ISUZU AXIOM 2002 Service Repair Manual

Manufacturer: ISUZU, Model Year: 2002, Model line: AXIOM, Model: ISUZU AXIOM 2002Pages: 2100, PDF Size: 19.35 MB

Page 311 of 2100

INTELLIGENT SUSPENSION3F±35

Removal

1. Disconnect the battery ground cable.

2. Disconnect the connector from the harness and

remove the connector from the bracket.

3. Remove the clip.

View B

450RY00005

Legend

(1) Screw

(2) Actuator

(3) Nut

(4) Bracket

(5) Nut

(6) Washer

(7) Shock Absorber

1. Remove 2 screws.

2. Remove the actuator.

3. Remove the nut (3).

4. Disconnect bracket.

5. Remove the nut (5).

6. Disconnect the washer.

7. Remove the shock absorber.

Refer to

Shock Absorber in this section.

Inspection and Repair

Refer to shock Abosorber in this section.

Installation

1. Install the shock absorber.

Refer to

Shock Absorber in this section.

2. Install the washer and nut (5), then tighten it to the

specified torque.

Torque: 15 N´m (11 lb ft)

3. Install the bracket and nut (3), then tighten it to the

specified torque.

Torque: 39 N´m (29 lb ft)

NOTE: Fix the lower nut with wrench not to turn and

tighten upper nut.

4. Fit the top of the shock absorber rod in the connection

part of the actuator.

NOTE:

The mating section is width fitting across flats.

If these normally fit, the distance between the

actuator lower face and the bracket upper face is

about 1 mm.

5. Install 2 screws then tighten it to the specified torque.

3 N´m (26 lb in)

6. Connect the connector to the harness and insert the

connector to the bracket.

7. Connect the actuator harness with the clip.

8. Connect the battery ground cable.

Page 312 of 2100

3F±36INTELLIGENT SUSPENSION

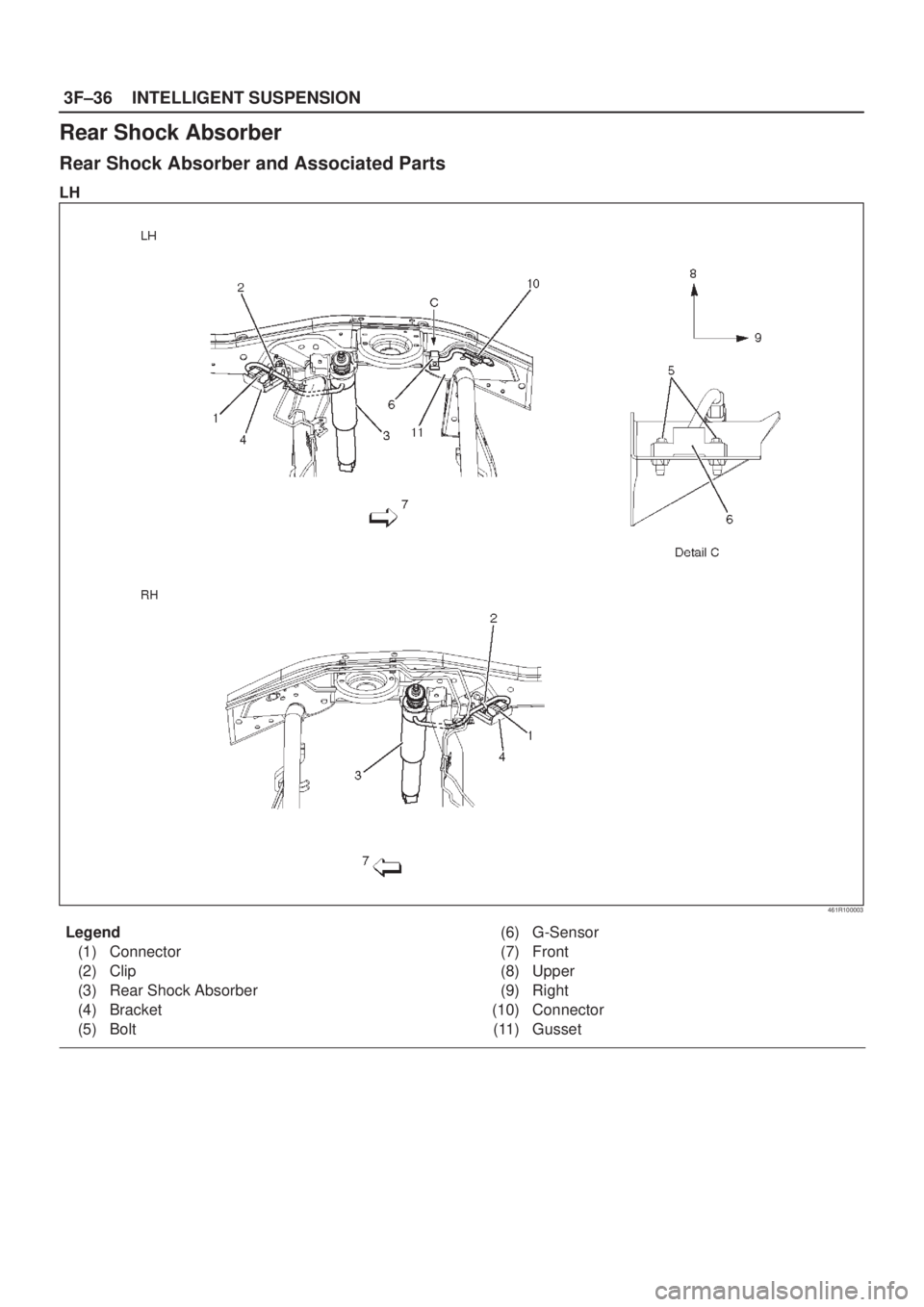

Rear Shock Absorber

Rear Shock Absorber and Associated Parts

LH

461R100003

Legend

(1) Connector

(2) Clip

(3) Rear Shock Absorber

(4) Bracket

(5) Bolt(6) G-Sensor

(7) Front

(8) Upper

(9) Right

(10) Connector

(11) Gusset

Page 313 of 2100

INTELLIGENT SUSPENSION3F±37

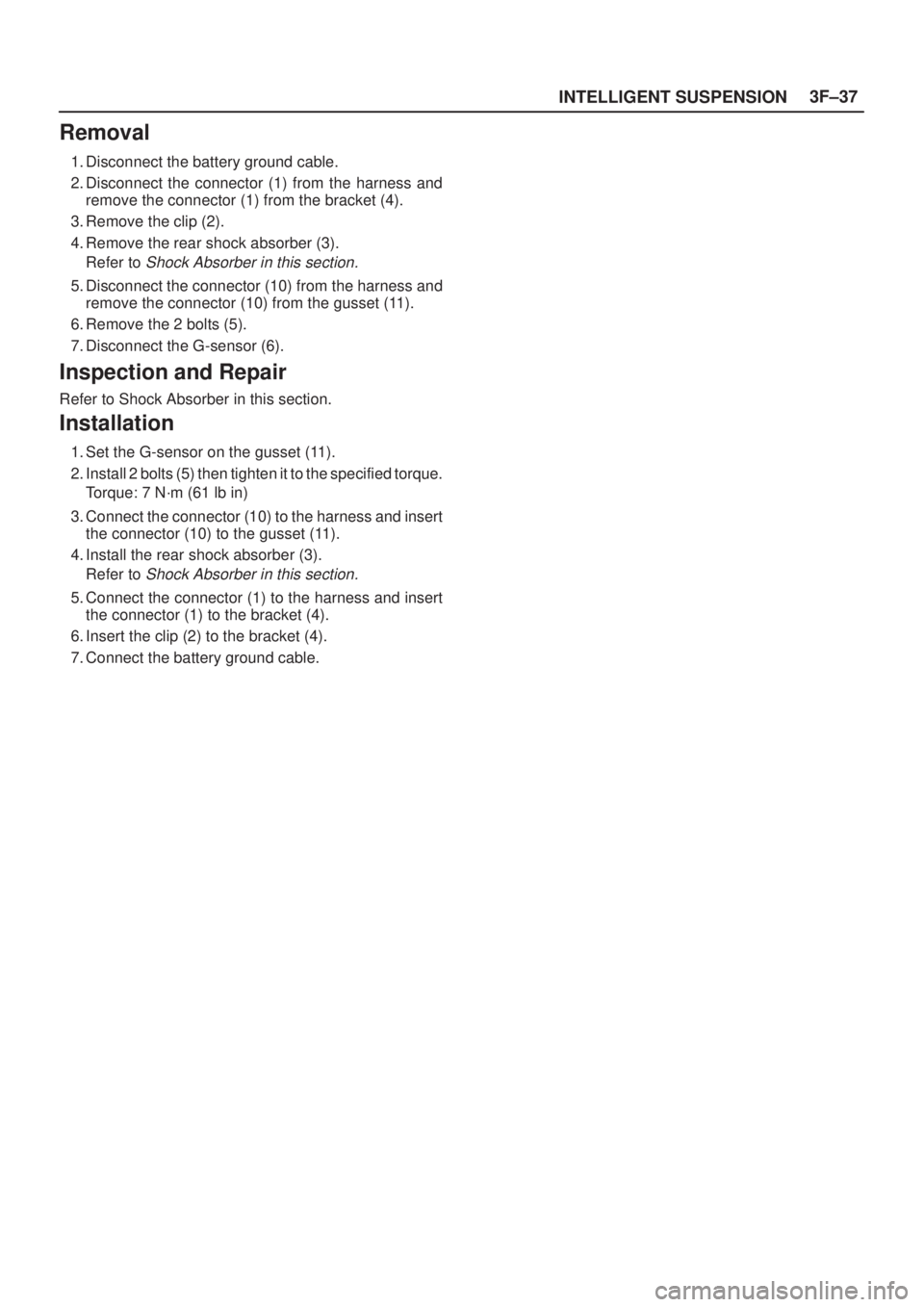

Removal

1. Disconnect the battery ground cable.

2. Disconnect the connector (1) from the harness and

remove the connector (1) from the bracket (4).

3. Remove the clip (2).

4. Remove the rear shock absorber (3).

Refer to

Shock Absorber in this section.

5. Disconnect the connector (10) from the harness and

remove the connector (10) from the gusset (11).

6. Remove the 2 bolts (5).

7. Disconnect the G-sensor (6).

Inspection and Repair

Refer to Shock Absorber in this section.

Installation

1. Set the G-sensor on the gusset (11).

2. Install 2 bolts (5) then tighten it to the specified torque.

Torque: 7 N´m (61 lb in)

3. Connect the connector (10) to the harness and insert

the connector (10) to the gusset (11).

4. Install the rear shock absorber (3).

Refer to

Shock Absorber in this section.

5. Connect the connector (1) to the harness and insert

the connector (1) to the bracket (4).

6. Insert the clip (2) to the bracket (4).

7. Connect the battery ground cable.

Page 314 of 2100

4A1±1 DIFFERENTIAL (FRONT)

AXIOM

DRIVELINE/AXLE

CONTENTS

Differential (Front) 4A1. . . . . . . . . . . . . . . . . . . . . . .

Differential (Rear) 4A2. . . . . . . . . . . . . . . . . . . . . . .

Driveline Control System 4B1. . . . . . . . . . . . . . . . . Driveline Control System (TOD) 4B2. . . . . . . . . . .

Drive Shaft System 4C. . . . . . . . . . . . . . . . . . . . . .

Transfer Case (TOD) 4D2. . . . . . . . . . . . . . . . . . . .

Differential (Front)

CONTENTS

Service Precaution 4A1±1. . . . . . . . . . . . . . . . . . . . . .

Front Drive Axle 4A1±2. . . . . . . . . . . . . . . . . . . . . . . . .

Diagnosis 4A1±2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pinion Shaft Oil Seal 4A1±3. . . . . . . . . . . . . . . . . . . . .

Pinion Shaft Oil Seal and Associated Parts 4A1±3

Removal 4A1±3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4A1±4. . . . . . . . . . . . . . . . . .

Installation 4A1±4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Drive Axle Assembly 4A1±5. . . . . . . . . . . . . . .

Front Drive Axle Assembly and

Associated Parts 4A1±5. . . . . . . . . . . . . . . . . . . . . .

Removal 4A1±6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . Installation 4A1±6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Differential Assembly 4A1±8. . . . . . . . . . . . . . . . . . . .

Disassembled View 4A1±8. . . . . . . . . . . . . . . . . . . .

Disassembly 4A1±9. . . . . . . . . . . . . . . . . . . . . . . . . .

Reassembly 4A1±11. . . . . . . . . . . . . . . . . . . . . . . . . .

Differential Cage Assembly 4A1±20. . . . . . . . . . . . . . .

Disassembled View 4A1±20. . . . . . . . . . . . . . . . . . . .

Disassembly 4A1±20. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4A1±21. . . . . . . . . . . . . . . . . .

Reassembly 4A1±21. . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 4A1±23. . . . . . . . . . .

Special Tools 4A1±25. . . . . . . . . . . . . . . . . . . . . . . . . .

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM(SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE REFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING, REFER TO

THE SRS SERVICE INFOMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN POSSIBLE

AIR BAG DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED , do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally,such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specification. Following these

instructions can help you avoid damage to parts and

systems.

Page 315 of 2100

DIFFERENTIAL (FRONT) 4A1±2

Front Drive Axle

Diagnosis

ConditionPossible causeCorrection

Oil Leak At Front AxleWorn or defective oil seal.Replace the oil seal.

Front axle housing cracked.Repair or replace.

Oil Leak At Pinion ShaftToo much gear oil.Correct the oil level.

Oil seal worn or defective.Replace the oil seal.

Pinion flange loose or damaged.Tighten or replace.

Noises In Front Axle Drive Shaft

JointBroken or worn drive shaft joints and

bellows (BJ and DOJ).Replace the drive shaft joints and

bellows.

ªClankº When Accelerating From

ªCoastºLoose drive shaft joint to output shaft

bolts.Tighten.

Damaged inner drive shaft joint.Replace.

Shudder or Vibration During

Acceleration

Excessive drive shaft joint angle.Repair.

AccelerationWorn or damaged drive shaft joints.Replace.

Sticking spider assembly (inner drive

shaft joint).Lubricate or replace.

Sticking joint assembly (outer drive

shaft joint).Lubricate or replace.

Vibration At Highway SpeedsOut of balance or out of round tires.Balance or replace.

Front end out of alignment.Align.

Noises in Front AxleInsufficient gear oil.Replenish the gear oil.

Wrong or poor grade gear oil.Replace the gear oil.

Drive pinion to ring gear backlash

incorrect.Adjust the backlash.

Worn or chipped ring gear, pinion

gear or side gear.Replace the ring gear, pinion gear or

side gear.

Pinion shaft bearing worn.Replace the pinion shaft bearing.

Wheel bearing worn.Replace the wheel bearing.

Differential bearing loose or worn.Tighten or replace.

Wanders and PullsWheel bearing preload too tight.Adjust the wheel bearing preload.

Incorrect front alignment.Adjust the front alignment.

Steering unit loose or worn.Tighten or replace.

Tire worn or improperly inflated.Adjust the inflation or replace.

Front or rear suspension parts loose

or broken.Tighten or replace.

Front Wheel ShimmyWheel bearing worn or improperly

adjusted.Adjust or replace.

Incorrect front alignment.Adjust the front alignment.

Worn ball joint or bush.Replace the ball joint or bush.

Steering unit loose or worn.Tighten or replace.

Tire worn or improperly inflated.Replace or adjust the inflation.

Shock absorber worn.Replace the shock absorber.

Page 316 of 2100

4A1±3 DIFFERENTIAL (FRONT)

Pinion Shaft Oil Seal

Pinion Shaft Oil Seal and Associated Parts

415R200001

Legend

(1) Flange Nut

(2) Flange(3) Oil Seal

(4) Outer Bearing

(5) Collapsible Spacer

Removal

1. Raise the vehicle and support it at the frame.

The hoist must remain under the front axle housing.

2. Drain the front axle oil by loosening the drain plug(1).

412RS001

Page 317 of 2100

DIFFERENTIAL (FRONT) 4A1±4

3. Remove the front propeller shaft. Refer to Front

Propeller Shaft

in this section.

4. Remove flange nut by using pinion flange holder

J±8614±01.

415RS018

5. Remove flange.

6. Remove oil seal.

7. Remove outer bearing by using remover J±39602.

415RS001

8. Remove collapsible spacer.

Inspection and Repair

Make necessary correction or parts replacement if wear,

damage, corrosion or any other abnormal condition are

found through inspection.

Check the following parts.

1. Seal surface of the pinion.

2. Cage bore for burns.

Installation

1. Install collapsible spacer. Discard the used

collapsible spacer and install a new one.

2. Install outer bearing.

NOTE: Do not drive in, but just temporarily set in the outer

bearing by hand, which should be indirectly pressed in

finally by tightening the flange nut.

3. Install oil seal, use oil seal installer J±24250 to install a

new oil seal that has been soaked in axle lubricant.

415RS002

4. Install flange.

5. Install flange nut, refer to

Differential Assembly

Overhaul for flange nut reassembly

in this section.

NOTE: Discard the used nut and install a new one.

Page 318 of 2100

4A1±5 DIFFERENTIAL (FRONT)

Front Drive Axle Assembly

Front Drive Axle Assembly and Associated Parts

412R200003

Legend

(1) Propeller Shaft

(2) Mounting Nut

(3) Front Axle Case Assembly and Front Drive

Shaft Assembly

(4) Washer(5) Mounting Bolt

(6) Tie±rod End; Power Steering Unit

(7) Knuckle and Back Plate

(8) Hub and Disc Assembly

(9) Suspension Crossmember

Page 319 of 2100

DIFFERENTIAL (FRONT) 4A1±6

Removal

1. Jack up the vehicle and support it using jack stand.

2. Remove the tire and wheel.

3. Remove the stone guard.

4. Remove the brake caliper fixing bolt and hang the

caliper. Refer to

Disc Brakes in Brake section.

5. Remove the antilock brake system speed sensor.

Refer to

Front Wheel Speed Sensor in Brake section.

6. Remove the hub and disc assembly.

Refer to

Front Hub and Disc in this section.

7. Remove the propeller shaft, refer to

Front Propeller

Shaft

in this section.

8. Loosen the height control arm of the torsion bar, then

remove the torsion bar from lower control arm.

Refer to

Torsion Bar in Suspension section.

9. Remove the suspension crossmember.

10. Remove the lower nut (1) of the stabilizer link.

11. Remove the lower bolt and nut (2) of the shock

absorber.

412RW057

12. Remove the tie-rod end from the knuckle. Refer to

Power Steering Unit in Steering Section.

13. Disconnect the hose of the shift on the fly.

14. Disconnect the actuator connector.

15. Remove the bolts and nuts of the lower control arm

(Frame side), then disconnect the lower control arm

from frame.

16. Disconnect between the right side upper control arm

and the knuckle, then remove the knuckle with lower

control arm.CAUTION: When removing the knuckle, be careful

not to damage the oil seal inside of the knuckle.

410RW008

17. Support the differential case by the jack.

18. Remove the front axle mounting bolts and nuts, lower

the jack slowly. Remove the left side drive shaft end

from the knuckle, then lower the axle assembly from

the vehicle.

CAUTION:

1. Make sure the axle assembly is supported

securely when performing repairs.

2. Do not damage the power steering unit when

performing the repairs.

3. Do not damage the shift±on±the fly hose bracket

when performing the repairs.

Installation

1. Support the differential case with a jack.

2. Jack up the front drive axle assembly, install the left

side drive shaft to the knuckle, then install the mount

bolts and nuts.

CAUTION:

1. Do not damage the power steering unit when

performing the repairs.

2. Do not damage the shift±on±the fly hose bracket

when performing the repairs.

3. When installing the drive shaft to the knuckle, be

careful not to damage the oil seal inside of the

knuckle.

Page 320 of 2100

4A1±7 DIFFERENTIAL (FRONT)

3. Tighten the mounting bolts and nuts to the specified

torque.

Torque: 168 N´m (124 lb ft)

412R200004

4. Install the right side knuckle with lower control arm to

the upper control arm.

Refer to

Knuckle in Suspension section.

CAUTION: Carefully insert the drive shaft into the

knuckle, to avoid damaging the oil seal.

5. Align the bolt hole of the lower control arm, then install

the bolts and nuts.

NOTE: Adjust the buffer clearance before tightening the

bolts and nuts of the lower control arm.

6. Install the hose of the shift on the fly.

7. Install the actuator connector of the shift on the fly.

8. Install the tie-rod end of the power steering unit to the

knuckle, tighten the nut to the specified torque.

Torque: 118 N´m (87 lb ft)

9. Install lower bolts and nuts of the shock absorber,

tighten it to the specified torque.

Torque: 93 N´m (69 lb ft)

10. Install lower nuts of the stabilizer link, tighten it to the

specified torque.

11. Install the suspension crossmember.

12. Install the torsion bar.

Refer to

Torsion Bar in Suspension section.

13. Install the front propeller shaft.

Refer to

Front Propeller Shaft in this section.

14. Install the hub and disc assembly and adjust the

bearing preload.

Refer to

Front Hub and Disc in this section.

15. Install the wheel speed sensor of the antilock brake

system.

16. Install the brake caliper. Tighten the bolt of the caliper

bracket to the specified torque.

Torque: 50 N´m (37 lb ft)

17. Install the stone guard.18. Install the tire and wheel.

19. Lower the vehicle, adjust the trim height.

Refer to

Trim Height Adjustment in Steering section.

20. Tighten the bolts and nuts of the lower control arm to

the specified torque.

Refer to

Lower Control Arm in Suspension section.