wheel alignment INFINITI QX56 2010 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 5 of 4210

QUICK REFERENCE CHART: QX56

2010

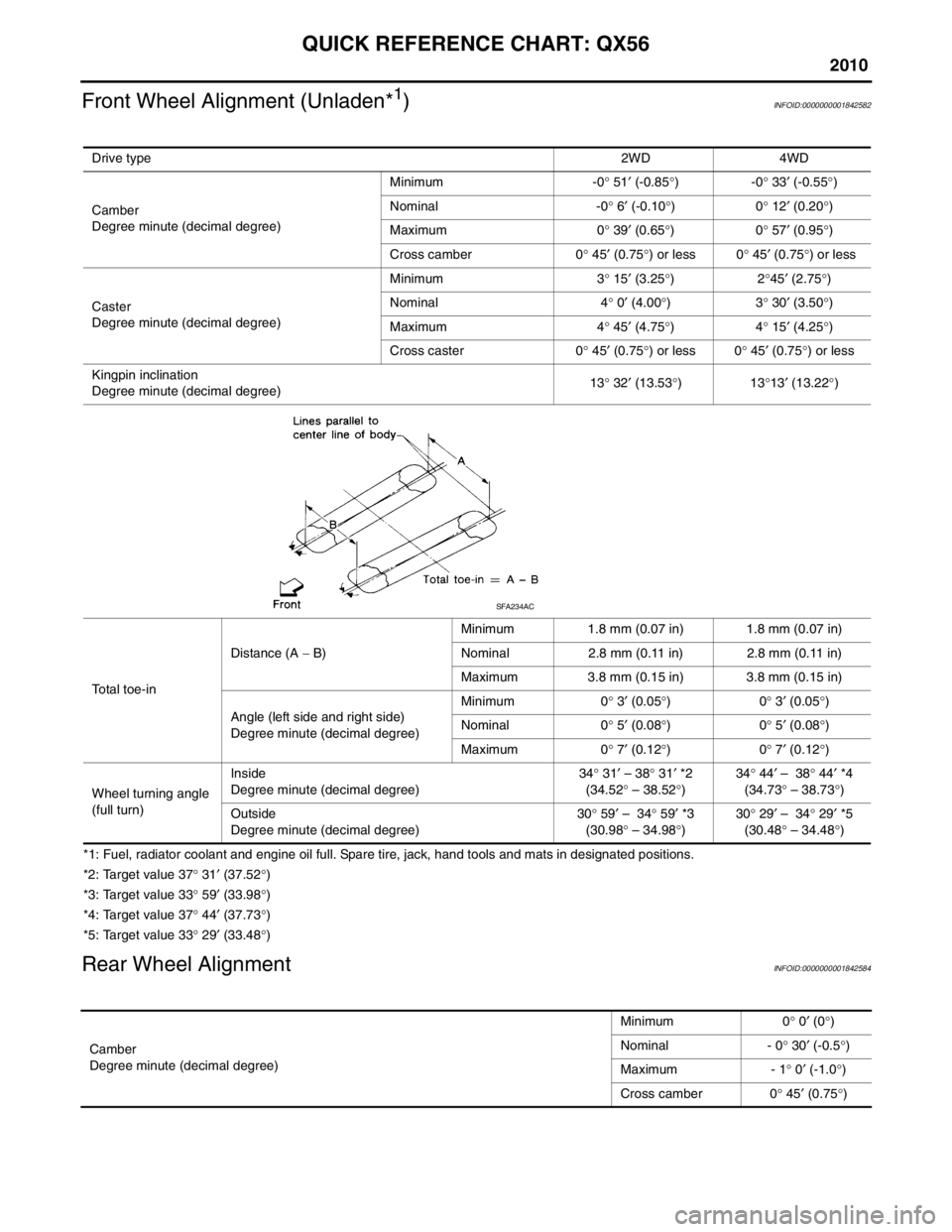

Front Wheel Alignment (Unladen*1)INFOID:0000000001842582

*1: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

*2: Target value 37° 31 ′ (37.52 °)

*3: Target value 33 ° 59 ′ (33.98 °)

*4: Target value 37 ° 44 ′ (37.73 °)

*5: Target value 33 ° 29 ′ (33.48 °)

Rear Wheel AlignmentINFOID:0000000001842584

Drive type 2WD 4WD

Camber

Degree minute (decimal degree) Minimum -0

° 51 ′ (-0.85 °)-0 ° 33 ′ (-0.55 °)

Nominal -0 ° 6 ′ (-0.10 °)0 ° 12 ′ (0.20 °)

Maximum 0 ° 39 ′ (0.65 °)0 ° 57 ′ (0.95 °)

Cross camber 0 ° 45 ′ (0.75 °) or less 0 ° 45 ′ (0.75 °) or less

Caster

Degree minute (decimal degree) Minimum 3

° 15 ′ (3.25 °)2 °45 ′ (2.75 °)

Nominal 4 ° 0 ′ (4.00 °)3 ° 30 ′ (3.50 °)

Maximum 4 ° 45 ′ (4.75 °)4 ° 15 ′ (4.25 °)

Cross caster 0 ° 45 ′

(0.75 °) or less 0 ° 45 ′ (0.75 °) or less

Kingpin inclination

Degree minute (decimal degree) 13

° 32 ′ (13.53 °)13 °13 ′ (13.22 °)

Total toe-in Distance (A

− B) Minimum 1.8 mm (0.07 in) 1.8 mm (0.07 in)

Nominal 2.8 mm (0.11 in) 2.8 mm (0.11 in)

Maximum 3.8 mm (0.15 in) 3.8 mm (0.15 in)

Angle (left side and right side)

Degree minute (decimal degree) Minimum 0

° 3 ′ (0.05 °)0 ° 3 ′ (0.05 °)

Nominal 0 ° 5 ′ (0.08 °)0 ° 5 ′ (0.08 °)

Maximum 0 ° 7 ′ (0.12 °)0 ° 7 ′ (0.12 °)

Wheel turning angle

(full turn) Inside

Degree minute (decimal degree)

34

° 31 ′ – 38 ° 31 ′ *2

(34.52 ° – 38.52 °) 34

° 44 ′ – 38 ° 44 ′ *4

(34.73 ° – 38.73

° )

Outside

Degree minute (decimal degree) 30

° 59 ′ – 34 ° 59 ′ *3

(30.98 ° – 34.98 °) 30

° 29 ′ – 34 ° 29 ′ *5

(30.48 ° – 34.48 °)

SFA234AC

Camber

Degree minute (decimal degree) Minimum 0

° 0 ′ (0 °)

Nominal - 0 ° 30 ′ (-0.5 °)

Maximum - 1 ° 0 ′ (-1.0 °)

Cross camber 0 ° 45 ′ (0.75 °)

Page 500 of 4210

![INFINITI QX56 2010 Factory Service Manual BRC-8

< BASIC INSPECTION >[VDC/TCS/ABS]

INSPECTION AND ADJUSTMENT

INSPECTION AND ADJUSTMENT

ADDITIONAL SERVICE WHEN

REPLACING CONTROL UNIT

ADDITIONAL SERVICE WHEN REPL ACING CONTROL UNIT : Descriptio INFINITI QX56 2010 Factory Service Manual BRC-8

< BASIC INSPECTION >[VDC/TCS/ABS]

INSPECTION AND ADJUSTMENT

INSPECTION AND ADJUSTMENT

ADDITIONAL SERVICE WHEN

REPLACING CONTROL UNIT

ADDITIONAL SERVICE WHEN REPL ACING CONTROL UNIT : Descriptio](/img/42/57032/w960_57032-499.png)

BRC-8

< BASIC INSPECTION >[VDC/TCS/ABS]

INSPECTION AND ADJUSTMENT

INSPECTION AND ADJUSTMENT

ADDITIONAL SERVICE WHEN

REPLACING CONTROL UNIT

ADDITIONAL SERVICE WHEN REPL ACING CONTROL UNIT : Description

INFOID:0000000005147940

After replacing the ABS actuator and electric unit (control unit), perform the following procedures:

• Neutral position adjustment for the steering angle sensor

• Calibration of the decel G sensor

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Special Repair Re-

quirement

INFOID:0000000005147941

1.PERFORM THE NEUTRAL POSITION ADJUST MENT FOR THE STEERING ANGLE SENSOR

Perform the neutral position adjustm ent for the steering angle sensor.

>> Refer to BRC-8, "

ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL POSITION : Spe-

cial Repair Requirement", GO TO 2

2.PERFORM CALIBRATION OF THE DECEL G SENSOR

Perform calibration of the decel G sensor.

>> Refer to BRC-9, "

CALIBRATION OF DECEL G SENSOR : Special Repair Requirement".

ADJUSTMENT OF STEERING ANGL E SENSOR NEUTRAL POSITION

ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL POSITION : Description

INFOID:0000000005147942

Refer to the table below to determine if adjustment of steering angle sensor neutral position is required.

×: Required –: Not required

ADJUSTMENT OF STEERING ANGLE SENS OR NEUTRAL POSITION : Special Re-

pair Requirement

INFOID:0000000005147943

ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL POSITION

CAUTION:

To adjust neutral position of steering angl e sensor, make sure to use CONSULT-III

(Adjustment cannot be done without CONSULT-III)

1.ALIGN THE VEHICLE STATUS

Stop vehicle with front wheels in straight-ahead position.

Situation Adjustment of steering angle sensor neutral position

Removing/Installing ABS actuator and electric unit (control unit) —

Replacing ABS actuator and electric unit (control unit) ×

Removing/Installing steering angle sensor ×

Replacing steering angle sensor ×

Removing/Installing steering components ×

Replacing steering components ×

Removing/Installing suspension components ×

Replacing suspension components ×

Change tires to new ones —

Tire rotation —

Adjusting wheel alignment ×

Battery disconnection ×

Revision: April 20092010 QX56

Page 501 of 4210

![INFINITI QX56 2010 Factory Service Manual INSPECTION AND ADJUSTMENTBRC-9

< BASIC INSPECTION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

>> GO TO 2

2.PERFORM THE NEUTRAL POSITION ADJUST MENT FOR THE STEERING ANGLE SENSOR

1. On the CONSUL INFINITI QX56 2010 Factory Service Manual INSPECTION AND ADJUSTMENTBRC-9

< BASIC INSPECTION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

>> GO TO 2

2.PERFORM THE NEUTRAL POSITION ADJUST MENT FOR THE STEERING ANGLE SENSOR

1. On the CONSUL](/img/42/57032/w960_57032-500.png)

INSPECTION AND ADJUSTMENTBRC-9

< BASIC INSPECTION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

>> GO TO 2

2.PERFORM THE NEUTRAL POSITION ADJUST MENT FOR THE STEERING ANGLE SENSOR

1. On the CONSULT-III screen, touch “WORK SUPP ORT” and “ST ANG SEN ADJUSTMENT” in order.

2. Touch “START”. CAUTION:

Do not touch steering wheel whil e adjusting steering angle sensor.

3. After approximately 10 seconds, touch “END”. NOTE:

After approximately 60 seconds, it ends automatically.

4. Turn ignition switch OFF, then turn it ON again. CAUTION:

Be sure to perform above operation.

>> GO TO 3

3.CHECK DATA MONITOR

1. Run vehicle with front wheels in straight-ahead position, then stop.

2. Select “DATA MONITOR”. Then make sure “STR ANGLE SIG” is within 0 ±2.5 °.

Is the steering angle within the specified range?

YES >> GO TO 4

NO >> Perform the neutral position adjustment fo r the steering angle sensor again, GO TO 1

4.ERASE THE SELF-DIAGNOSIS MEMORY

Erase the self-diagnosis memory of the ABS ac tuator and electric unit (control unit) and ECM.

• ABS actuator and electric unit (control unit): Refer to BRC-23, "

CONSULT-III Function (ABS)".

• ECM: Refer to EC-63, "

CONSULT-III Function (ENGINE)".

Are the memories erased?

YES >> Inspection End

NO >> Check the items indica ted by the self-diagnosis.

CALIBRATION OF DECEL G SENSOR

CALIBRATION OF DECEL G SENSOR : DescriptionINFOID:0000000005147944

Refer to the table below to determine if calibration of the decel G sensor is required.

×: Required –: Not required

CALIBRATION OF DECEL G SENSOR : Special Repair RequirementINFOID:0000000005147945

CALIBRATION OF DECEL G SENSOR

CAUTION:

To calibrate the decel G sensor, make sure to use CONSULT-III

Situation Calibration of decel G sensor

Removing/Insta lling ABS actuator and electr ic unit (control unit) —

Replacing ABS actuator and elec tric unit (control unit) ×

Removing/Installing steering angle sensor ×

Replacing steering angle sensor ×

Removing/Installing steering components ×

Replacing steering components ×

Removing/Installing suspension components ×

Replacing suspension components ×

Change tires to new ones —

Tire rotation —

Adjusting wheel alignment ×

Revision: April 20092010 QX56

Page 612 of 4210

BRM-1

BODY EXTERIOR, DOORS, ROOF & VEHICLE SECURITY

C

DE

F

G H

I

J

L

M

SECTION BRM

A

B

BRM

N

O P

CONTENTS

BODY REPAIR

PRECAUTION ....... ........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

Handling Precaution For Plastics ..............................3

SERVICE INFORMATION ............................6

BODY REPAIR ...................................................6

Body Mounting ..................................................... .....6

Body Exterior Paint Color .........................................7

Body Component Parts ............................................8

Corrosion Protection ................................................13

Body Sealing ...........................................................16

Body Construction ...................................................20

Body Alignment .......................................................20

Handling Precaution for Plastics ..............................35

Precaution in Repairing High Strength Steel ...........38

Foam Repair ............................................................40

Replacement Operation ...........................................41

Revision: April 20092010 QX56

Page 2173 of 4210

WHEEL HUBFAX-7

< REMOVAL AND INSTALLATION >

CEF

G H

I

J

K L

M A

B

FA X

N

O P

REMOVAL AND INSTALLATION

WHEEL HUB

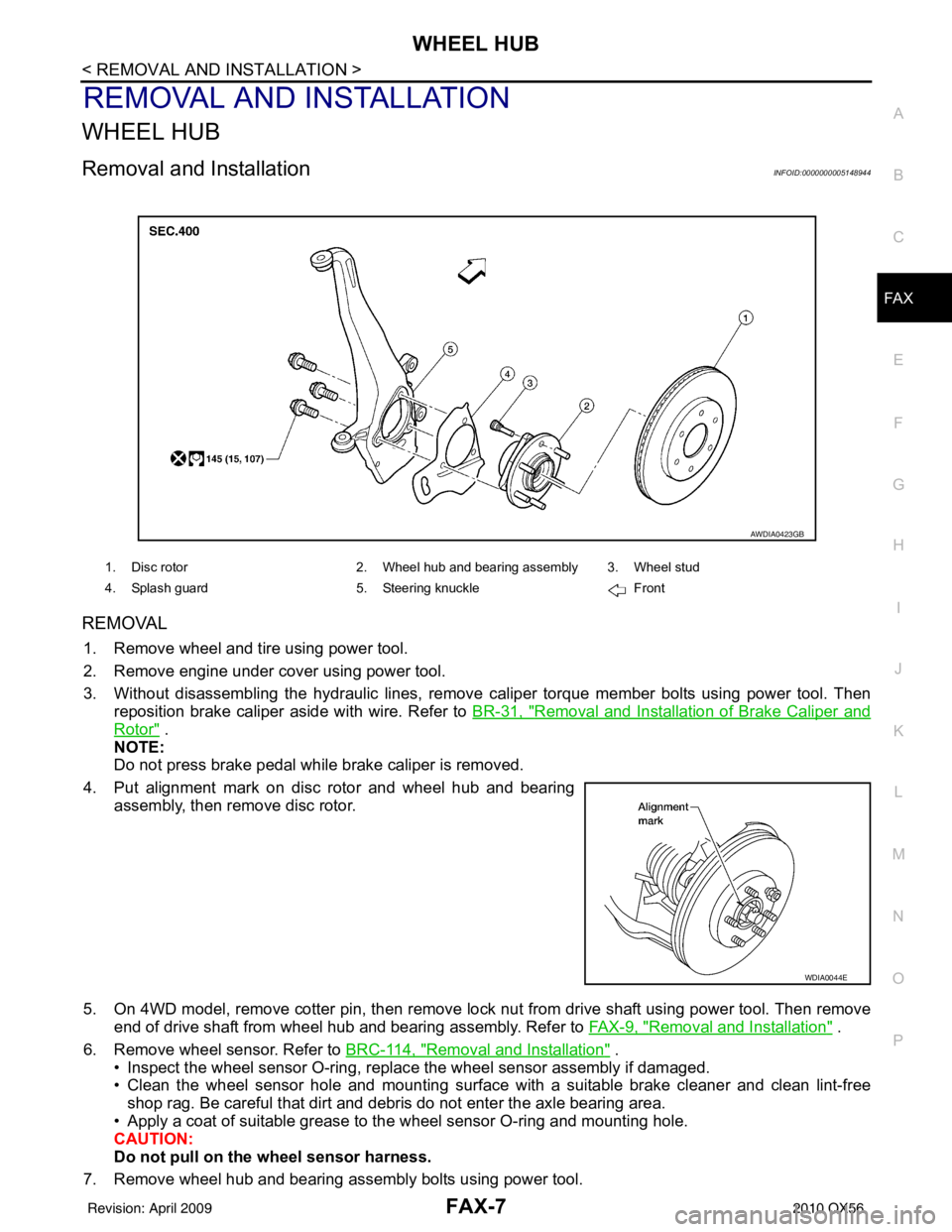

Removal and InstallationINFOID:0000000005148944

REMOVAL

1. Remove wheel and tire using power tool.

2. Remove engine under cover using power tool.

3. Without disassembling the hydraulic lines, remove caliper torque member bolts using power tool. Then

reposition brake caliper aside with wire. Refer to BR-31, "

Removal and Installation of Brake Caliper and

Rotor" .

NOTE:

Do not press brake pedal while brake caliper is removed.

4. Put alignment mark on disc rotor and wheel hub and bearing assembly, then remove disc rotor.

5. On 4WD model, remove cotter pin, then remove lock nut from drive shaft using power tool. Then remove end of drive shaft from wheel hub and bearing assembly. Refer to FAX-9, "

Removal and Installation" .

6. Remove wheel sensor. Refer to BRC-114, "

Removal and Installation" .

• Inspect the wheel sensor O-ring, replac e the wheel sensor assembly if damaged.

• Clean the wheel sensor hole and mounting surface with a suitable brake cleaner and clean lint-free shop rag. Be careful that dirt and debris do not enter the axle bearing area.

• Apply a coat of suitable grease to the wheel sensor O-ring and mounting hole.

CAUTION:

Do not pull on the wheel sensor harness.

7. Remove wheel hub and bearing assembly bolts using power tool.

1. Disc rotor 2. Wheel hub and bearing assembly 3. Wheel stud

4. Splash guard 5. Steering knuckle Front

AWDIA0423GB

WDIA0044E

Revision: April 20092010 QX56

Page 2174 of 4210

FAX-8

< REMOVAL AND INSTALLATION >

WHEEL HUB

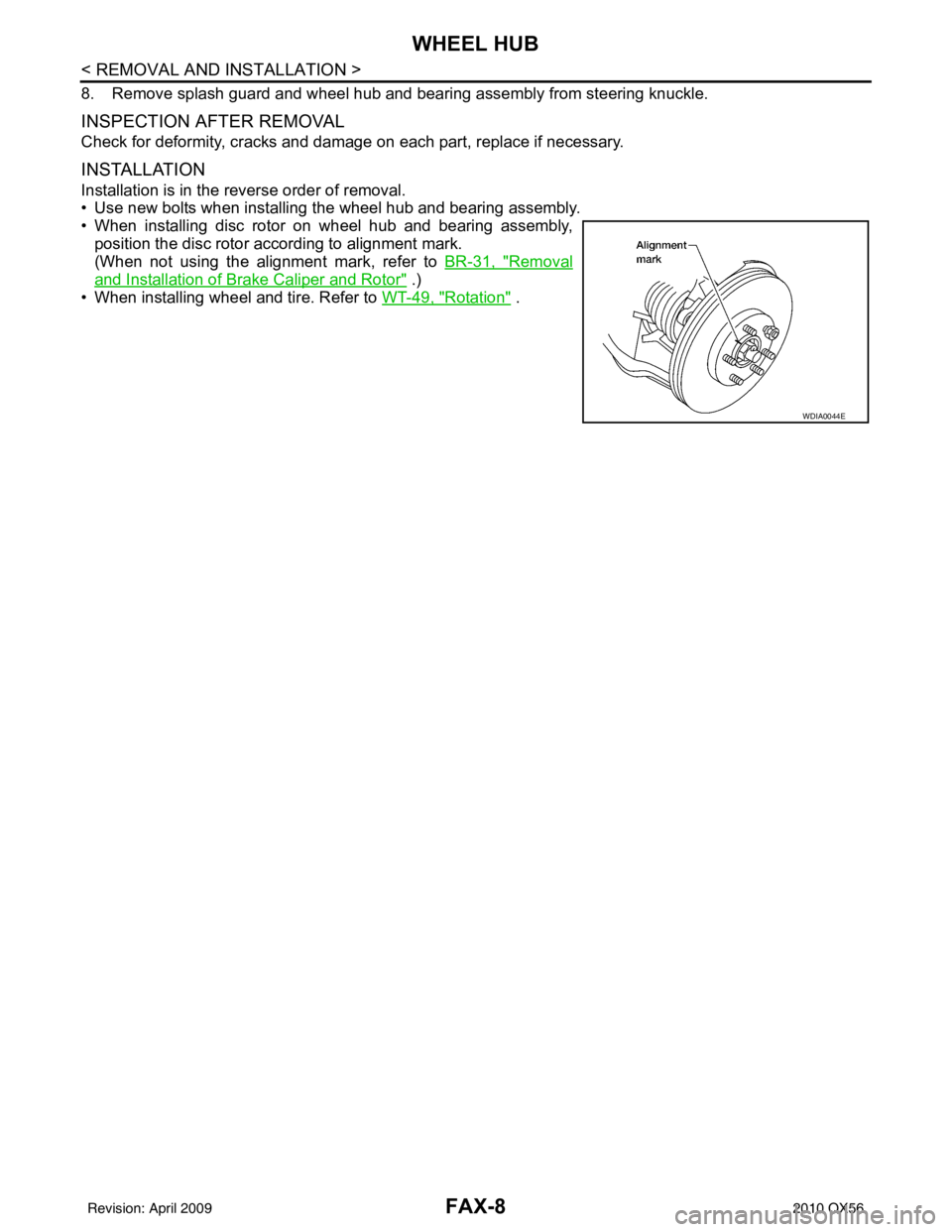

8. Remove splash guard and wheel hub and bearing assembly from steering knuckle.

INSPECTION AFTER REMOVAL

Check for deformity, cracks and damage on each part, replace if necessary.

INSTALLATION

Installation is in the reverse order of removal.

• Use new bolts when installing the wheel hub and bearing assembly.

• When installing disc rotor on wheel hub and bearing assembly,

position the disc rotor according to alignment mark.

(When not using the alignment mark, refer to BR-31, "

Removal

and Installation of Brake Caliper and Rotor" .)

• When installing wheel and tire. Refer to WT-49, "

Rotation" .

WDIA0044E

Revision: April 20092010 QX56

Page 2200 of 4210

FSU-1

SUSPENSION

C

DF

G H

I

J

K L

M

SECTION FSU

A

B

FSU

N

O PCONTENTS

FRONT SUSPENSION

PRECAUTION ....... ........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

Precaution .................................................................3

PREPARATION ............................................4

PREPARATION .............................................. .....4

Special Service Tool ........................................... ......4

Commercial Service Tool ..........................................4

SYMPTOM DIAGNOSIS ...............................5

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ........................ .....

5

NVH Troubleshooting Chart ................................ ......5

ON-VEHICLE MAINTENANCE .....................6

ON-VEHICLE SERVICE ................................. .....6

Front Suspension Parts ....................................... ......6

Front Wheel Alignment ..............................................6

UPPER BALL JOINT AND LOWER BALL

JOINT .................................................................

10

Inspection ............................................................ ....10

KNUCKLE ...................................................... ....12

On-Vehicle Inspection and Service ..................... ....12

ON-VEHICLE REPAIR .................................13

FRONT SUSPENSION ASSEMBLY .............. ....13

Component .......................................................... ....13

REMOVAL AND INSTALLATION ...............14

COIL SPRING AND SHOCK ABSORBER .......14

Removal and Installation ..................................... ....14

Disposal ...................................................................14

STABILIZER BAR .............................................15

Removal and Installation .........................................15

UPPER LINK .....................................................16

Removal and Installation ..................................... ....16

LOWER LINK ....................................................17

Removal and Installation .........................................17

UPPER BALL JOINT AND LOWER BALL

JOINT ................................................................

18

Removal and Installation .........................................18

KNUCKLE .........................................................19

Removal and Installation ..................................... ....19

DISASSEMBLY AND ASSEMBLY ..............21

COIL SPRING AND SHOCK ABSORBER .......21

Disassembly and Assembly ................................. ....21

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... ...

23

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

23

General Specification .......................................... ....23

Spring Free Height ..................................................23

Wheel Alignment (Unladen*1) ..................................23

Ball Joint .............................................................. ....24

Wheelarch Height (Unladen*1) ................................24

Revision: April 20092010 QX56

Page 2202 of 4210

PRECAUTIONSFSU-3

< PRECAUTION >

C

DF

G H

I

J

K L

M A

B

FSU

N

O P

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

PrecautionINFOID:0000000005148104

• When installing the rubber bushings, the final tightening must be done under unladen condition and with the

tires on level ground. Oil will shorten the life of the rubber bushings, so wipe off any spilled oil immediately.

• Unladen condition means the fuel tank, engine coolant and lubricants are at the full specification. The spare

tire, jack, hand tools, and mats are in their designated positions.

• After installing suspension components, check the wheel alignment.

• Lock nuts are not reusable. Always use new lock nuts for installation. New lock nuts are pre-oiled, do not

apply any additional lubrication.

Revision: April 20092010 QX56

Page 2203 of 4210

FSU-4

< PREPARATION >

PREPARATION

PREPARATION

PREPARATION

Special Service ToolINFOID:0000000005148105

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Commercial Service ToolINFOID:0000000005148106

Tool number

(Kent-Moore No.)

Tool name Description

ST29020001

(J-24319-01)

Pitman arm puller Removing upper link ball joint from knuckle

spindle

a: 34 mm (1.34 in)

b: 6.5 mm (0.256 in)

c: 61.5 mm (2.421 in)

HT72520000

(J-25730-A)

Ball joint remover Removing tie-rod outer end

NT694

NT146

Tool name

Description

Attachment wheel alignment Measure wheel alignment

a: Screw M24 x 1.5 pitch

b: 35 mm (1.38 in) dia.

c: 65 mm (2.56 in) dia.

d: 56 mm (2.20 in)

e: 12 mm (0.47 in)

Spring compressor Removing and installing coil spring

Power tool Loosening bolts and nuts

NT148

NT717

PBIC0190E

Revision: April 20092010 QX56

Page 2204 of 4210

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGFSU-5

< SYMPTOM DIAGNOSIS >

C

DF

G H

I

J

K L

M A

B

FSU

N

O P

SYMPTOM DIAGNOSIS

NOISE, VIBRATION AND HARSHN ESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000005148107

Use the chart below to help you find the cause of the symptom. Repair or replace parts as necessary.

x: ApplicableReference page

FSU-13FSU-14FSU-13FSU-13FSU-24FSU-6FSU-6FSU-6

DLN-184, "

NVH Troubleshooting Chart

"

DLN-208, "

NVH Troubleshooting Chart

"

FAX-5, "

NVH Troubleshooting Chart

"

FAX-5, "

NVH Troubleshooting Chart

"

WT-43, "

NVH Troubleshooting Chart

"

WT-43, "

NVH Troubleshooting Chart

"

BR-6, "

NVH Troubleshooting Chart

"

ST-12, "

NVH Troubleshooting Chart

"

Possible Cause and

SUSPECTED PARTS

Improper installation, looseness

Shock absorber deformation,

damage or deflection

Bushing or mounting deterioration

Parts interference

Spring fatigue

Suspension looseness

Incorrect wheel alignment

Stabilizer bar fatigue

PROPELLER SHAFT

FRONT FINAL DRIVE

DRIVE SHAFT

WHEEL HUB

TIRES

ROAD WHEEL

BRAKES

STEERING

Symptom

Noise

× × ×××× × × ×× × × ××

Shake × × ×× × × ×× × × ××

Vibration × × ××× × ×× × ×

Shimmy × × ×× × × × × ××

Shudder ××× ×××××

Poor quality ride or handling × × ××× ×× × × ×

Revision: April 20092010 QX56