engine INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 5047 of 5598

STC-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006303358

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision that would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the “SRS AIR BAG”.

Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation after Battery Disconnect

INFOID:0000000006303360

NOTE:

Before removing and installing any control units, first tu rn the push-button ignition switch to the LOCK posi-

tion, then disconnect bot h battery cables.

After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If a DTC is detected, perform trouble diagnos is according to self-diagnosis results.

For vehicle with steering lock unit, if the battery is disconnected or discharged, the steering wheel will lock and

cannot be turned.

If turning the steering wheel is required with the bat tery disconnected or discharged, follow the operation pro-

cedure below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Turn the push-button ignition switch to ACC position. (At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock wi ll remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

Revision: 2010 May2011 QX56

Page 5049 of 5598

STC-4

< SYSTEM DESCRIPTION >

COMPONENT PARTS

SYSTEM DESCRIPTION

COMPONENT PARTS

Component Parts LocationINFOID:0000000006256115

Component DescriptionINFOID:0000000006256116

Power Steering Control UnitINFOID:0000000006256117

Signals from various sensors control the driving voltage to the power steering solenoid valve.

The power steering control unit controls the driving vo ltage to the power steering solenoid valve for maintain-

ing the power steering assist force when the fail-safe function is activated. (The engine speed signals control

EPS system if any vehicle s peed signal error is detected.)

Power Steering Solenoid ValveINFOID:0000000006256118

Power steering solenoid valve controls the power steering oil pressure in the gear housing assembly.

1. ECM

Refer to EC-16, "

Component Parts

Location". 2. Combination meter

Refer to MWI-6, "

METER SYSTEM :

Component Parts Location". 3. Power steering control unit

4. Power steering solenoid valve

A. Glove box assembly removed B. Steering gear assembly

JPGIB0006ZZ

Component parts Reference/Function

Power steering control unit STC-4, "

Power Steering Control Unit"

Power steering solenoid valveSTC-4, "Power Steering Solenoid Valve"

Combination meter Transmits vehicle speed signal to power steering control unit.

ECM Transmits engine speed signal to power steering control unit.

Revision: 2010 May2011 QX56

Page 5051 of 5598

STC-6

< SYSTEM DESCRIPTION >

SYSTEM

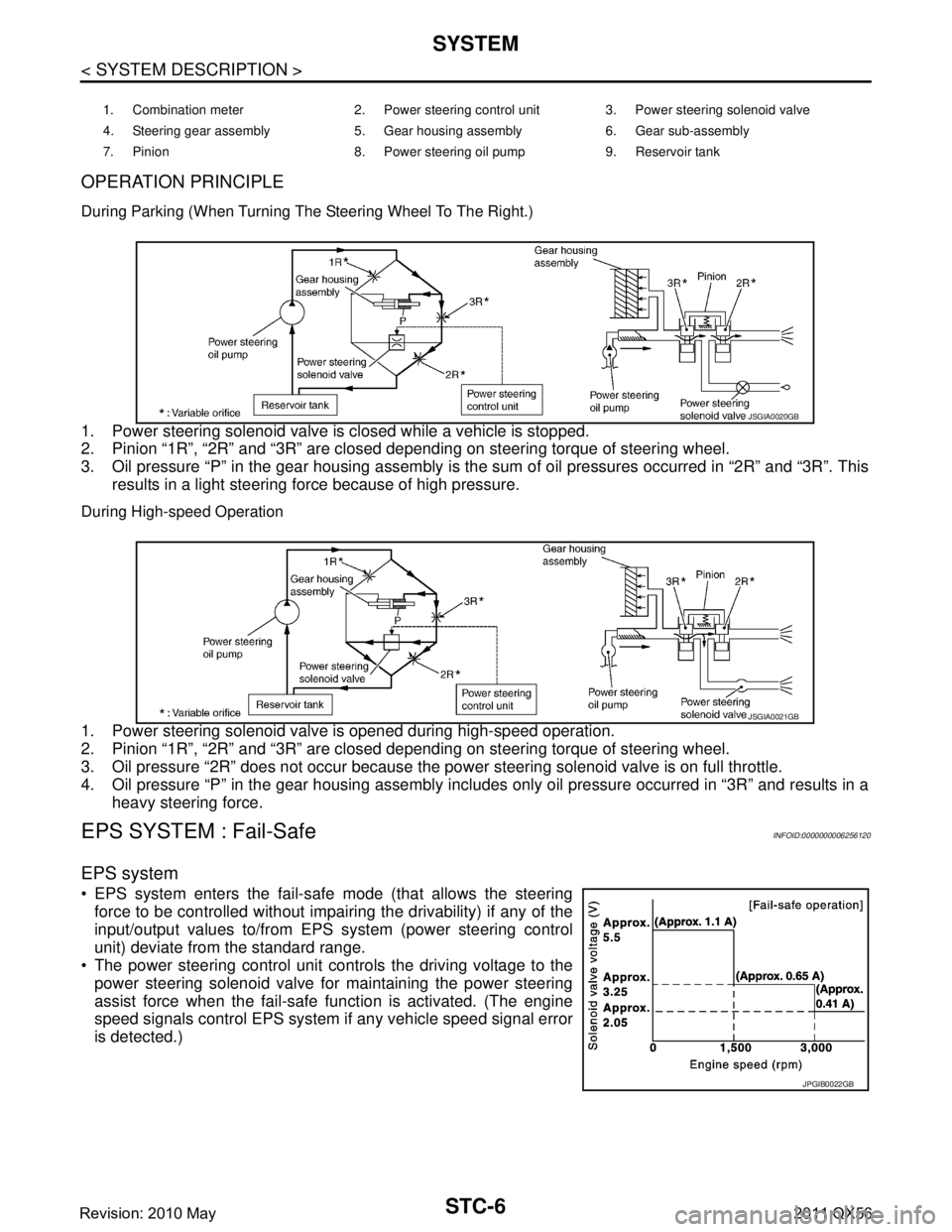

OPERATION PRINCIPLE

During Parking (When Turning The Steering Wheel To The Right.)

1. Power steering solenoid valve is closed while a vehicle is stopped.

2. Pinion “1R”, “2R” and “3R” are closed depending on steering torque of steering wheel.

3. Oil pressure “P” in the gear housing assembly is the sum of oil pressures occurred in “2R” and “3R”. Thisresults in a light steering force because of high pressure.

During High-speed Operation

1. Power steering solenoid valve is opened during high-speed operation.

2. Pinion “1R”, “2R” and “3R” are closed depending on steering torque of steering wheel.

3. Oil pressure “2R” does not occur because the pow er steering solenoid valve is on full throttle.

4. Oil pressure “P” in the gear housing assembly includes only oil pressure occurred in “3R” and results in a heavy steering force.

EPS SYSTEM : Fail-Safe INFOID:0000000006256120

EPS system

EPS system enters the fail-safe mode (that allows the steering

force to be controlled without impairi ng the drivability) if any of the

input/output values to/from EPS system (power steering control

unit) deviate from the standard range.

The power steering control unit controls the driving voltage to the

power steering solenoid valve for maintaining the power steering

assist force when the fail-safe function is activated. (The engine

speed signals control EPS system if any vehicle speed signal error

is detected.)

1. Combination meter 2. Power steering control unit 3. Power steering solenoid valve

4. Steering gear assembly 5. Gear housing assembly 6. Gear sub-assembly

7. Pinion 8. Power steering oil pump 9. Reservoir tank

JSGIA0020GB

JSGIA0021GB

JPGIB0022GB

Revision: 2010 May2011 QX56

Page 5052 of 5598

SYSTEMSTC-7

< SYSTEM DESCRIPTION >

C

DE

F

H I

J

K L

M A

B

STC

N

O P

Error area and root cause Cancel condition

Engine speed is 1,500 rpm or more and there is no vehicle speed signal input for

over 10 seconds during vehicle travel. When a vehicle speed signal of 2 km/h (1.2

MPH) or more is inputted.

Ignition switch is turned OFF to ON.

Vehicle speed signal has abruptly dropped from 30 km/h (19 MPH) or more to 2

km/h (1.2 MPH) or less within 1.4 seconds.

Revision: 2010 May2011 QX56

Page 5053 of 5598

STC-8

< ECU DIAGNOSIS INFORMATION >

POWER STEERING CONTROL UNIT

ECU DIAGNOSIS INFORMATION

POWER STEERING CONTROL UNIT

Reference Value INFOID:0000000006256121

TERMINAL LAYOUT

PHYSICAL VALUES

JSGIA0023ZZ

Te r m i n a l N o .(Wire color) Description

Condition Value (Approx.)

+ - Signal name Input/

Output

1

(R) GroundPower steering

solenoid

valve control voltage OutputVehicle speed: 0 km/h (0 MPH)

(Engine is running)

4.4 – 6.6 V

Vehicle speed: 100 km/h (62 MPH) 2.4 – 3.6 V

3

(GR) GroundIgnition switch power

supply InputIgnition switch: ON Battery voltage

Ignition switch: OFF 0 V

5

(L) Ground

Power steering

solenoid

valve ground —Always 0 V

6

(B) Ground Ground — Always 0 V

8

(SB) Ground Vehicle speed signal Input Vehicle speed: 40 km/h (25 MPH)

CAUTION:

Check air pressure of tire under

standard condition.NOTE:

The maximum voltage varies de-

pending on the specification

(destination unit).

JSNIA0015GB

Revision: 2010 May2011 QX56

Page 5054 of 5598

POWER STEERING CONTROL UNITSTC-9

< ECU DIAGNOSIS INFORMATION >

C

DE

F

H I

J

K L

M A

B

STC

N

O PCAUTION:

When using circuit tester or osci lloscope to measure voltage for in spection, be sure not to forcibly

extend any connector terminals.

Fail-Safe INFOID:0000000006256122

EPS system

EPS system enters the fail-safe mode (that allows the steering

force to be controlled without impair ing the drivability) if any of the

input/output values to/from EPS system (power steering control

unit) deviate from the standard range.

The power steering control unit controls the driving voltage to the

power steering solenoid valve for maintaining the power steering

assist force when the fail-safe function is activated. (The engine

speed signals control EPS system if any vehicle speed signal error

is detected.)

10

(B/SB) Ground Engine speed signal Input Engine is running

Warm-up condition

Idle speed

Engine is running

Warm-up condition

Engine speed: Approx. 2,000

rpm

Te r m i n a l N o .

(Wire color) Description

Condition Value (Approx.)

+ - Signal name Input/

OutputJPBIA3352ZZ

JPBIA3354ZZ

JPGIB0022GB

Error area and root cause Cancel condition

Engine speed is 1,500 rpm or more and there is no vehicle speed signal input for

over 10 seconds during vehicle travel. When a vehicle speed signal of 2 km/h (1.2

MPH) or more is inputted.

Ignition switch is turned OFF to ON.

Vehicle speed signal has abruptly dropped from 30 km/h (19 MPH) or more to 2

km/h (1.2 MPH) or less within 1.4 seconds.

Revision: 2010 May2011 QX56

Page 5059 of 5598

STC-14

< DTC/CIRCUIT DIAGNOSIS >

POWER SUPPLY AND GROUND CIRCUIT

DTC/CIRCUIT DIAGNOSIS

POWER SUPPLY AND GROUND CIRCUIT

Diagnosis ProcedureINFOID:0000000006256125

1.CHECK POWER SUPPLY (1)

1. Turn the ignition switch OFF.

2. Disconnect power steering control unit harness connector.

3. Check the voltage between power steering control unit harness connector and ground.

4. Turn the ignition switch ON. CAUTION:

Never start the engine.

5. Check the voltage between power steering control unit harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK POWER SUPPLY (2)

1. Turn the ignition switch OFF.

2. Check 10A fuse (#3).

3. Disconnect fuse block (J/B) harness connector.

4. Check the continuity between power steering cont rol unit harness connector and fuse block (J/B) harness

connector.

5. Check the continuity between power st eering control unit harness connector and ground.

Is the inspection result normal?

YES >> Perform trouble diagnosis for ignition power supply circuit. Refer to PG-89, "Wiring Diagram -

IGNITION POWER SUPPLY -".

NO >> Repair or replace damaged parts.

3.CHECK GROUND CIRCUIT

1. Turn the ignition switch OFF.

2. Check the continuity between power st eering control unit harness connector and ground.

Power steering control unit

—Voltage

Connector Terminal

M108 3 Ground 0 V

Power steering control unit — Voltage

Connector Terminal

M108 3 Ground Battery voltage

Power steering control unit Fuse block (J/B) Continuity

Connector Terminal Connector Terminal

M108 3 M1 2A Existed

Power steering control unit —Continuity

Connector Terminal

M108 3 Ground Not existed

Revision: 2010 May2011 QX56

Page 5061 of 5598

STC-16

< DTC/CIRCUIT DIAGNOSIS >

POWER STEERING SOLENOID VALVE

POWER STEERING SOLENOID VALVE

Component Function CheckINFOID:0000000006256126

1.CHECK POWER STEERING SOLENOID VALVE OPERATION

Check changes in steering force from a halt condition to high-speed driving.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Check the power steering solenoid valve. Refer to STC-16, "

Diagnosis Procedure".

Diagnosis Procedure INFOID:0000000006256127

1.CHECK POWER STEERING SOLENOID VALVE SIGNAL

1. Turn the ignition switch OFF.

2. Check the voltage between power steering control unit harness connector and ground.

Is the inspection result normal?

YES >> GO TO 4.

NO >> GO TO 2.

2.CHECK HARNESS BETWEEN POWER STEERING SO LENOID VALVE AND POWER STEERING CON-

TROL UNIT

1. Turn the ignition switch OFF.

2. Disconnect power steering solenoid valve harness connector.

3. Disconnect power steering control unit harness connector.

4. Check the continuity between power steering solenoid valve harness connector and the power steering

control unit harness connector.

5. Check the continuity between power st eering control unit harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace error-detected parts.

3.CHECK POWER STEERING SOLENOID VALVE

Check the power steering solenoid valve. Refer to STC-17, "

Component Inspection".

Is the inspection result normal?

YES >> GO TO 4.

NO >> Replace gear-sub assembly. Refer to ST-43, "

Disassembly and Assembly".

Power steering control unit

— Condition Voltage (Approx.)

Connector Terminal

M108 1 Ground Vehicle speed: 0 km/h (0 MPH)

(Engine is running)

4.4 – 6.6 V

Vehicle speed: 100 km/h (62 MPH) 2.4 – 3.6 V

Power steering solenoid valve Power steering control unit Continuity

Connector Terminal Connector Terminal

F45 1

M108 1 Existed

25Existed

Power steering control unit — Continuity

Connector Terminal

M108 1

Ground Not existed

5

Revision: 2010 May2011 QX56

Page 5063 of 5598

STC-18

< DTC/CIRCUIT DIAGNOSIS >

ENGINE SPEED SIGNAL CIRCUIT

ENGINE SPEED SIGNAL CIRCUIT

Diagnosis ProcedureINFOID:0000000006256129

1.PERFORM ECM SELF-DIAGNOSIS

With CONSULT-III

Perform “ENGINE” self-diagnosis.

Is any DTC detected?

YES >> Check the DTC. Refer to EC-98, "DTC Index".

NO >> GO TO 2.

2.CHECK HARNESS BETWEEN ECM AND POWER STEERING CONTROL UNIT

1. Turn the ignition switch OFF.

2. Disconnect ECM harness connectors.

3. Disconnect power steering control unit harness connector.

4. Check the continuity between ECM harness connecto r and power steering control unit harness connector.

5. Check the continuity between power st eering control unit harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace error-detected parts.

3.CHECK ENGINE SPEED SIGNAL (ECM)

1. Connect ECM harness connectors.

2. Check the signal between ECM harness connector and ground with oscilloscope.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Replace ECM. Refer to EC-143, "

Description".

ECM Power steering control unit

Continuity

Connector Terminal Connector Terminal

E80 169 M108 10 Existed

Power steering control unit — Continuity

Connector Terminal

M108 10 Ground Not existed

ECM — Condition Voltage (Approx.)

Connector Terminal

E80 169 Ground Engine is running

Warm-up condition

Idle speed

Engine is running

Warm-up condition

Engine speed: Approx. 2,000 rpm

JPBIA3352ZZ

JPBIA3354ZZ

Revision: 2010 May2011 QX56

Page 5064 of 5598

ENGINE SPEED SIGNAL CIRCUITSTC-19

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

H I

J

K L

M A

B

STC

N

O P

4.CHECK ENGINE SPEED SIGNAL (P OWER STEERING CONTROL UNIT)

1. Turn the ignition switch OFF.

2. Connect power steering control unit harness connector.

3. Check the signal between power steering control unit harness connector and ground with oscilloscope.

Is the inspection result normal?

YES >> GO TO 5.

NO >> Replace power steering control unit. Refer to STC-23, "

Removal and Installation".

5.CHECK TERMINALS AND HARNESS CONNECTORS

Check the power steering control unit pin terminal s for damage or loose connection with harness connector.

Check the ECM pin terminals for damage or loose connection with harness connector.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Repair or replace error-detected parts.

Power steering control unit — Condition Voltage (Approx.)

Connector Terminal

M108 10 Ground Engine is running

Warm-up condition

Idle speed

Engine is running

Warm-up condition

Engine speed: Approx. 2,000 rpm

JPBIA3352ZZ

JPBIA3354ZZ

Revision: 2010 May2011 QX56