ISUZU AXIOM 2002 Service Repair Manual

Manufacturer: ISUZU, Model Year: 2002, Model line: AXIOM, Model: ISUZU AXIOM 2002Pages: 2100, PDF Size: 19.35 MB

Page 371 of 2100

4A2±32DIFFERNTIAL (REAR)

Special Tools

ILLUSTRATIONTOOL NO.

TOOL NAME

J±8614±01

Pinion flange holder

J±37263

Installer; Pinion oil seal

J±42379

Remover; Bearing

J±39830

Adapter; Side bearing

plug

J±8611±01

Installer; Outer bearing

outer race

J±8592

Grip

ILLUSTRATIONTOOL NO.

TOOL NAME

J±42836

Installer; Inner bearing

outer race

J±42824

Pilot;Outer

J±21777±43

Nut & Stud

J±42827

Pilot;Inner

J±39837±2

Gauge plate

J±8001

Dial indicator

Page 372 of 2100

DIFFERENTIAL (REAR)4A2±33

ILLUSTRATIONTOOL NO.

TOOL NAME

J±39837±1

Disc (2 required)

J±23597±1

Arbor

J±42828

Installer; Pinion bearing

J±21784

Installer; Side bearing

J±39602

Remover; Outer bearing

J±24385±B

Spreader

ILLUSTRATIONTOOL NO.

TOOL NAME

J±39858

Clutch pack unloading

tool kit Includes

J±34174±1/J±34174±2

Screw cap and Cap

J±22342±15

Forcing screw

J±39834

Limited±slip differential

(LSD) service adapter

J±39824

Holder

J±39836

Side bearing preload

master bearings

Page 373 of 2100

4B1±1

DRIVELINE CONTROL SYSTEM

AXIOM

DRIVELINE/AXLE

DRIVELINE CONTROL SYSTEM

CONTENTS

Service Precaution 4B1±1. . . . . . . . . . . . . . . . . . . . . .

Shift On The Fly System 4B1±2. . . . . . . . . . . . . . . . .

Outline of Shift on The Fly System 4B1±2. . . . . . . . .

Functions of Indicator Lamp 4B1±4. . . . . . . . . . . . . .

Shift On The Fly Electrical Equipment 4B1±5. . . . . .

Axle Shaft Connection and Disconnection 4B1±5. . Shift On The Fly Controller 4B1±7. . . . . . . . . . . . . . .

Shift On The Fly Controller and

Associated Parts 4B1±7. . . . . . . . . . . . . . . . . . . . . .

Removal 4B1±7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 4B1±7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING, REFER TO

THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN POSSIBLE

AIR BAG DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

Page 374 of 2100

4B1±2

DRIVELINE CONTROL SYSTEM

Shift On The Fly System

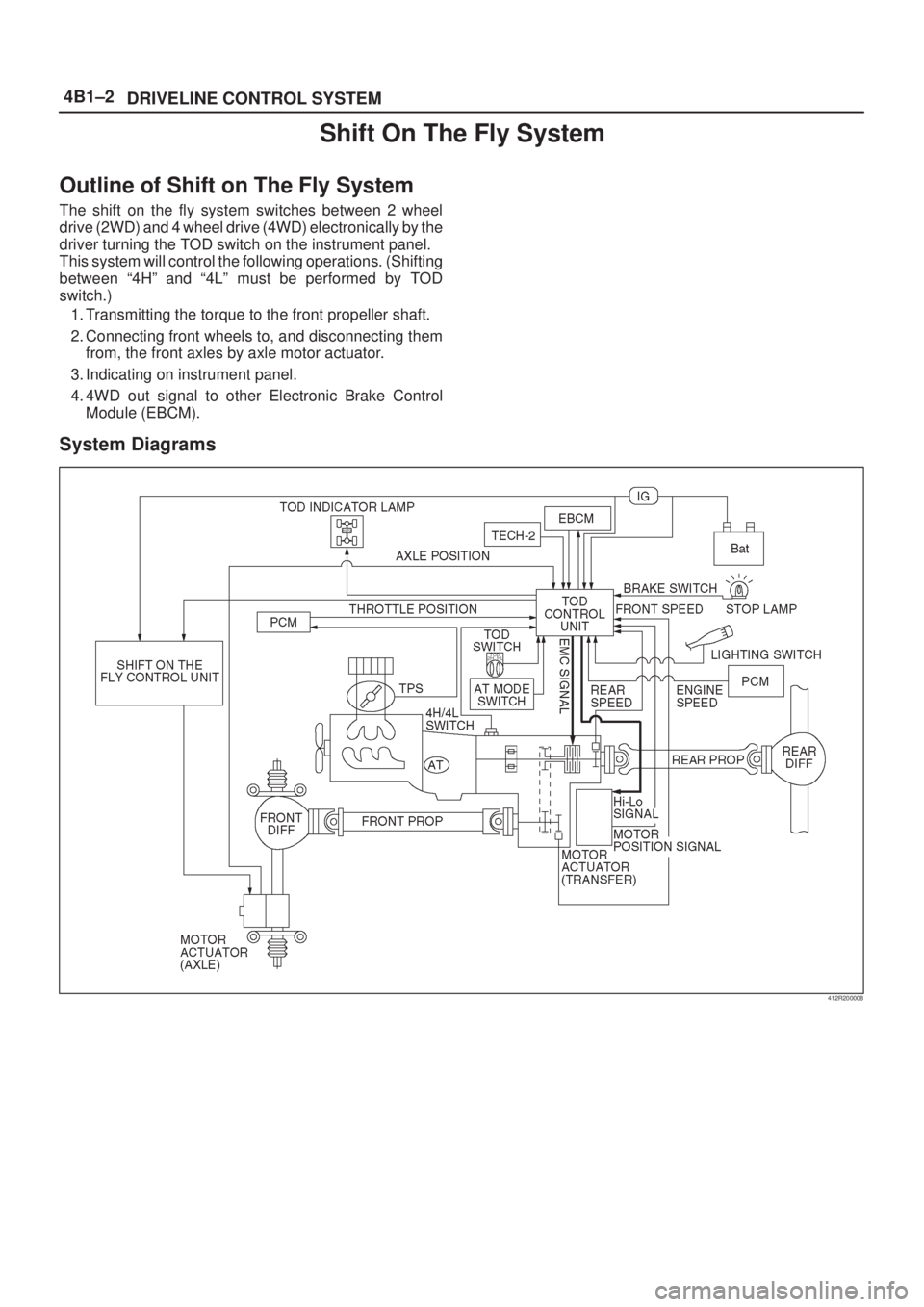

Outline of Shift on The Fly System

The shift on the fly system switches between 2 wheel

drive (2WD) and 4 wheel drive (4WD) electronically by the

driver turning the TOD switch on the instrument panel.

This system will control the following operations. (Shifting

between ª4Hº and ª4Lº must be performed by TOD

switch.)

1. Transmitting the torque to the front propeller shaft.

2. Connecting front wheels to, and disconnecting them

from, the front axles by axle motor actuator.

3. Indicating on instrument panel.

4. 4WD out signal to other Electronic Brake Control

Module (EBCM).

System Diagrams

412R200008

Page 375 of 2100

4B1±3

DRIVELINE CONTROL SYSTEM

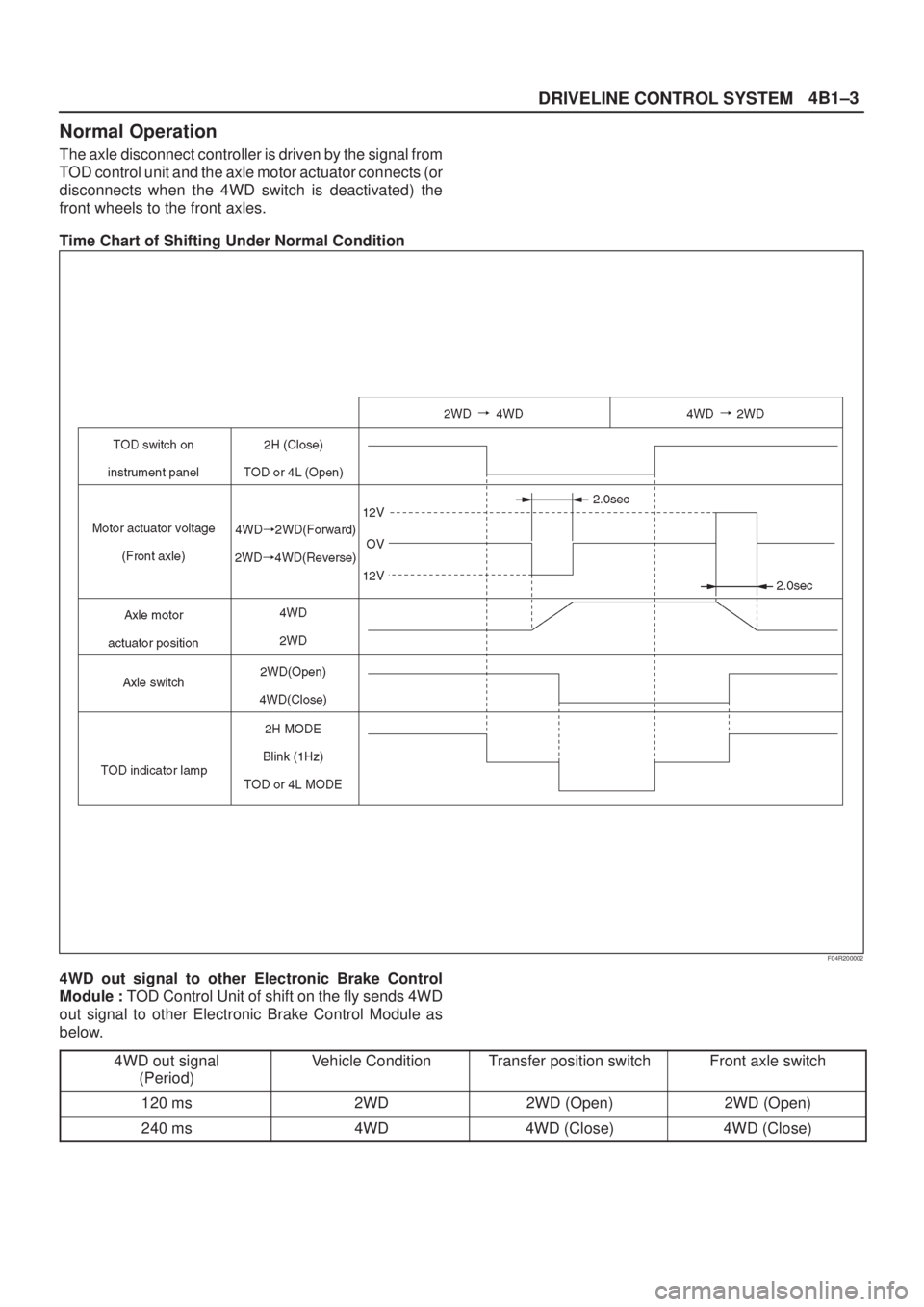

Normal Operation

The axle disconnect controller is driven by the signal from

TOD control unit and the axle motor actuator connects (or

disconnects when the 4WD switch is deactivated) the

front wheels to the front axles.

Time Chart of Shifting Under Normal Condition

F04R200002

4WD out signal to other Electronic Brake Control

Module : TOD Control Unit of shift on the fly sends 4WD

out signal to other Electronic Brake Control Module as

below.

4WD out signal

(Period)

Vehicle ConditionTransfer position switchFront axle switch

120 ms2WD2WD (Open)2WD (Open)

240 ms4WD4WD (Close)4WD (Close)

Page 376 of 2100

4B1±4

DRIVELINE CONTROL SYSTEM

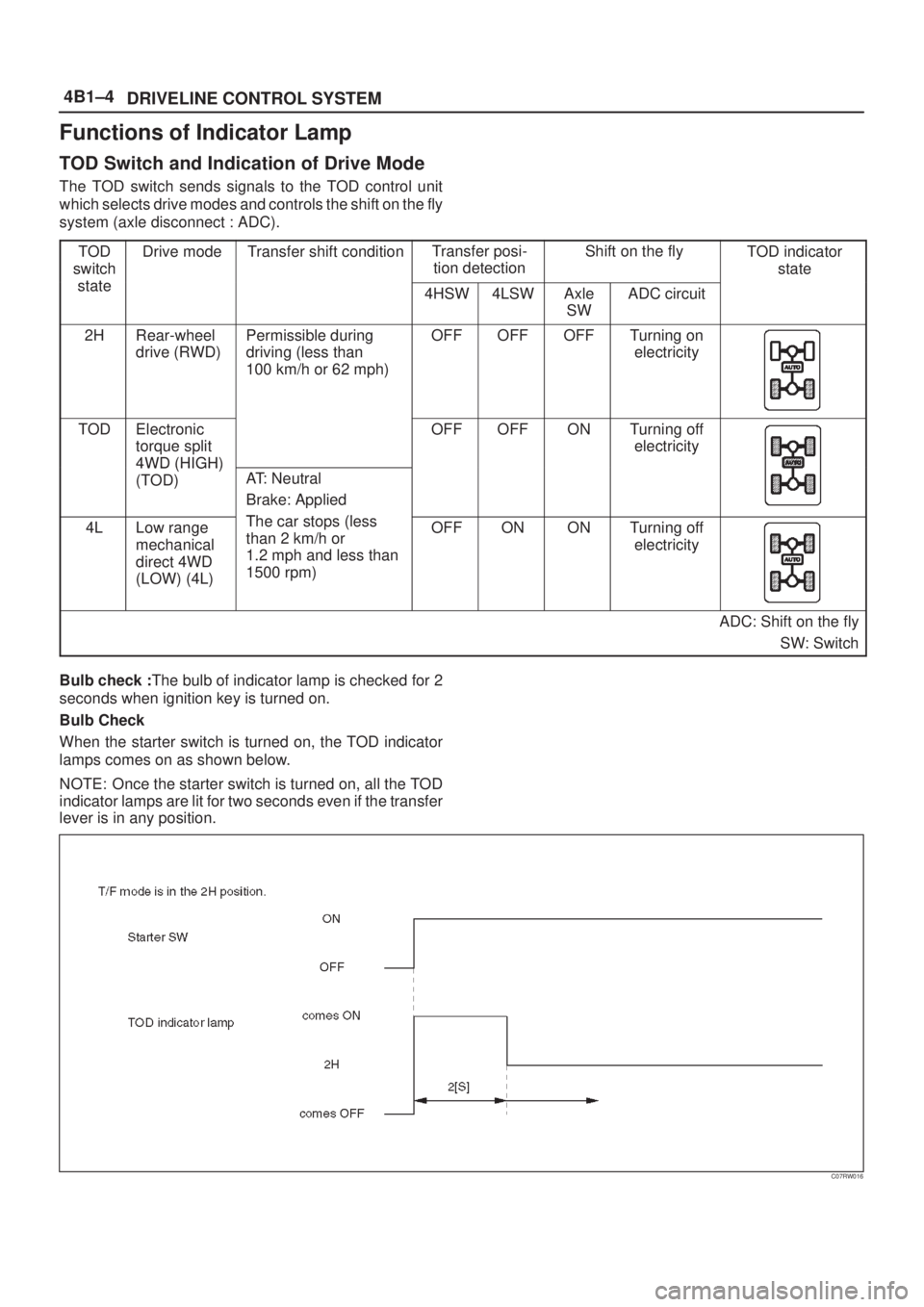

Functions of Indicator Lamp

TOD Switch and Indication of Drive Mode

The TOD switch sends signals to the TOD control unit

which selects drive modes and controls the shift on the fly

system (axle disconnect : ADC).

TOD

switch

tt

Drive modeTransfer shift conditionTransfer posi-

tion detectionShift on the flyTOD indicator

state

state4HSW4LSWAxle

SWADC circuit

2HRear-wheel

drive (RWD)Permissible during

driving (less than

100 km/h or 62 mph)OFFOFFOFFTurning on

electricity

TODElectronic

torque split

4WD (HIGH)

OFFOFFONTurning off

electricity

4WD (HIGH)

(TOD)AT: Neutral

Brake: Applied

Th t (l4LLow range

mechanical

direct 4WD

(LOW) (4L)The car stops (less

than 2 km/h or

1.2 mph and less than

1500 rpm)OFFONONTurning off

electricity

ADC: Shift on the fly

SW: Switch

Bulb check :The bulb of indicator lamp is checked for 2

seconds when ignition key is turned on.

Bulb Check

When the starter switch is turned on, the TOD indicator

lamps comes on as shown below.

NOTE: Once the starter switch is turned on, all the TOD

indicator lamps are lit for two seconds even if the transfer

lever is in any position.

C07RW016

Page 377 of 2100

4B1±5

DRIVELINE CONTROL SYSTEM

Shift On The Fly Electrical Equipment

Axle Shaft Connection and Disconnection

412R200006

Actuator Assembly

412RY00004

Axle Disconnect Controller

828RY00009

Page 378 of 2100

4B1±6

DRIVELINE CONTROL SYSTEM

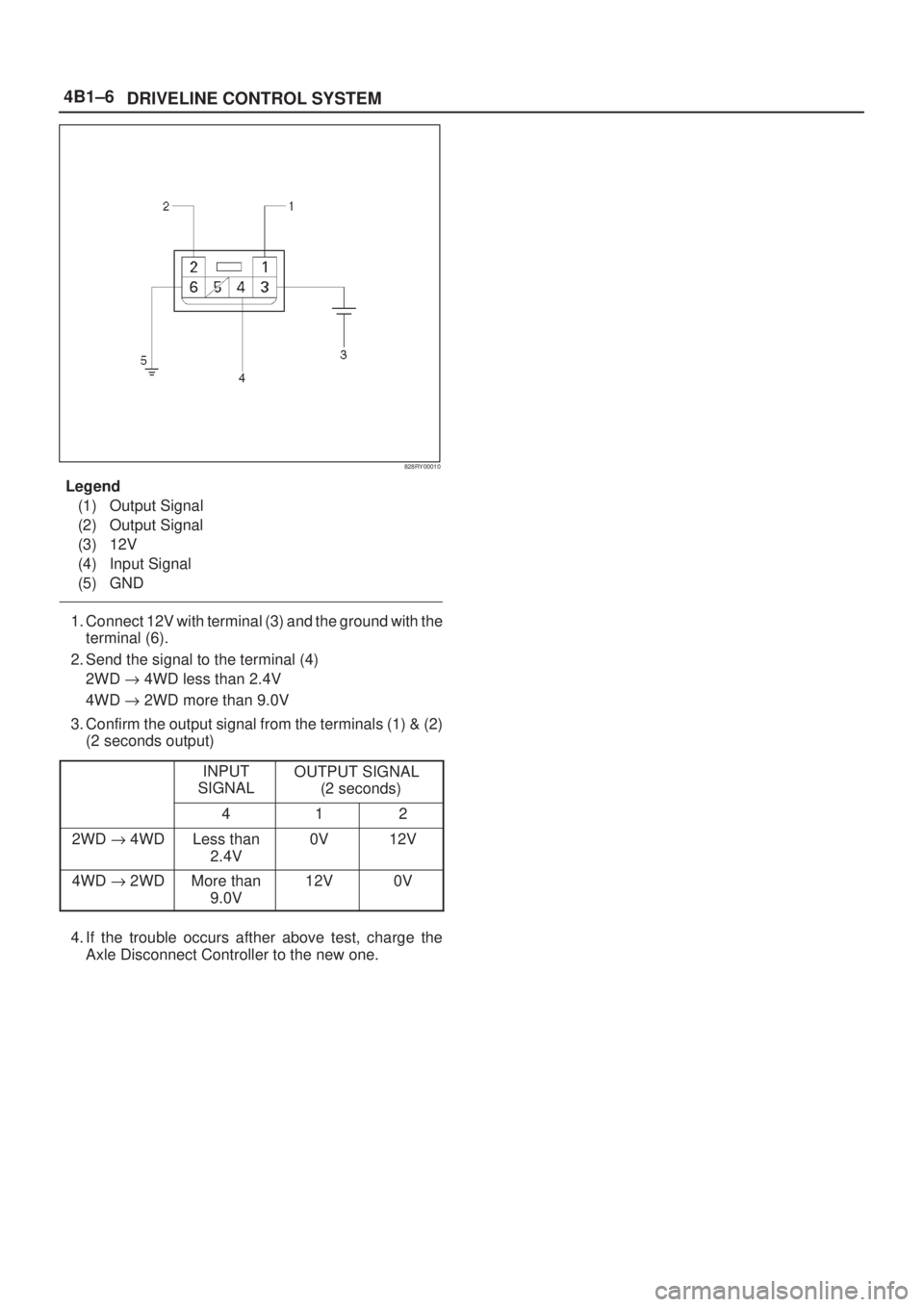

828RY00010

Legend

(1) Output Signal

(2) Output Signal

(3) 12V

(4) Input Signal

(5) GND

1. Connect 12V with terminal (3) and the ground with the

terminal (6).

2. Send the signal to the terminal (4)

2WD " 4WD less than 2.4V

4WD " 2WD more than 9.0V

3. Confirm the output signal from the terminals (1) & (2)

(2 seconds output)

INPUT

SIGNALOUTPUT SIGNAL

(2 seconds)

412

2WD " 4WDLess than

2.4V0V12V

4WD " 2WDMore than

9.0V12V0V

4. If the trouble occurs afther above test, charge the

Axle Disconnect Controller to the new one.

Page 379 of 2100

4B1±7

DRIVELINE CONTROL SYSTEM

Shift On The Fly Controller

Shift On The Fly Controller and Associated Parts

828RY00003

Legend

(1) Nut(2) SOF Controller

(3) Connector

Removal

1. Disconnect the battery ground cable.

2. Remove the front console assembly.

Refer to

Consoles in Body and Accessories section.

3. Disconnect the connector from the controller.

4. Remove the nut.

5. Remove the controller.

Installation

To install, follow the removal steps in the reverse order,

noting the following points.

Torque: Nut (1) 8 N´m (69 Ib in)

Page 380 of 2100

4B2±1

DRIVE LINE CONTROL SYSTEM (TOD)

AXIOM

DRIVELINE/AXLE

DRIVELINE CONTROL SYSTEM (TOD)

CONTENTS

Service Precaution 4B2±1. . . . . . . . . . . . . . . . . . . . . .

General Description 4B2±2. . . . . . . . . . . . . . . . . . . . .

Transfer Position and Drive Mode 4B2±2. . . . . . . .

TOD Control 4B2±3. . . . . . . . . . . . . . . . . . . . . . . . . .

TOD Indicator Control 4B2±3. . . . . . . . . . . . . . . . . .

Abbreviations 4B2±3. . . . . . . . . . . . . . . . . . . . . . . . .

System Components 4B2±4. . . . . . . . . . . . . . . . . . . .

Parts Location 4B2±4. . . . . . . . . . . . . . . . . . . . . . . .

Front and Rear Speed Sensors 4B2±5. . . . . . . . . .

Electromagnetic Coil 4B2±5. . . . . . . . . . . . . . . . . . .

Multi Plate Disk Clutch Pack 4B2±5. . . . . . . . . . . .

Mechanical Lock Sleeve 4B2±5. . . . . . . . . . . . . . . .

High-Low Planetary Gear Set 4B2±6. . . . . . . . . . .

4H and 4L Switch 4B2±6. . . . . . . . . . . . . . . . . . . . . .

Transfer Connector (12-pin type) 4B2±6. . . . . . . .

Transfer Connector (8-pin type) 4B2±6. . . . . . . . .

TOD Indicator Lamps

(on the instrument panel) 4B2±7. . . . . . . . . . . . . .

Check Lamp 4B2±7. . . . . . . . . . . . . . . . . . . . . . . . . .

TOD ECU 4B2±8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

High-Low Shift Motor 4B2±9. . . . . . . . . . . . . . . . . . .

Motor Position and Encoder Position Code 4B2±10

Encode Position Plate 4B2±10. . . . . . . . . . . . . . . . . .

Shift High Range and Low Range 4B2±10. . . . . . . . Functions of TOD Switch and Indicator

Lamp 4B2±11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TOD Switch and Indication of Drive Mode 4B2±11.

Check Lamp 4B2±13. . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnosis 4B2±14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Information Diagnosis 4B2±14. . . . . . . . . .

Self-diagnosis 4B2±14. . . . . . . . . . . . . . . . . . . . . . . . .

Precautions on Diagnosis 4B2±16. . . . . . . . . . . . . . .

Basic Diagnostic Flow Chart 4B2±18. . . . . . . . . . . . . .

Parts Location 4B2±19. . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Diagram 4B2±20. . . . . . . . . . . . . . . . . . . . . . . . .

Connector List 4B2±24. . . . . . . . . . . . . . . . . . . . . . . . . .

Checking Failed Pin 4B2±26. . . . . . . . . . . . . . . . . . . . .

Connector Pin Assignment 4B2±26. . . . . . . . . . . . . .

Reference 4B2±28. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking Failed TOD Control Unit Pin 4B2±30. . . . .

Tech 2 Scan Tool 4B2±32. . . . . . . . . . . . . . . . . . . . . .

Getting Started 4B2±33. . . . . . . . . . . . . . . . . . . . . . . .

Operating Procedure 4B2±33. . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Codes 4B2±35. . . . . . . . . . . . . . . .

Diagnosis from Trouble Codes 4B2±36. . . . . . . . . . . .

Trouble Diagnosis Depending on The Status

of TOD Indicator 4B2±67. . . . . . . . . . . . . . . . . . . . . . . .

Diagnosis from Symptom 4B2±102. . . . . . . . . . . . . . . . .

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING, REFER TO

THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN POSSIBLE

AIR BAG DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.