ignition ISUZU AXIOM 2002 Service Workshop Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2002, Model line: AXIOM, Model: ISUZU AXIOM 2002Pages: 2100, PDF Size: 19.35 MB

Page 668 of 2100

5A±49

BRAKE CONTROL SYSTEM

Chart B-21 FR Speed Sensor Missing Signal (DTC 62 (Flash out) / C0222, C0223 (Serial

communications))

StepActionYe sNo

11. Turn the key off.

2. Disconnect coil integrated module connector.

3. Measure the FR speed sensor resistance between coil

integrated module connector (C-6) terminals 3 and 11.

Is the resistance between 2.0k and 2.8k ohms?

Go to Step 2Go to Step 3

2Is there play sensor/sensor rotor?Repair.

Go to

Step 6Go to Step 4

3Measure the FR speed sensor resistance at the sensor

connector.

Is the resistance between 2.0k and 2.8k ohms?Repair harness

abnormality

between sensors

and coil

integrated

module.

Go to

Step 6

Replace sensor.

Go to

Step 6

4Damage and powered iron sticking to sensor/sensor ring?Repair.

Go to

Step 6Go to Step 5

5Is sensor output normal? (Chart C-1-2 or TC-1)Check for faults

in harness

between speed

sensor and coil

integrated

module.

Fault found:

repair, and

perform system

self-check.

No fault found:

replace EHCU.

Go to

Step 6

Replace sensor.

Go to

Step 6

61. Reconnect all components, ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat the ªBasic

diagnostic flow

chartº

Go to Step 6

NOTE: Even after repairing the faulty part the warning

light (W/L) does not go out if the vehicle is at a stop. Turn

the ignition switch to the ON position and drive the vehicle

at 12 km/h (8 mph) or higher to make sure that the

warning light goes out.

Page 669 of 2100

5A±50BRAKE CONTROL SYSTEM

Chart B-22 Rear Speed Sensor Missing Signal (DTC 63 (Flash out) / C0236, C0237 (Serial

communications))

StepActionYe sNo

11. Turn the key off.

2. Disconnect coil integrated module connector.

3. Measure the Rear speed sensor resistance between coil

integrated module connector (C-6) terminals 4 and 12.

Is the resistance between 1.0k and 1.7k ohms?

Go to Step 2Go to Step 3

2Is there play sensor/sensor rotor?Repair.

Go to

Step 6Go to Step 4

3Measure the rear speed sensor resistance at the sensor

connector.

Is the resistance between 1.0k and 1.7k ohms?Repair harness

abnormality

between sensors

and coil

integrated

module.

Go to

Step 6

Replace sensor.

Go to

Step 6

4Damage and powered iron sticking to sensor/sensor ring?Repair.

Go to

Step 6Go to Step 5

5Is sensor output normal? (Chart C-1-3 or TC-1)Check for faults

in harness

between speed

sensor and coil

integrated

module.

Fault found:

repair, and

perform system

self-check.

No fault found:

replace EHCU.

Go to

Step 6

Replace sensor.

Go to

Step 6

61. Reconnect all components, ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat the ªBasic

diagnostic flow

chartº

Go to Step 6

NOTE: Even after repairing the faulty part the warning

light (W/L) does not go out if the vehicle is at a stop. Turn

the ignition switch to the ON position and drive the vehicle

at 12 km/h (8 mph) or higher to make sure that the

warning light goes out.

Page 670 of 2100

5A±51

BRAKE CONTROL SYSTEM

Chart B-23 Simultaneous Drop-out of Front Speed Sensor Signal (DTC 64 (Flash out) /

C0229 (Serial communications))

StepActionYe sNo

11. Turn the key off.

2. Disconnect coil integrated module connector.

3. Measure the FL speed sensor resistance between coil

integrated module connector (C-6) terminals 2 and 10.

Is the resistance between 2.0k and 2.8k ohms?

Go to Step 2Go to Step 3

2Measure the FR speed sensor resistance between coil integrated

module connector (C-6) terminals 3 and 11.

Is the resistance between 2.0k and 2.8 k ohms?

Go to Step 5Go to Step 4

3Measure the FL speed sensor resistance at the sensor connector.

Is the resistance between 2.0k and 2.8k ohms?Repair harness

abnormality

between sensors

and coil

integrated

module.

Go to

Step 2

Replace sensor.

Go to

Step 2

4Measure the FR speed sensor resistance at the sensor

connector.

Is the resistance between 2.0k and 2.8k ohms?Repair harness

abnormality

between sensors

and coil

integrated

module.

Go to

Step 5

Replace sensor.

Go to

Step 5

5Damage and powered iron sticking to sensor/sensor ring?Repair.

Go to

Step 6Go to Step 6

6Is there play sensor/sensor rotor?Repair.

Go to

Step 7Go to Step 7

7Is sensor output normal? (Chart C-1-1&C-1-2 or TC-1)Check for faults

in harness

between speed

sensor and coil

integrated

module.

Fault found:

repair, and

perform system

self-check.

No fault found:

replace EHCU.

Go to

Step 8

Replace sensor.

Go to

Step 8

81. Reconnect all components, ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat ªBasic

diagnostic flow

chartº

Go to Step 8

NOTE: Even after repairing the faulty part the warning

light (W/L) does not go out if the vehicle is at a stop. Turn

the ignition switch to the ON position and drive the vehicle

at 12 km/h (8 mph) or higher to make sure that the

warning light goes out.

Page 671 of 2100

5A±52BRAKE CONTROL SYSTEM

Chart B-24 Wheel Speed Input Abnormality (DTC 65 (Flash out) / C0238 (Serial

communications))

StepActionYe sNo

1Using TECH 2?Go to Step 2Go to Step 3

21. Connect TECH 2.

2. Select Snap shot manual trigger.

3. With wheel speed data displayed, run the vehicle when speed

has arrived at 30 km/h (18 mph).

4. Check speed data on each wheel (refer to the criterion given

below). * 1

Is the abnormal sensor condition found?

Replace.

Go to

Step 8

Go to Step 3

All the sensors

should follow the

following

flowchart (without

using TECH 2).

3Is there play in sensor/sensor ring?Repair.

Go to

Step 8Go to Step 4

4Is there powdered iron sticking to sensor/sensor ring?Repair.

Go to

Step 8Go to Step 5

5Is there a broken tooth or indentation in sensor ring?Replace sensor

ring.

Go to

Step 8Go to Step 6

6Is there play in wheel bearing?Adjust or repair.

Go to

Step 8Go to Step 7

7Is the check wiring between sensor and coil integrated module

normal?

Replace EHCU.

Go to

Step 8

Repair, and

perform system

self-check.

Go to

Step 8

81. Reconnect all components, ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat `Basic

diagnostic flow

chartº

Go to Step 8

Sensor Signal Abnormality Criteria using TECH 2

1. While driving, the speed of one or two wheels is 25%

or more higher or lower than that of the other wheels.

2. The speed of one or two wheels is 10 km/h (6 mph) or

more higher or lower than that of the other wheels.

3. During steady driving, wheel speed changes abruptly.

*1 The vehicle must run on a level paved road.

NOTE: Even after repairing the faulty part the warning

light (W/L) does not go out if the vehicle is at a stop.

Turn the ignition switch to the ON position and drive the

vehicle at 12 km/h (8 mph) or higher to make sure that the

warning light goes out.

It is important to verify that the correct tires are installed

on vehicle.

Page 686 of 2100

5C±6

POWER±ASSISTED BRAKE SYSTEM

Diagnosis

Road Testing The Brakes

Brake Test

Brakes should be tested on a dry, clean, reasonably

smooth and level roadway. A true test of brake

performance cannot be made if the roadway is wet,

greasy or covered with loose dirt where all tires do not grip

the road equally. Testing will also be adversely affected if

the roadway is crowned so as to throw the weight of the

vehicle toward wheels on one side or if the roadway is so

rough that wheels tend to bounce. Test the brakes at

different vehicle speeds with both light and heavy pedal

pressure; however, avoid locking the wheels and sliding

the tires. Braking without locking the tires will stop the

vehicle in less distance than braking to a skid (which has

no brake efficiency). More tire to road friction is present

while braking without locking the tires than braking to a

skid.

The standard brake system is designed and balanced to

avoid locking the wheels except at very high deceleration

levels.

It is designed this way because the shortest stopping

distance and best control is achieved without brake

lock±up.

Because of high deceleration capability, a firmer pedal

may be felt at higher deceleration levels.

External Conditions That Affect Brake Performance

1. Tires: Tires having unequal contact and grip on the

road will cause unequal braking. Tires must be

equally inflated, identical in size, and the thread

pattern of right and left tires must be approximately

equal.

2. Vehicle Loading: A heavily loaded vehicle requires

more braking effort.

3. Wheel Alignment: Misalignment of the wheels,

particularly in regard to excessive camber and caster,

will cause the brakes to pull to one side.

Brake Fluid Leaks

With engine running at idle and the transmission in

ªNeutralº, depress the brake pedal and hold a constant

foot pressure on the pedal. If pedal gradually falls away

with the constant pressure, the hydraulic system may be

leaking.

Check the master cylinder fluid level. While a slight drop in

the reservoir level will result from normal lining wear, an

abnormally low level in reservoir indicates a leak in the

system. The hydraulic system may be leaking internally

as well as externally. Refer to

Master Cylinder Inspection.

Also, the system may appear to pass this test but still

have slight leakage. If fluid level is normal, check the

vacuum booster push rod length. If an incorrect length

push rod is found, adjust or replace the push rod. Check

the brake pedal travel and the parking brake adjustment.

When checking the fluid level, the master cylinder fluid

level may be lower than the ªMAXº mark if the front and

rear linings are worn. This is normal.

Warning Light Operation

When the ignition switch is in the START position, the

ªBRAKEº warning light should turn on and go off when the

ignition switch returns to the ON position.

The following conditions will activate the ªBRAKEº light:

1. Parking brake applied. The light should be on

whenever the parking brake is applied and the ignition

switch is on.

2. Low fluid level. A low fluid level in the master cylinder

will turn the ªBRAKEº light on.

3. During engine cranking the ªBRAKEº light should

remain on. This notifies the driver that the warning

circuit is operating properly.

Page 746 of 2100

5C±66

POWER±ASSISTED BRAKE SYSTEM

Diagnosis

Road Testing The Brakes

Brake Test

Brakes should be tested on a dry, clean, reasonably

smooth and level roadway. A true test of brake

performance cannot be made if the roadway is wet,

greasy or covered with loose dirt where all tires do not grip

the road equally. Testing will also be adversely affected if

the roadway is crowned so as to throw the weight of the

vehicle toward wheels on one side or if the roadway is so

rough that wheels tend to bounce. Test the brakes at

different vehicle speeds with both light and heavy pedal

pressure; however, avoid locking the wheels and sliding

the tires. Braking without locking the tires will stop the

vehicle in less distance than braking to a skid (which has

no brake efficiency). More tire to road friction is present

while braking without locking the tires than braking to a

skid.

The standard brake system is designed and balanced to

avoid locking the wheels except at very high deceleration

levels.

It is designed this way because the shortest stopping

distance and best control is achieved without brake

lock±up.

Because of high deceleration capability, a firmer pedal

may be felt at higher deceleration levels.

External Conditions That Affect Brake Performance

1. Tires: Tires having unequal contact and grip on the

road will cause unequal braking. Tires must be

equally inflated, identical in size, and the thread

pattern of right and left tires must be approximately

equal.

2. Vehicle Loading: A heavily loaded vehicle requires

more braking effort.

3. Wheel Alignment: Misalignment of the wheels,

particularly in regard to excessive camber and caster,

will cause the brakes to pull to one side.

Brake Fluid Leaks

With engine running at idle and the transmission in

ªNeutralº, depress the brake pedal and hold a constant

foot pressure on the pedal. If pedal gradually falls away

with the constant pressure, the hydraulic system may be

leaking.

Check the master cylinder fluid level. While a slight drop in

the reservoir level will result from normal lining wear, an

abnormally low level in reservoir indicates a leak in the

system. The hydraulic system may be leaking internally

as well as externally. Refer to

Master Cylinder Inspection.

Also, the system may appear to pass this test but still

have slight leakage. If fluid level is normal, check the

vacuum booster push rod length. If an incorrect length

push rod is found, adjust or replace the push rod. Check

the brake pedal travel and the parking brake adjustment.

When checking the fluid level, the master cylinder fluid

level may be lower than the ªMAXº mark if the front and

rear linings are worn. This is normal.

Warning Light Operation

When the ignition switch is in the START position, the

ªBRAKEº warning light should turn on and go off when the

ignition switch returns to the ON position.

The following conditions will activate the ªBRAKEº light:

1. Parking brake applied. The light should be on

whenever the parking brake is applied and the ignition

switch is on.

2. Low fluid level. A low fluid level in the master cylinder

will turn the ªBRAKEº light on.

3. During engine cranking the ªBRAKEº light should

remain on. This notifies the driver that the warning

circuit is operating properly.

Page 799 of 2100

5D1±1

PARKING BRAKE SYSTEM (4x4 Model)

AXIOM

BRAKES

PARKING BRAKE SYSTEM (4y4 Model)

CONTENTS

Service Precaution 5D1±1. . . . . . . . . . . . . . . . . . . . . .

General Description 5D1±1. . . . . . . . . . . . . . . . . . . . .

Operation 5D1±2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parking Brake Lever and Front Cable 5D1±3. . . . . .

Parking Brake Lever Assembly and

Associated Parts 5D1±3. . . . . . . . . . . . . . . . . . . . . .

Removal 5D1±3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 5D1±3. . . . . . . . . . . . . . . . . . . . . . . . . . . . Parking Brake Rear Cable 5D1±4. . . . . . . . . . . . . . . .

Parking Brake Rear Cable and Associated

Parts 5D1±4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 5D1±5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 5D1±5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 5D1±6. . . . . . . . . . . . . . . . . .

Parking Brake Adjustment 5D1±6. . . . . . . . . . . . . . . .

Main Data and Specifications 5D1±7. . . . . . . . . . . . .

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING, REFER TO

THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN POSSIBLE

AIR BAG DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fasteners joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fasteners.

When you install fasteners, use the correct

tightening sequence and specifications. Following

these instructions can help you avoid damage to

parts and systems.

General Description

Pulling up the parking brake lever by hand will set the

parking brake. By means of a ratchet type lock, the lever

can be held in that position until it is released. The position

of the lever is transmitted through cable/lever systems to

the rear wheels. These parts are designed to obtain

sufficient braking force even when parking on slopes.

When the parking brake is set, or when the ignition SW is

in theªONº position, the brake warning light illuminates.

The rear wheel parking brake is a duo±servo brake

(mechanical inside expansion type) built in the rear disc

brake. Parking brake adjustment is made through the

adjusting hole (bored through back plate). Parking brake

lever stroke should be adjusted to 6±8 notches. Refer to

Parking Brake Adjustment in this section.

Page 806 of 2100

PARKING BRAKE SYSTEM (4X2 Model)

5D2±1

AXIOM

BRAKES

PARKING BRAKE SYSTEM (4y2 Model)

CONTENTS

Service Precaution 5D2±1. . . . . . . . . . . . . . . . . . . . . .

General Description 5D2±1. . . . . . . . . . . . . . . . . . . . .

Parking Brake Lever 5D2±2. . . . . . . . . . . . . . . . . . . . .

Parking Brake Lever Assembly and

Associated Parts 5D2±2. . . . . . . . . . . . . . . . . . . . . .

Removal 5D2±2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 5D2±2. . . . . . . . . . . . . . . . . . . . . . . . . . . . Parking Brake Rear Cable 5D2±3. . . . . . . . . . . . . . . .

Parking Brake Rear Cable and Associated

Parts 5D2±3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 5D2±4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 5D2±4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parking Brake Adjustment 5D2±4. . . . . . . . . . . . . . . .

Main Data and Specifications 5D2±5. . . . . . . . . . . . .

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING, REFER TO

THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN POSSIBLE

AIR BAG DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

General Description

Pulling up the parking brake lever by hand will set the

parking brake. By means of a ratchet type lock, the lever

can be held in that position until it is released. The position

of the lever is transmitted through cable/lever systems to

the rear wheels. These parts are designed to obtain

sufficient braking force even when parking on slopes.

When the parking brake is set, or when the ignition SW is

in theªONº position, the brake warning light illuminates.

The rear wheel parking brake is a leading/trailing brake

(mechanical inside expansion type). Parking brake

adjustment is made through the adjusting hole (bored

through back plate). Parking brake lever stroke should be

adjusted to 6 notches. Refer to

Parking Brake Adjustment

in this section.

Page 811 of 2100

6A±1

ENGINE MECHANICAL (6VE1 3.5L)

AXIOM

ENGINE

CONTENTS

Engine Mechanical 6A. . . . . . . . . . . . . . . . . . . . . .

Engine Cooling 6B. . . . . . . . . . . . . . . . . . . . . . . . .

Engine Fuel 6C. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Electrical 6D1. . . . . . . . . . . . . . . . . . . . . . . .

Ignition System 6D2. . . . . . . . . . . . . . . . . . . . . . . . .

Starting and Charging System 6D3. . . . . . . . . . . . Driveability and Emissions 6E. . . . . . . . . . . . . . . .

Engine Exhaust 6F. . . . . . . . . . . . . . . . . . . . . . . . .

Engine Lubrication 6G. . . . . . . . . . . . . . . . . . . . . .

Engine Speed Control System 6H. . . . . . . . . . . .

Induction 6J. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE MECHANICAL (6VE1 3.5L)

CONTENTS

Service Precaution 6A±2. . . . . . . . . . . . . . . . . . . . . .

General Description 6A±3. . . . . . . . . . . . . . . . . . . . .

Engine Diagnosis 6A±4. . . . . . . . . . . . . . . . . . . . . . .

Cylinder Head Cover LH 6A±19. . . . . . . . . . . . . . . . .

Removal 6A±19. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A±20. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Head Cover RH 6A±21. . . . . . . . . . . . . . . . .

Removal 6A±21. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A±21. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Common Chamber 6A±22. . . . . . . . . . . . . . . . . . . . . .

Removal 6A±22. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A±22. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exhaust Manifold LH 6A±24. . . . . . . . . . . . . . . . . . . . .

Removal 6A±24. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A±24. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exhaust Manifold RH 6A±25. . . . . . . . . . . . . . . . . . . .

Removal 6A±25. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A±25. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Crankshaft Pulley 6A±26. . . . . . . . . . . . . . . . . . . . . . .

Removal 6A±26. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A±26. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Timing Belt 6A±27. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 6A±27. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A±28. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Camshaft 6A±32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 6A±32. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A±33. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Head 6A±35. . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 6A±35. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A±35. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Valve Stem Oil Controller , Valve Spring

and Valve Guide 6A±37. . . . . . . . . . . . . . . . . . . . . . . .

Removal 6A±37. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A±37. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Piston, Piston Ring and Connecting Rod 6A±38. . . Removal 6A±38. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A±39. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Crankshaft and Main Bearings 6A±40. . . . . . . . . . . .

Removal 6A±40. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A±41. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Oil Seal 6A±45. . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 6A±45. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A±45. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Assembly 6A±46. . . . . . . . . . . . . . . . . . . . . . . .

Removal 6A±46. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A±47. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Head 6A±49. . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Head and Associated Parts 6A±49. . . . .

Disassembly 6A±50. . . . . . . . . . . . . . . . . . . . . . . . . .

Clean 6A±50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 6A±50. . . . . . . . . . . . . . . . . .

Reassembly 6A±51. . . . . . . . . . . . . . . . . . . . . . . . . .

Valve Spring, Oil Controller, Valve, Valve

Guide 6A±53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Valve Spring, Oil Controller, Valve, Valve

Guide and Associated Parts 6A±53. . . . . . . . . . . .

Disassembly 6A±53. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 6A±54. . . . . . . . . . . . . . . . . .

Reassembly 6A±57. . . . . . . . . . . . . . . . . . . . . . . . . .

Camshaft 6A±60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Camshaft and Associated Parts 6A±60. . . . . . . . .

Disassembly 6A±60. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 6A±61. . . . . . . . . . . . . . . . . .

Reassembly 6A±63. . . . . . . . . . . . . . . . . . . . . . . . . .

Crankshaft 6A±67. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Crankshaft and Associated Parts 6A±67. . . . . . . .

Disassembly 6A±67. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair for Bearings 6A±68. . . . . .

Inspection and Repair for Crankshaft 6A±70. . . . .

Reassembly 6A±71. . . . . . . . . . . . . . . . . . . . . . . . . .

Page 814 of 2100

6A±4

ENGINE MECHANICAL (6VE1 3.5L)

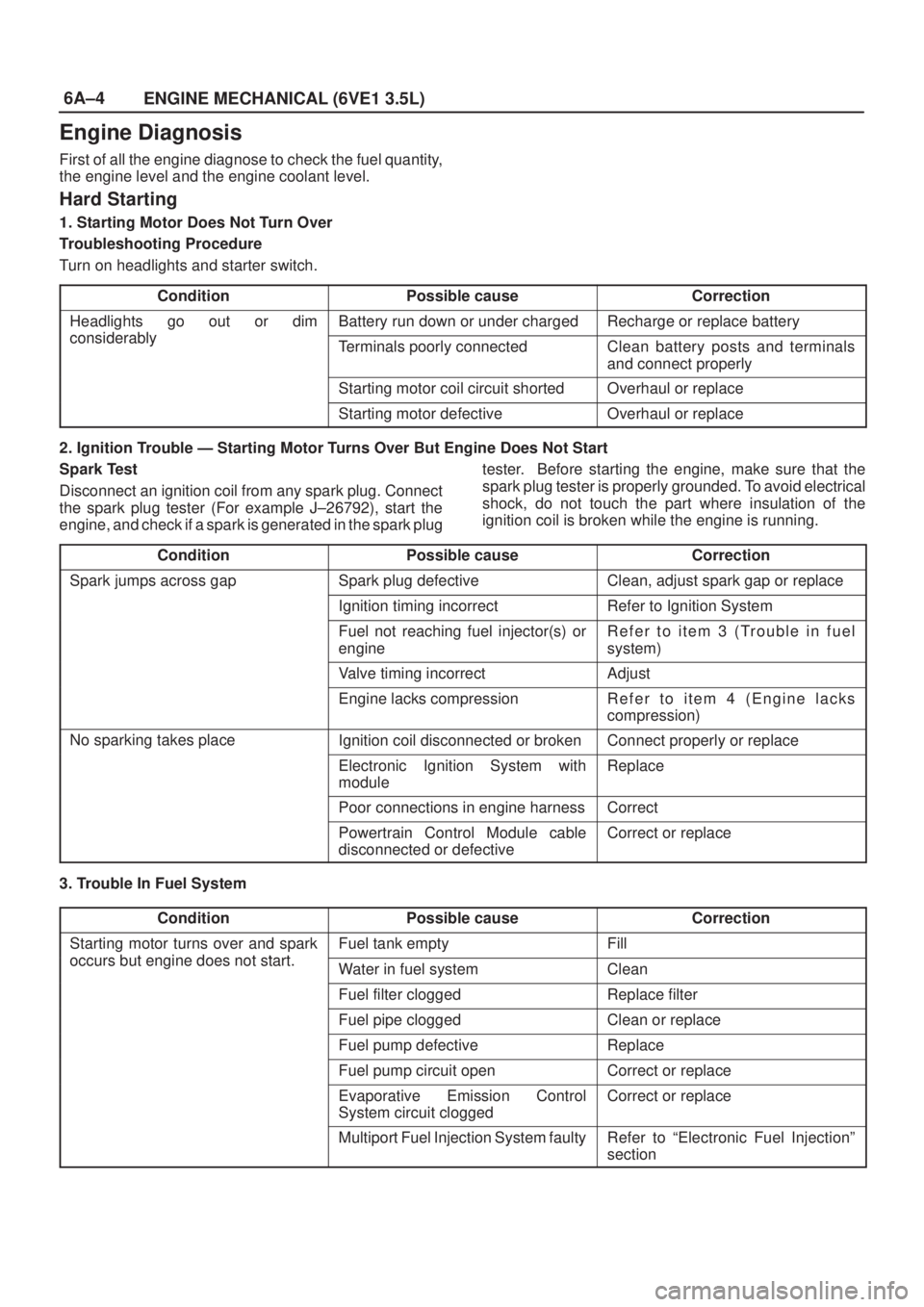

Engine Diagnosis

First of all the engine diagnose to check the fuel quantity,

the engine level and the engine coolant level.

Hard Starting

1. Starting Motor Does Not Turn Over

Troubleshooting Procedure

Turn on headlights and starter switch.

Condition

Possible causeCorrection

Headlights go out or dim

considerably

Battery run down or under chargedRecharge or replace battery

considerablyTerminals poorly connectedClean battery posts and terminals

and connect properly

Starting motor coil circuit shortedOverhaul or replace

Starting motor defectiveOverhaul or replace

2. Ignition Trouble Ð Starting Motor Turns Over But Engine Does Not Start

Spark Test

Disconnect an ignition coil from any spark plug. Connect

the spark plug tester (For example J±26792), start the

engine, and check if a spark is generated in the spark plugtester. Before starting the engine, make sure that the

spark plug tester is properly grounded. To avoid electrical

shock, do not touch the part where insulation of the

ignition coil is broken while the engine is running.

Condition

Possible causeCorrection

Spark jumps across gapSpark plug defectiveClean, adjust spark gap or replace

Ignition timing incorrectRefer to Ignition System

Fuel not reaching fuel injector(s) or

engineRefer to item 3 (Trouble in fuel

system)

Valve timing incorrectAdjust

Engine lacks compressionRefer to item 4 (Engine lacks

compression)

No sparking takes placeIgnition coil disconnected or brokenConnect properly or replace

Electronic Ignition System with

moduleReplace

Poor connections in engine harnessCorrect

Powertrain Control Module cable

disconnected or defectiveCorrect or replace

3. Trouble In Fuel System

Condition

Possible causeCorrection

Starting motor turns over and spark

occurs but engine does not start

Fuel tank emptyFill

occurs but engine does not start.Water in fuel systemClean

Fuel filter cloggedReplace filter

Fuel pipe cloggedClean or replace

Fuel pump defectiveReplace

Fuel pump circuit openCorrect or replace

Evaporative Emission Control

System circuit cloggedCorrect or replace

Multiport Fuel Injection System faultyRefer to ªElectronic Fuel Injectionº

section