Camshaft position sensor INFINITI QX56 2011 Factory Repair Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 2634 of 5598

EM-72

< REMOVAL AND INSTALLATION >

TIMING CHAIN

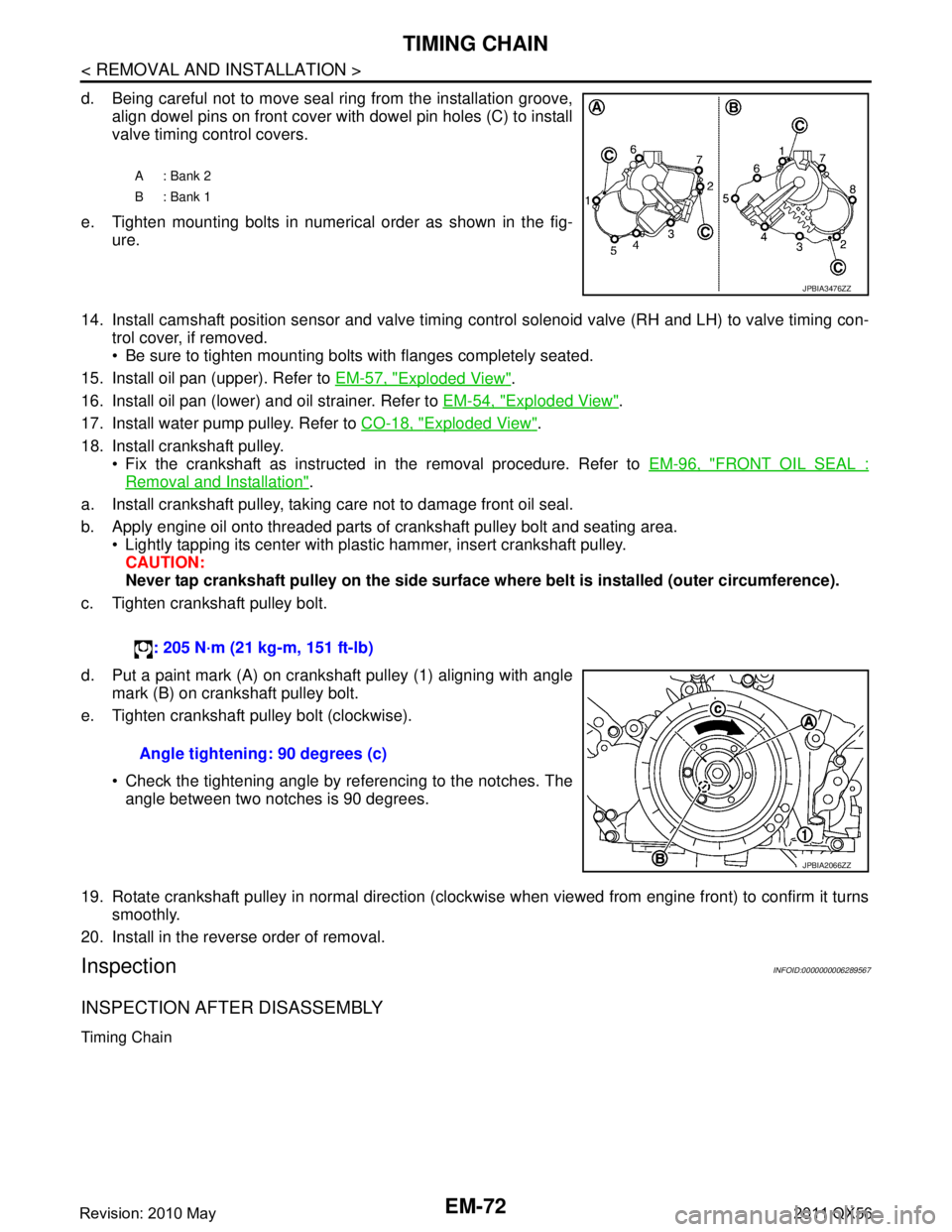

d. Being careful not to move seal ring from the installation groove,align dowel pins on front cover with dowel pin holes (C) to install

valve timing control covers.

e. Tighten mounting bolts in numerical order as shown in the fig- ure.

14. Install camshaft position sensor and valve timing c ontrol solenoid valve (RH and LH) to valve timing con-

trol cover, if removed.

Be sure to tighten mounting bolts with flanges completely seated.

15. Install oil pan (upper). Refer to EM-57, "

Exploded View".

16. Install oil pan (lower) and oil strainer. Refer to EM-54, "

Exploded View".

17. Install water pump pulley. Refer to CO-18, "

Exploded View".

18. Install crankshaft pulley. Fix the crankshaft as instructed in the removal procedure. Refer to EM-96, "

FRONT OIL SEAL :

Removal and Installation".

a. Install crankshaft pulley, taking care not to damage front oil seal.

b. Apply engine oil onto threaded parts of crankshaft pulley bolt and seating area. Lightly tapping its center with plastic hammer, insert crankshaft pulley.

CAUTION:

Never tap crankshaft pulley on the side surface wh ere belt is installed (outer circumference).

c. Tighten crankshaft pulley bolt.

d. Put a paint mark (A) on crankshaft pulley (1) aligning with angle mark (B) on crankshaft pulley bolt.

e. Tighten crankshaft pulley bolt (clockwise).

Check the tightening angle by referencing to the notches. Theangle between two notches is 90 degrees.

19. Rotate crankshaft pulley in normal direction (clockwise when viewed from engine front) to confirm it turns smoothly.

20. Install in the reverse order of removal.

InspectionINFOID:0000000006289567

INSPECTION AFTER DISASSEMBLY

Timing Chain

A: Bank 2

B: Bank 1

JPBIA3476ZZ

: 205 N·m (21 kg-m, 151 ft-lb)

Angle tightening: 90 degrees (c)

JPBIA2066ZZ

Revision: 2010 May2011 QX56

Page 2636 of 5598

EM-74

< REMOVAL AND INSTALLATION >

CAMSHAFT

CAMSHAFT

Exploded ViewINFOID:0000000006289568

1.VVEL actuator motor assembly

(bank 2) 2. Gasket 3.

VVEL actuator ho

using assembly

(bank 2)

4. Washer 5. VVEL ladder as sembly (bank 2) 6. Exhaust camshaft (bank 2)

7. Cylinder head (bank 2) 8. Cylinder head (bank 1) 9. Exhaust camshaft (bank 1)

10. VVEL ladder assembly (bank 1) 11. VVEL actuator housing assembly

(bank 1)12. Gasket

13. VVEL actuator motor assembly

(bank 1) 14.

VVEL control shaft

position sensor

(bank 1) 15.

VVEL control shaft

position sensor

(bank 2)

A. Comply with the installation proce-

dure when tightening. Refer to

EM-

75, "Removal and Installation".B. View B C. View C

Refer to GI-4, "

Components" for symbols in the figure.

JSBIA0403GB

Revision: 2010 May2011 QX56

Page 2637 of 5598

CAMSHAFTEM-75

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

Removal and InstallationINFOID:0000000006289569

REMOVAL

CAUTION:

Never loosen adjusting bolts (A), mounting bolt

s (black color) (B) of VVEL ladder assembly and

mounting bolts (C) of VVEL control shaft position sen sor. If loosened, the stroke of cam lift becomes

out of adjustment. In such case, replacement of VVEL ladder assembly and cylinder head assembly

is required.

Never loosen the mounting bolts (C) of the VVEL control shaft position sensor. VVEL control shaft

position sensor mounting bolts are required to be loosened for adjustment only when using a new

VVEL ladder assembly. Refer to EC-150, "

Work Procedure".

NOTE:

VVEL ladder assembly cannot be replaced as a singl e part, because it is machined together with cylinder

head assembly.

1. Remove VVEL actuator motor assembly. Refer to EM-36, "

Exploded View".

2. Remove rocker covers (bank 1 and bank 2). Refer to EM-33, "

Exploded View".

3. Remove VVEL actuator housing assembly. Refer to EM-36, "

Exploded View".

4. Remove front cover, camshaft sprockets, and timing chains. Refer to EM-61, "

Exploded View".

5. Remove VVEL ladder assembly.

JPBIA3512ZZ

VVEL control shaft positi on sensor mounting bolt

: 7.0 N·m (0.71 kg-m, 62 in-lb)

Revision: 2010 May2011 QX56

Page 2639 of 5598

CAMSHAFTEM-77

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

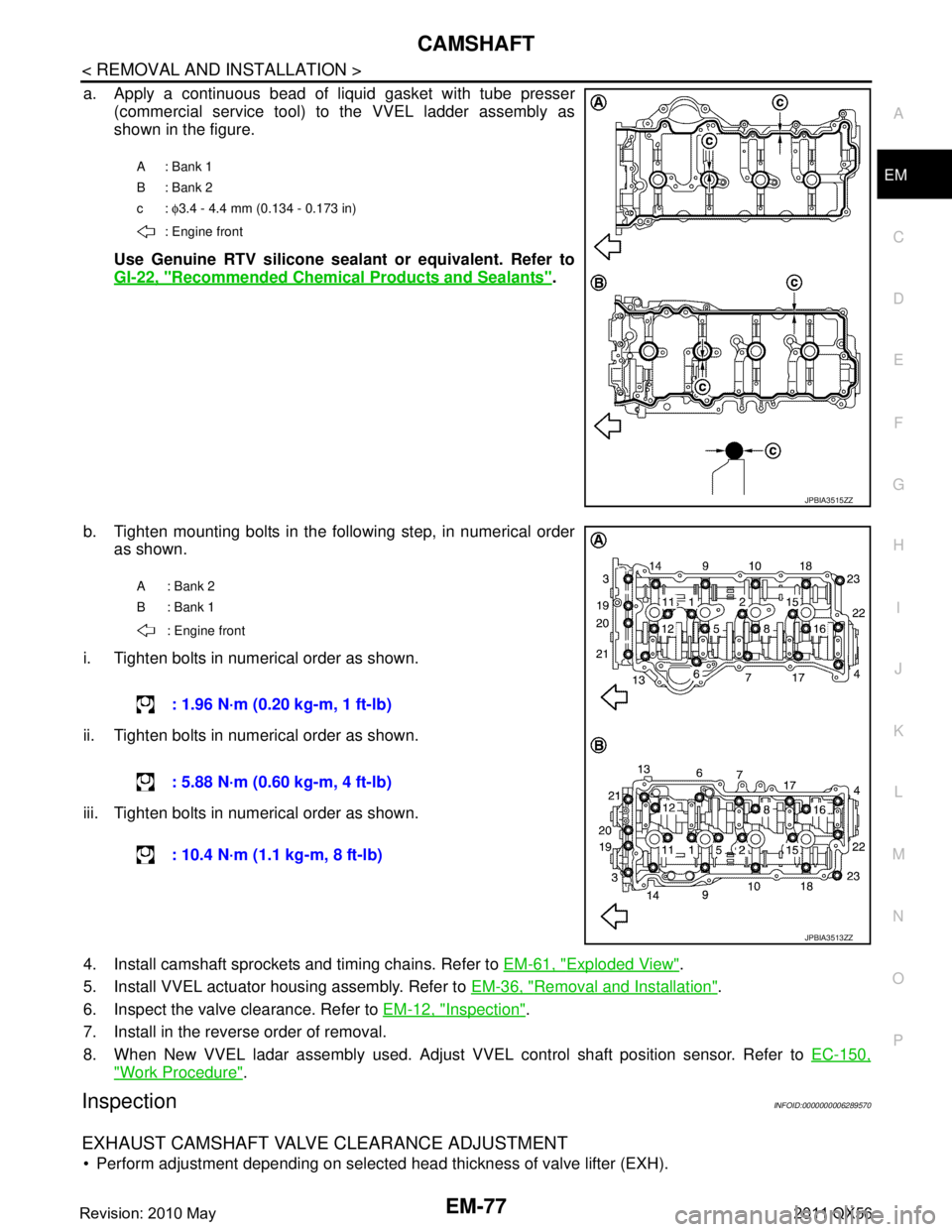

a. Apply a continuous bead of liquid gasket with tube presser

(commercial service tool) to the VVEL ladder assembly as

shown in the figure.

Use Genuine RTV silicone seal ant or equivalent. Refer to

GI-22, "

Recommended Chemical Products and Sealants".

b. Tighten mounting bolts in the following step, in numerical order as shown.

i. Tighten bolts in numerical order as shown.

ii. Tighten bolts in numerical order as shown.

iii. Tighten bolts in numerical order as shown.

4. Install camshaft sprockets and timing chains. Refer to EM-61, "

Exploded View".

5. Install VVEL actuator housing assembly. Refer to EM-36, "

Removal and Installation".

6. Inspect the valve clearance. Refer to EM-12, "

Inspection".

7. Install in the reverse order of removal.

8. When New VVEL ladar assembly used. Adjust VVEL control shaft position sensor. Refer to EC-150,

"Work Procedure".

InspectionINFOID:0000000006289570

EXHAUST CAMSHAFT VALVE CLEARANCE ADJUSTMENT

Perform adjustment depending on selected head thickness of valve lifter (EXH).

A: Bank 1

B: Bank 2

c: φ3.4 - 4.4 mm (0.134 - 0.173 in)

: Engine front

JPBIA3515ZZ

A: Bank 2

B: Bank 1

: Engine front

: 1.96 N·m (0.20 kg-m, 1 ft-lb)

: 5.88 N·m (0.60 kg-m, 4 ft-lb)

: 10.4 N·m (1.1 kg-m, 8 ft-lb)

JPBIA3513ZZ

Revision: 2010 May2011 QX56

Page 2978 of 5598

GI-14

< HOW TO USE THIS MANUAL >

ABBREVIATIONS

ABBREVIATIONS

Abbreviation ListINFOID:0000000006280882

The following ABBREVIATIONS are used:

A

B

C

D

ABBREVIATION DESCRIPTION

A/C Air conditioner

A/C Air conditioning

A/F sensor Air fuel ratio sensor A/T Automatic transaxle/transmission

ABS Anti-lock braking system

ACCS Advance climate control system ACL Air cleaner

AP Accelerator pedal

APP Accelerator pedal position ATF Automatic transmission fluid AV Audio visual

AWD All wheel drive

ABBREVIATION DESCRIPTION BARO Barometric pressureBCM Body control module

BLSD Brake limited slip differential BPP Brake pedal positionBSI Blind spot intervention

BSW Blind spot warning

ABBREVIATION DESCRIPTION CKP Crankshaft positionCL Closed loop

CMP Camshaft position CPP Clutch pedal positionCTP Closed throttle position

CVT Continuously Variable transaxle/transmission

ABBREVIATION DESCRIPTION D

1Drive range first gear

D

2Drive range second gear

D

3Drive range third gear

D

4Drive range fourth gear

DCA Distance control assist DFI Direct fuel injection system

DLC Data link connector

DTC Diagnostic trouble code

Revision: 2010 May2011 QX56