010 QX56

Page 1408 of 4210

![INFINITI QX56 2010 Factory Service Manual ON BOARD DIAGNOSTIC (OBD) SYSTEMEC-55

< FUNCTION DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

4. Touch “ERASE”. (DTC in ECM will be erased.)

WITH GST

NOTE:

• If the ignition switch stay INFINITI QX56 2010 Factory Service Manual ON BOARD DIAGNOSTIC (OBD) SYSTEMEC-55

< FUNCTION DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

4. Touch “ERASE”. (DTC in ECM will be erased.)

WITH GST

NOTE:

• If the ignition switch stay](/img/42/57032/w960_57032-1407.png)

ON BOARD DIAGNOSTIC (OBD) SYSTEMEC-55

< FUNCTION DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

4. Touch “ERASE”. (DTC in ECM will be erased.)

WITH GST

NOTE:

• If the ignition switch stays ON after repair wo rk, be sure to turn ignition switch OFF once.

Wait at least 10 seconds and then tu rn it on (engine stopped) again.

1. Select Service $04 with GST (Generic Scan Tool).

No Tools

NOTE:

• If the ignition switch stays ON after repair wo rk, be sure to turn ignition switch OFF once.

Wait at least 10 seconds and then tu rn it on (engine stopped) again.

1. Erase DTC in ECM. Refer to How to Erase Diagnostic Test Mode II (Self-Diagnostic Results).

• If the battery is disconnected, the emission-relate d diagnostic information will be lost within 24

hours.

• The following data are cleared when the ECM memory is erased.

- Diagnostic trouble codes

- 1st trip diagnostic trouble codes

- Freeze frame data

- 1st trip freeze frame data

- System readiness test (SRT) codes

- Test values

Actual work procedures are explained using a DTC as an example. Be careful so that not only the DTC, but all

of the data listed above, are cleared from the ECM memory during work procedures.

Malfunction Indicator Lamp (MIL)INFOID:0000000005149077

DESCRIPTION

The MIL is located on the instrument panel.

1. The MIL will light up when the ignition switch is turned ON with- out the engine running. This is a bulb check.

If the MIL does not light up, refer to MWI-18

or see EC-41.

2. When the engine is start ed, the MIL should go off.

If the MIL remains on, the on board diagnostic system has

detected an engine system malfunction.

ON BOARD DIAGNOSTIC SYSTEM FUNCTION

The on board diagnostic system has the following three functions.

SEF217U

Revision: April 20092010 QX56

Page 1573 of 4210

![INFINITI QX56 2010 Factory Service Manual EC-220

< COMPONENT DIAGNOSIS >[VK56DE]

P0442 EVAP CONTROL SYSTEM

OK or NG

OK >> GO TO 3.

NG >> 1. Open fuel filler cap, then clean cap and

fuel filler neck threads using air blower.

2. Retighten unti INFINITI QX56 2010 Factory Service Manual EC-220

< COMPONENT DIAGNOSIS >[VK56DE]

P0442 EVAP CONTROL SYSTEM

OK or NG

OK >> GO TO 3.

NG >> 1. Open fuel filler cap, then clean cap and

fuel filler neck threads using air blower.

2. Retighten unti](/img/42/57032/w960_57032-1572.png)

EC-220

< COMPONENT DIAGNOSIS >[VK56DE]

P0442 EVAP CONTROL SYSTEM

OK or NG

OK >> GO TO 3.

NG >> 1. Open fuel filler cap, then clean cap and

fuel filler neck threads using air blower.

2. Retighten until ratcheting sound is heard.

3.CHECK FUEL FILLER CAP FUNCTION

Check for air releasing sound while opening the fuel filler cap.

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

4.CHECK FUEL TANK VACUUM RELIEF VALVE

Refer to EC-268, "

Component Inspection".

OK or NG

OK >> GO TO 5.

NG >> Replace fuel filler cap with a genuine one.

5.INSTALL THE PRESSURE PUMP

To locate the EVAP leak, install EVAP service port adapter (commer-

cial service tool) and pressure pump to EVAP service port securely.

NOTE:

Improper installation of the EV AP service port adapter to the

EVAP service port may cause leaking.

With CONSULT-III>>GO TO 6.

Without CONSULT-III>>GO TO 7.

6.CHECK FOR EVAP LEAK

With CONSULT-III

1. Turn ignition switch ON.

2. Select “EVAP SYSTEM CLOSE” of “WORK SUPPORT” mode with CONSULT-III.

3. Touch “START” and apply pressure into the EVAP line until the pressure indicator reaches the middle of the bar graph.

CAUTION:

• Never use compressed air or a high pressure pump.

• Do not exceed 4.12 kPa (0.042 kg/cm

2, 0.6 psi) of pressure in the system.

BBIA0366E

SEF916U

Revision: April 20092010 QX56

Page 1610 of 4210

![INFINITI QX56 2010 Factory Service Manual P0455 EVAP CONTROL SYSTEMEC-257

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

To locate the EVAP leak, install EVAP service port adapter and pres-

sure pump to EVAP service port sec INFINITI QX56 2010 Factory Service Manual P0455 EVAP CONTROL SYSTEMEC-257

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

To locate the EVAP leak, install EVAP service port adapter and pres-

sure pump to EVAP service port sec](/img/42/57032/w960_57032-1609.png)

P0455 EVAP CONTROL SYSTEMEC-257

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

To locate the EVAP leak, install EVAP service port adapter and pres-

sure pump to EVAP service port securely.

NOTE:

Improper installation of the EV

AP service port adapter to the

EVAP service port may cause leaking.

With CONSULT-III>>GO TO 9.

Without CONSULT-III>>GO TO 10.

9.CHECK FOR EVAP LEAK

With CONSULT-II I

1. Turn ignition switch ON.

2. Select “EVAP SYSTEM CLOSE” of “WORK SUPPORT” mode with CONSULT-III.

3. Touch “START” and apply pressure into the EVAP line until the pressure indicator reaches the middle of the bar graph.

CAUTION:

• Do not use compressed air or a high pressure pump.

• Do not exceed 4.12 kPa (0.042 kg/cm

2, 0.6 psi) of pressure in the system.

4. Using EVAP leak detector, locate the EVAP leak. For the leak detector, refer to the instruction manual for more details.

Refer to EC-37, "

Description".

OK or NG

OK >> GO TO 11.

NG >> Repair or replace.

10.CHECK FOR EVAP LEAK

Without CONSULT-III

1. Turn ignition switch OFF.

BBIA0366E

SEF916U

SEF200U

Revision: April 20092010 QX56

Page 1617 of 4210

![INFINITI QX56 2010 Factory Service Manual EC-264

< COMPONENT DIAGNOSIS >[VK56DE]

P0456 EVAP CONTROL SYSTEM

3.CHECK FUEL FILLER CAP FUNCTION

Check for air releasing sound while opening the fuel filler cap.

OK or NG

OK >> GO TO 5.

NG >> GO TO 4 INFINITI QX56 2010 Factory Service Manual EC-264

< COMPONENT DIAGNOSIS >[VK56DE]

P0456 EVAP CONTROL SYSTEM

3.CHECK FUEL FILLER CAP FUNCTION

Check for air releasing sound while opening the fuel filler cap.

OK or NG

OK >> GO TO 5.

NG >> GO TO 4](/img/42/57032/w960_57032-1616.png)

EC-264

< COMPONENT DIAGNOSIS >[VK56DE]

P0456 EVAP CONTROL SYSTEM

3.CHECK FUEL FILLER CAP FUNCTION

Check for air releasing sound while opening the fuel filler cap.

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

4.CHECK FUEL TANK VACUUM RELIEF VALVE

Refer to EC-268, "

Component Inspection".

OK or NG

OK >> GO TO 5.

NG >> Replace fuel filler cap with a genuine one.

5.INSTALL THE PRESSURE PUMP

To locate the EVAP leak, install EVAP service port adapter and pres-

sure pump to EVAP service port securely.

NOTE:

Improper installation of the EV AP service port adapter to the

EVAP service port may cause leaking.

With CONSULT-III>>GO TO 6.

Without CONSULT-III>>GO TO 7.

6.CHECK FOR EVAP LEAK

With CONSULT-III

1. Turn ignition switch ON.

2. Select “EVAP SYSTEM CLOSE” of “WORK SUPPORT” mode with CONSULT-III.

3. Touch “START” and apply pressure into the EVAP line until the pressure indicator reaches the middle of

the bar graph.

CAUTION:

• Do not use compressed air or a high pressure pump.

• Do not exceed 4.12 kPa (0.042 kg/cm

2, 0.6 psi) of pressure in the system.

BBIA0366E

SEF916U

Revision: April 20092010 QX56