relay ISUZU AXIOM 2002 Service Owner's Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2002, Model line: AXIOM, Model: ISUZU AXIOM 2002Pages: 2100, PDF Size: 19.35 MB

Page 750 of 2100

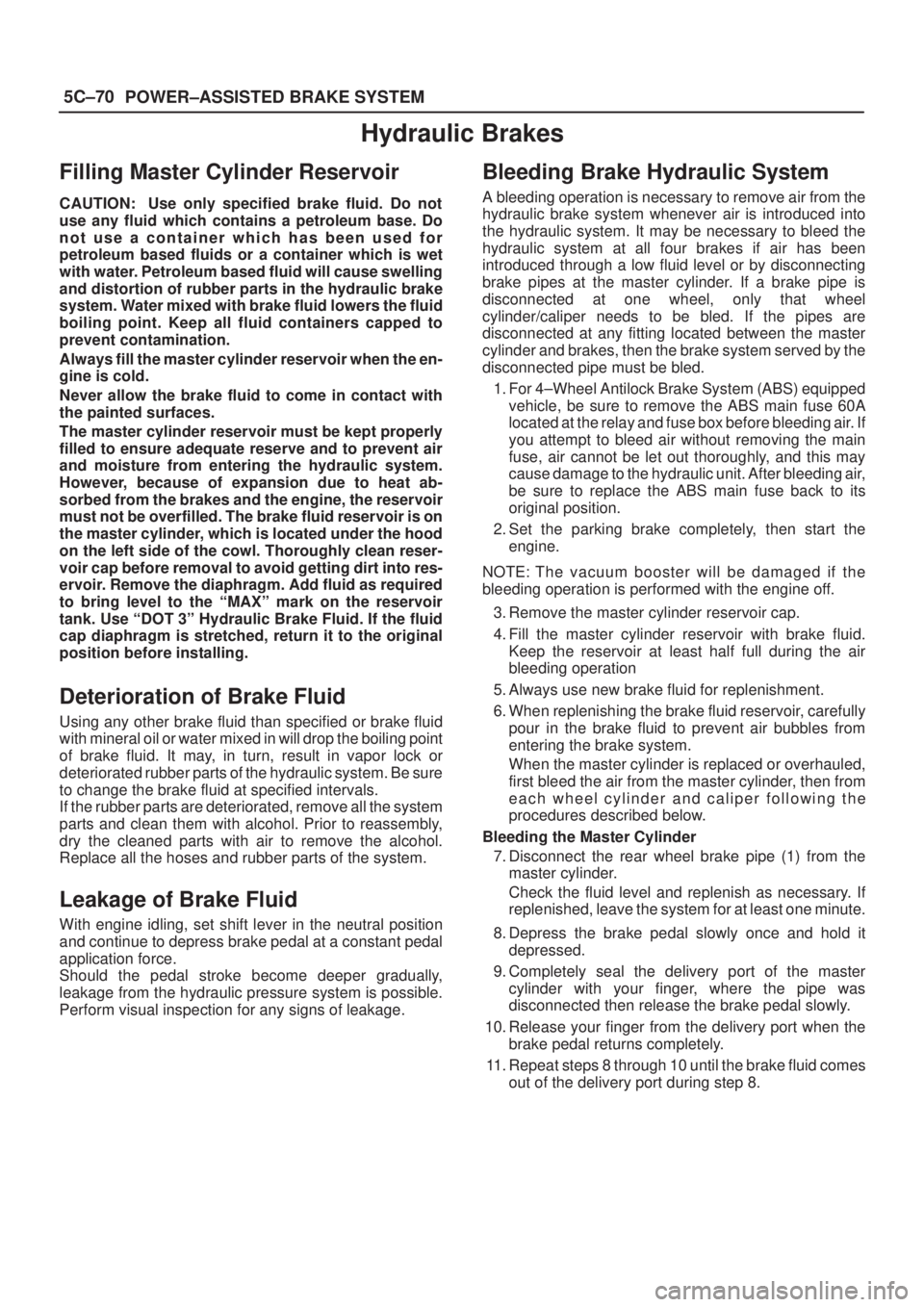

5C±70

POWER±ASSISTED BRAKE SYSTEM

Hydraulic Brakes

Filling Master Cylinder Reservoir

CAUTION: Use only specified brake fluid. Do not

use any fluid which contains a petroleum base. Do

not use a container which has been used for

petroleum based fluids or a container which is wet

with water. Petroleum based fluid will cause swelling

and distortion of rubber parts in the hydraulic brake

system. Water mixed with brake fluid lowers the fluid

boiling point. Keep all fluid containers capped to

prevent contamination.

Always fill the master cylinder reservoir when the en-

gine is cold.

Never allow the brake fluid to come in contact with

the painted surfaces.

The master cylinder reservoir must be kept properly

filled to ensure adequate reserve and to prevent air

and moisture from entering the hydraulic system.

However, because of expansion due to heat ab-

sorbed from the brakes and the engine, the reservoir

must not be overfilled. The brake fluid reservoir is on

the master cylinder, which is located under the hood

on the left side of the cowl. Thoroughly clean reser-

voir cap before removal to avoid getting dirt into res-

ervoir. Remove the diaphragm. Add fluid as required

to bring level to the ªMAXº mark on the reservoir

tank. Use ªDOT 3º Hydraulic Brake Fluid. If the fluid

cap diaphragm is stretched, return it to the original

position before installing.

Deterioration of Brake Fluid

Using any other brake fluid than specified or brake fluid

with mineral oil or water mixed in will drop the boiling point

of brake fluid. It may, in turn, result in vapor lock or

deteriorated rubber parts of the hydraulic system. Be sure

to change the brake fluid at specified intervals.

If the rubber parts are deteriorated, remove all the system

parts and clean them with alcohol. Prior to reassembly,

dry the cleaned parts with air to remove the alcohol.

Replace all the hoses and rubber parts of the system.

Leakage of Brake Fluid

With engine idling, set shift lever in the neutral position

and continue to depress brake pedal at a constant pedal

application force.

Should the pedal stroke become deeper gradually,

leakage from the hydraulic pressure system is possible.

Perform visual inspection for any signs of leakage.

Bleeding Brake Hydraulic System

A bleeding operation is necessary to remove air from the

hydraulic brake system whenever air is introduced into

the hydraulic system. It may be necessary to bleed the

hydraulic system at all four brakes if air has been

introduced through a low fluid level or by disconnecting

brake pipes at the master cylinder. If a brake pipe is

disconnected at one wheel, only that wheel

cylinder/caliper needs to be bled. If the pipes are

disconnected at any fitting located between the master

cylinder and brakes, then the brake system served by the

disconnected pipe must be bled.

1. For 4±Wheel Antilock Brake System (ABS) equipped

vehicle, be sure to remove the ABS main fuse 60A

located at the relay and fuse box before bleeding air. If

you attempt to bleed air without removing the main

fuse, air cannot be let out thoroughly, and this may

cause damage to the hydraulic unit. After bleeding air,

be sure to replace the ABS main fuse back to its

original position.

2. Set the parking brake completely, then start the

engine.

NOTE: The vacuum booster will be damaged if the

bleeding operation is performed with the engine off.

3. Remove the master cylinder reservoir cap.

4. Fill the master cylinder reservoir with brake fluid.

Keep the reservoir at least half full during the air

bleeding operation

5. Always use new brake fluid for replenishment.

6. When replenishing the brake fluid reservoir, carefully

pour in the brake fluid to prevent air bubbles from

entering the brake system.

When the master cylinder is replaced or overhauled,

first bleed the air from the master cylinder, then from

each wheel cylinder and caliper following the

procedures described below.

Bleeding the Master Cylinder

7. Disconnect the rear wheel brake pipe (1) from the

master cylinder.

Check the fluid level and replenish as necessary. If

replenished, leave the system for at least one minute.

8. Depress the brake pedal slowly once and hold it

depressed.

9. Completely seal the delivery port of the master

cylinder with your finger, where the pipe was

disconnected then release the brake pedal slowly.

10. Release your finger from the delivery port when the

brake pedal returns completely.

11. Repeat steps 8 through 10 until the brake fluid comes

out of the delivery port during step 8.

Page 815 of 2100

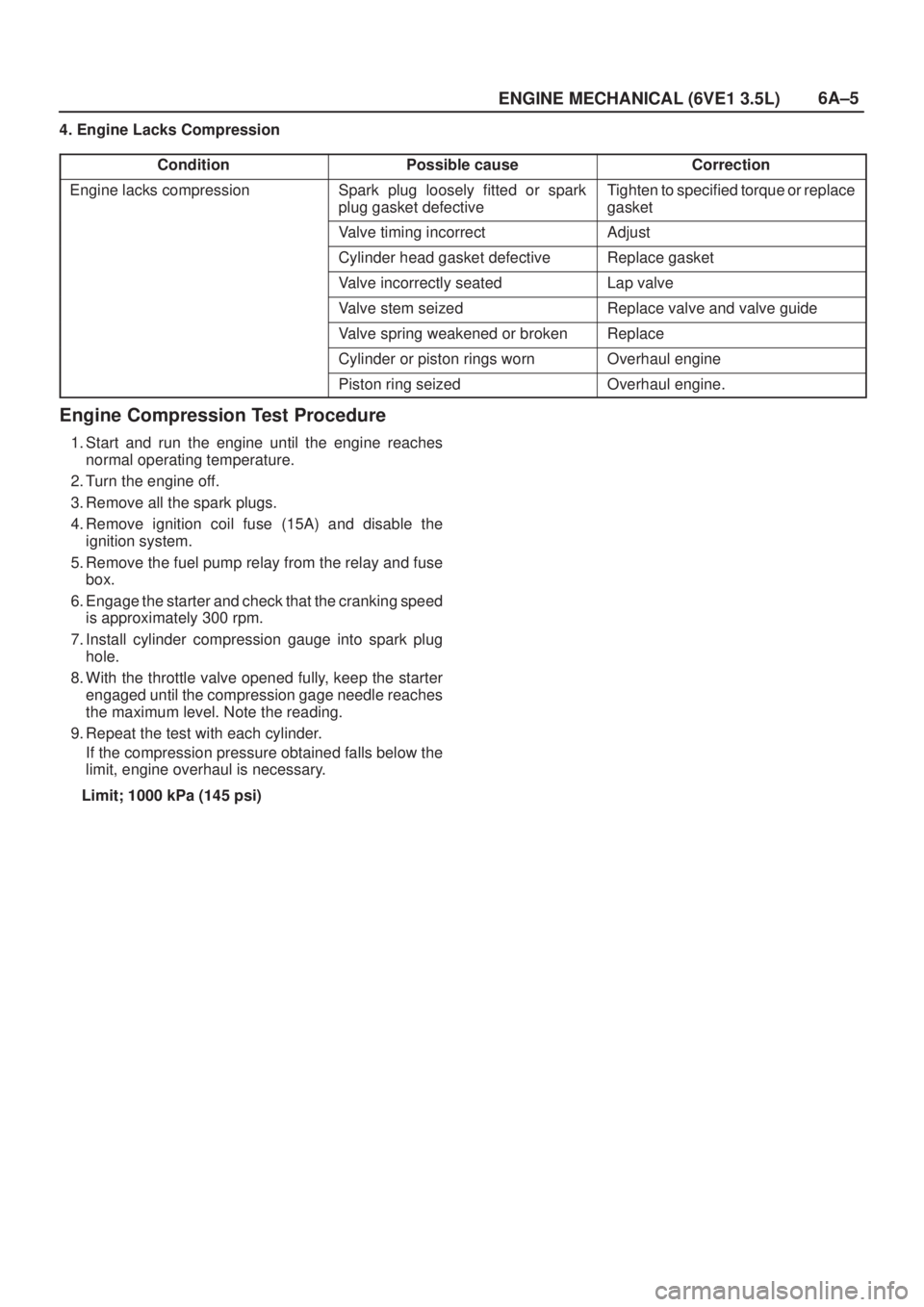

6A±5

ENGINE MECHANICAL (6VE1 3.5L)

4. Engine Lacks Compression

Condition

Possible causeCorrection

Engine lacks compressionSpark plug loosely fitted or spark

plug gasket defectiveTighten to specified torque or replace

gasket

Valve timing incorrectAdjust

Cylinder head gasket defectiveReplace gasket

Valve incorrectly seatedLap valve

Valve stem seizedReplace valve and valve guide

Valve spring weakened or brokenReplace

Cylinder or piston rings wornOverhaul engine

Piston ring seizedOverhaul engine.

Engine Compression Test Procedure

1. Start and run the engine until the engine reaches

normal operating temperature.

2. Turn the engine off.

3. Remove all the spark plugs.

4. Remove ignition coil fuse (15A) and disable the

ignition system.

5. Remove the fuel pump relay from the relay and fuse

box.

6. Engage the starter and check that the cranking speed

is approximately 300 rpm.

7. Install cylinder compression gauge into spark plug

hole.

8. With the throttle valve opened fully, keep the starter

engaged until the compression gage needle reaches

the maximum level. Note the reading.

9. Repeat the test with each cylinder.

If the compression pressure obtained falls below the

limit, engine overhaul is necessary.

Limit; 1000 kPa (145 psi)

Page 816 of 2100

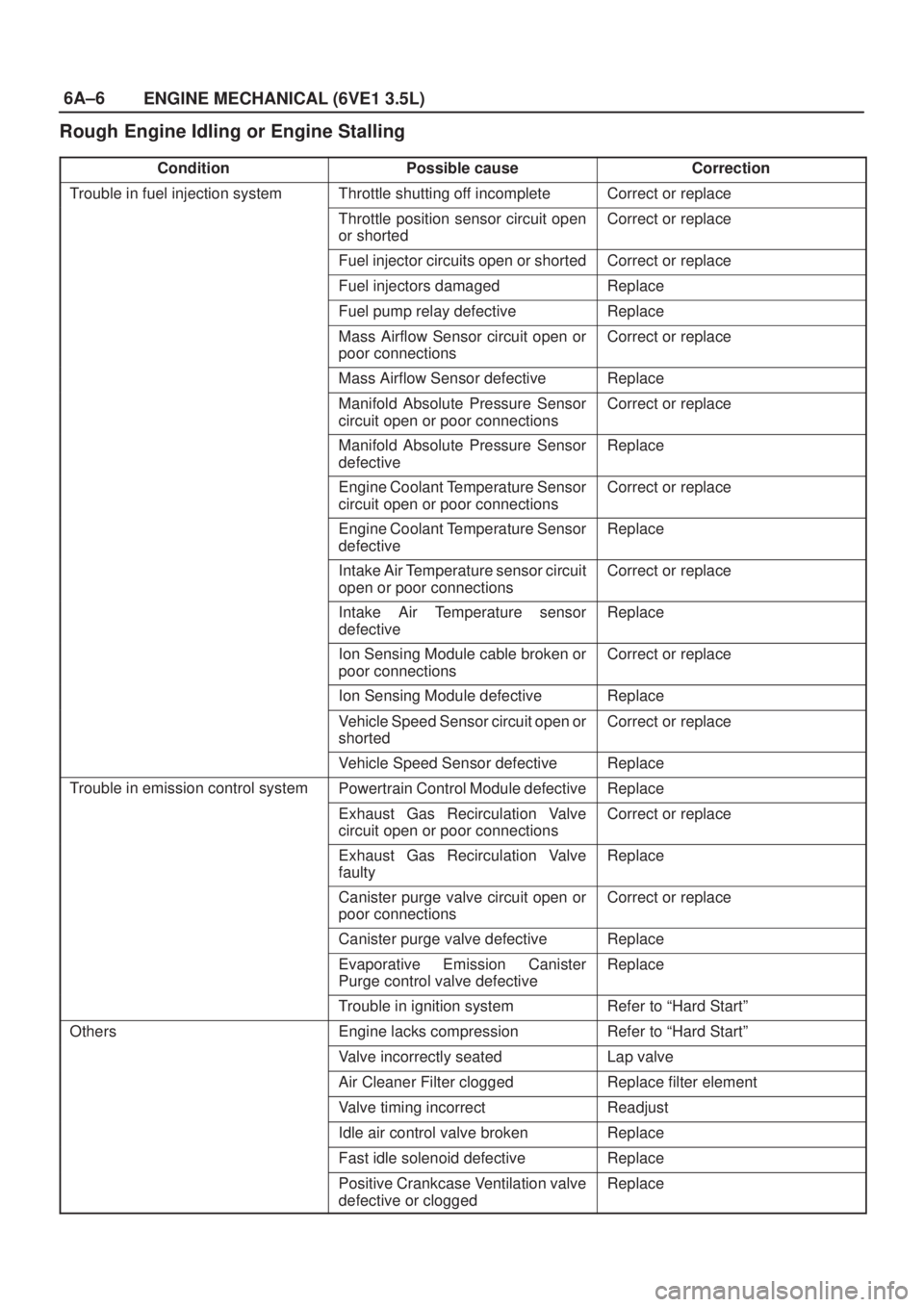

6A±6

ENGINE MECHANICAL (6VE1 3.5L)

Rough Engine Idling or Engine Stalling

ConditionPossible causeCorrection

Trouble in fuel injection systemThrottle shutting off incompleteCorrect or replace

Throttle position sensor circuit open

or shortedCorrect or replace

Fuel injector circuits open or shortedCorrect or replace

Fuel injectors damagedReplace

Fuel pump relay defectiveReplace

Mass Airflow Sensor circuit open or

poor connectionsCorrect or replace

Mass Airflow Sensor defectiveReplace

Manifold Absolute Pressure Sensor

circuit open or poor connectionsCorrect or replace

Manifold Absolute Pressure Sensor

defectiveReplace

Engine Coolant Temperature Sensor

circuit open or poor connectionsCorrect or replace

Engine Coolant Temperature Sensor

defectiveReplace

Intake Air Temperature sensor circuit

open or poor connectionsCorrect or replace

Intake Air Temperature sensor

defectiveReplace

Ion Sensing Module cable broken or

poor connectionsCorrect or replace

Ion Sensing Module defectiveReplace

Vehicle Speed Sensor circuit open or

shortedCorrect or replace

Vehicle Speed Sensor defectiveReplace

Trouble in emission control systemPowertrain Control Module defectiveReplace

Exhaust Gas Recirculation Valve

circuit open or poor connectionsCorrect or replace

Exhaust Gas Recirculation Valve

faultyReplace

Canister purge valve circuit open or

poor connectionsCorrect or replace

Canister purge valve defectiveReplace

Evaporative Emission Canister

Purge control valve defectiveReplace

Trouble in ignition systemRefer to ªHard Startº

OthersEngine lacks compressionRefer to ªHard Startº

Valve incorrectly seatedLap valve

Air Cleaner Filter cloggedReplace filter element

Valve timing incorrectReadjust

Idle air control valve brokenReplace

Fast idle solenoid defectiveReplace

Positive Crankcase Ventilation valve

defective or cloggedReplace

Page 824 of 2100

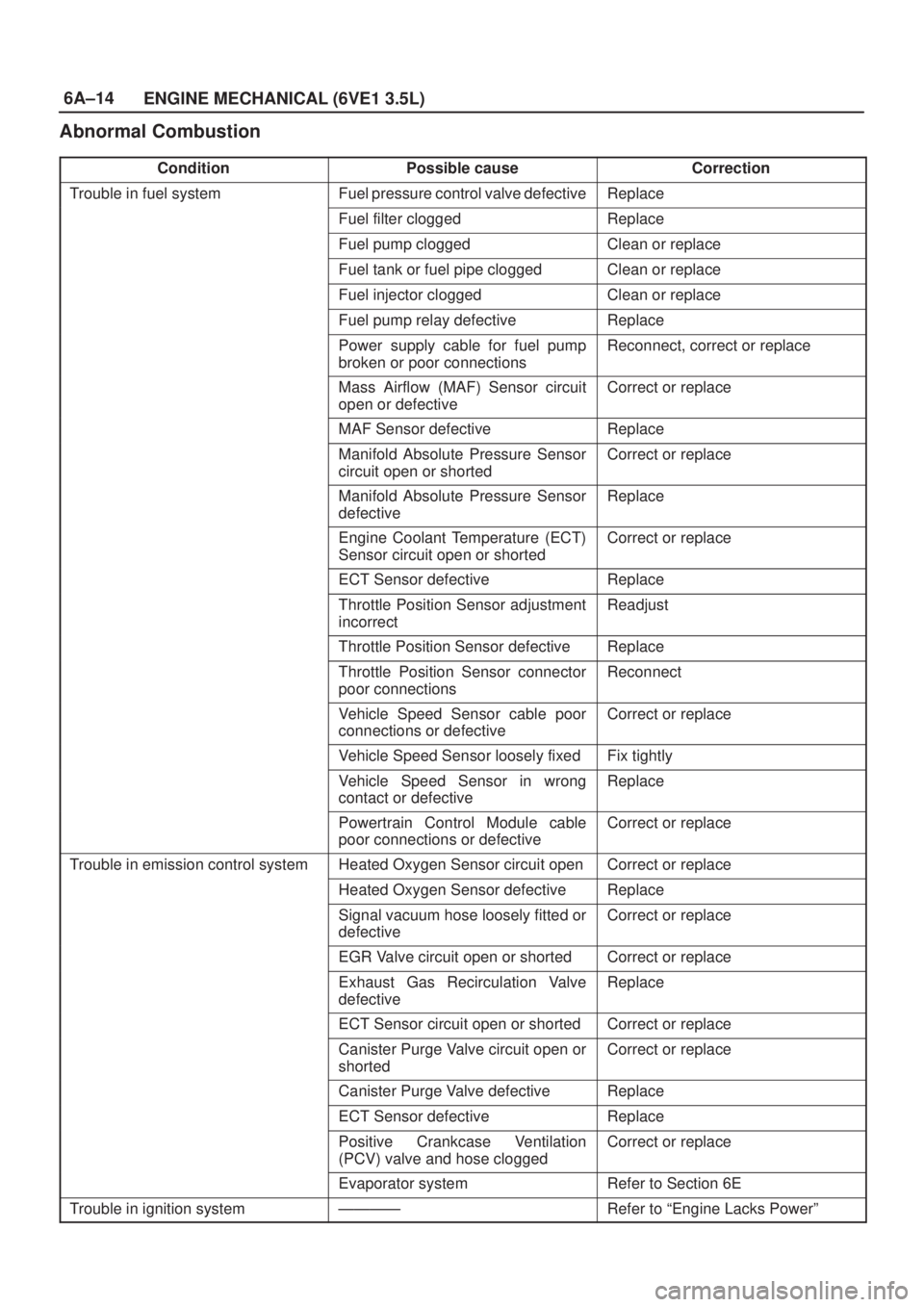

6A±14

ENGINE MECHANICAL (6VE1 3.5L)

Abnormal Combustion

ConditionPossible causeCorrection

Trouble in fuel systemFuel pressure control valve defectiveReplace

Fuel filter cloggedReplace

Fuel pump cloggedClean or replace

Fuel tank or fuel pipe cloggedClean or replace

Fuel injector cloggedClean or replace

Fuel pump relay defectiveReplace

Power supply cable for fuel pump

broken or poor connectionsReconnect, correct or replace

Mass Airflow (MAF) Sensor circuit

open or defectiveCorrect or replace

MAF Sensor defectiveReplace

Manifold Absolute Pressure Sensor

circuit open or shortedCorrect or replace

Manifold Absolute Pressure Sensor

defectiveReplace

Engine Coolant Temperature (ECT)

Sensor circuit open or shortedCorrect or replace

ECT Sensor defectiveReplace

Throttle Position Sensor adjustment

incorrectReadjust

Throttle Position Sensor defectiveReplace

Throttle Position Sensor connector

poor connectionsReconnect

Vehicle Speed Sensor cable poor

connections or defectiveCorrect or replace

Vehicle Speed Sensor loosely fixedFix tightly

Vehicle Speed Sensor in wrong

contact or defectiveReplace

Powertrain Control Module cable

poor connections or defectiveCorrect or replace

Trouble in emission control systemHeated Oxygen Sensor circuit openCorrect or replace

Heated Oxygen Sensor defectiveReplace

Signal vacuum hose loosely fitted or

defectiveCorrect or replace

EGR Valve circuit open or shortedCorrect or replace

Exhaust Gas Recirculation Valve

defectiveReplace

ECT Sensor circuit open or shortedCorrect or replace

Canister Purge Valve circuit open or

shortedCorrect or replace

Canister Purge Valve defectiveReplace

ECT Sensor defectiveReplace

Positive Crankcase Ventilation

(PCV) valve and hose cloggedCorrect or replace

Evaporator systemRefer to Section 6E

Trouble in ignition systemÐÐÐÐRefer to ªEngine Lacks Powerº

Page 918 of 2100

6C±1 ENGINE FUEL (6VE1 3.5L)

AXIOM

ENGINE

ENGINE FUEL

CONTENTS

Service Precaution 6C±1. . . . . . . . . . . . . . . . . . . . . .

General Description 6C±2. . . . . . . . . . . . . . . . . . . . .

Fuel Metering 6C±3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Filter 6C±4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 6C±4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 6C±4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6C±5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 6C±5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

In±Tank Fuel Filter 6C±5. . . . . . . . . . . . . . . . . . . . .

Fuel Pump Flow Test 6C±5. . . . . . . . . . . . . . . . . . .

Fuel Pump 6C±6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Pump and Associated Parts 6C±6. . . . . . . .

Removal 6C±6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6C±7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Tube / Quick ± Connector Fittings 6C±8. . . . .

Precautions 6C±8. . . . . . . . . . . . . . . . . . . . . . . . . . .

Cautions During Work 6C±8. . . . . . . . . . . . . . . . . . Removal 6C±8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reuse of Quick±Connector 6C±9. . . . . . . . . . . . .

Assembling Advice 6C±9. . . . . . . . . . . . . . . . . . . .

Fuel Pump Relay 6C±10. . . . . . . . . . . . . . . . . . . . . . . .

General Description 6C±10. . . . . . . . . . . . . . . . . . . .

Fuel Tank 6C±10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Tank and Associated Parts 6C±10. . . . . . . . .

Removal 6C±11. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6C±11. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Gauge Unit 6C±12. . . . . . . . . . . . . . . . . . . . . . . .

Removal and Installation 6C±12. . . . . . . . . . . . . . .

Fuel Filler Cap 6C±12. . . . . . . . . . . . . . . . . . . . . . . . . .

General Description 6C±12. . . . . . . . . . . . . . . . . . . .

Inspection 6C±12. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 6C±13. . . . . . . . . . . . .

Special Tool 6C±13. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING, REFER TO

THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN POSSIBLE

AIR BAG DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

Page 922 of 2100

6C±5 ENGINE FUEL (6VE1 3.5L)

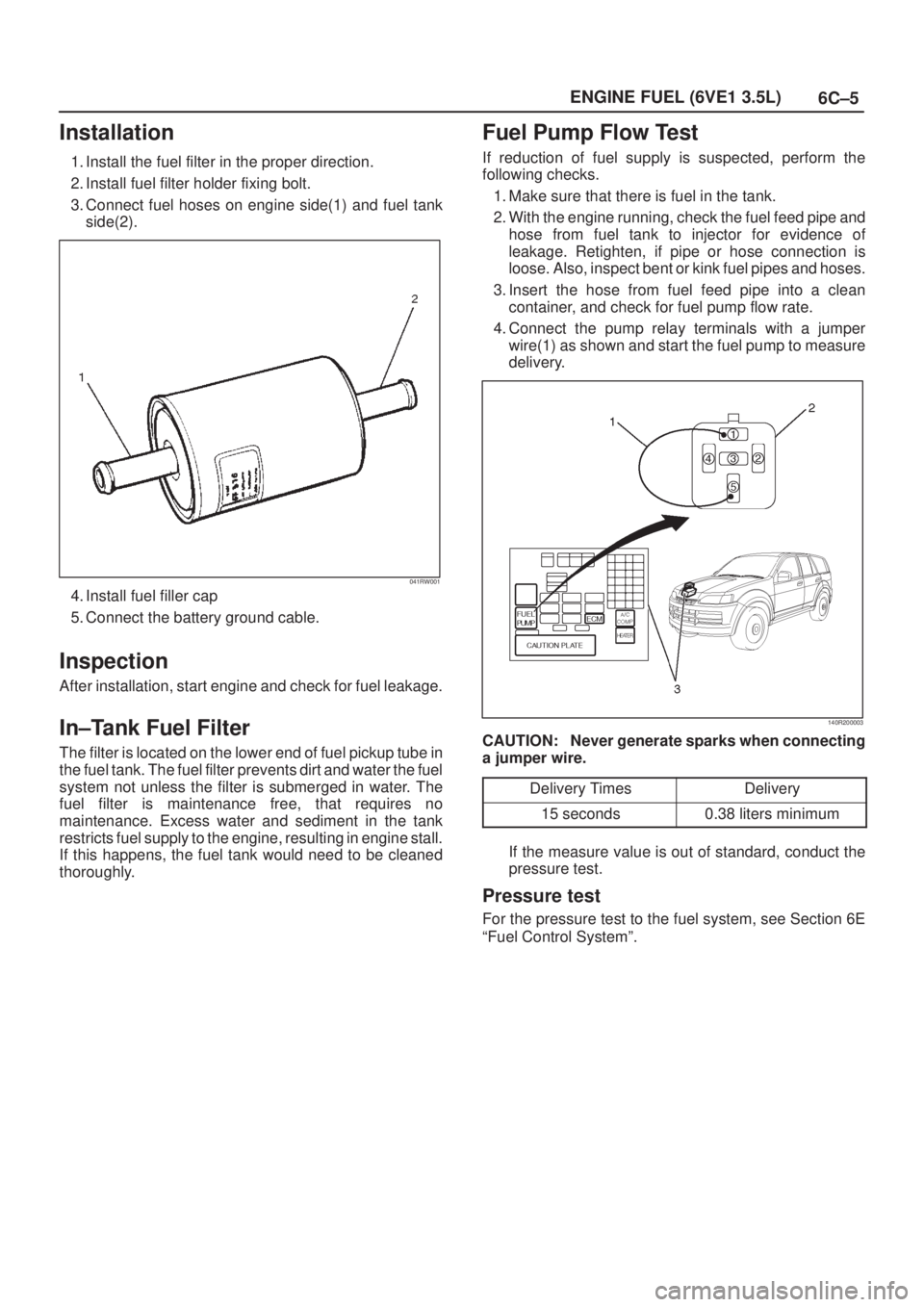

Installation

1. Install the fuel filter in the proper direction.

2. Install fuel filter holder fixing bolt.

3. Connect fuel hoses on engine side(1) and fuel tank

side(2).

041RW001

4. Install fuel filler cap

5. Connect the battery ground cable.

Inspection

After installation, start engine and check for fuel leakage.

In±Tank Fuel Filter

The filter is located on the lower end of fuel pickup tube in

the fuel tank. The fuel filter prevents dirt and water the fuel

system not unless the filter is submerged in water. The

fuel filter is maintenance free, that requires no

maintenance. Excess water and sediment in the tank

restricts fuel supply to the engine, resulting in engine stall.

If this happens, the fuel tank would need to be cleaned

thoroughly.

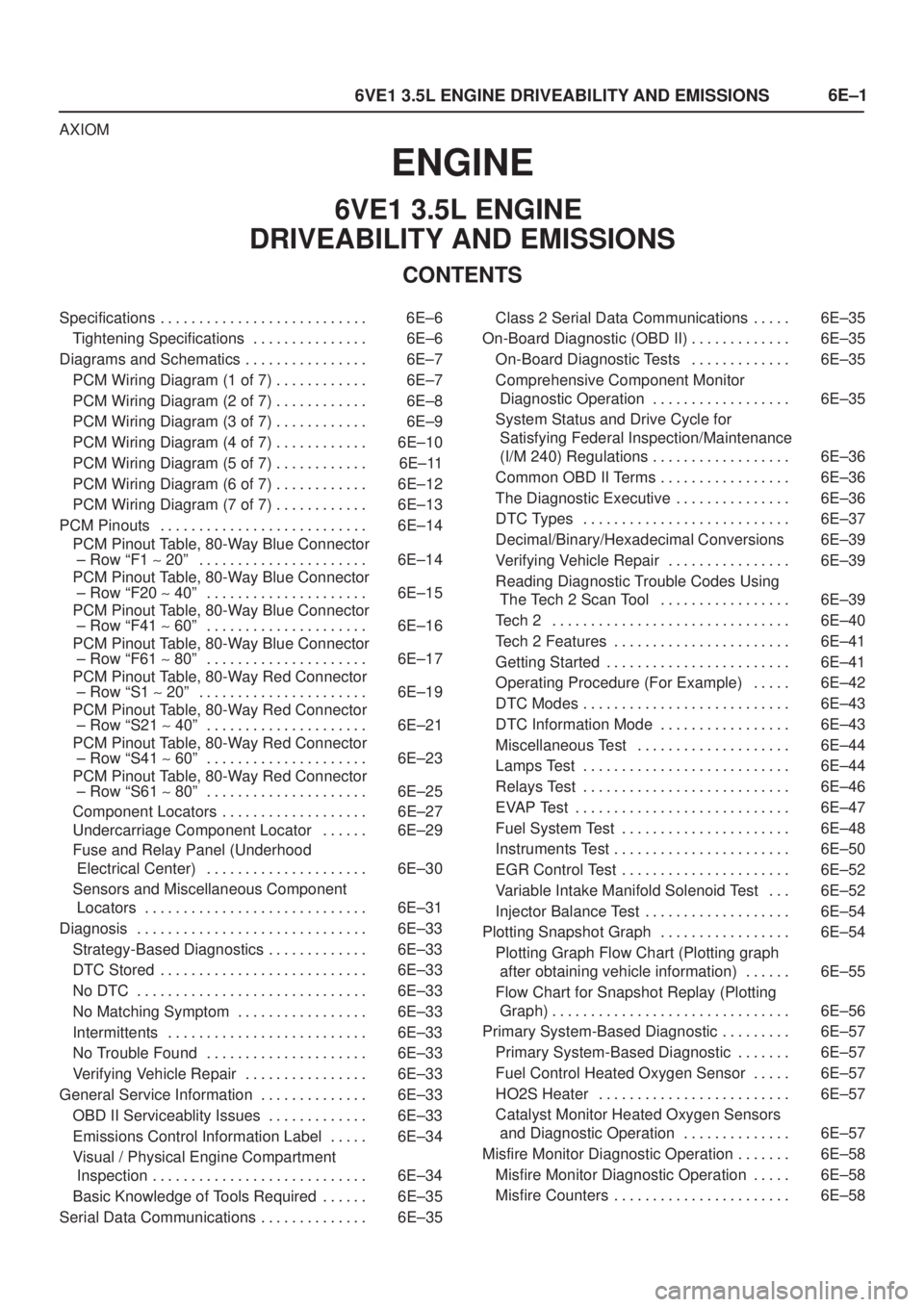

Fuel Pump Flow Test

If reduction of fuel supply is suspected, perform the

following checks.

1. Make sure that there is fuel in the tank.

2. With the engine running, check the fuel feed pipe and

hose from fuel tank to injector for evidence of

leakage. Retighten, if pipe or hose connection is

loose. Also, inspect bent or kink fuel pipes and hoses.

3. Insert the hose from fuel feed pipe into a clean

container, and check for fuel pump flow rate.

4. Connect the pump relay terminals with a jumper

wire(1) as shown and start the fuel pump to measure

delivery.

140R200003

CAUTION: Never generate sparks when connecting

a jumper wire.

Delivery Times

Delivery

15 seconds0.38 liters minimum

If the measure value is out of standard, conduct the

pressure test.

Pressure test

For the pressure test to the fuel system, see Section 6E

ªFuel Control Systemº.

Page 927 of 2100

6C±10

ENGINE FUEL (6VE1 3.5L)

Fuel Pump Relay

General Description

In order to control the fuel pump and sender (FPS)

operation, the FPS relay is provided. When the starter

switch is turned to ªONº position, the FPS relay operates

the FPS for 2 seconds.

When the key is turned to ªSTARTº position, the Engine

Control Module receives the reference pulse from the

Ignition Control Module and it operates the relay, again

causing the FPS to feed fuel.

Fuel Tank

Fuel Tank and Associated Parts

140R200006

Legend

(1) Fuel Tank Assembly

(2) Fuel Tank Fixing Bolt (QTY: 5)

(3) Fuel Tank Fixing Nut (QTY: 1)

(4) Separator Fixing Bolt (QTY: 2)

(5) Fuel Filler Hose(6) Fuel Vent Hose

(7) Fuel Feed Hose

(8) Fuel Return Hose

(9) Vapor Pressure Sensor Connector

(10) Fuel Feed Pump Connector

Page 944 of 2100

6D3±2

STARTING AND CHARGING SYSTEM (6VE1 3.5L)

Starting System

General Description

Cranking Circuit

The cranking system consists of a battery, starter, starter

switch, starter relay, etc. These main components are

connected.

Starter

The cranking system employs a magnetic type reduction

starter in which the motor shaft is also used as a pinion

shaft. When the starter switch is turned on, the contacts of

magnetic switch are closed, and the armature rotates. At

the same time, the plunger is attracted, and the pinion is

pushed forward by the shift lever to mesh with the ring

gear.

Then, the ring gear runs to start the engine. When the

engine starts and the starter switch is turned off, the

plunger returns, the pinion is disengaged from the ring

gear, and the armature stops rotation. When the engine

speed is higher than the pinion, the pinion idles, so that

the armature is not driven.

Page 946 of 2100

6D3±4

STARTING AND CHARGING SYSTEM (6VE1 3.5L)

Diagnosis

ConditionPossible causeCorrection

Starter does not runCharging failureRepair charging system

Battery FailureReplace Battery

Terminal connection failureRepair or replace terminal connector

and/or wiring harness

Starter switch failureRepair or replace starter switch

Starter relay failureReplace

Starter failureRepair or replace starter

Page 968 of 2100

6E±1

6VE1 3.5L ENGINE DRIVEABILITY AND EMISSIONS

AXIOM

ENGINE

6VE1 3.5L ENGINE

DRIVEABILITY AND EMISSIONS

CONTENTS

Specifications 6E±6. . . . . . . . . . . . . . . . . . . . . . . . . . .

Tightening Specifications 6E±6. . . . . . . . . . . . . . .

Diagrams and Schematics 6E±7. . . . . . . . . . . . . . . .

PCM Wiring Diagram (1 of 7) 6E±7. . . . . . . . . . . .

PCM Wiring Diagram (2 of 7) 6E±8. . . . . . . . . . . .

PCM Wiring Diagram (3 of 7) 6E±9. . . . . . . . . . . .

PCM Wiring Diagram (4 of 7) 6E±10. . . . . . . . . . . .

PCM Wiring Diagram (5 of 7) 6E±11. . . . . . . . . . . .

PCM Wiring Diagram (6 of 7) 6E±12. . . . . . . . . . . .

PCM Wiring Diagram (7 of 7) 6E±13. . . . . . . . . . . .

PCM Pinouts 6E±14. . . . . . . . . . . . . . . . . . . . . . . . . . .

PCM Pinout Table, 80-Way Blue Connector

± Row ªF1 ~ 20º 6E±14. . . . . . . . . . . . . . . . . . . . . .

PCM Pinout Table, 80-Way Blue Connector

± Row ªF20 ~ 40º 6E±15. . . . . . . . . . . . . . . . . . . . .

PCM Pinout Table, 80-Way Blue Connector

± Row ªF41 ~ 60º 6E±16. . . . . . . . . . . . . . . . . . . . .

PCM Pinout Table, 80-Way Blue Connector

± Row ªF61 ~ 80º 6E±17. . . . . . . . . . . . . . . . . . . . .

PCM Pinout Table, 80-Way Red Connector

± Row ªS1 ~ 20º 6E±19. . . . . . . . . . . . . . . . . . . . . .

PCM Pinout Table, 80-Way Red Connector

± Row ªS21 ~ 40º 6E±21. . . . . . . . . . . . . . . . . . . . .

PCM Pinout Table, 80-Way Red Connector

± Row ªS41 ~ 60º 6E±23. . . . . . . . . . . . . . . . . . . . .

PCM Pinout Table, 80-Way Red Connector

± Row ªS61 ~ 80º 6E±25. . . . . . . . . . . . . . . . . . . . .

Component Locators 6E±27. . . . . . . . . . . . . . . . . . .

Undercarriage Component Locator 6E±29. . . . . .

Fuse and Relay Panel (Underhood

Electrical Center) 6E±30. . . . . . . . . . . . . . . . . . . . .

Sensors and Miscellaneous Component

Locators 6E±31. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnosis 6E±33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Strategy-Based Diagnostics 6E±33. . . . . . . . . . . . .

DTC Stored 6E±33. . . . . . . . . . . . . . . . . . . . . . . . . . .

No DTC 6E±33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

No Matching Symptom 6E±33. . . . . . . . . . . . . . . . .

Intermittents 6E±33. . . . . . . . . . . . . . . . . . . . . . . . . .

No Trouble Found 6E±33. . . . . . . . . . . . . . . . . . . . .

Verifying Vehicle Repair 6E±33. . . . . . . . . . . . . . . .

General Service Information 6E±33. . . . . . . . . . . . . .

OBD II Serviceablity Issues 6E±33. . . . . . . . . . . . .

Emissions Control Information Label 6E±34. . . . .

Visual / Physical Engine Compartment

Inspection 6E±34. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Basic Knowledge of Tools Required 6E±35. . . . . .

Serial Data Communications 6E±35. . . . . . . . . . . . . . Class 2 Serial Data Communications 6E±35. . . . .

On-Board Diagnostic (OBD II) 6E±35. . . . . . . . . . . . .

On-Board Diagnostic Tests 6E±35. . . . . . . . . . . . .

Comprehensive Component Monitor

Diagnostic Operation 6E±35. . . . . . . . . . . . . . . . . .

System Status and Drive Cycle for

Satisfying Federal Inspection/Maintenance

(I/M 240) Regulations 6E±36. . . . . . . . . . . . . . . . . .

Common OBD II Terms 6E±36. . . . . . . . . . . . . . . . .

The Diagnostic Executive 6E±36. . . . . . . . . . . . . . .

DTC Types 6E±37. . . . . . . . . . . . . . . . . . . . . . . . . . .

Decimal/Binary/Hexadecimal Conversions 6E±39

Verifying Vehicle Repair 6E±39. . . . . . . . . . . . . . . .

Reading Diagnostic Trouble Codes Using

The Tech 2 Scan Tool 6E±39. . . . . . . . . . . . . . . . .

Tech 2 6E±40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tech 2 Features 6E±41. . . . . . . . . . . . . . . . . . . . . . .

Getting Started 6E±41. . . . . . . . . . . . . . . . . . . . . . . .

Operating Procedure (For Example) 6E±42. . . . .

DTC Modes 6E±43. . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC Information Mode 6E±43. . . . . . . . . . . . . . . . .

Miscellaneous Test 6E±44. . . . . . . . . . . . . . . . . . . .

Lamps Test 6E±44. . . . . . . . . . . . . . . . . . . . . . . . . . .

Relays Test 6E±46. . . . . . . . . . . . . . . . . . . . . . . . . . .

EVAP Test 6E±47. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel System Test 6E±48. . . . . . . . . . . . . . . . . . . . . .

Instruments Test 6E±50. . . . . . . . . . . . . . . . . . . . . . .

EGR Control Test 6E±52. . . . . . . . . . . . . . . . . . . . . .

Variable Intake Manifold Solenoid Test 6E±52. . .

Injector Balance Test 6E±54. . . . . . . . . . . . . . . . . . .

Plotting Snapshot Graph 6E±54. . . . . . . . . . . . . . . . .

Plotting Graph Flow Chart (Plotting graph

after obtaining vehicle information) 6E±55. . . . . .

Flow Chart for Snapshot Replay (Plotting

Graph) 6E±56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Primary System-Based Diagnostic 6E±57. . . . . . . . .

Primary System-Based Diagnostic 6E±57. . . . . . .

Fuel Control Heated Oxygen Sensor 6E±57. . . . .

HO2S Heater 6E±57. . . . . . . . . . . . . . . . . . . . . . . . .

Catalyst Monitor Heated Oxygen Sensors

and Diagnostic Operation 6E±57. . . . . . . . . . . . . .

Misfire Monitor Diagnostic Operation 6E±58. . . . . . .

Misfire Monitor Diagnostic Operation 6E±58. . . . .

Misfire Counters 6E±58. . . . . . . . . . . . . . . . . . . . . . .