remove seats INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 2318 of 5598

![INFINITI QX56 2011 Factory Service Manual

EC-294

< DTC/CIRCUIT DIAGNOSIS >[VK56VD]

P0300, P0301, P0302, P

0303, P0304, P0305, P0306, P0307, P0308 MISFIRE

When the gap is less than 13 mm (0.52 in), a spark might be generated even if the coi INFINITI QX56 2011 Factory Service Manual

EC-294

< DTC/CIRCUIT DIAGNOSIS >[VK56VD]

P0300, P0301, P0302, P

0303, P0304, P0305, P0306, P0307, P0308 MISFIRE

When the gap is less than 13 mm (0.52 in), a spark might be generated even if the coi](/img/42/57033/w960_57033-2317.png)

EC-294

< DTC/CIRCUIT DIAGNOSIS >[VK56VD]

P0300, P0301, P0302, P

0303, P0304, P0305, P0306, P0307, P0308 MISFIRE

When the gap is less than 13 mm (0.52 in), a spark might be generated even if the coil is malfunc-

tioning.

Is the inspection result normal?

YES >> GO TO 9.

NO >> GO TO 6.

6.CHECK FUNCTION OF IGNITION COIL-II

1. Turn ignition switch OFF.

2. Disconnect spark plug and connect a non-malfunctioning spark plug.

3. Crank engine for approximately 3 seconds, and rec heck whether spark is generated between the spark

plug and the grounded metal portion.

Is the inspection result normal?

YES >> GO TO 7.

NO >> Check ignition coil, power transistor and their circuits. Refer to EC-506, "

Diagnosis Procedure".

7.CHECK SPARK PLUG

Check the initial spark plug for fouling, etc.

Is the inspection result normal?

YES >> Replace spark plug(s) with standard type one(s). For spark plug type, refer to EM-132, "

Spark Plug".

NO >> Repair or clean spark plug. Then GO TO 8.

8.CHECK FUNCTION OF IGNITION COIL-III

1. Reconnect the initial spark plugs.

2. Crank engine for approximately 3 seconds, and rec heck whether spark is generated between the spark

plug and the grounded portion.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace spark plug(s) with standard type one(s). For spark plug type, refer to EM-132, "

Spark

Plug".

9.CHECK COMPRESSION PRESSURE

Check compression pressure. Refer to EM-16, "

Inspection".

Is the inspection result normal?

YES >> GO TO 10.

NO >> Check pistons, piston rings, valves, valve seats and cylinder head gaskets.

10.CHECK FUEL PRESSURE

1. Install all removed parts.

2. Check fuel pressure. Refer to EC-153, "

Work Procedure".

Is the inspection result normal?

YES >> GO TO 12.

NO >> GO TO 11.

11 .DETECT MALFUNCTIONING PART

Check fuel hoses and fuel tubes for clogging.

Is the inspection result normal?

Spark should be generated.

SEF156I

Spark should be generated.

Revision: 2010 May2011 QX56

Page 2653 of 5598

CYLINDER HEADEM-91

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

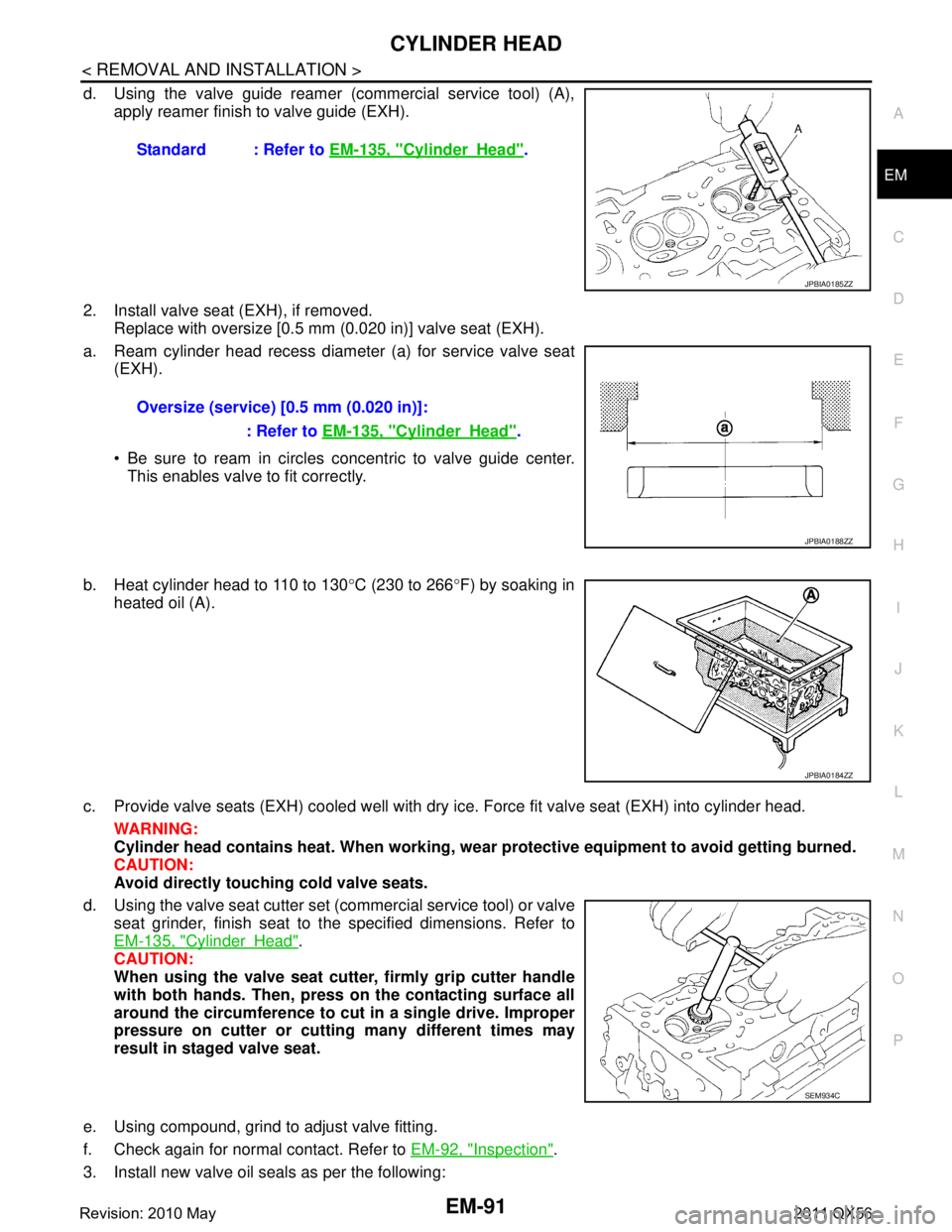

d. Using the valve guide reamer (commercial service tool) (A),

apply reamer finish to valve guide (EXH).

2. Install valve seat (EXH), if removed. Replace with oversize [0.5 mm (0.020 in)] valve seat (EXH).

a. Ream cylinder head recess diameter (a) for service valve seat (EXH).

Be sure to ream in circles concentric to valve guide center.

This enables valve to fit correctly.

b. Heat cylinder head to 110 to 130 °C (230 to 266 °F) by soaking in

heated oil (A).

c. Provide valve seats (EXH) cooled well with dry ice. Force fit valve seat (EXH) into cylinder head. WARNING:

Cylinder head contains heat. When working, w ear protective equipment to avoid getting burned.

CAUTION:

Avoid directly touching cold valve seats.

d. Using the valve seat cutter set (commercial service tool) or valve seat grinder, finish seat to the specified dimensions. Refer to

EM-135, "

CylinderHead".

CAUTION:

When using the valve seat cutt er, firmly grip cutter handle

with both hands. Then, press on the contacting surface all

around the circumference to cu t in a single drive. Improper

pressure on cutter or cutting many different times may

result in staged valve seat.

e. Using compound, grind to adjust valve fitting.

f. Check again for normal contact. Refer to EM-92, "

Inspection".

3. Install new valve oil seals as per the following: Standard : Refer to

EM-135, "

CylinderHead".

JPBIA0185ZZ

Oversize (service) [0.5 mm (0.020 in)]:

: Refer to EM-135, "

CylinderHead".

JPBIA0188ZZ

JPBIA0184ZZ

SEM934C

Revision: 2010 May2011 QX56

Page 3419 of 5598

REAR CONSOLE ASSEMBLYIP-29

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

K L

M A

B

IP

N

O P

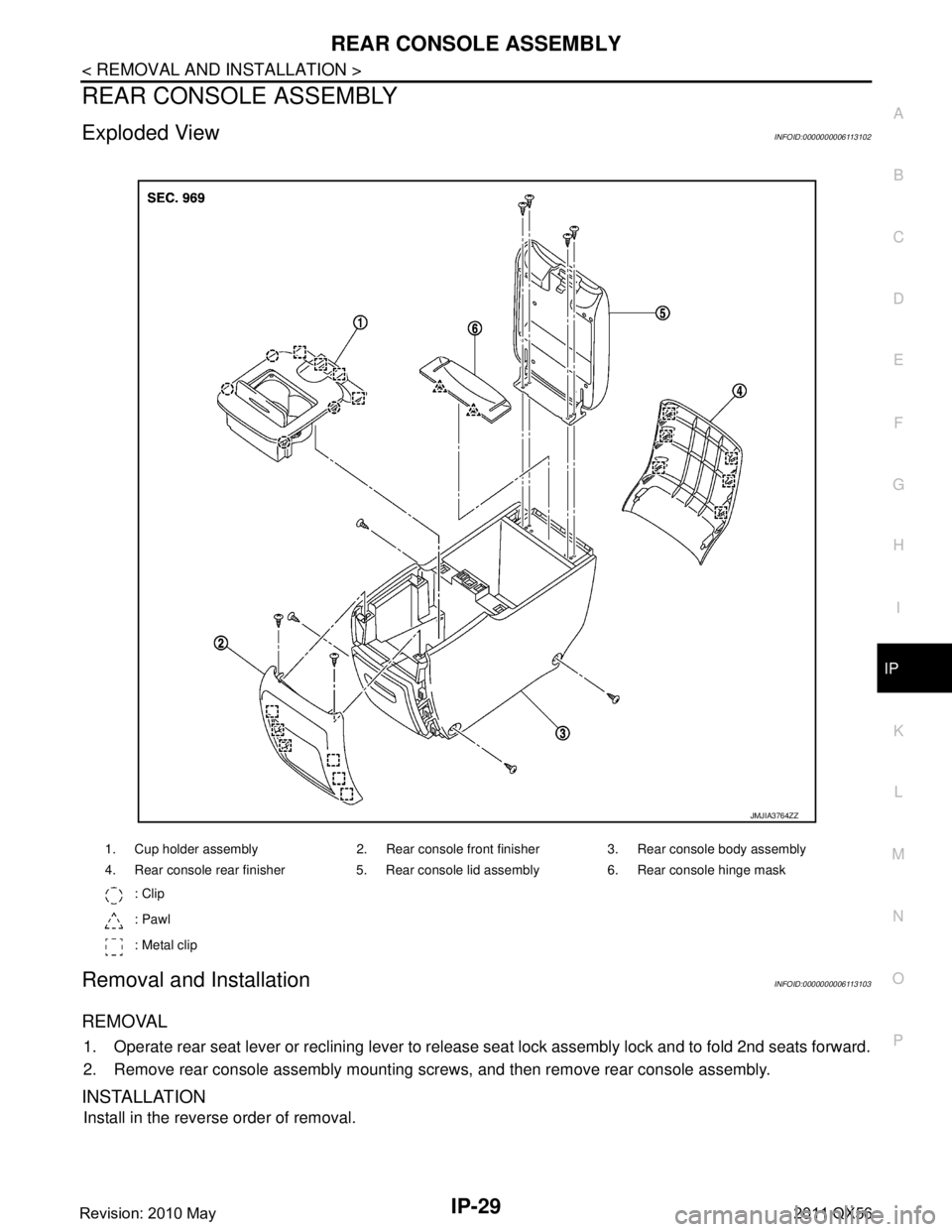

REAR CONSOLE ASSEMBLY

Exploded ViewINFOID:0000000006113102

Removal and InstallationINFOID:0000000006113103

REMOVAL

1. Operate rear seat lever or reclining lever to release seat lock assembly lock and to fold 2nd seats forward.

2. Remove rear console assembly mounting screws, and then remove rear console assembly.

INSTALLATION

Install in the reverse order of removal.

1. Cup holder assembly 2. Rear console front finisher 3. Rear console body assembly

4. Rear console rear finisher 5. Rear console lid assembly 6. Rear console hinge mask : Clip

: Pawl

: Metal clip

JMJIA3764ZZ

Revision: 2010 May2011 QX56

Page 3675 of 5598

GENERAL MAINTENANCEMA-5

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should

be checked periodically (e.g. each time you check the engine oil or refuel).

Seats Check seat position controls such as seat adjusters, seatback recliner, etc. to

make sure they operate smoothly and that all latches lock securely in every po-

sition. Check that the head restrains move up and down smoothly and that the

locks (if equipped) hold securely in all latched positions. Check that the latches

lock securely for folding-down rear seatbacks. —

Seat belts Check that all parts of the seat belt system (e.g. buckles, anchors, adjusters

and retractors) operate properly and smoothly, and are installed securely.

Check the belt webbing for cuts, fraying, wear or damage. MA-34

Accelerator pedal

Check the pedal for smooth operation and make sure the pedal does not catch

or require uneven effort. Keep the floor mats away from the pedal. —

Brakes Check that the brake does not pull the vehicle to one side when applied. —

Brake pedal and

booster Check the pedal for smooth operation and make sure it has the proper distance

under it when depressed fully. Check the brake booster function. Be sure to

keep the floor mats away from the pedal. BR-7

BR-15

Parking brake

Check that the lever or pedal has the proper travel and make sure that the ve-

hicle is held securely on a fairly steep hill when only the parking brake is ap-

plied. PB-3

Automatic transmis-

sion “Park” mecha-

nismCheck that the lock release button on the selector lever operates properly and

smoothly. On a fairly steep hill check that the vehicle is held securely with the

selector lever in the P (Park) position without applying any brakes.

—

Item

Reference page

Item Reference page

Windshield washer

fluid Check that there is adequate fluid in the tank. —

Engine coolant level Check the coolant level when the engine is cold. MA-12

Radiator and hosesCheck the front of the radiator and clean off any dirt, insects, leaves, etc., that

may have accumulated. Make sure the hoses have no cracks, deformation, de-

terioration or loose connections. MA-16

Brake fluid levels

Make sure that the brake fluid level is between the “MAX” and “MIN” lines on the

reservoir(s). MA-28

Battery

Check the fluid level in each cell. It should be between the “MAX” and “MIN”

lines. Vehicles operated in high temperatures or under severe conditions re-

quire frequent checks of the battery fluid level. PG-159

Engine drive belts

Make sure that no belt is frayed, worn, cracked or oily. MA-12

Engine oil levelCheck the level on the oil level gauge after parking the vehicle on a level spot

and turning off the engine. LU-7

Power steering fluid

level and linesCheck the level on the dipstick with the engine off. Check the lines for improper

attachment, leaks, cracks, etc.

MA-32

Exhaust system

Make sure there are no loose supports, cracks or holes. If the sound of the ex-

haust seems unusual or there is a smell of exhaust fumes, immediately locate

the trouble and correct it. MA-21

Underbody

The underbody is frequently exposed to corrosive substances such as those

used on icy roads or to control dust. It is very important to remove these sub-

stances, otherwise rust will form on the floor pan, frame, fuel lines and around

the exhaust system. At the end of winter, the underbody should be thoroughly

flushed with plain water, being careful to clean those areas where mud and dirt

can easily accumulate. —

Fluid leaks Check under the vehicle for fuel, oil, water or other fluid leaks after the vehicle

has been parked for a while. Water dripping from the air conditioner after use is

normal. If you should notice any leaks or gasoline fumes are evident, check for

the cause and correct it immediately. —

Revision: 2010 May2011 QX56

Page 4252 of 5598

RF-38

< REMOVAL AND INSTALLATION >

SUNROOF UNIT ASSEMBLY

Removal and Installation

INFOID:0000000006141251

REMOVAL

CAUTION:

Always work with a helper.

Fully close the glass lid assembly, before removal , then never operate sunroof motor assembly after

removal.

When taking sunroof unit out, use cloths to protect the seats and trim from damage.

After installing the sunroof unit and glass lid, perform the leak test and check that there is no mal-

function.

1. Remove the headlining. Refer to INT-29, "

Removal and Installation".

2. Disconnect drain hoses.

3. Remove the glass lid. Refer to RF-33, "

Removal and Installation".

4. Remove the sunroof motor assembly. Refer to RF-36, "

Removal and Installation".

1. Rear drain assembly 2. Wind deflector 3. Sunshade stopper

4. Sunroof frame 5. Sunshade

JMKIA5378ZZ

Revision: 2010 May2011 QX56

Page 4253 of 5598

SUNROOF UNIT ASSEMBLYRF-39

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

L

M A

B

RF

N

O P

5. Remove grip bracket.

6. Remove sunroof bracket bolts.

7. Remove nuts from the front end and side rail, and then remove sunroof unit assembly from roof panel.

8. Remove sunroof unit assembly through the passenger compartment while being careful not to damage the seats and trim.

INSTALLATION

1. Temporarily tighten the mounting nuts to the side rail of sunroof unit assembly.

2. Temporarily tighten the mounting nuts to the front end of sunroof unit assembly.

3. Temporarily tighten the mounting bolts to the sunroof brackets (LH,RH).

4. Tighten the installation points diagonally excluding the installation points of the sunroof brackets around the roof opening.

5. Tighten the mounting nuts to the front end and side rail.

6. Tighten the sunroof bracket bolts of the vehicl e side, and then tighten the bolt of the rail side.

7. Install the glass lid. NOTE:

After installation, perform fitting adjustment. Refer to RF-33, "

Adjustment".

8. Connect drain hoses.

9. Install headlining. Refer to INT-29, "

Removal and Installation".

Disassembly and AssemblyINFOID:0000000006141252

DISASSEMBLY

1. Remove sunshade stopper mounting from the rear end of sunroof frame.

2. Remove rear drain assembly from sunroof guide assembly.

3. Remove sunshade from the rear end of sunroof frame.

ASSEMBLY

Assemble in the reverse order of disassembly.

Revision: 2010 May2011 QX56

Page 4279 of 5598

SB-4

< REMOVAL AND INSTALLATION >

FRONT SEAT BELT

REMOVAL AND INSTALLATION

FRONT SEAT BELT

SEAT BELT RETRACTOR

SEAT BELT RETRACTOR : InspectionINFOID:0000000006217615

AFTER A COLLISION

WARNING:

Inspect all seat belt assemblies including retractors and attached hardware after any collision.

NISSAN/INFINITI recommends that all seat belt assemblies in use during a collision be replaced

unless the collision was minor and th e belts show no damage and continue to operate properly. Fail-

ure to do so could result in seri ous personal injury in an accident. Seat belt assemblies not in use dur-

ing a collision should also be re placed if either damage or improper operation was noted. Seat belt

pre-tensioners should be replaced even if the seat be lts were not in use during a frontal collision in

which the air bags were deployed.

Replace any seat belt assembly (including anchor bolts) if:

The seat belt is in use at the time of a collision (e xcept for minor collisions and the belts, retractors and buck-

les show no damage and continue to operate properly).

The seat belt is damaged in an accident (i.e. to rn webbing, bent retractor or guide, etc.).

The seat belt attaching point is damaged in an accident . Inspect the seat belt attaching area for damage or

distortion and repair if necessary before installing a new seat belt assembly.

Anchor bolts are deformed or worn out.

The seat belt pre-tensioners must be replaced even if t he seat belts were not in use during the collision in

which the air bags were deployed.

PRELIMINARY CHECKS

1. Check the seat belt warning lamp for proper operation as per the following:

a. Turn ignition switch ON. The seat belt warning lamp should illuminate.

b. Fasten driver seat belt. The seat belt warning lamp should turn OFF.

2. If the air bag warning lamp is blinking, perform self-diagnosis with CONSULT-III and air bag warning lamp. Refer to SRC-14, "

Description".

3. Check that the seat belt retractor, s eat belt anchor and buckle bolts are tightened firmly.

4. Check the shoulder seat belt guide and shoulder belt height adjuster for front seats. Check that guide

swivels freely and that webbing lays flat and does not bind in guide. Check that height adjuster operates

properly and holds securely.

5. Check retractor operation:

a. Fully extend the seat belt webbing and c heck for twists, tears or other damage.

b. Allow the seat belt to retract. Check that webbing retu rns smoothly and completely into the retractor. If the

seat belt does not return smoothly, wipe the inside of the loops with a clean paper cloth. Dirt build-up in the

loops of the upper anchors can cause the seat belts to retract slowly.

c. Fasten the seat belt. Check that seat belt returns sm oothly and completely to the retractor. If the webbing

does not return smoothly, the cause may be an accumulation of dust or dirt. Use the “SEAT BELT TAPE

SET” and perform the following steps.

Inspect the front seat belt through-anchor

1. Pull the seat belt out to a length of 500 mm (19.69 in) or more.

2. Fix the seat belt at the center pillar webbing opening with a clip or other device.

3. Pass a thin wire through the through-anchor webbing opening. Hold both ends of the wire and pull it tightly while moving it up and down several times along the webbing opening surface to remove dirt

stuck there.

4. Any dirt that cannot be removed with the wir e can be removed by cleaning the opening with a clean

cloth.

5. Apply tape at the point where the webbi ng contacts the through-anchor webbing opening.

NOTE:

Apply the tape so that there is no slack or wrinkling.

6. Remove the clip fixing the seat belt and check that the webbing returns smoothly.

6. Repeat steps above if necessary to check the other seat belts.

Revision: 2010 May2011 QX56

Page 4280 of 5598

FRONT SEAT BELTSB-5

< REMOVAL AND INSTALLATION >

C

DE

F

G

I

J

K L

M A

B

SB

N

O P

SEAT BELT RETRACTOR ON-VEHICLE CHECK

Emergency Locking Retractors (ELR) and Automatic Locking Retractors (ALR)

NOTE:

All seat belt retractors are Emergency Locking Retr actors (ELR) type. In an emergency (sudden stop) the

retractor will lock and prevent the webbing from extendi ng any further. All 3-point type seat belt retractors

except the driver seat belt also have an Automati c Locking Retractors (ALR) mode. The ALR mode (also

called child restraint mode) is used when installing child seats. The ALR mode is activated when the seat belt

is fully extended. When the webbing is then retracted part ially, the ALR mode automatically locks the seat belt

in a specific position so the webbi ng cannot be extended any further. To c ancel the ALR mode, allow the seat

belt to fully wind back into the retractor.

Check the seat belt retractors with the following test(s ) to determine if a retractor assembly is operating prop-

erly.

ELR Function Stationary Check

Grasp the shoulder webbing and pull forward quickly. The retractor should lock and prevent the belt from

extending further.

ALR Function Stationary Check

1. Pull out the entire length of seat bel t from retractor until a click is heard.

2. Retract the webbing partially. A clicking noise should be heard as the webbing retracts indicating that the

retractor is in the Automatic Locking Retractors (ALR) mode.

3. Grasp the seat belt and try to pull out the retractor. The webbing must lock and not extend any further. If it

does not operate normally, replace the retractor assembly.

4. Allow the entire length of the webbing to retract to cancel the automatic locking mode.

ELR Function Moving Check

WARNING:

Perform the following test in a safe, open area clear of other vehicles and obstructions (for example, a

large, empty parking lot). Road surface must be p aved and dry. Never perform the following test on

wet or gravel roads or on public streets and highways. This could result in an accident and serious

personal injury. The driver and passenger must be prepared to brace themselves in the event that the

retractor does not lock.

1. Fasten driver seat belt. Buckle a passenger into the seat for the belt that is to be tested.

2. Proceed to the designated safe area.

3. Drive the vehicle at approximately 16 km/h ( 10 MPH). Notify any passengers of a pending sudden stop

and the driver and passenger must be prepared to brac e themselves in the event that the retractor does

not lock. Apply brakes firmly and make a very hard stop.

During stopping, seat belts should lock and not be extended. If the seat belt retractor assembly does not lock,

perform the retractor off-vehicle check.

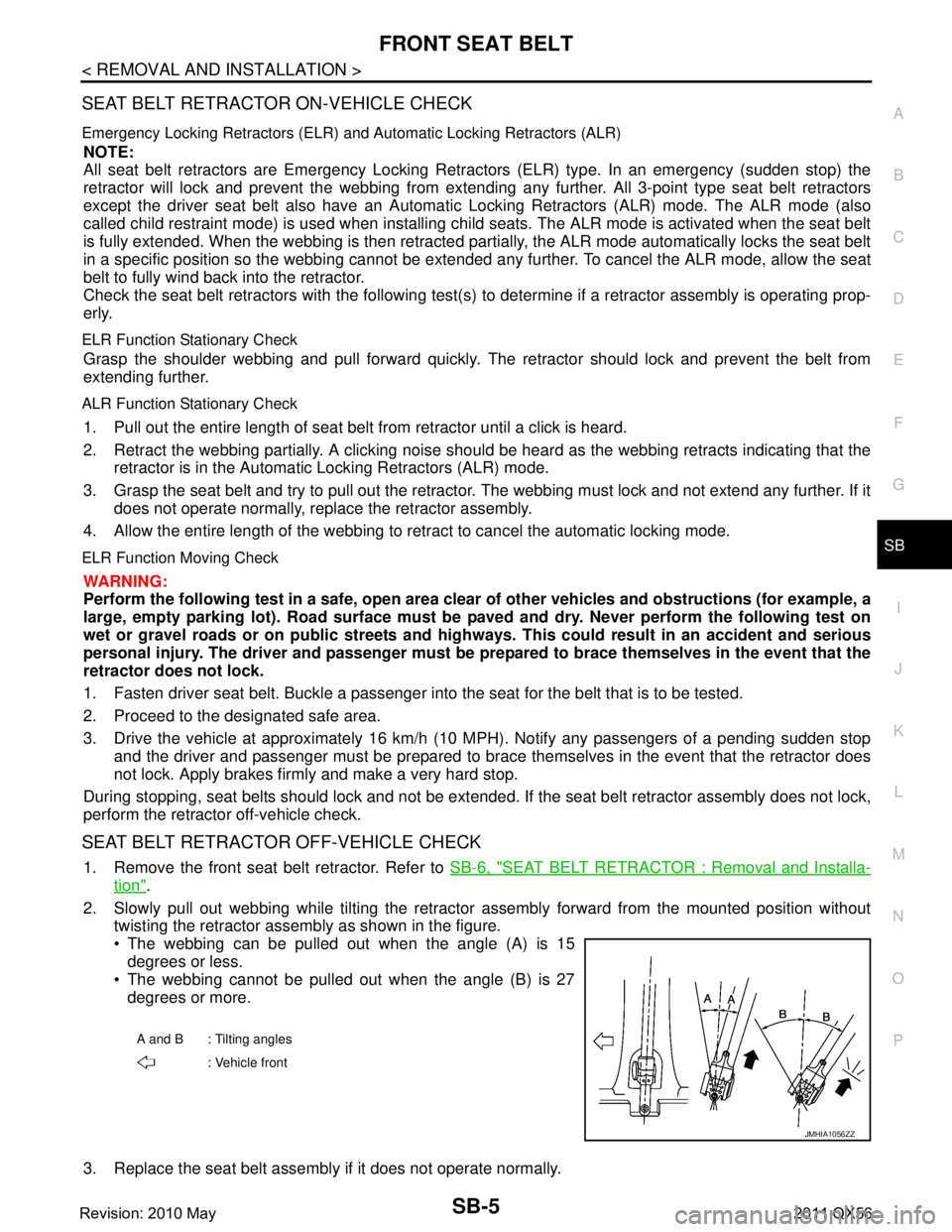

SEAT BELT RETRACTOR OFF-VEHICLE CHECK

1. Remove the front seat belt retractor. Refer to SB-6, "SEAT BELT RETRACTOR : Removal and Installa-

tion".

2. Slowly pull out webbing while tilting the retracto r assembly forward from the mounted position without

twisting the retractor assembly as shown in the figure.

The webbing can be pulled out when the angle (A) is 15

degrees or less.

The webbing cannot be pulled out when the angle (B) is 27

degrees or more.

3. Replace the seat belt assembly if it does not operate normally.

A and B : Tilting angles : Vehicle front

JMHIA1056ZZ

Revision: 2010 May2011 QX56

Page 4572 of 5598

FRONT SEATSE-113

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

K L

M A

B

SE

N

O P

b. Front inner slide cover Slide the seat to the rearmost position.

Pull up the front edge of the front slide cover to release thepawls.

Slide the front slide cover forward to release the pawls.

2. Remove the mounting bolts on the front side of the front seat.

3. Remove the rear slide cover.

a. Rear inner slide cover Slide the seat to the foremost position.

Pull up the rear edge of the rear inner slide cover to releasethe pawls.

Slide the rear inner slide cover rearward to release the pawls.

b. Rear outer slide cover Slide the seat to the foremost position.

Pull up the rear edge of the rear outer slide cover to releasethe pawls.

Slide the rear outer slide cover rearward to release the pawls.

4. Remove the mounting bolts on t he rear side of the front seat.

5. Set seatback in a standing position.

6. Slide the seat to the rearmost position.

7. Disconnect harness connectors under the seat and remove harness securing clips. CAUTION:

Before removal, turn ignition sw itch OFF, disconnect battery negative terminal and then wait for at

least 3 minutes or more.

8. Remove seat from the vehicle. CAUTION:

When removing and installing, use shop cloths to protect parts from damage.

INSTALLATION

Note the following items, and then install in the reverse order of removal.

CAUTION:

Before installation, turn ignition switch OFF, disconnect battery ne gative terminal and then wait for

at least 3 minutes or more.

Clamp the harness in position.

NOTE:

After installing the front seat, perform additional serv ice when removing battery negative terminal. Refer to

ADP-51, "

ADDITIONAL SERVICE WHEN REMOVING BATTERY NEGATIVE TERMINAL : Description".

: Pawl

JMJIA3823ZZ

: Pawl

JMJIA3826ZZ

: Pawl

JMJIA3825ZZ

Revision: 2010 May2011 QX56

Page 4574 of 5598

FRONT SEATSE-115

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

K L

M A

B

SE

N

O P

3. Remove the headrest holder from the seatback while pressing the pawls as shown by the arrows in the figure.

CAUTION:

Before installing headrest holder check its orientation.

(Front/rear and right/left)

4. Disconnect the seatback heater unit harness connector (A). (with heater seat model only)

5. Remove the seatback pad and seatback trim. 1. Disconnect the foot welcome lamp harness connector and the harness clamp.

2. Remove the seatback retainer on the back side of the seatback.

3. Remove the side air bag harness clamp.

4. Remove the side air bag module mounting nuts.

5. Remove the headrest display harness lower tube (1) from

the seat frame assembly (2) while pressing up the pawls as

shown by the arrows in the figure.

6. Remove the seatback trim and the seatback pad from the seat frame assembly. Remove them

together with the headrest display harness lower tube and the side air bag module.

7. Remove the hog rings, and separate the seatback trim and seatback pad.

6. Remove the seatback silencer.

7. Remove the following parts after removing seatback silencer. Seatback climate controlled seat unit (wit h climate controlled seat model only).

Refer to SE-117, "

CLIMATE CONTROLLED SEAT UNIT : Disassembly and Assembly".

Remove the lumber support unit assembly.

ASSEMBLY

Assemble in the reverse order of disassembly.

CAUTION:

Install the hog rings of seatback trim in position, and then securely connect the trim or trim cord with

the pad side wire.

SEAT CUSHION

JMJIA4073ZZ

JMJIA4326ZZ

JMJIA3976ZZ

Revision: 2010 May2011 QX56