warning INFINITI QX56 2011 Factory Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 415 of 5598

BCS

DIAGNOSIS SYSTEM (BCM)BCS-27

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K L

B A

O P

N

COMB SW

COMB SW : CONSULT-III Fu

nction (BCM - COMB SW)INFOID:0000000006274810

DATA MONITOR

LCD This test is able to check meter display information

Engine start information displays when “BP N” on CONSULT-III screen is touched

Engine start information displays when “BP I” on CONSULT-III screen is touched

Key ID warning displays when “ID NG” on CONSULT-III screen is touched

Steering lock information displays when “ROTAT” on CONSULT-III screen is touched

P position warning displays when “SFT P” on CONSULT-III screen is touched

INSRT: This item is displayed, but cannot be monitored

BATT: This item is displayed, but cannot be monitored

Take away through window warning displays when “NO KY” on CONSULT-III screen is

touched

Take away warning displa y when “OUTKEY” on CONSUL T-III screen is touched

OFF position warning display when “LK WN” on CONSULT-III screen is touched

FLASHER This test is able to check security hazard lamp operation

The hazard lamps are activated after “LH/RH/Off” on CONSULT-III screen is touched

P RANGE This test is able to check A/T shift selector power supply

On: Operate

Off: Non-operation

ENGINE SW ILLUMI This test is able to check push-button ignition switch illumination operation

Push-ignition switch illumination illuminates when “ON” on CONSULT-III screen is touched

LOCK INDICATOR This test is able to check LOCK indicator (push-button ignition switch) operation

On: Operate

Off: Non-operation

ACC INDICATOR This test is able to check ACC indicator (push-button ignition switch) operation

On: Operate

Off: Non-operation

IGNITION ON IND This test is able to check ON indicator (push-button ignition switch) operation

On: Operate

Off: Non-operation

HORN This test is able to check horn operation

On: Operate

Off: Non-operation

TRUNK/BACK DOOR NOTE:

This item is displayed, but cannot be used

Test item Description

Monitor item [U

NIT] Description

FR WIPER HI

[Off/On] Displays the status of the FR WIPER HI switch in combination switch judged by BCM with the combination

switch reading function.

FR WIPER LOW

[Off/On] Displays the status of the FR WIPER LOW switch in combination switch judged by BCM with the combination

switch reading function.

FR WASHER SW

[Off/On] Displays the status of the FR WASHER switch in combination switch judged by BCM with the combination

switch reading function.

FR WIPER INT

[Off/On] Displays the status of the FR WIPER AUTO switch in combination switch judged by BCM with the combina-

tion switch reading function.

INT VOLUME

[1 - 7] Displays the status of wiper volume dial position judged by BCM with the combination switch reading function.

RR WIPER ON

[Off/On] Displays the status of the RR WIPER ON switch in combination switch judged by BCM with the combination

switch reading function.

RR WIPER INT

[Off/On] Displays the status of the RR WIPER INT switch in combination switch judged by BCM with the combination

switch reading function.

RR WASHER SW

[Off/On] Displays the status of the RR WASHER switch in combination switch judged by BCM with the combination

switch reading function.

Revision: 2010 May2011 QX56

Page 419 of 5598

BCS

DIAGNOSIS SYSTEM (BCM)BCS-31

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K L

B A

O P

N

WORK SUPPORT

ACTIVE TEST

RETAIND PWR

RETAIND PWR : CONSULT-III F

unction (BCM - RETAINED PWR)INFOID:0000000006376459

Data monitor

SIGNAL BUFFER

SIGNAL BUFFER : CONSULT-III F unction (BCM - SIGNAL BUFFER)INFOID:0000000006274818

DATA MONITOR

DOOR SW-RL Indicates [ON/OFF] condition of rear door switch LH.

DOOR SW-BK Indicates [ON/OFF] condition of back door switch.

CDL LOCK SW Indicates [ON/OFF] condition of lock signal from door lock/unlock switch LH and RH.

CDL UNLOCK SW Indicates [ON/OFF] condition of unlock signal from door lock/unlock switch LH and RH.

KEY CYL LK-SW Indicates [ON/OFF] condition of lock signal from door key cylinder.

KEY CYL UN-SW Indicates [ON/OFF] condition of unlock signal from door key cylinder.

TR/BD OPEN SW Indicates [ON/OFF] condition of back door opener switch.

TRNK/HAT MNTR NOTE:

This item is displayed, but cannot be monitored.

RKE-LOCK Indicates [ON/OFF] condition of LOCK signal from Intelligent Key.

RKE-UNLOCK Indicates [ON/OFF] condition of UNLOCK signal from Intelligent Key.

RKE-TR/BD NOTE:

This item is displayed, but cannot be monitored.

Monitored Item Description

Service Item Description

SECURITY ALARM SET This mode is able to confirm and change security alarm ON-OFF setting.

THEFT ALM TRG The switch which triggered vehicle security alarm is recorded.

This mode is able to confirm and erase the record of vehicle security alarm.

The trigger data can be erased by touching “CLEAR” on CONSULT-III screen.

Test Item Description

THEFT IND This test is able to check security indicator lamp operation. Security indicator lamp is turned on

when “ON” on CONSULT-III screen is touched.

VEHICLE SECURITY HORN This test is able to check horn operation. Horn is activated for 0.5 seconds after “ON” on CONSULT-

III screen is touched.

HEADLAMP(HI) This test is able to check headlamp operation. Headlamps are activated for 0.5 seconds after “ON”

on CONSULT-III screen is touched.

FLASHER This test is able to check hazard warning lamp operation. Hazard warning lamps are activated after

“ON” on CONSULT-III screen is touched.

Monitor Item Description

DOOR SW-DR Indicates [ON/OFF] condition of driver side door switch.

DOOR SW-AS Indicates [ON/OFF] condition of passenger side door switch.

Monitor item [UNIT] Description

PUSH SW

[Off/On] Displays the status of the push-button ignition switch (push switch) judged by BCM.

Revision: 2010 May2011 QX56

Page 420 of 5598

BCS-32

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (BCM)

ACTIVE TEST

Te s t i t e mOpera-

tion Description

OIL PRESSURE SW Off OFF

On

BCM transmits the oil pressure switch signal to the combination meter via CAN communica-

tion, which illuminates the oil pressure warning lamp in the combination meter.

Revision: 2010 May2011 QX56

Page 425 of 5598

BCS

BCM

BCS-37

< ECU DIAGNOSIS INFORMATION >

C

D E

F

G H

I

J

K L

B A

O P

N

CONFIRM ID2

The key ID that the key slot receives is not recognized by the second key

ID registered to BCM.

Ye t

The key ID that the key slot receives is recognized by the second key ID

registered to BCM. Done

CONFIRM ID1 The key ID that the key slot receives is not recognized by the first key ID

registered to BCM.

Ye t

The key ID that the key slot receives is recognized by the first key ID reg-

istered to BCM. Done

NOT REGISTERED BCM detects registered key ID, or BCM does not detect key ID. ID OK

BCM detects non-registration key ID. ID NG

TP 4 The ID of fourth key is not registered to BCM Yet

The ID of fourth key is registered to BCM Done

TP 3 The ID of third key is not registered to BCM Yet

The ID of third key is registered to BCM Done

TP 2 The ID of second key is not registered to BCM Yet

The ID of second key is registered to BCM Done

TP 1 The ID of first key is not registered to BCM Yet

The ID of first key is registered to BCM Done

BUZZER Tire pressure warning alarm is not sounding Off

Tire pressure warning alarm is sounding On

Monitor Item Condition Value/Status

Revision: 2010 May2011 QX56

Page 441 of 5598

BCS

BCM

BCS-53

< ECU DIAGNOSIS INFORMATION >

C

D E

F

G H

I

J

K L

B A

O P

N

90

(Y) Ground Push-button ignition

switch illumination OutputPush-button ig-

nition switch illu-

mination ON 12 V

OFF 0 V

91

(O) Ground LOCK indicator lamp Output LOCK indicator

lampOFF (Ignition switch OFF) Battery voltage

ON 0 V

92

(L) Ground Push-button ignition

switch illumination

ground Output Tail lamp OFF 0 V

ON

NOTE:

When the illumination brighten-

ing/dimming level is in the neutral position

6.0 - 7.0 V

93

(GR/R) GroundIntelligent Key warn-

ing buzzer

OutputIntelligent Key

warning buzzer Sounding 0 V

Not sounding 12 V

94

(Y/G) Ground Steering lock unit

communication Input/

Output Steering lock LOCK status 12 V

LOCK or UNLOCK

For 15 seconds after UN-

LOCK

12 V

15 seconds or later after

UNLOCK 0 V

95

(W) Ground

Steering lock unit

power supply Output Ignition switch OFF or ACC 12 V

ON 0 V

96

(BR) Ground ACC relay control Output Ignition switch OFF 0 V

ACC or ON 12 V

97

(R/W) Ground Starter relay control Output Ignition switch

ONWhen selector lever is in

P or N position

12 V

When selector lever is not

in P or N position 0 V

98

(O) Ground Ignition relay (IPDM

E/R) control

Output Ignition switch OFF or ACC 12 V

ON 0 V

99

(R) Ground Ignition relay-1 con-

trol

Output Ignition switch OFF or ACC 0 V

ON 12 V

100

(SB) Ground

Push-button ignition

switch (push switch) InputPush-button ig-

nition switch

(push switch) Pressed 0 V

Not pressed 12 V

101

(W/B) Ground Ignition power sup-

ply No. 2 Output Ignition switch OFF or ACC 0 V

ON 12 V

Terminal No.

(Wire color) Description

Condition Va l u e

(Approx.)

Signal name Input/

Output

+ −

JPMIA1554GB

JMKIA0066GB

Revision: 2010 May2011 QX56

Page 462 of 5598

BCS-74

< DTC/CIRCUIT DIAGNOSIS >

B26E7 TPMS CAN COMM

B26E7 TPMS CAN COMM

DTC LogicINFOID:0000000006274839

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.DTC CONFIRMATION

1. Erase the DTC.

2. Turn ignition switch OFF.

3. Perform the “Self Diagnostic Result” of BCM with CONS ULT-III, when passed 2 seconds or more after the

ignition switch is turned ON.

Is any DTC detected?

YES >> Refer to BCS-74, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000006274840

NOTE:

If DTC “B26E7” detected along with DTC “U1000” , first diagnose the DTC “U1000”. Refer to BCS-70, "

Diagno-

sis Procedure".

1.LOW TIRE PRESSURE WARNING CONTRO L UNIT SELF DIAGNOSTIC RESULT

Perform “Self Diagnostic Result” of low tire pressu re warning control unit with CONSULT-III. Refer to WT-12,

"CONSULT-III Function".

Is any DTC detected?

YES >> GO TO 2.

NO >> GO TO 4.

2.LOW TIRE PRESSURE WARNING CONTROL UNIT DIAGNOSIS

Perform low tire pressure warning control uni t component diagnosis of detected DTC. Refer to WT-18, "

DTC

Index".

>> GO TO 3.

3.BCM SELF DIAGNOSTIC RESULT

Erase DTC of BCM, and perform “Self Diagnostic Result” again.

Is DTC

“B26E7” detected?

YES >> Replace BCM. Refer to BCS-81, "Removal and Installation".

NO >> INSPECTION END

4.REPLACE LOW TIRE PRESSURE WA RNING CONTROL UNIT TEMPORARILY

Remove low tire pressure warning control unit, and in stall normal low tire pressure warning control unit.

>> GO TO 5.

5.BCM SELF-DIAGNOSTIC RESULT

Erase DTC of BCM, and perform “S elf Diagnostic Result” of BCM again.

Is DTC

“B26E7” detected?

YES >> Replace BCM. Refer to BCS-81, "Removal and Installation".

NO >> Replace low tire pressure warning control unit. Refer to WT-65, "

Removal and Installation".

DTC CONSULT-III display description DTC Detection Condition Probable cause

B26E7 TPMS CAN COMM When ignition switch is ON, BCM cannot re-

ceived CAN communication signal from low

tire pressure warn

ing control unit. CAN communication system

Low tire pressure warning control unit

BCM

Revision: 2010 May2011 QX56

Page 473 of 5598

PRECAUTIONSBR-3

< PRECAUTION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006228171

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision that would result in air ba g inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIR BAG”.

Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the

ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wh eel Rotation after Battery Disconnect

INFOID:0000000006228172

NOTE:

Before removing and installing any control units, first tu rn the push-button ignition switch to the LOCK posi-

tion, then disconnect both battery cables.

After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If a DTC is detected, perform trouble diagnos is according to self-diagnosis results.

For vehicle with steering lock unit, if the battery is disconnected or discharged, the steering wheel will lock and

cannot be turned.

If turning the steering wheel is required with the batte ry disconnected or discharged, follow the operation pro-

cedure below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Turn the push-button ignition switch to ACC position. (At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock wil l remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

Revision: 2010 May2011 QX56

Page 474 of 5598

BR-4

< PRECAUTION >

PRECAUTIONS

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button igniti on switch is turned to LOCK position.)

6. Perform self-diagnosis check of all control units using CONSULT-III.

Precaution for Procedure without Cowl Top CoverINFOID:0000000006228173

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precaution for Brake systemINFOID:0000000006222459

WARNING:

Clean any dust from the front brake and rear brake wi th a vacuum dust collector. Never blow with com-

pressed air.

Brake fluid use refer to MA-10, "

Fluids and Lubricants".

Never reuse drained brake fluid.

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it off

immediately and wash with water if it gets on a painted surface.

Always confirm the specified tightening torque when installing the brake pipes.

After pressing the brake pedal more deeply or harder t han normal driving, such as air bleeding, check each

item of brake pedal. Adjust brake pedal if it is outside the standard value.

Always clean with new brake fluid when cleaning the brake caliper and other components.

Never use mineral oils such as gasoline or light oil to clean. They may damage rubber parts and cause

improper operation.

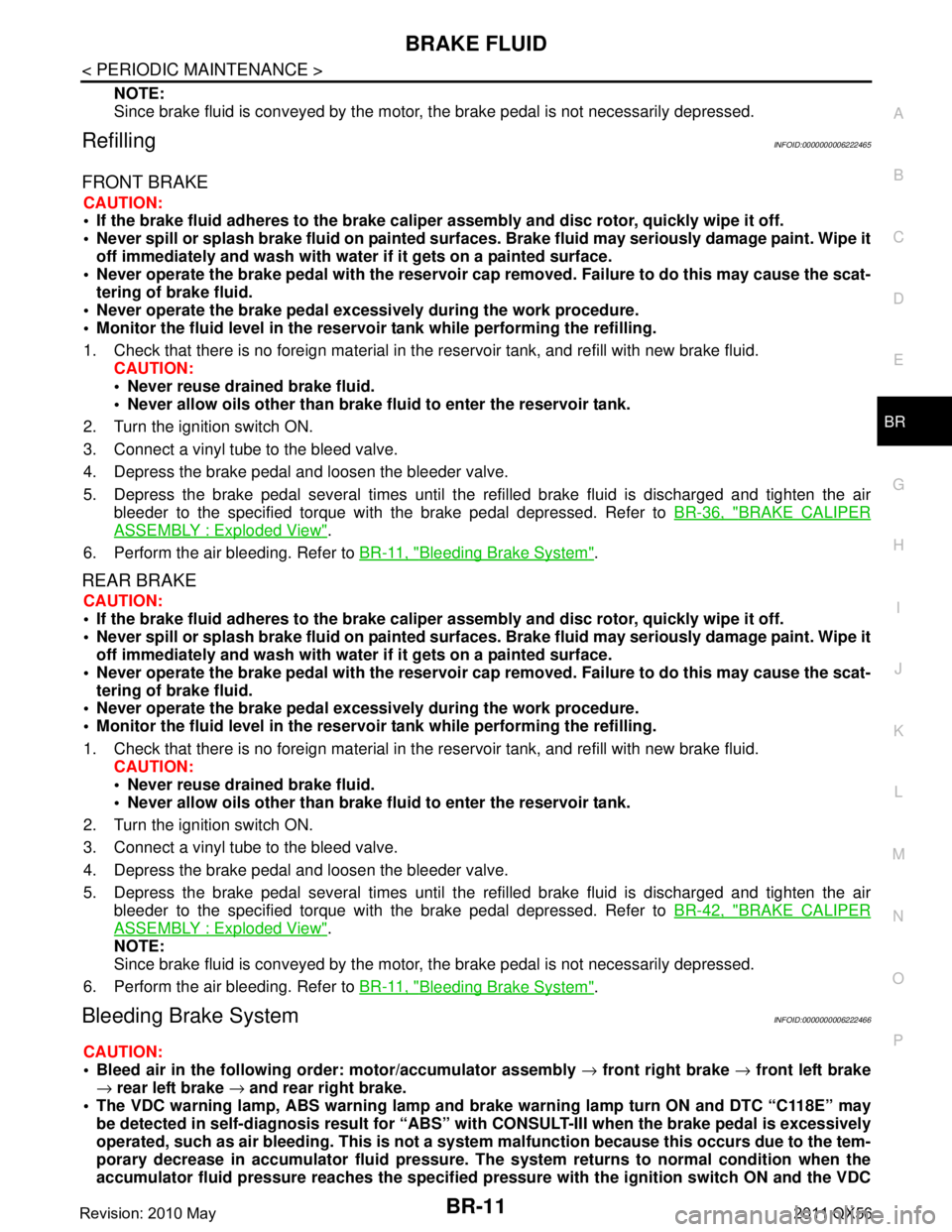

Always loosen the brake tube flar e nut with a flare nut wrench.

Tighten the brake tube flare nut to the specified torque with a crow-

foot (A) and torque wrench (B).

Brake system is an important safety part. If a brake fluid leak is detected, always disassemble the affected part. If a malfunction is

detected, replace part with a new one.

Always connect the battery terminals when moving the vehicle.

Turn the ignition switch OFF and disconnect the hydraulic booster assembly harness connector or the battery negative terminal

before performing the work.

Check that no brake fluid leakage is present after replacing the

parts.

Burnish the brake contact surfaces after refinishing or replacing rotors, after replacing pads, or if a soft pedal occurs at very low mileage.

- Front brake pad: Refer to BR-16, "

BRAKE PAD : Inspection and Adjustment".

- Front disc rotor: Refer to BR-16, "

DISC ROTOR : Inspection and Adjustment".

- Rear brake pad: refer to BR-18, "

BRAKE PAD : Inspection and Adjustment".

- Rear disc rotor: BR-18, "

DISC ROTOR : Inspection and Adjustment".

PIIB3706J

JPFIA0001ZZ

Revision: 2010 May2011 QX56

Page 481 of 5598

BRAKE FLUIDBR-11

< PERIODIC MAINTENANCE >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

NOTE:

Since brake fluid is conveyed by the motor, the brake pedal is not necessarily depressed.

RefillingINFOID:0000000006222465

FRONT BRAKE

CAUTION:

If the brake fluid adheres to the brake caliper assembly and disc rotor, quickly wipe it off.

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

Never operate the brake pedal with the reservoir cap removed. Failure to do this may cause the scat-

tering of brake fluid.

Never operate the brake pedal excessively during the work procedure.

Monitor the fluid level in the reservoir tank while performing the refilling.

1. Check that there is no foreign material in t he reservoir tank, and refill with new brake fluid.

CAUTION:

Never reuse drained brake fluid.

Never allow oils other than brake fl uid to enter the reservoir tank.

2. Turn the ignition switch ON.

3. Connect a vinyl tube to the bleed valve.

4. Depress the brake pedal and loosen the bleeder valve.

5. Depress the brake pedal several times until the re filled brake fluid is discharged and tighten the air

bleeder to the specified torque with the brake pedal depressed. Refer to BR-36, "

BRAKE CALIPER

ASSEMBLY : Exploded View".

6. Perform the air bleeding. Refer to BR-11, "

Bleeding Brake System".

REAR BRAKE

CAUTION:

If the brake fluid adheres to the brake caliper assembly and disc rotor, quickly wipe it off.

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

Never operate the brake pedal with the reservoir cap removed. Failure to do this may cause the scat-

tering of brake fluid.

Never operate the brake pedal excessively during the work procedure.

Monitor the fluid level in the reservoir tank while performing the refilling.

1. Check that there is no foreign material in t he reservoir tank, and refill with new brake fluid.

CAUTION:

Never reuse drained brake fluid.

Never allow oils other than brake fl uid to enter the reservoir tank.

2. Turn the ignition switch ON.

3. Connect a vinyl tube to the bleed valve.

4. Depress the brake pedal and loosen the bleeder valve.

5. Depress the brake pedal several times until the re filled brake fluid is discharged and tighten the air

bleeder to the specified torque with the brake pedal depressed. Refer to BR-42, "

BRAKE CALIPER

ASSEMBLY : Exploded View".

NOTE:

Since brake fluid is conveyed by the motor, the brake pedal is not necessarily depressed.

6. Perform the air bleeding. Refer to BR-11, "

Bleeding Brake System".

Bleeding Brake SystemINFOID:0000000006222466

CAUTION:

Bleed air in the following order: motor/accumulator assembly → front right brake → front left brake

→ rear left brake → and rear right brake.

The VDC warning lamp, ABS warning lamp and br ake warning lamp turn ON and DTC “C118E” may

be detected in self-diagnosis result for “ABS” with CONSULT-III when the brake pedal is excessively

operated, such as air bleeding. This is not a system malfunction because this occurs due to the tem-

porary decrease in accumulator fl uid pressure. The system returns to normal condition when the

accumulator fluid pressure reaches the specified pressu re with the ignition switch ON and the VDC

Revision: 2010 May2011 QX56

Page 482 of 5598

BR-12

< PERIODIC MAINTENANCE >

BRAKE FLUID

warning lamp, ABS warning lamp, and brake warning lamp turn OFF. After these steps, erase self-

diagnosis results for “ABS” with CONSULT-III.

- DTC other than “C118E” is detected: Refer to BRC-51, "

DTC Index".

NOTE:

When the ignition switch is ON, the brake warning la mp may turns ON even when the parking brake pedal is

released with the brake fluid within the specified level. This indicates the decrease in accumulator fluid pres-

sure.

MOTOR/ACCUMULATOR ASSEMBLY

CAUTION:

If the brake fluid adheres to the brake caliper assembly and disc rotor, quickly wipe it off.

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

Never operate the brake pedal with the reservoir cap removed. Failure to do this may cause the scat-

tering of brake fluid.

Never operate the brake pedal excessively during the work procedure.

Monitor the fluid level in the reservoir tank while performing the air bleeding.

Bleed air in the following order: motor/accumulator assembly → front right brake → front left brake

→ rear left brake → and rear right brake.

1. Turn the ignition switch OFF.

2. Depress the brake pedal 20 times or more.

3. Check that there is no foreign material in the reservoir tank, and refill with new brake fluid. CAUTION:

Never reuse drained brake fluid.

Never allow oils other than brake fluid to enter the reservoir tank.

4. Turn the ignition switch ON. NOTE:

The motor is activated and automatically stops.

5. Turn the ignition switch OFF.

6. Depress the brake pedal 20 times or more. NOTE:

The pressure loss in the accumulator results in a large brake pedal stroke. In addition to this, the brake

pedal depression becomes lighter in initial stage.

7. Repeat steps 4 to 6 for 5 times.

8. Turn the ignition switch ON to check that the time between motor activation and automatic stop is less

than 18 seconds. If the time is 18 seconds or more, repeat from Step 4 to 8.

FRONT BRAKE

CAUTION:

If the brake fluid adheres to the brake caliper assembly and disc rotor, quickly wipe it off.

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

Never operate the brake pedal with the reservoir cap removed. Failure to do this may cause the scat- tering of brake fluid.

Never operate the brake pedal excessively during the work procedure.

Monitor the fluid level in the reservoir tank while performing the air bleeding.

Bleed air in the following order: motor/accumulator assembly → front right brake → front left brake

→ rear left brake → and rear right brake.

1. Turn the ignition switch OFF.

2. Depress the brake pedal 20 times or more. NOTE:

The pressure loss in the accumulator results in a large brake pedal stroke. In addition to this, the brake

pedal depression becomes lighter in initial stage.

3. Check that there is no foreign material in the reservoir tank, and refill with new brake fluid. CAUTION:

Never reuse drained brake fluid.

Never allow oils other than brake fluid to enter the reservoir tank.

4. Turn the ignition switch ON.

Revision: 2010 May2011 QX56