ground INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 4188 of 5598

![INFINITI QX56 2011 Factory Service Manual

PWO

AC 120 V OUTLET MAIN SWITCH INDICATOR CIRCUIT

PWO-29

< DTC/CIRCUIT DIAGNOSIS > [AC 120 V OUTLET]

C

D

E

F

G H

I

J

K L

B A

O P

N

AC 120 V OUTLET MAIN SWITCH INDICATOR CIRCUIT

Diagnosis ProcedureINF INFINITI QX56 2011 Factory Service Manual

PWO

AC 120 V OUTLET MAIN SWITCH INDICATOR CIRCUIT

PWO-29

< DTC/CIRCUIT DIAGNOSIS > [AC 120 V OUTLET]

C

D

E

F

G H

I

J

K L

B A

O P

N

AC 120 V OUTLET MAIN SWITCH INDICATOR CIRCUIT

Diagnosis ProcedureINF](/img/42/57033/w960_57033-4187.png)

PWO

AC 120 V OUTLET MAIN SWITCH INDICATOR CIRCUIT

PWO-29

< DTC/CIRCUIT DIAGNOSIS > [AC 120 V OUTLET]

C

D

E

F

G H

I

J

K L

B A

O P

N

AC 120 V OUTLET MAIN SWITCH INDICATOR CIRCUIT

Diagnosis ProcedureINFOID:0000000006257098

1.CHECK HARNESS BETWEEN IN

VERTER UNIT AND AC 120 V OUTLET MAIN SWITCH

1. Turn ignition switch OFF.

2. Disconnect inverter unit connector and AC 120 V outlet main switch connector.

3. Check continuity between inverter unit harness connector and AC 120 V main switch harness connector.

4. Check continuity between inverter unit harness connector and ground.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair the harnesses or connectors.

2.CHECK AC 120 V OUTLET MAIN SWITCH GROUND CIRCUIT

Check continuity between AC 120 V outle t main switch harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair the harnesses or connectors.

3.CHECK AC 120 V OUTLET MAIN SWITCH INDICATOR OUTPUT SIGNAL

1. Connect AC 120 V outlet main switch connector and inverter unit connector.

2. Turn ignition switch ON.

3. AC 120 V outlet main switch ON. (AC 120 V output is normal)

4. Check for voltage between the inverter unit harness connector and ground.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Replace inverter unit.

4.CHECK AC 120 V OUTLET MAIN SWITCH INDICATOR

1. AC 120 V outlet main switch ON. (AC 120 V output is normal)

2. Check that AC 120 V outlet main switch indicator is illuminated.

Is the inspection result normal?

Inverter unit AC 120 V outlet main switch Continuity

Connector Terminal Connector Terminal

M1437M1445Existed

Inverter unit GroundContinuity

Connector Terminal

M143 7 Not existed

AC 120 V outlet main switch GroundContinuity

Connector Terminal

M144 6 Existed

Te r m i n a l s Condition

Vol tag e

(Approx.)

(+) (–)

Inverter unit

GroundAC 120 V out-

let main

switch

Connector Terminal

M143 7 OFF 0 V

ON 5.2 V

Revision: 2010 May2011 QX56

Page 4215 of 5598

RF-1

BODY EXTERIOR, DOORS, ROOF & VEHICLE SECURITY

C

D

E

F

G H

I

J

L

M

SECTION RF

A

B

RF

N

O P

CONTENTS

ROOF

PRECAUTION ................ ...............................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

PREPARATION ............................................4

PREPARATION .............................................. .....4

Commercial Service Tool .................................... ......4

SYSTEM DESCRIPTION ..............................5

COMPONENT PARTS ................................... .....5

Component Parts Location ................................ ......5

Component Description ............................................5

SYSTEM ..............................................................6

System Diagram ................................................. ......6

System Description ...................................................6

ECU DIAGNOSIS INFORMATION ...............7

BCM (BODY CONTROL MODULE) ............... .....7

List of ECU Reference ........................................ ......7

SUNROOF SYSTEM ...................................... .....8

Reference Value ................................................. ......8

WIRING DIAGRAM .......................................9

SUNROOF MOTOR ASSEMBLY ................... .....9

Wiring Diagram ................................................... ......9

BASIC INSPECTION ...................................16

DIAGNOSIS AND REPAIR WORKFLOW ..... ....16

WorkFlow ............................................................ ....16

INSPECTION AND ADJUSTMENT ....................17

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT .................................................... ....

17

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Description .................................

17

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Special Repair Requirement ......

17

DTC/CIRCUIT DIAGNOSIS .........................18

POWER SUPPLY AND GROUND CIRCUIT ....18

Diagnosis Procedure .......................................... ....18

VEHICLE SPEED SIGNAL CIRCUIT ................20

Component Function Check ..................................20

Diagnosis Procedure ..............................................20

SUNROOF SWITCH ..........................................21

Component Function Check ..................................21

Diagnosis Procedure ..............................................21

Component Inspection .............................................22

SYMPTOM DIAGNOSIS ..............................23

SUNROOF DOES NOT OPERATE PROPER-

LY ......................................................................

23

Description ........................................................... ....23

Diagnosis Procedure ...............................................23

SUNROOF DOES NOT OPERATE ANTI-

PINCH FUNCTION ............................................

24

Diagnosis Procedure ........................................... ....24

RETAINED POWER OPERATION DOES NOT

OPERATE PROPERLY .....................................

25

Diagnosis Procedure ...............................................25

SQUEAK AND RATTLE TROUBLE DIAG-

NOSES ..............................................................

26

Work Flow ................................................................26

Inspection Procedure ...............................................28

Diagnostic Worksheet ..............................................30

REMOVAL AND INSTALLATION ...............32

GLASS LID ........................................................32

Revision: 2010 May2011 QX56

Page 4222 of 5598

RF-8

< ECU DIAGNOSIS INFORMATION >

SUNROOF SYSTEM

SUNROOF SYSTEM

Reference ValueINFOID:0000000006141227

TERMINAL LAYOUT

PHYSICAL VALUES

JMKIA2225ZZ

Te r m i n a l N o .(Wire color) Description

ConditionVoltage (V)

(Approx.)

+ – Signal name Input/

Output

1

(B) Ground Ground — — 0

3

(Y) Ground Retained power signal Input Ignition switch ON

12

Within 45 seconds after ignition

switch is turned to OFF

When driver side or passenger side

door is opened during retained pow-

er operation 0

5

(P) Ground Sunroof open signal Input Sunroof switch in following position

TILT DOWN

SLIDE OPEN

0

Ignition switch ON 12

6

(W) Ground Sunroof power supply Input — 12

8

(SB) Ground Vehicle speed signal (2-

pulse)

InputSpeedometer operated [When vehi-

cle speed is approx.40km/ h

(25MPH)]

10

(GR) Ground Sunroof close signal Input Sunroof switch in following position

TILT UP

SLIDE CLOSE

0

Ignition switch ON 12

ELF1080D

Revision: 2010 May2011 QX56

Page 4232 of 5598

RF-18

< DTC/CIRCUIT DIAGNOSIS >

POWER SUPPLY AND GROUND CIRCUIT

DTC/CIRCUIT DIAGNOSIS

POWER SUPPLY AND GROUND CIRCUIT

Diagnosis ProcedureINFOID:0000000006141232

SUNROOF MOTOR ASSEMBLY

1.CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect sunroof motor assembly harness connector.

3. Check continuity between sunroof mo tor assembly harness connector and ground.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace harness or connector.

2.CHECK POWER SUPPLY CIRCUIT-I

1. Turn ignition switch ON.

2. Check voltage between sunroof moto r assembly harness connector and ground.

Is the inspection result normal?

YES >> Check intermittent incident. Refer to GI-40, "Intermittent Incident".

NO >> GO TO 3.

3.CHECK POWER SUPPLY CIRCUIT-II

1. Turn ignition switch OFF.

2. Disconnect BCM harness connector and power window main switch harness connector.

3. Check continuity between BCM harness connecto r and sunroof motor assembly harness connector.

4. Check continuity between sunroof mo tor assembly harness connector and ground.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair or replace harness or connector.

4.CHECK POWER SUPPLY CIRCUIT-III

1. Check continuity between BCM harness connecto r and sunroof motor assembly harness connector.

Sunroof motor assembly

GroundContinuity

Connector Terminal

R4 1 Existed

(+) (–)Voltage (V)

(Approx.)

Sunroof motor assembly

Connector Terminal

R4 3

Ground 12

6

BCM Sunroof mo tor assembly

Continuity

Connector Terminal Connector Terminal

M70 68 R4 3 Existed

Sunroof motor assembly GroundContinuity

Connector Terminal

R4 3 Not existed

Revision: 2010 May2011 QX56

Page 4233 of 5598

POWER SUPPLY AND GROUND CIRCUITRF-19

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

G H

I

J

L

M A

B

RF

N

O P

2. Check continuity between sunroof mo tor assembly harness connector and ground.

Is the inspection result normal?

YES >> Check BCM power supply and ground circuit. Refer to BCS-75, "Diagnosis Procedure".

NO >> Repair or replace harness or connector.

BCM Sunroof mo tor assembly

Continuity

Connector Terminal Connector Terminal

M70 69 R4 6 Existed

Sunroof motor assembly GroundContinuity

Connector Terminal

R4 6 Not existed

Revision: 2010 May2011 QX56

Page 4234 of 5598

RF-20

< DTC/CIRCUIT DIAGNOSIS >

VEHICLE SPEED SIGNAL CIRCUIT

VEHICLE SPEED SIGNAL CIRCUIT

Component Function CheckINFOID:0000000006141233

1.CHECK SUNROOF MOTOR FUNCTION

Check tilt up/down & slide open/close operations with sunroof switch.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Check sunroof switch. Refer to RF-21, "

DiagnosisProcedure".

2.CHECK SUNROOF MOTOR ASSEMBLY INPUT SIGNAL

1. Start engine.

2. Drive the vehicle at more than 40 km/h (25 MPH). CAUTION:

Always drive vehicle at a safe speed.

NOTE:

This procedure may be conducted with the drive wheel s lifted in the shop or by driving the vehicle.

If a road test is expected to be easier , it is unnecessary to lift the vehicle.

3. Check tilt up/down & slide open/clos e operations with sunroof switch.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Refer to RF-20, "

DiagnosisProcedure".

Diagnosis ProcedureINFOID:0000000006141234

SUNROOF MOTOR ASSEMBLY

1.CHECK SUNROOF MOTOR ASSEMBLY INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect combination meter harness connector and sunroof motor assembly harness connector.

3. Check continuity between combination meter harness connector and sunroof motor assembly harness connector.

4. Check continuity between sunroof mo tor assembly harness connector and ground.

Is the inspection result normal?

YES >> Check combination meter. Refer to MWI-61, "DiagnosisProcedure".

NO >> Repair or replace harness or connector.

Combination meter Sunroof motor assembly Continuity

Connector Terminal Connector Terminal

M34 30 R4 8 Exists

Sunroof motor assembly GroundContinuity

Connector Terminal

R4 8 Not existed

Revision: 2010 May2011 QX56

Page 4235 of 5598

SUNROOF SWITCHRF-21

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

G H

I

J

L

M A

B

RF

N

O P

SUNROOF SWITCH

Component Function CheckINFOID:0000000006141235

1.CHECK SUNROOF MOTOR FUNCTION

Check tilt up/down & slide open/close operations with sunroof switch.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Refer to RF-21, "

DiagnosisProcedure".

Diagnosis ProcedureINFOID:0000000006141236

1.PERFORM INITIALIZATION PROCEDURE

1. Initialization procedure is executed and operation is confirmed. Refer to RF-17, "

ADDITIONAL SERVICE

WHEN REPLACING CONTROL UNIT : Special Repair Requirement".

2. Check tilt up/down & slide open/close operations with sunroof switch.

Is the inspection result normal?

YES >> INSPECTION END

NO >> GO TO 2.

2.CHECK SUNROOF SWITCH GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect sunroof switch harness connector.

3. Check continuity between sunroof switch harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace harness or connector.

3.CHECK SUNROOF SWITCH INPUT SIGNAL

1. Turn ignition switch ON.

2. Check voltage between sunroof switch harness connector and ground.

Is the inspection result normal?

YES >> GO TO 5.

NO >> GO TO 4.

4.CHECK SUNROOF SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect sunroof motor assembly harness connector.

3. Check continuity between sunroof motor assemb ly harness connector and sunroof switch harness con-

nector.

Sunroof switch

GroundContinuity

Connector Terminal

R16 2 Existed

(+) (− ) Voltage (V)

(Approx.)

sunroof switch

Connector Terminal

R16 1

Ground 12

3

Revision: 2010 May2011 QX56

Page 4236 of 5598

RF-22

< DTC/CIRCUIT DIAGNOSIS >

SUNROOF SWITCH

4. Check continuity between sunroof motor assembly harness connector and ground.

Is the inspection result normal?

YES >> Replace sunroof motor assembly. Refer to RF-36, "Removal and Installation".

NO >> Repair or replace harness or connector.

5.CHECK SUNROOF SWITCH

Check sunroof switch.

Refer to RF-22, "

Component Inspection".

Is the inspection result normal?

YES >> Check intermittent incident. Refer to GI-40, "Intermittent Incident".

NO >> Replace sunroof switch. Refer to RF-41, "

Removal and Installation".

Component InspectionINFOID:0000000006141237

SUNROOF SWITCH

1.CHECK SUNROOF SWITCH

1. Turn ignition switch OFF.

2. Disconnect sunroof switch connector.

3. Check continuity sunroof switch terminals.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace sunroof switch. Refer to RF-41, "

Removal and Installation".

Sunroof motor assembly Sunroof switch

Continuity

Connector Terminal Connector Terminal

R4 5

R16 1

Existed

10 3

Sunroof motor assembly GroundContinuity

Connector Terminal

R4 5

Not existed

10

Terminals Condition Continuity

1 2 Sunroof switch is operated

TILT DOWN or SLIDE OPEN Existed

Other than above Not existed

3 Sunroof switch is operated

TILT UP or SLIDE CLOSE Existed

Other than above Not existed

Revision: 2010 May2011 QX56

Page 4237 of 5598

SUNROOF DOES NOT OPERATE PROPERLYRF-23

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

J

L

M A

B

RF

N

O P

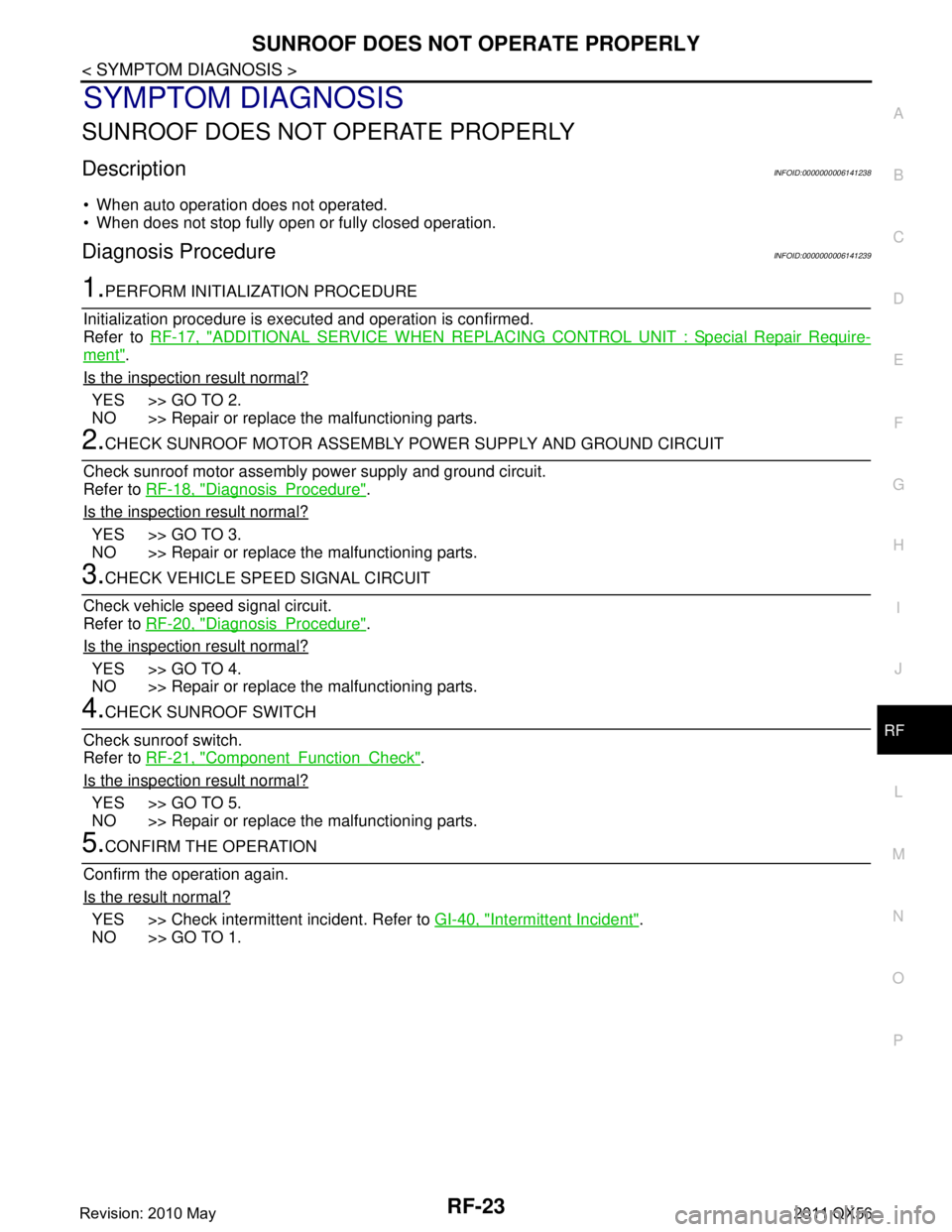

SYMPTOM DIAGNOSIS

SUNROOF DOES NOT OPERATE PROPERLY

DescriptionINFOID:0000000006141238

When auto operation does not operated.

When does not stop fully open or fully closed operation.

Diagnosis ProcedureINFOID:0000000006141239

1.PERFORM INITIALIZATION PROCEDURE

Initialization procedure is executed and operation is confirmed.

Refer to RF-17, "

ADDITIONAL SERVICE WHEN REPLACING CO NTROL UNIT : Special Repair Require-

ment".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace the malfunctioning parts.

2.CHECK SUNROOF MOTOR ASSEMBLY POWER SUPPLY AND GROUND CIRCUIT

Check sunroof motor assembly power supply and ground circuit.

Refer to RF-18, "

DiagnosisProcedure".

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace the malfunctioning parts.

3.CHECK VEHICLE SPEED SIGNAL CIRCUIT

Check vehicle speed signal circuit.

Refer to RF-20, "

DiagnosisProcedure".

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair or replace the malfunctioning parts.

4.CHECK SUNROOF SWITCH

Check sunroof switch.

Refer to RF-21, "

ComponentFunctionCheck".

Is the inspection result normal?

YES >> GO TO 5.

NO >> Repair or replace the malfunctioning parts.

5.CONFIRM THE OPERATION

Confirm the operation again.

Is the result normal?

YES >> Check intermittent incident. Refer to GI-40, "Intermittent Incident".

NO >> GO TO 1.

Revision: 2010 May2011 QX56

Page 4257 of 5598

RSU-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precautions for SuspensionINFOID:0000000006225656

• When installing rubber bushings, the final tightening must be carried out under unladen conditions with tires

on ground. Spilled oil might shorten the life of rubber bushings. Be sure to wipe off any spilled oil.

- Unladen conditions mean that fuel, engine coolant and l ubricant are full. Spare tire, jack, hand tools and

mats are in designated positions.

After servicing suspension parts, be sure to check wheel alignment.

Self-lock nuts are not reusable. Always use new ones when installing. Since new self-lock nuts are pre-oiled,

tighten as they are.

Revision: 2010 May2011 QX56