ignition ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 4937 of 6020

TRANSFER CONTROL SYSTEM 7D1-63

To neutral: After the correction step 5-2(*), neutral indicator blinks at 4Hz.

Check the function between H and L according to the chart for 4L to 4H instead of check

for the requirements of neutral.

Step Action Yes No

1 Is the ignition switch ON? Turn it OFF once. Go to step 2.

2 Turn ON the ignition switch and

check the valve. Do not start the

engine.

Has the valve check for 2

seconds been completed

normally? Go to step 3.

Refer to the paragraph about the

indicator when it does not react

when shifted from 2H to 4H (7D1-

37).

After taking the remedy, trace this

chart from the beginning.

3 Can be shifted to 2H and then to 4L? Go to step 4.

(Impossible usually.)

Failed controller Refer to the paragraph about

shifting from 2H to 4H.

In particular, check if not at the

Check4W D condition, return to

this chart and trace it from the

beginning.

In case of Check4W D, shifting to

2H is possible.

Returning to 4H is impossible.

Refer to the paragraph about

Check4W D.

4 Set to N position in case of AT and set to the neutral position in

case of MT and check if the lamp

blinks at 4Hz after operation. Failed T/M position switch and

harness (failure of TM1 and TM2

harness and their related

switches shown in the figure).

Incorrect wiring.

Repair as required and trace this

chart from the beginning. Shift back to 4H and go to step 5.

5 Start the engine and use the

vehicle.

Does the speedometer run at this

time? Go to step 6.

Failure of speed sensor or

disconnection or short of harness

(for the meter).

After repairing, trace this chart

from the beginning.

6 Check the harness between the transfer controller and speed

sensor.

(Check the engine rotation

detection harness at the same

time.)

Is any trouble noticed? Failed harness between the

transfer controller and speed

sensor.

After repairing, trace this chart

from the beginning.

(Repair the engine rotation

detection unit, if required.) Go to step 7.

7 Run the vehicle for several

meters, stop it, meet the

permission requirements for

operation limits.

Did you wait for several seconds

after the requirements were met? Failed controller.

Replace the controller and trace

this chart from the beginning. You did not wait for enough time.

Optimum waiting time is 1 second

or maximum 3 minutes,

depending on the previous

conditions.

Refer to the paragraph about

operation without failure.

*Before determining a trouble (Non-trouble mode)

For shifting to neutral, 2H and 4L switches should be pressed at the same time for 10 seconds.

For shifting from neutral to other position, 2H, 4H or 4L switch should be pressed for 10 seconds.

W hen shifting from neutral to other position, the lamp blinking at 2Hz indicates active condition.

W hen the lamp keeps blinking at 2Hz, follow the step for the case when the lamp keeps blinking at 2Hz when

shifting between positions.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4950 of 6020

8A-12 ELECTRICAL-BODY AND CHASSIS

ABBREVIATIONS

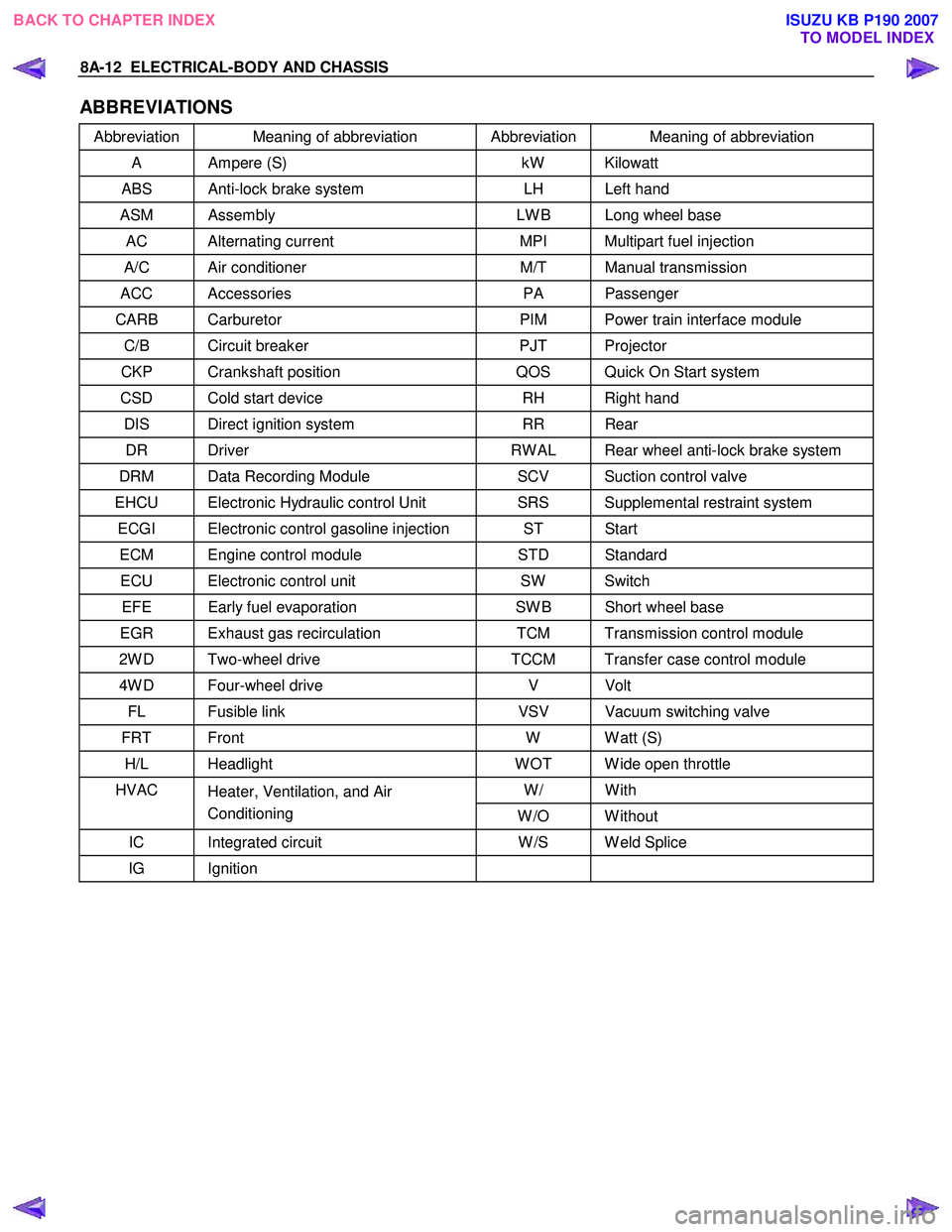

Abbreviation Meaning of abbreviation Abbreviation Meaning of abbreviation

A Ampere (S) kW Kilowatt

ABS Anti-lock brake system LH Left hand

ASM Assembly LW B Long wheel base

AC Alternating current MPI Multipart fuel injection

A/C Air conditioner M/T Manual transmission

ACC Accessories PA Passenger

CARB Carburetor PIM Power train interface module

C/B Circuit breaker PJT Projector

CKP Crankshaft position QOS Quick On Start system

CSD Cold start device RH Right hand

DIS Direct ignition system RR Rear

DR Driver RW AL Rear wheel anti-lock brake system

DRM Data Recording Module SCV Suction control valve

EHCU Electronic Hydraulic control Unit SRS Supplemental restraint system

ECGI Electronic control gasoline injection ST Start

ECM Engine control module STD Standard

ECU Electronic control unit SW Switch

EFE Early fuel evaporation SW B Short wheel base

EGR Exhaust gas recirculation TCM Transmission control module

2W D Two-wheel drive TCCM Transfer case control module

4W D Four-wheel drive V Volt

FL Fusible link VSV Vacuum switching valve

FRT Front W W att (S)

H/L Headlight W OT W ide open throttle

W/ With HVAC

Heater, Ventilation, and Air

Conditioning W /O W ithout

IC Integrated circuit W /S W eld Splice

IG Ignition

BACK TO CHAPTER INDEX

TO MODEL INDEXISUZU KB P190 2007

Page 4958 of 6020

8A-20 ELECTRICAL-BODY AND CHASSIS

Caution:

Never push or tow the vehicle in an attempt to start it.

Extensive damage to the emission system and other

vehicle parts will result.

(Only catalytic converter vehicle)

Treat both the discharged battery and the booster battery

with great care when using jumper cables.

Carefully follow the procedure outlined below.

Always be aware of the dangers of sparking.

Failure to follow the following procedure can result in:

a. Serious personal injury, specially to your eyes.

b. Extensive property damage from a battery explosion, battery acid discharge, or electrical file.

c. Extensive damage to the electronic components o

f

both vehicles.

Do not use a 24 volt booster battery.

Serious damage to the vehicle's electrical system and

electronic components will result.

Jump Starting Procedure

1. Set the parking brake on both vehicles.

2. If one or both vehicles is equipped with a manual transmission, place the gear shift in the "NEUTRAL"

position.

3. Turn off the ignition on both vehicles.

4. Turn off all vehicle lights and accessories.

5 Be sure that the two vehicles are not touching.

Attach the end of one jumper cable to the booster battery

positive terminal.

6

Attach the other end of the same cable to the discharged

battery positive terminal.

7. Once again, check that the booster battery has a 12 volt rating.

8.

Attach one end of the remaining booster cable to the

booster battery negative terminal.

9.

Attach the other end of the booster cable to a solid ground

(such as the air conditioner compressor mounting bracket

or the alternator mounting bracket) in the engine room o

f

the vehicle with the discharged battery.

10.Be sure that the ground connection is at least 500 mm (20 in) from the discharged battery.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5300 of 6020

8A-362 ELECTRICAL-BODY AND CHASSIS

Tachometer Off-Vehicle Inspection

Remove the tachometer from the meter assembly and

measure the resistance value and the current consumption

between each terminal.

SELF DIAGNOSTIC FUNCTION

Check that the speedometer, tachometer, fuel gauge, and

temperature gauge operate properly.

821R300033

Entering the self-diagnostic mode

1. Push in and hold the “Change Indicator and Reset” knob.

2. Turn the ignition ON.

3. W hen the LCD odometer turns ON, release the “Change Indicator and Reset” knob.

4. Push in and release the “Change Indicator and Reset” knob three times in quick succession.

The meter cluster is now in “Self-diagnostic” mode.

NOTE: Steps 2-4 must be performed within 7 seconds.

The meter cluster will not enter “Self-diagnostic” mode if any of

the following conditions occur:

1. The “Change Indicator and Reset” knob is not depressed when the ignition is turned ON.

2. The “Change Indicator and Reset” knob is released within 600ms of turning the ignition ON.

3. The “Change Indicator and Reset” knob is not depressed and released three times within 7 seconds.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5301 of 6020

ELECTRICAL-BODY AND CHASSIS 8A-363

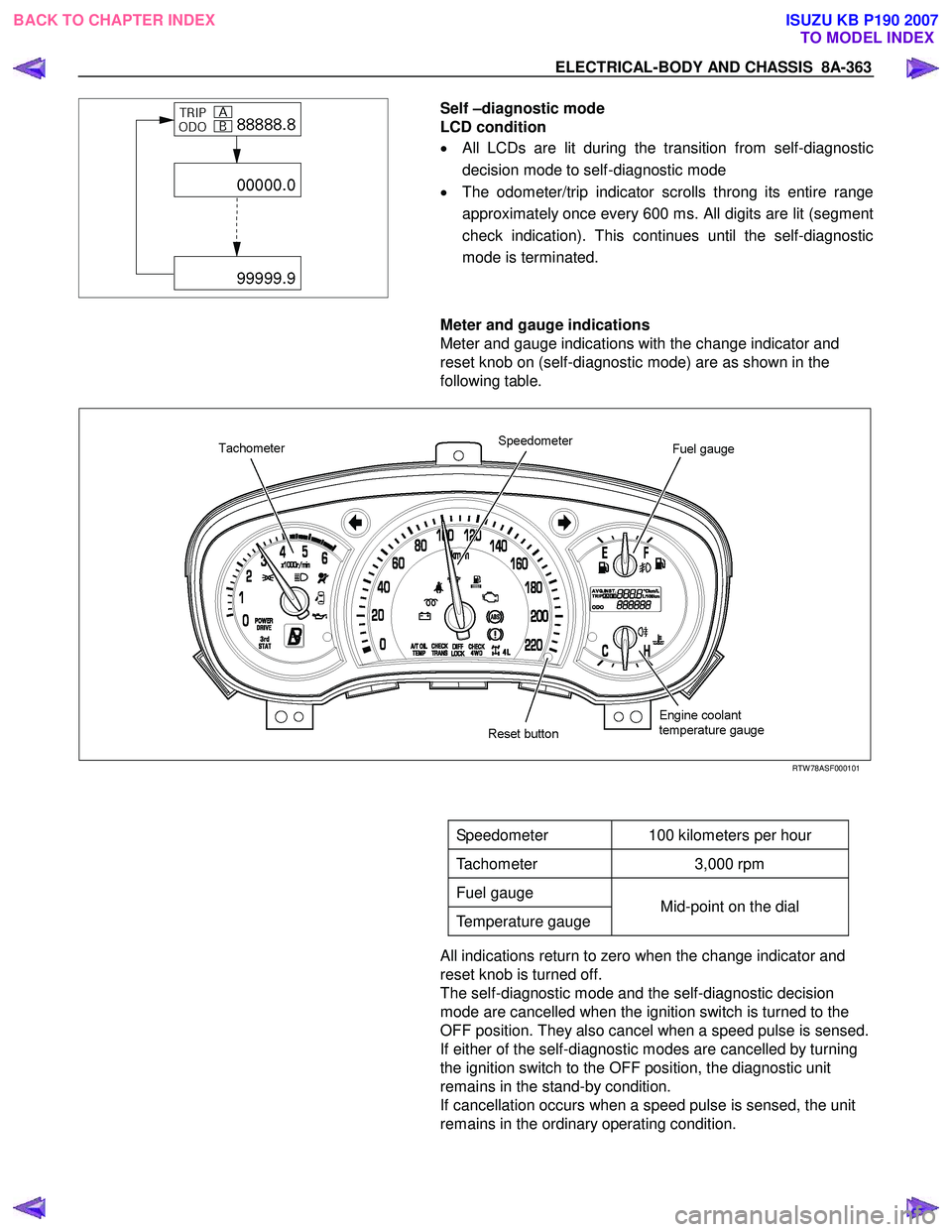

Self –diagnostic mode

LCD condition

• All LCDs are lit during the transition from self-diagnostic

decision mode to self-diagnostic mode

• The odometer/trip indicator scrolls throng its entire range

approximately once every 600 ms. All digits are lit (segment

check indication). This continues until the self-diagnostic

mode is terminated.

Meter and gauge indications

Meter and gauge indications with the change indicator and

reset knob on (self-diagnostic mode) are as shown in the

following table.

RTW 78ASF000101

Speedometer 100 kilometers per hour

Tachometer 3,000 rpm

Fuel gauge

Temperature gauge Mid-point on the dial

All indications return to zero when the change indicator and

reset knob is turned off.

The self-diagnostic mode and the self-diagnostic decision

mode are cancelled when the ignition switch is turned to the

OFF position. They also cancel when a speed pulse is sensed.

If either of the self-diagnostic modes are cancelled by turning

the ignition switch to the OFF position, the diagnostic unit

remains in the stand-by condition.

If cancellation occurs when a speed pulse is sensed, the unit

remains in the ordinary operating condition.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5303 of 6020

ELECTRICAL-BODY AND CHASSIS 8A-365

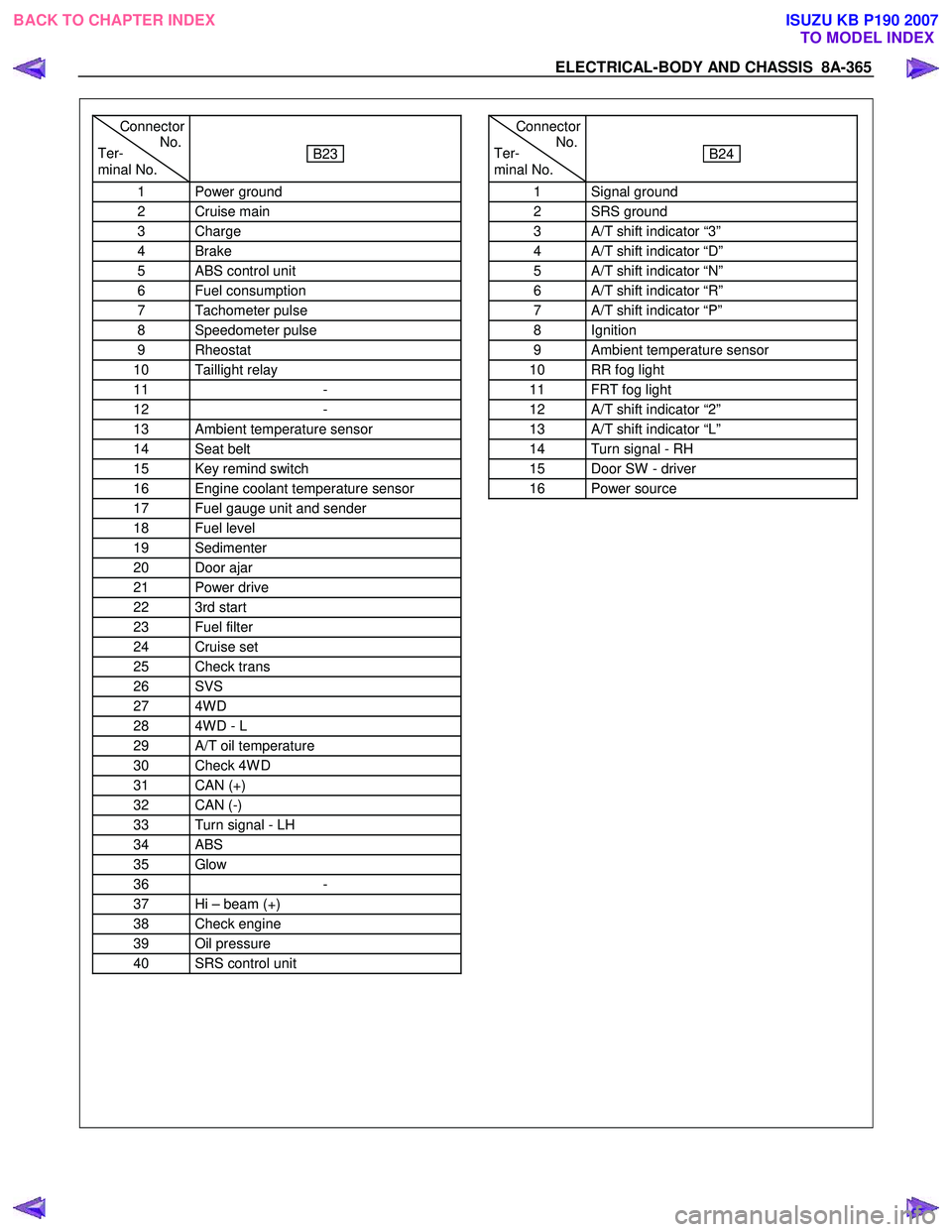

Connector

Ter- No.

minal No.

B23

1 Power ground

2 Cruise main

3 Charge

4 Brake

5 ABS control unit

6 Fuel consumption

7 Tachometer pulse

8 Speedometer pulse

9 Rheostat

10 Taillight relay

11 -

12 -

13 Ambient temperature sensor

14 Seat belt

15 Key remind switch

16 Engine coolant temperature sensor

17 Fuel gauge unit and sender

18 Fuel level

19 Sedimenter

20 Door ajar

21 Power drive

22 3rd start

23 Fuel filter

24 Cruise set

25 Check trans

26 SVS

27 4W D

28 4W D - L

29 A/T oil temperature

30 Check 4W D

31 CAN (+)

32 CAN (-)

33 Turn signal - LH

34 ABS

35 Glow

36 -

37 Hi – beam (+)

38 Check engine

39 Oil pressure

40 SRS control unit

Connector

Ter- No.

minal No.

B24

1 Signal ground

2 SRS ground

3 A/T shift indicator “3”

4 A/T shift indicator “D”

5 A/T shift indicator “N”

6 A/T shift indicator “R”

7 A/T shift indicator “P”

8 Ignition

9 Ambient temperature sensor

10 RR fog light

11 FRT fog light

12 A/T shift indicator “2”

13 A/T shift indicator “L”

14 Turn signal - RH

15 Door SW - driver

16 Power source

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5305 of 6020

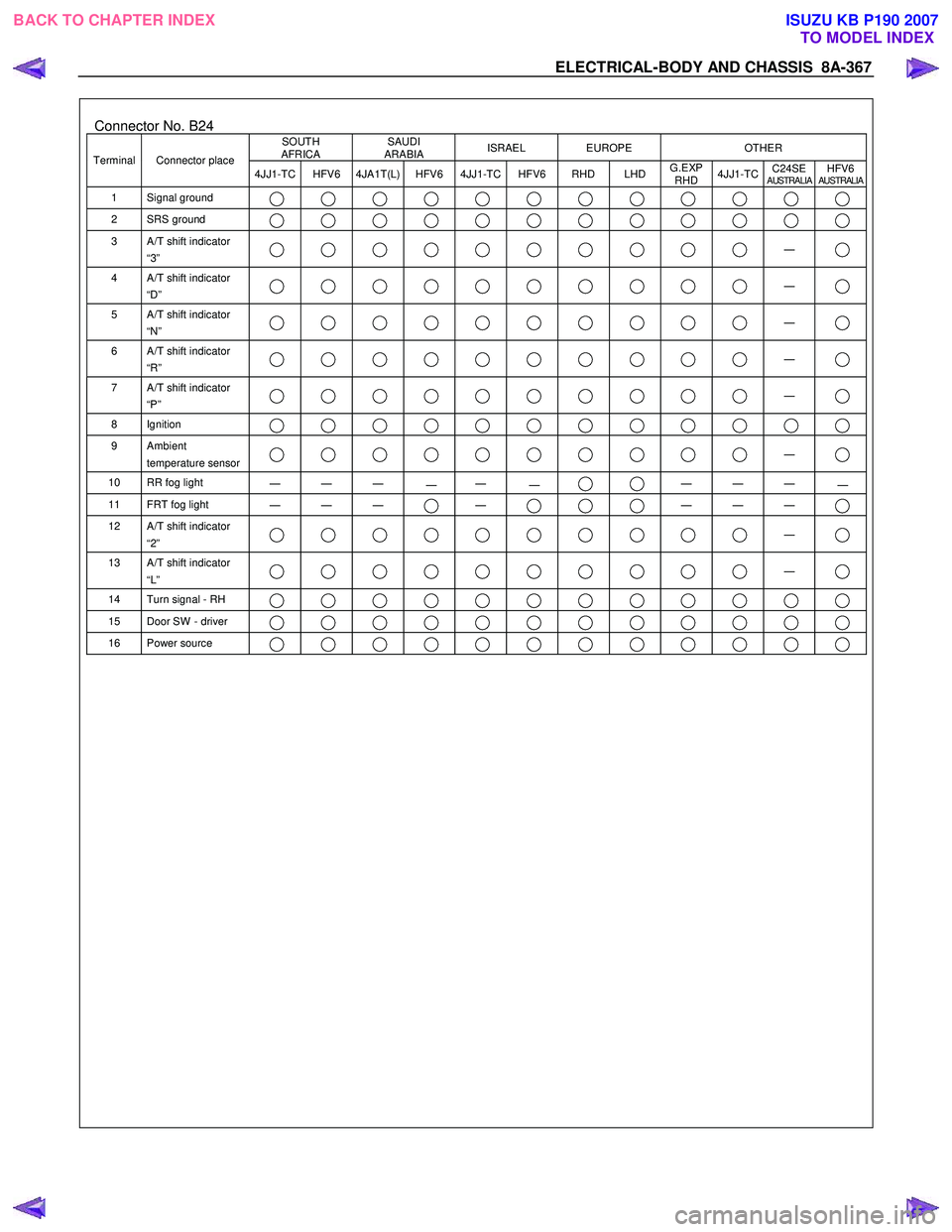

ELECTRICAL-BODY AND CHASSIS 8A-367

Connector No. B24 SOUTH

AFRICA SAUDI

ARABIA ISRAEL EUROPE OTHER

Terminal Connector place

4JJ1-TC HFV6 4JA1T(L) HFV6 4JJ1-TC HFV6 RHD LHD G.EXP

RHD 4JJ1-TC

C24SE

AUSTRALIAHFV6AUSTRALIA

1 Signal ground

2 SRS ground

3 A/T shift indicator

“3” ―

4 A/T shift indicator

“D” ―

5 A/T shift indicator

“N” ―

6 A/T shift indicator

“R” ―

7 A/T shift indicator

“P” ―

8 Ignition

9 Ambient

temperature sensor ―

10 RR fog light

― ― ― ― ― ―

―

― ― ―

11 FRT fog light

― ― ― ― ―

― ―

12 A/T shift indicator

“2” ―

13 A/T shift indicator

“L” ―

14 Turn signal - RH

15 Door SW - driver

16 Power source

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5427 of 6020

ELECTRICAL-BODY AND CHASSIS 8A-489

INSPECTION AND REPAIR

Switch side

B57

REAR DEFOGGER SWITCH

Rear Defogger Switch Connections

Terminal No.

SW position 9 7 8

ON

OFF

B7

RTW 78ASH002901

REAR DEFOGGER RELAY

Check continuity between the relay terminals.

2- 1........................ No continuity

(W hen battery voltage is applied between 4 and 3)

2- 1........................ Continuity

INSPECTION OF REAR DEFOGGER HEAT

WIRE

• Heat wires are printed on the inner side of glass.

To clean, use a soft cloth and wipe horizontally along the wires.

• Never use glass cleaner or equivalent.

• W hen measuring voltage, wind a piece of tin foil around the

tip of the negative probe and press the foil against the wire

with your finger as shown.

(1) Turn the ignition switch on.

(2) Turn the defogger switch on.

(3) Measure the voltage between the three points on the heat wire and the (-) terminal with a voltmeter.

(4) Check that the voltage becomes smaller from

A to B to C.

(5) If there is a place where the voltage suddenly changes to

0V, there is a broken wire between there and the powe

r

side.

(6) Move the tester probe from the position where the voltage changes to 0V toward the power side and find where the

voltage suddenly increases.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5476 of 6020

8A-538 ELECTRICAL-BODY AND CHASSIS

TROUBLESHOOTING

Diagnostic procedure

•

Check the operation "Lock / unlock" by using

transmitter (remote key) on the vehicle.

• Check the operation "ON / OFF" for Driver side

door SW on the vehicle.

• Perform the Keyless entry System Check.

Diagnostic Aids

An intermittent may be caused by the following:

• Poor connections.

• Miss routed harness.

• Rubbed through wire insulation.

• Broken wire inside the insulation.

Check for the following conditions:

• Poor connection at keyless entry control unit-

Inspect harness connectors for backed out

terminals, improper mating, broken locks,

improperly formed or damaged terminals, and poo

r

terminal to wire connection.

• Damaged harness-Inspect the wiring harness fo

r

damage.

Check the Electro-Magnetic Interference (EMI)

• Location of vehicle check

Move the vehicle to a new location and perform

the check again.

• Non-OEM Parts.

Switch is “OFF” or remove the Non-OEM parts and

perform the check again.

• Other

Remove the accessory and another key from key.

Check the other items.

• Battery voltage is low.

• Keyless entry programming functions.

• Registration for security code.

• Ignition switch operation.

• Meter system is malfunction.

Check the operation

Check the operation "Lock / unlock" by using

transmitter (remote key) on the vehicle.

Notice

If so equipped the Anti Theft, Refer to ANTI

THEFT SYSTEM in 11B Section.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5477 of 6020

ELECTRICAL-BODY AND CHASSIS 8A-539

Keyless Entry System Check

Step Action Value (s) Yes No

1 Check the fuse for the keyless entry power feed

circuit. (EB16 10A)

If a problem found, repair as necessary.

W as the problem found? — Verify repair Go to Step 2

2

1. Check the KCU (Keyless Entry Control Unit)

ground circuit for an open, or short to voltage.

Also, check the KCU ignition feed circuit for an

open or short to ground and the KCU ground

circuit for an open.

2. If a problem is found, repair as necessary.

W as the problem found? — Verify repair Go to Step 3

3

1. Check the front drive side SW circuit for an open,

or short to voltage.

2. If a problem is found, repair as necessary.

W as the problem found? — Verify repair Go to Step 4

4

1. Check the operation "Lock / unlock" by using

transmitter (Remote key) on the vehicle.

W as the problem found? — Go to

Diagnostic Chart Go to

Diagnostic Aids

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007