engine INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 5013 of 5598

ST-26

< SYMPTOM DIAGNOSIS >

HEATED STEERING WHEEL SWITCH INDICATOR LAMP DOES NOT TURN ON

HEATED STEERING WHEEL SWITCH INDICATOR LAMP DOES NOT

TURN ON

Description INFOID:0000000006225594

Heated steering wheel switch indicator lamp does not turn on the lamp.

Heated steering wheel switch indicator lamp does not turn off the lamp.

Diagnosis ProcedureINFOID:0000000006225595

1.CHECK POWER SOURCE AND GROUND CIRCUIT

1. Turn ignition switch ON. CAUTION:

Never start the engine.

2. Turn heated steering wheel switch ON.

3. Check voltage between heated steering wheel switch harness connector terminals.

Is the inspection result normal?

YES >> GO TO 7.

NO >> GO TO 2.

2.CHECK GROUND CIRCUIT

Check continuity between heated steering wheel switch harness connector terminal and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace damaged parts.

3.CHECK HARNESS BETWEEN HEATED STEERING WHEEL RELAY AND HEATED STEERING WHEEL

SWITCH

1. Turn ignition switch OFF.

2. Disconnect heated steering wheel relay connector. Refer to ST-7, "

Component Parts Location (Heated

Steering Wheel)".

3. Disconnect heated steering wheel switch connector. Refer to ST-56, "

Removal and Installation".

4. Check continuity between heated steering wheel relay harness connector terminal and heated steering

wheel switch harness connector terminal.

5. Check continuity between heated steering w heel relay harness connector terminal and ground.

Heated steering wheel

Condition Voltage (Approx.)

Connector Terminal

M52 5 − 6 Within 30 minutes after

turning ON the heated

steering switch.

Battery voltage

Other conditions. 0 V

Heated steering wheel switch GroundContinuity

Connector Terminal

M52 6 Existed

Heated steering wheel relay Heated steering wheel switch Continuity

Connector Terminal Connector Terminal

E90 5 M52 5 Existed

Heated steering wheel relay GroundContinuity

Connector Terminal

E90 5 Not existed

Revision: 2010 May2011 QX56

Page 5017 of 5598

ST-30

< PERIODIC MAINTENANCE >

POWER STEERING FLUID

PERIODIC MAINTENANCE

POWER STEERING FLUID

InspectionINFOID:0000000006225597

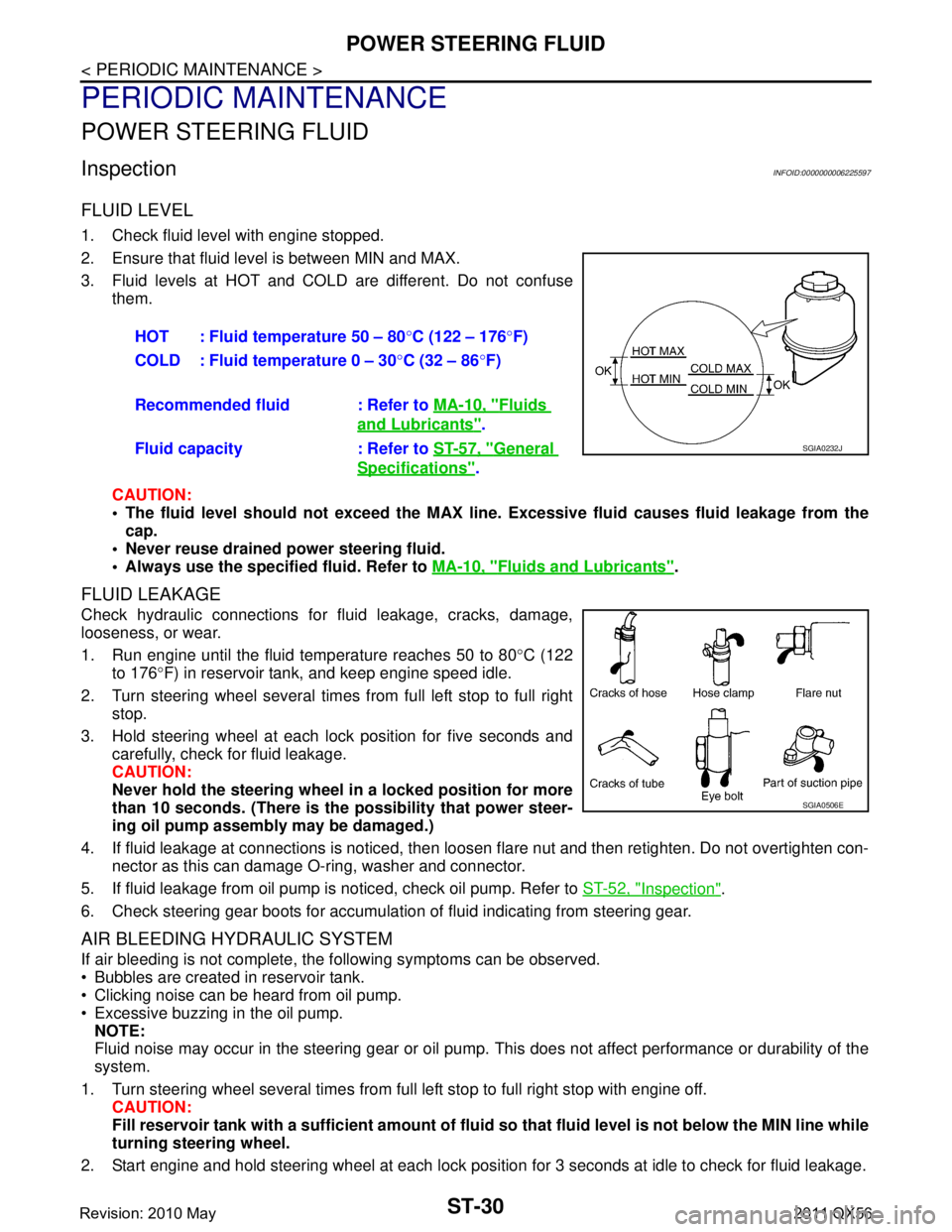

FLUID LEVEL

1. Check fluid level with engine stopped.

2. Ensure that fluid level is between MIN and MAX.

3. Fluid levels at HOT and COLD are different. Do not confuse

them.

CAUTION:

The fluid level should not exceed the MAX line. Excessive flui d causes fluid leakage from the

cap.

Never reuse drained power steering fluid.

Always use the specified fluid. Refer to MA-10, "

Fluids and Lubricants".

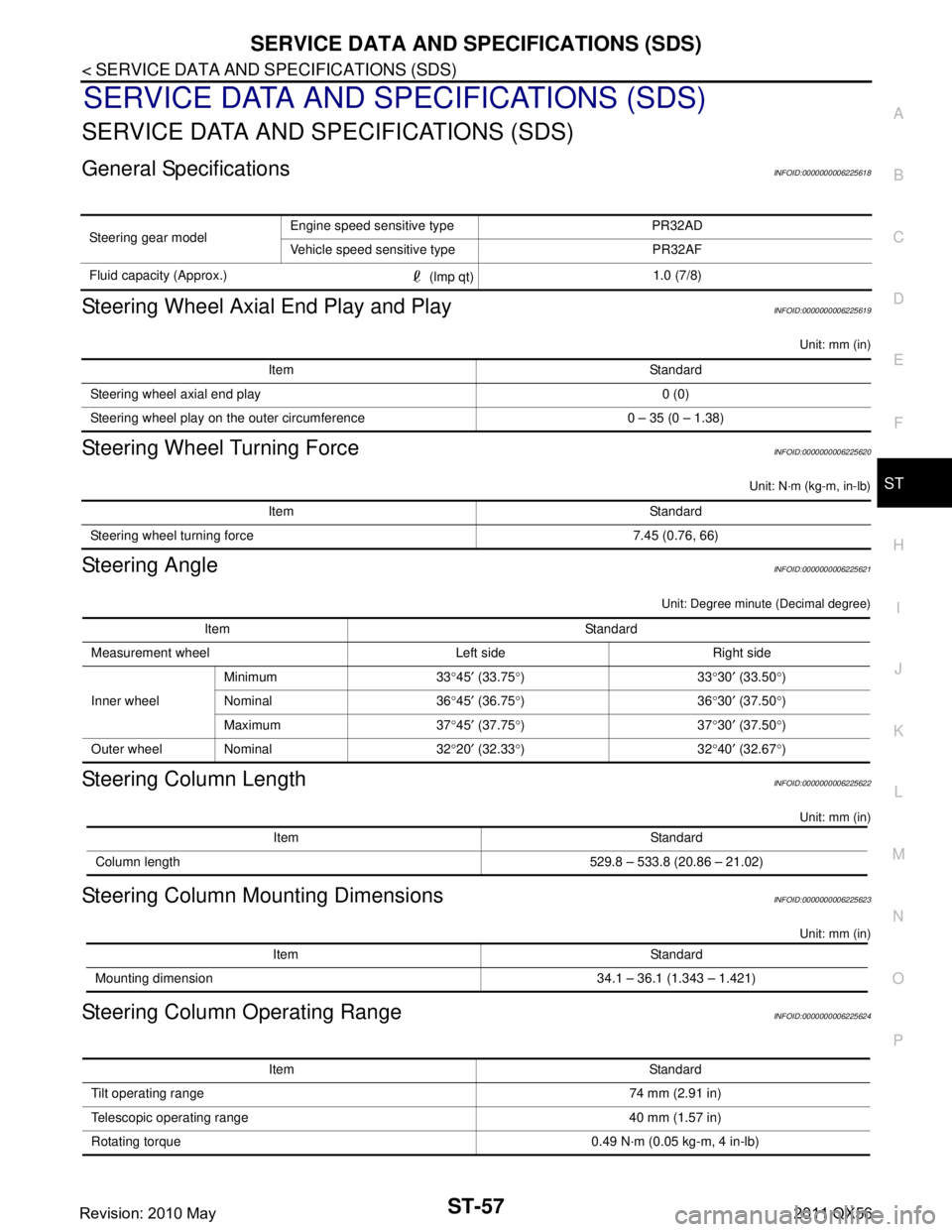

FLUID LEAKAGE

Check hydraulic connections for fluid leakage, cracks, damage,

looseness, or wear.

1. Run engine until the fluid temperature reaches 50 to 80 °C (122

to 176 °F) in reservoir tank, and keep engine speed idle.

2. Turn steering wheel several times from full left stop to full right stop.

3. Hold steering wheel at each lock position for five seconds and carefully, check for fluid leakage.

CAUTION:

Never hold the steering wheel in a locked position for more

than 10 seconds. (There is the possibility that power steer-

ing oil pump assembly may be damaged.)

4. If fluid leakage at connections is noticed, then loos en flare nut and then retighten. Do not overtighten con-

nector as this can damage O-ring, washer and connector.

5. If fluid leakage from oil pump is noticed, check oil pump. Refer to ST-52, "

Inspection".

6. Check steering gear boots for accumulation of fluid indicating from steering gear.

AIR BLEEDING HYDRAULIC SYSTEM

If air bleeding is not complete, the following symptoms can be observed.

Bubbles are created in reservoir tank.

Clicking noise can be heard from oil pump.

Excessive buzzing in the oil pump. NOTE:

Fluid noise may occur in the steering gear or oil pump. This does not affect performance or durability of the

system.

1. Turn steering wheel several times from full left stop to full right stop with engine off. CAUTION:

Fill reservoir tank with a sufficien t amount of fluid so that fluid level is not below the MIN line while

turning steering wheel.

2. Start engine and hold steering wheel at each lock position for 3 seconds at idle to check for fluid leakage.

HOT : Fluid temperature 50 – 80

°C (122 – 176 °F)

COLD : Fluid temperature 0 – 30 °C (32 – 86 °F)

Recommended fluid : Refer to MA-10, "

Fluids

and Lubricants".

Fluid capacity : Refer to ST-57, "

General

Specifications".

SGIA0232J

SGIA0506E

Revision: 2010 May2011 QX56

Page 5018 of 5598

POWER STEERING FLUIDST-31

< PERIODIC MAINTENANCE >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

3. Repeat step 2 above several times at approximately 3 seconds intervals. CAUTION:

Never hold the steering wheel in a locked positio n for more than 10 seconds. (There is the possi-

bility that oil pump may be damaged.)

4. Check fluid for bubbles and while contamination.

5. Stop engine if bubbles and white contamination do not drain out. Perform step 2 and 3 above after waiting

until bubbles and white contamination drain out.

6. Stop the engine, and then check fluid level.

Revision: 2010 May2011 QX56

Page 5019 of 5598

ST-32

< PERIODIC MAINTENANCE >

STEERING WHEEL

STEERING WHEEL

InspectionINFOID:0000000006225598

STEERING WHEEL AXIAL END PLAY

1. Check installation conditions of steering gear assembly, front suspension assembly, axle and steering col-

umn assembly.

2. Check if movement exists when steering wheel is moved up and down, to the left and right and to the axial direction.

3. Check the following items when steering w heel axial end play is out of the standard.

Check the steering column assembly mounting condition. Refer to ST-34, "

Exploded View".

Check steering gear assembly mounting condition for looseness. Refer to ST-41, "

Exploded View".

STEERING WHEEL PLAY

1. Turn steering wheel so that front wheels come to the straight-ahead position.

2. Start engine and lightly turn steering wheel to the left and right until front wheels start to move.

3. Measure steering wheel movement on the outer circumference.

4. Check the following items when steeri ng wheel play is out of the standard.

Check backlash for each joint of steering column assembly.

Check installation condition of steering gear assembly. Steering wheel axial end play : Refer to

ST-57, "

Steering Wheel Axial End Play and Play".

Steering wheel play : Refer to ST-57, "

Steering Wheel Axial End Play and Play".

Revision: 2010 May2011 QX56

Page 5028 of 5598

STEERING GEAR AND LINKAGEST-41

< REMOVAL AND INSTALLATION >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

STEERING GEAR AND LINKAGE

Exploded ViewINFOID:0000000006225607

REMOVAL

DISASSEMBLY

Engine speed sensitive type

1. Steering gear assembly 2. Cotter pin

Refer to GI-4, "

Components" for symbols in the figure.

JPGIA0072GB

JPGIA0095GB

1. Outer socket 2. Boot clamp 3. Boot

4. Inner socket 5. Boot clamp 6. Gear housing assembly

7. Adjusting screw 8. Adjusting screw lock nut 9. Spring

Revision: 2010 May2011 QX56

Page 5032 of 5598

STEERING GEAR AND LINKAGEST-45

< REMOVAL AND INSTALLATION >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

a. Measure pinion rotating torque within ±180 ° of neutral position

of the rack assembly using Tools. Stop the gear at the point

where highest torque is read.

b. Loosen adjusting screw lock nut and adjusting screw and then retighten to 5.4 N·m (0.55 kg-m, 48 in-lb), and then loosen by 20

to 40 °.

c. Measure pinion rotating torque using tools to make sure that the measured value is within the standard. Readjust if the value is

outside the standard. Replace steering gear assembly, if the

value is outside the standard after readjusting, or adjusting

screw rotating torque is 5 N·m (0.51 kg-m, 44 in-lb) or less.

d. Apply thread locking sealant to inner socket and turn pinion fully to left with inner socket installed to gear housing assembly.

e. Install dial gauge at 5 mm (0.20 in) (L) from the edge of gear housing assembly (1), and tooth point.

f. Measure vertical movement of rack assembly when pinion is turned clockwise with torque of 19.6 N·m (2.0 kg-m, 14 ft-lb).

Readjust adjusting screw angle if the measured value is outside

the standard.

If reading is outside of the specification, readjust screw angle

with adjusting screw.

CAUTION:

If reading is still outside of sp ecification, or if the rotating torque of adjusting screw is less

than 5 N·m (0.51 kg-m, 44 in-lb), replace steering gear assembly.

Never turn adjusting scr ew more than twice.

Replace steering gear assembly when adjusting screw is removed or turned more than twice.

A: Preload gauge [SST: ST3127S000 (J-25765-A)]

B: Preload adapter [SST: KV48103400 ( — )]

SGIA1383E

Pinion rotating torque (engine speed sensitive type)

Around neutral position

(within ±100 °) average “A” : 1.16 – 1.31 N·m (0.12 –

0.13 kg-m, 10.3 – 11.5 in-lb)

Maximum variation “B” : 1.43 N·m (0.15 kg-m, 13 in-lb)

Pinion rotating torque (veh icle speed sensitive type)

Around neutral position

(within ±100 °) average “A” : 1.10 – 1.41 N·m (0.12 –

0.14 kg-m, 10 – 12 in-lb)

Maximum variation “B” : 1.43 N·m (0.15 kg-m, 13 in-lb)

Vertical movement : 0.265 mm (0.0104 in)

PGIA0084E

JSGIA0104ZZ

Revision: 2010 May2011 QX56

Page 5040 of 5598

![INFINITI QX56 2011 Factory Service Manual

POWER STEERING OIL PUMPST-53

< REMOVAL AND INSTALLATION >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

1. Connect the oil pressure gauge [SST: KV48103500 (J-26357)] and the oil pressure gauge adapter [SST: KV4810 INFINITI QX56 2011 Factory Service Manual

POWER STEERING OIL PUMPST-53

< REMOVAL AND INSTALLATION >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

1. Connect the oil pressure gauge [SST: KV48103500 (J-26357)] and the oil pressure gauge adapter [SST: KV4810](/img/42/57033/w960_57033-5039.png)

POWER STEERING OIL PUMPST-53

< REMOVAL AND INSTALLATION >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

1. Connect the oil pressure gauge [SST: KV48103500 (J-26357)] and the oil pressure gauge adapter [SST: KV48102500 (J-

33914)] between oil pump discharge connector and high-pres-

sure hose. Bleed air from the hydraulic circuit while opening

valve fully. Refer to ST-30, "

Inspection".

2. Start engine. Run engine until oil temperature reaches 50 to 80°C (122 to 176 °F).

CAUTION:

Leave the valve of the oil pressure gauge fully open while

starting and running engine. If engine is started with the

valve closed, the hydraulic pressure in oil pump goes up

to the relief pressure along with unusual increase of oil

temperature.

Be sure to keep hose clear of belts and other parts when engine is started.

3. Fully close the oil pressure gauge valve with engine at idle and measure the relief oil pressure.

CAUTION:

Never keep valve closed for 10 seconds or longer.

4. Open the valve slowly after measuring. Repair oil pump if the relief oil pressure is outside the standard. Refer to ST-50, "

Disassembly and Assembly".

5. Disconnect the oil pressure gauge from hydraulic circuit.

6. When installing eye bolt (1) and copper washer (2) to oil pump (3), refer to the figure.

CAUTION:

Never reuse copper washers.

Apply power steering fluid to around copper washer, theninstall eye bolt.

Install eye bolt with eye join t (assembled to high pressure

hose) (B) protrusion (A) facing with pump side cutout, and

then tighten it to the specifi ed torque after tightening by

hand. Refer to ST-54, "

Exploded View".

Securely insert harness connector to pressure sensor.

7. Check fluid level, fluid leakage and air bleeding hydraulic sys- tem after the installation. Refer to ST-30, "

Inspection".

Relief oil pressure : Refer to

ST-58, "

Relief Oil Pres-

sure".

SGIA1225E

JSGIA0452ZZ

Revision: 2010 May2011 QX56

Page 5041 of 5598

ST-54

< REMOVAL AND INSTALLATION >

HYDRAULIC LINE

HYDRAULIC LINE

Exploded ViewINFOID:0000000006225615

Engine speed sensitive type

JPGIA0096GB

1. Reservoir tank bracket 2. Reservoir tank 3. Clamp

4. Suction hose 5. Return hose 6. Eye bolt

7. Copper washer 8. Pressure sensor 9. Oil cooler

10. High pressure piping 11. Low pressure piping 12. Steering gear assembly

A. To power steering oil pump suction hose.

B. To power steering oil pump.

Refer to GI-4, "

Components" for symbols in the figure.

Revision: 2010 May2011 QX56

Page 5044 of 5598

SERVICE DATA AND SPECIFICATIONS (SDS)

ST-57

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

D E

F

H I

J

K L

M A

B

ST

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

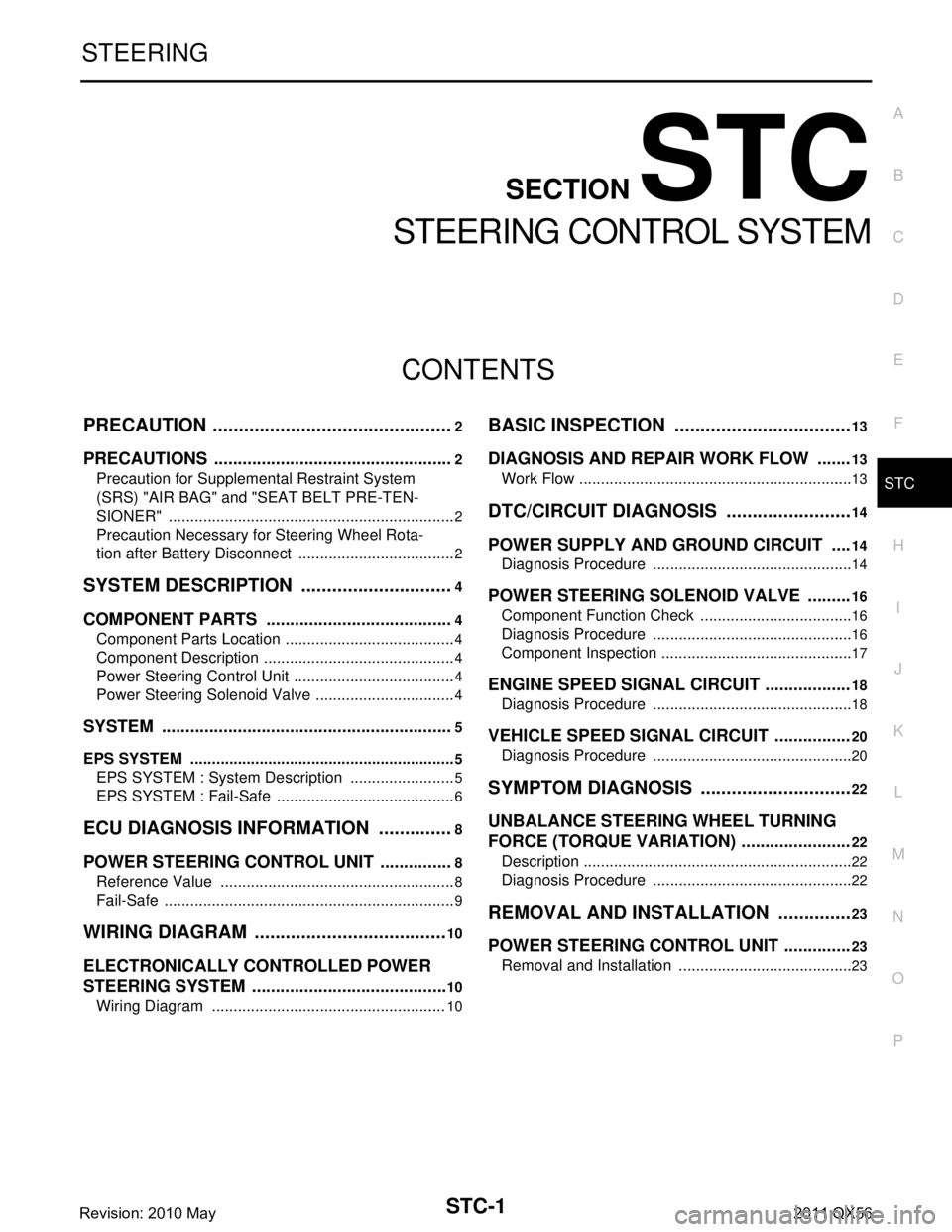

General SpecificationsINFOID:0000000006225618

Steering Wheel Axial End Play and PlayINFOID:0000000006225619

Unit: mm (in)

Steering Wheel Turning ForceINFOID:0000000006225620

Unit: N·m (kg-m, in-lb)

Steering AngleINFOID:0000000006225621

Unit: Degree minute (Decimal degree)

Steering Column LengthINFOID:0000000006225622

Unit: mm (in)

Steering Column Mounting DimensionsINFOID:0000000006225623

Unit: mm (in)

Steering Column Operating RangeINFOID:0000000006225624

Steering gear model Engine speed sensitive type PR32AD

Vehicle speed sensitive type PR32AF

Fluid capacity (Approx.) (lmp qt)1.0 (7/8)

Item Standard

Steering wheel axial end play 0 (0)

Steering wheel play on the outer circumference 0 – 35 (0 – 1.38)

Item Standard

Steering wheel turning force 7.45 (0.76, 66)

Item Standard

Measurement wheel Left side Right side

Inner wheel Minimum 33

°45 ′ (33.75 °)33 °30 ′ (33.50 °)

Nominal 36 °45 ′ (36.75 °)36 °30 ′ (37.50 °)

Maximum 37 °45 ′ (37.75 °)37 °30 ′ (37.50 °)

Outer wheel Nominal 32 °20 ′ (32.33 °)32 °40 ′ (32.67 °)

Item Standard

Column length 529.8 – 533.8 (20.86 – 21.02)

Item Standard

Mounting dimension 34.1 – 36.1 (1.343 – 1.421)

Item Standard

Tilt operating range 74 mm (2.91 in)

Telescopic operating range 40 mm (1.57 in)

Rotating torque 0.49 N· m (0.05 kg-m, 4 in-lb)

Revision: 2010 May2011 QX56

Page 5046 of 5598

STC-1

STEERING

C

DE

F

H I

J

K L

M

SECTION STC

A

B

STC

N

O P

CONTENTS

STEERING CONTROL SYSTEM

PRECAUTION ................ ...............................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect .....................................

2

SYSTEM DESCRIPTION ..............................4

COMPONENT PARTS ................................... .....4

Component Parts Location .................................. ......4

Component Description .............................................4

Power Steering Control Unit ......................................4

Power Steering Solenoid Valve .................................4

SYSTEM ..............................................................5

EPS SYSTEM ........................................ ......................5

EPS SYSTEM : System De scription .........................5

EPS SYSTEM : Fail-Safe ..........................................6

ECU DIAGNOSIS INFO RMATION ...............8

POWER STEERING CONTROL UNIT ........... .....8

Reference Value ................................................. ......8

Fail-Safe ....................................................................9

WIRING DIAGRAM ......................................10

ELECTRONICALLY CONTROLLED POWER

STEERING SYSTEM ...................................... ....

10

Wiring Diagram ................................................... ....10

BASIC INSPECTION ...................................13

DIAGNOSIS AND REPAIR WORK FLOW .......13

Work Flow ............................................................ ....13

DTC/CIRCUIT DIAGNOSIS .........................14

POWER SUPPLY AND GROUND CIRCUIT ....14

Diagnosis Procedure ........................................... ....14

POWER STEERING SOLENOID VALVE .........16

Component Function Check ....................................16

Diagnosis Procedure ...............................................16

Component Inspection .............................................17

ENGINE SPEED SIGNAL CIRCUIT ..................18

Diagnosis Procedure ........................................... ....18

VEHICLE SPEED SIGNAL CIRCUIT ................20

Diagnosis Procedure ...............................................20

SYMPTOM DIAGNOSIS ..............................22

UNBALANCE STEERING WHEEL TURNING

FORCE (TORQUE VARIATION) .......................

22

Description ........................................................... ....22

Diagnosis Procedure ...............................................22

REMOVAL AND INSTALLATION ...............23

POWER STEERING CONTROL UNIT ..............23

Removal and Installation ..................................... ....23

Revision: 2010 May2011 QX56