wiring INFINITI QX56 2010 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 10 of 4210

ACC-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005266449

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005266450

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: April 20092010 QX56

Page 17 of 4210

ADP-3

C

DE

F

G H

I

K L

M A

B

ADP

N

O P

RECLINING SENSOR .................................... ....83

Description .......................................................... ....83

Component Function Check ..................................83

Diagnosis Procedure ..............................................83

LIFTING SENSOR (FRONT) ..............................85

Description .......................................................... ....85

Component Function Check ..................................85

Diagnosis Procedure ..............................................85

LIFTING SENSOR (REAR) ................................87

Description .......................................................... ....87

Component Function Check ..................................87

Diagnosis Procedure ..............................................87

TILT SENSOR ....................................................89

Description ..............................................................89

Component Function Check ..................................89

Diagnosis Procedure ..............................................89

PEDAL ADJUSTING SENSOR ..........................91

Description .......................................................... ....91

Component Function Check ..................................91

Diagnosis Procedure ..............................................91

MIRROR SENSOR .............................................93

DRIVER SIDE ........................................................ ....93

DRIVER SIDE : Description ....................................93

DRIVER SIDE : Component Function Check ........93

DRIVER SIDE : Diagnosis Procedure ....................93

PASSENGER SIDE ...................................................95

PASSENGER SIDE : Description ....................... ....95

PASSENGER SIDE :

Component Function Check ..................................

95

PASSENGER SIDE : Diagnosis Procedure ...........95

SLIDING MOTOR ...............................................97

Description ..............................................................97

Component Function Check ..................................97

Diagnosis Procedure ..............................................97

RECLINING MOTOR ..........................................99

Description .......................................................... ....99

Component Function Check ..................................99

Diagnosis Procedure ..............................................99

LIFTING MOTOR (FRONT) ..............................101

Description .......................................................... ..101

Component Function Check ................................101

Diagnosis Procedure ............................................101

LIFTING MOTOR (REAR) ................................103

Description .......................................................... ..103

Component Function Check ................................103

Diagnosis Procedure ............................................103

TILT MOTOR ....................................................105

Description .......................................................... ..105

Component Function Check ................................105

Diagnosis Procedure ............................................105

PEDAL ADJUSTING MOTOR ........................107

Description ........................................................... ..107

Component Function Check ................................107

Diagnosis Procedure ............................................107

DOOR MIRROR MOTOR ................................109

Description .............................................................109

Component Function Check ..................................109

Diagnosis Procedure .............................................109

Component Inspection ...........................................111

SEAT MEMORY INDICATOR LAMP ..............112

Description .............................................................112

Component Function Check ................................112

Diagnosis Procedure ............................................112

Component Inspection ...........................................113

ECU DIAGNOSIS .......................................114

DRIVER SEAT CONTROL UNIT ....................114

Reference Value .................................................. ..114

Wiring Diagram ......................................................119

Fail Safe ................................................................133

DTC Index .............................................................134

AUTOMATIC DRIVE POSITIONER CON-

TROL UNIT ......................................................

135

Reference Value ....................................................135

Wiring Diagram ......................................................138

BCM (BODY CONTROL MODULE) ...............153

Reference Value ....................................................153

Terminal Layout .....................................................156

Physical Values ................................................... ..156

Wiring Diagram ......................................................162

Fail Safe ................................................................166

DTC Inspection Priority Chart .............................167

DTC Index .............................................................167

SYMPTOM DIAGNOSIS ............................169

ADP SYSTEM SYMPTOMS ............................169

Symptom Table ................................................... ..169

NORMAL OPERATING CONDITION .............171

Description .............................................................171

PRECAUTION ............................................172

PRECAUTIONS ...............................................172

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ..

172

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect .................................

172

Precaution for Work ...............................................173

ON-VEHICLE REPAIR ...............................174

DRIVER SEAT CONTROL UNIT ....................174

Removal and Installation ..................................... ..174

Revision: April 20092010 QX56

Page 22 of 4210

ADP-8

< BASIC INSPECTION >

INSPECTION AND ADJUSTMENT

INSPECTION AND ADJUSTMENT

Preliminary CheckINFOID:0000000005147422

1. FOREIGN OBJECTS

Check the following:

• objects on or behind the seats that could cause binding

• objects under the seats that may be interfering with the seat’s moving parts

• objects under pedals that may interfere with movement

Are there any foreign objects that could be causing interference?

YES >> Remove objects.

NO >> GO TO 2

2. WIRING CONNECTIONS

1. Disconnect harness connectors.

2. Check terminals for damage or loose connections.

3. Reconnect harness connectors.

Are any connectors damaged or loose?

YES >> Repair or replace damaged parts.

NO >> GO TO 3

3. POWER AND GROUND

Check power supply and ground circuits for control unit. Refer to ADP-47, "

DRIVER SEAT CONTROL UNIT :

DiagnosisProcedure".

Is the inspection result normal?

YES >> Refer to ADP-134, "DTCIndex".

NO >> Repair or replace as necessary.

Special Repair RequirementINFOID:0000000005147423

Refer to Owner’s Manual for Automatic Driv e Positioner system operating instructions.

Revision: April 20092010 QX56

Page 50 of 4210

ADP-36

< COMPONENT DIAGNOSIS >

B2117 ADJ PEDAL MOTOR

B2117 ADJ PEDAL MOTOR

DescriptionINFOID:0000000005147462

• The pedal adjusting motor is installed to the pedal assembly.

• The pedal adjusting motor is activated with the automatic drive positioner control unit.

• The pedal assembly is adjusted forward/backward by changing the rotation direction of pedal adjustingmotor.

DTC LogicINFOID:0000000005147463

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1. STEP 1

Turn ignition switch ON.

>> GO TO 2

2. STEP 2

Check “Self diagnostic result” with CONSULT-III.

Is the DTC detected?

YES >> Perform diagnosis procedure. Refer to ADP-36, "DiagnosisProcedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000005147464

Regarding Wiring Diagram information, refer to ADP-138, "Wiring Diagram".

1. CHECK PEDAL ADJUSTING MECHANISM

Check the following.

• Operation malfunction caused by pedal adjusting mechanism deformation or pinched harness or other for- eign materials

• Operation malfunction and interference wit h other parts by poor installation

Is the inspection result normal?

YES >> GO TO 2

NO >> Repair or replace the malfunctioning part and check again.

2. CHECK FUNCTION

1. Turn ignition switch ON.

2. Check “ADJ PEDAL MOTOR” in "Active test" mode with CONSULT-III.

Is the inspection result normal?

YES >> Pedal adjusting motor circuit is OK.

DTC No. Trouble diagnosis

name DTC detecting condition

Possible cause

B2117 ADJ PEDAL MOTOR When any manual or automatic operations are not

performed, if motor operation is detected for 0.1

second or more, status is judged "Output error". • Harness and connectors

(pedal adjusting motor circuit is

opened/shorted, pedal adjusting

motor power supp ly circuit is

opened/shorted.)

• Pedal adjusting motor

Test item Description

ADJ PEDAL MOTOR The pedal adjusting motor is activated by receiving the drive signal.

Revision: April 20092010 QX56

Page 52 of 4210

ADP-38

< COMPONENT DIAGNOSIS >

B2118 TILT SENSOR

B2118 TILT SENSOR

DescriptionINFOID:0000000005147465

• The tilt sensor is installed to the steering column assembly.

• The resistance of tilt sensor is changed according to the up/down position of steering column.

• The terminal voltage of automatic drive positioner control unit will be changed according to a change of tiltsensor resistance. Automatic drive positioner control unit calculates the tilt position from the voltage.

DTC LogicINFOID:0000000005147466

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1. STEP 1

Turn ignition switch ON.

>> GO TO 2

2. STEP 2

Check “Self diagnostic result” with CONSULT-III.

Is the DTC detected?

YES >> Perform diagnosis procedure. Refer to ADP-38, "DiagnosisProcedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000005147467

Regarding Wiring Diagram information, refer to ADP-138, "Wiring Diagram".

1. CHECK TILT SENSOR SIGNAL

1. Turn ignition switch ON.

2. Select “TILT SEN” in “Data m onitor” mode with CONSULT-III.

3. Check tilt sensor signal under the following condition.

Is the value normal?

YES >> GO TO 4

NO >> GO TO 2

2. CHECK FUNCTION

DTC No. Trouble diagnosis

name DTC detecting condition

Possible cause

B2118 TILT SENSOR The input voltage of tilt sensor is 0.1V or less or 4.9V

or more. • Harness and connectors

(Tilt sensor circuit is opened/

shorted, tilt sensor power supply

circuit is opened/shorted.)

• Tilt sensor

Monitor item Condition Value

TILT SEN Tilt position To p

2 V

Bottom 4 V

Revision: April 20092010 QX56

Page 54 of 4210

ADP-40

< COMPONENT DIAGNOSIS >

B2120 ADJ PEDAL SENSOR

B2120 ADJ PEDAL SENSOR

DescriptionINFOID:0000000005147468

• The pedal adjusting sensor is installed in the pedal assembly.

• The resistance of pedal adjusting sensor is changed according to the forward/backward position of pedalassembly.

• The terminal voltage of automatic drive positioner control unit will be changed according to a change of pedal adjusting sensor resistance. Automatic drive pos itioner control unit calculates the pedal assembly

position from the voltage.

DTC LogicINFOID:0000000005147469

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1. STEP 1

Turn ignition switch ON.

>> GO TO 2

2. STEP 2

Check “Self diagnostic result” with CONSULT-III.

Is the DTC is detected?

YES >> Perform diagnosis procedure. Refer to ADP-40, "DiagnosisProcedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000005147470

Regarding Wiring Diagram information, refer to ADP-138, "Wiring Diagram".

1. CHECK PEDAL ADJUSTING SENSOR SIGNAL

1. Turn ignition switch ON.

2. Select “PEDAL SEN” in “Dat a monitor” mode with CONSULT-III.

3. Check the pedal adjusting sensor signal under the following condition.

Is the value normal?

YES >> Pedal adjusting circuit is OK.

NO >> GO TO 2

2. CHECK PEDAL ADJUSTING SENSO R CIRCUIT HARNESS CONTINUITY

DTC No.Trouble diagnosis

name DTC detecting condition

Possible cause

B2120 ADJ PEDAL SENSOR The input voltage of pedal adjusting sensor is 0.5V

or less or 4.5V or higher, for 0.5 seconds or more. • Harness and connectors

(Pedal adjusting sensor circuit is

opened/shorted, pedal adjusting

sensor power supply circuit is

opened/shorted.)

• Pedal adjusting sensor

Monitor item Condition Value

PEDAL SEN Pedal position Forward

0.5V

Backward 4.5V

Revision: April 20092010 QX56

Page 56 of 4210

ADP-42

< COMPONENT DIAGNOSIS >

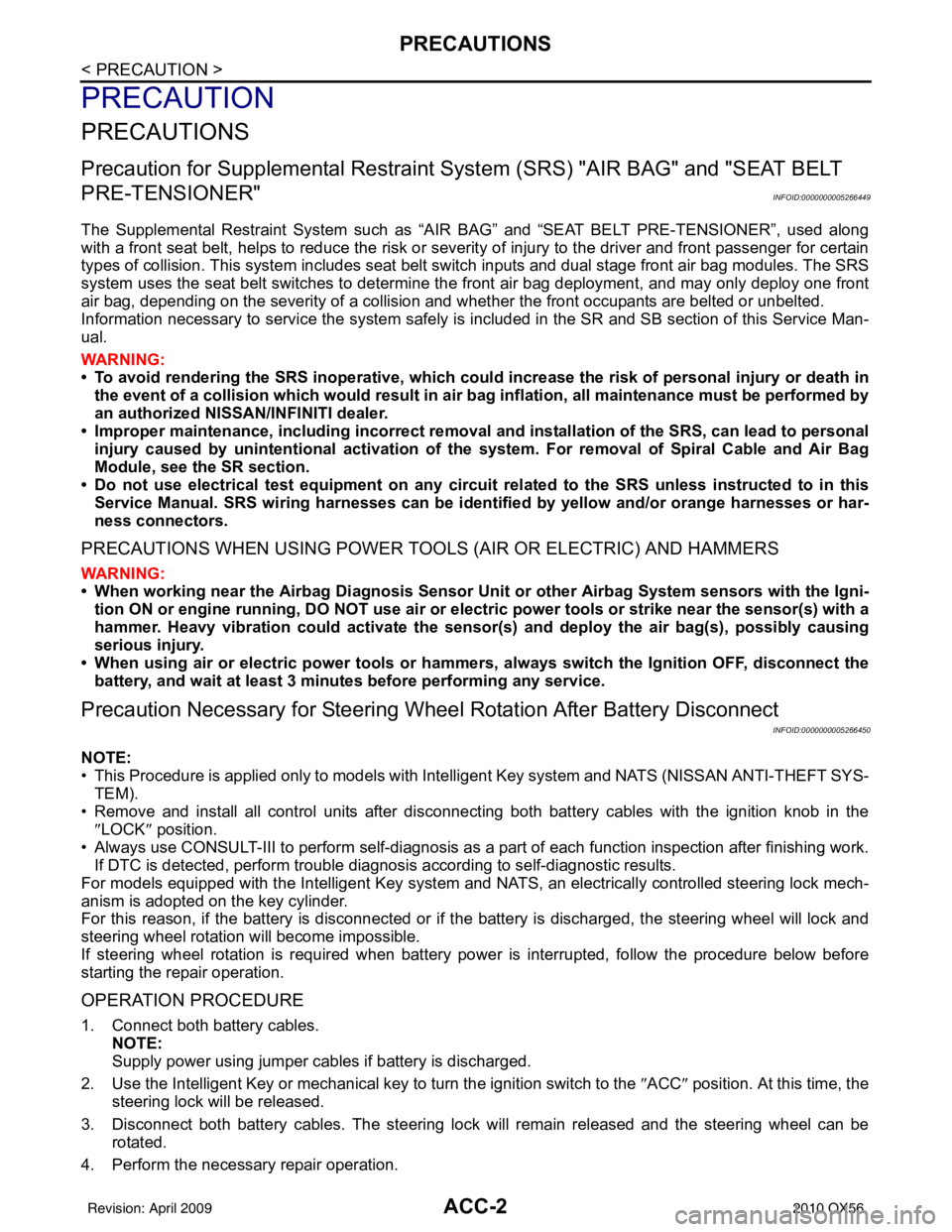

B2126 DETENT SW

B2126 DETENT SW

DescriptionINFOID:0000000005147471

• Park position switch is installed on A/T shift selector. It is turned OFF when the A/T selector lever is in P

position.

• The driver seat control unit judges that the A/T selector le ver is in P position if continuity does not exist in this

circuit.

DTC LogicINFOID:0000000005147472

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1. STEP 1

Drive the vehicle at 7 ±4km/h or more.

>> GO TO 2

2. STEP 2

Check “Self diagnostic result” with CONSULT-III.

Is the DTC detected?

YES >> Perform diagnosis procedure. Refer to ADP-42, "DiagnosisProcedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000005147473

Regarding Wiring Diagram information, refer to ADP-119, "Wiring Diagram".

1. CHECK DTC

Check “Self diagnostic result” for BCM with CONSULT-lll.

Are other DTCs detected?

YES >> Check the DTC.

NO >> GO TO 2

2. CHECK DETENTION SWITCH SIGNAL

1. Turn ignition switch ON.

2. Select “DETENT SW” in “Data Monitor” mode with CONSULT-lll.

3. Check detention switch signal under the following condition.

Is the status normal?

YES >> A/T shift selector (park position switch) circuit is OK.

DTC No. Trouble diagnosis

name DTC detecting condition

Possible cause

B2126 DETENT SW A/T selector lever is in P position and the vehicle

speed of 7

±4km/h is detected. • Harness and connectors

(Park position switch circuit is

opened/shorted.)

• Park position switch

• Combination meter (CAN communication )

Monitor item ConditionStatus

DETENT SW A/T selector lever P position

OFF

Other than above ON

Revision: April 20092010 QX56

Page 58 of 4210

ADP-44

< COMPONENT DIAGNOSIS >

B2128 UART COMMUNICATION LINE

B2128 UART COMMUNICATION LINE

DescriptionINFOID:0000000005147474

Driver seat control unit performs UART communication with the automatic drive positioner control unit using 2

communication lines, TX and RX line. Driver seat cont rol unit receives the operation signals of pedal adjusting

switch, door mirror remote control switch, set switch and memory switch and the position signals of adjustable

pedal sensor and door mirror sensor from the automatic drive positioner control unit and transmits the opera-

tion request signal.

DTC LogicINFOID:0000000005147475

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1. STEP 1

Turn ignition switch ON.

>> GO TO 2

2. STEP 2

Operate pedal adjusting switch for more than 2 seconds.

>> GO TO 3

3. PROCEDURE 3

Check “Self diagnostic result” with CONSULT-III.

Is the DTC detected?

YES >> Perform diagnosis procedure. Refer to ADP-44, "DiagnosisProcedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000005147476

Regarding Wiring Diagram information, refer to ADP-119, "Wiring Diagram".

1. CHECK UART COMMUNICATION LINE CONTINUITY

1. Turn ignition switch OFF.

2. Disconnect driver seat contro l unit and automatic drive posi-

tioner control unit.

3. Check continuity between driver seat control unit harness con- nector and automatic drive positioner control unit harness con-

nector.

DTC No. Trouble diagnosis name DTC detecting conditionPossible cause

B2128 UART COMM The communication between driver seat control unit

and automatic drive positioner control unit is interrupt-

ed for a period of time. • UART communication line

(UART communication line is

open or shorted)

• Driver seat control unit

• Automatic drive positioner control unit

Driver seat control unit connector Te r m i n a lAutomatic drive positioner

control unit connector Terminal Continuity

PIIA4598E

Revision: April 20092010 QX56

Page 60 of 4210

ADP-46

< COMPONENT DIAGNOSIS >

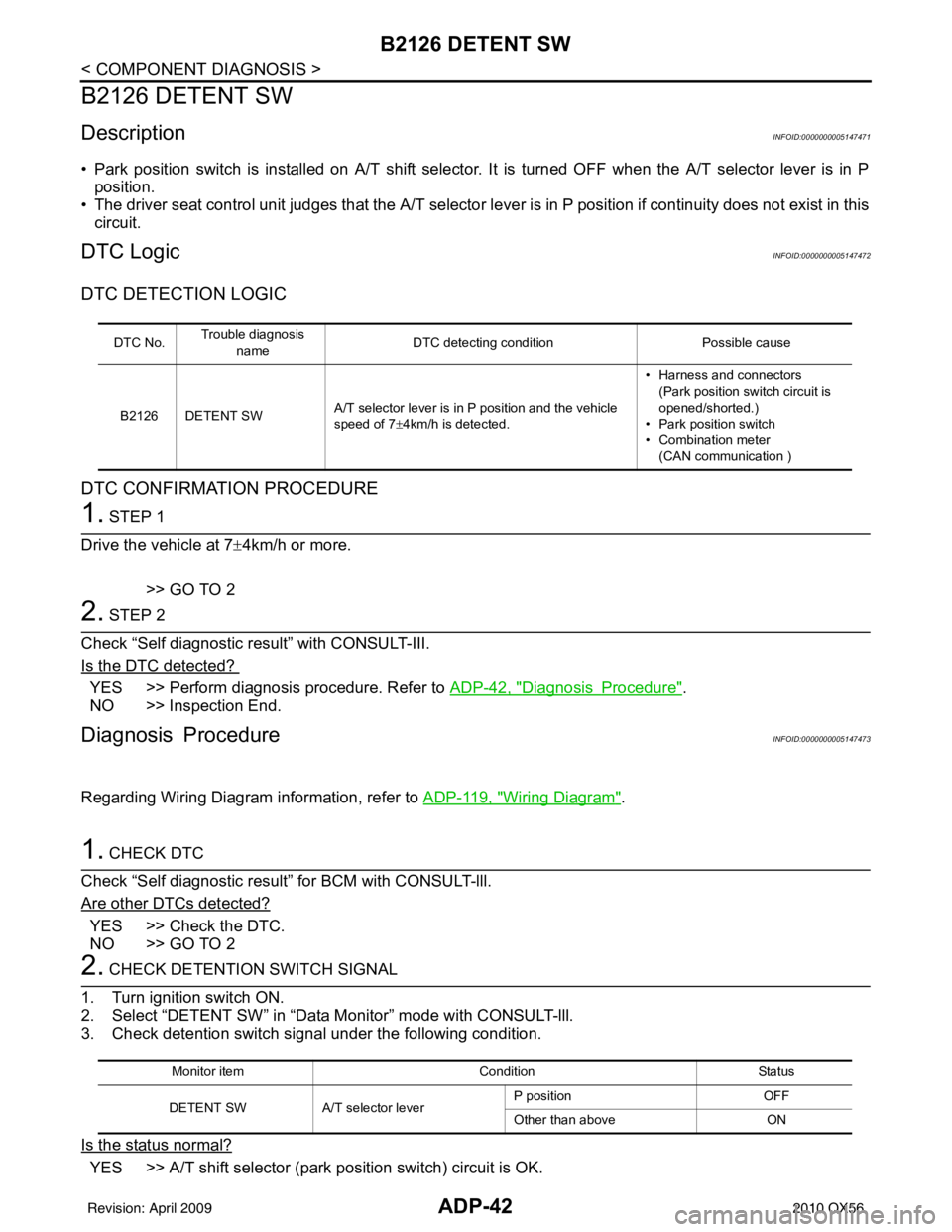

POWER SUPPLY AND GROUND CIRCUIT

POWER SUPPLY AND GROUND CIRCUIT

BCM

BCM : Diagnosis ProcedureINFOID:0000000005370325

Regarding Wiring Diagram information, refer to BCS-49, "Wiring Diagram".

1. CHECK FUSES AND FUSIBLE LINK

Check that the following fuses and fusible link are not blown.

Is the fuse blown?

YES >> Replace the blown fuse or fusible link after repairing the affected circuit.

NO >> GO TO 2

2. CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM.

3. Check voltage between BCM harness connector and ground.

Is the measurement value normal?

YES >> GO TO 3

NO >> Repair or replace harness.

3. CHECK GROUND CIRCUIT

Terminal No. Signal nameFuses and fusible link No.

57 Battery power supply 22 (15A)

70 F (50A)

11 Ignition ACC or ON 4 (10A)

38 Ignition ON or START 59 (10A)

ConnectorTe r m i n a l s

Power

source Condition

Voltage (V) (Ap-

prox.)

(+) (-)

M18 11 Ground

ACC

power

supply Ignition

switch

ACC or ON Battery voltage

38 Ground Ignition

power

supply Ignition

switch ON or START Battery voltage

M20 57 Ground

Battery

power

supply Ignition

switch

OFF Battery voltage

70 Ground Battery

power

supply Ignition

switch OFF Battery voltage

LIIA2415E

Revision: April 20092010 QX56

Page 61 of 4210

POWER SUPPLY AND GROUND CIRCUITADP-47

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

ADP

N

O P

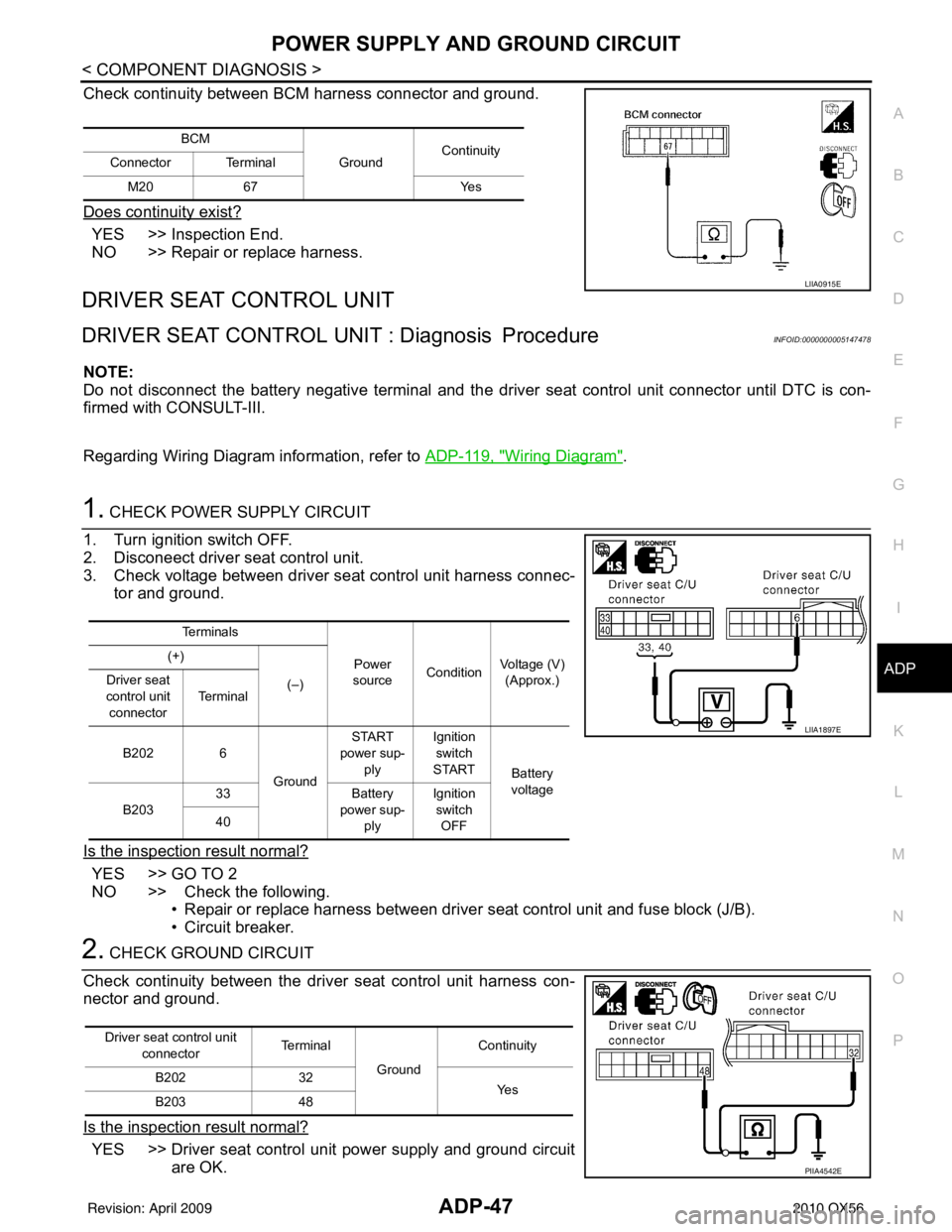

Check continuity between BCM harness connector and ground.

Does continuity exist?

YES >> Inspection End.

NO >> Repair or replace harness.

DRIVER SEAT CONTROL UNIT

DRIVER SEAT CONTROL UNIT : Diagnosis ProcedureINFOID:0000000005147478

NOTE:

Do not disconnect the battery negative terminal and the dr iver seat control unit connector until DTC is con-

firmed with CONSULT-III.

Regarding Wiring Diagram information, refer to ADP-119, "

Wiring Diagram".

1. CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconeect driver seat control unit.

3. Check voltage between driver s eat control unit harness connec-

tor and ground.

Is the inspection result normal?

YES >> GO TO 2

NO >> Check the following. • Repair or replace harness between driver seat control unit and fuse block (J/B).

• Circuit breaker.

2. CHECK GROUND CIRCUIT

Check continuity between the driv er seat control unit harness con-

nector and ground.

Is the inspection result normal?

YES >> Driver seat control unit power supply and ground circuit are OK.

BCM

GroundContinuity

Connector Terminal

M20 67 Yes

LIIA0915E

Te r m i n a l s

Power

source ConditionVoltage (V)

(Approx.)

(+)

(–)

Driver seat

control unit connector Terminal

B202 6

Ground START

power sup- ply Ignition

switch

START Battery

voltage

B203 33

Battery

power sup-

ply Ignition

switch

OFF

40

LIIA1897E

Driver seat control unit

connector Te r m i n a l

Ground Continuity

B202 32

Ye s

B203 48

PIIA4542E

Revision: April 20092010 QX56