ISUZU KB P190 2007 Workshop Repair Manual

Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1 of 6020

1

WORKSHOP

REPAIR MANUAL

GE NERAL INFORMATION 0

HEATING AND VENTILATION

BRAKESMAIN INDEX ISUZU

CONTENTS

WHEELS AND TYRES

4

5

BODY 8

SECURITY 11 SUSPENSION

3

STEERING

2

AXLE

FRAME AND CAB

ENGINE

6

TRANSMISSION 7

MY 2007

RESTRAINTS 9

CAB 10

BACK TO FRONT PAGE

KB P190

ISUZU KB P190 2007

Page 2 of 6020

G EN ER AL INFOR MATION 0-1

SECTION 0

GENERAL I NFORMATI ON

TABLE OF CONTENTS

PA GE

Section 0A General Informantion ........................................................................................... 3

Section 0B Maintainance and Lubrication ............................................................................... 19

TO MODEL INDEX

BACK TO MAIN INDEX

ISUZU KB P190 2007

Page 3 of 6020

SECTION 0A

GENERAL I NFORMATI ON

TABLE OF CONTENTS

GE NERA L INFORM ATION 0A -1

General Repair Inst ructions ........................................................................................... 0A - 2

PA

GE

Not es on t he Format of th is Manual ............................................................................... 0A - 3

Ident ificat ion................................................................................................................. ... 0A - 6

Lif ting Inst ructions .......................................................................................................... 0A - 7

Conv ersion Table ............................................................................................................ 0A - 9

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4 of 6020

0A-2 GENERAL INFORMATION

GENERAL REPAIR INSTRUCTIONS

1. Park the vehicle on level ground and chock the front or rear wheels before lifting the vehicle.

2. Raise the vehicle with a jack set against the axle or the frame.

3. Support the vehicle on chassis stands.

4. Use covers on the vehicle body, seats, and floor to prevent damage and/or contamination.

5. Disconnect the grounding cable from the battery before performing service operations.

This will prevent cable damage or burning due to short circuiting.

6. Handle brake fluid and antifreeze solution with great care.

Spilling these liquids on painted surfaces will damage the paint.

7. The use of the proper tool(s) and special tool(s) where specified is essential to efficient, reliable, and safe

service operations.

8. Always use genuine ISUZU replacement parts.

9. Discard used cotter pins, gaskets, O-rings, oil seals, lock washers, and self-locking nuts at disassembly.

Normal function of these parts cannot be guaranteed if they are reused.

10. Prepare new cotter pins, gaskets, O-rings, oil seals, lock washers, and self-locking nuts for installation.

11. Keep the disassembled parts neatly in groups. This will facilitate smooth and correct reassembly.

12. Keep fixing nuts and bolts separate. Fixing nuts and bolts vary in hardness and design according to installation position.

13. Clean all parts before inspection or reassembly.

14. Clean the oil ports and other openings with compressed air to make certain that they are free from dirt and obstructions.

15. Lubricate the rotating and sliding faces of all moving parts with oil or grease before installation.

16. Use the recommended liquid gasket to prevent leakage.

17. Carefully observe all nut and bolt torque specifications.

18. W hen removing or replacing parts that require refrigerant to the discharged from the air conditioning system, be sure to use the Vehicle Refrigerant Recovery and Recycling Equipment (VRRRE) to recover and recycle R134a,

to promote the aim of the protection of the ozone layer covering the earth.

19. Check and recheck your work. No service operation is complete until you have done this.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 5 of 6020

GENERAL INFORMATION 0A-3

NOTES ON THE FORMAT OF THIS MANUAL

1. Find the applicable section by referring to the index at the front of the W orkshop Manual binder.

2. The following technical service information is included in this Section: • Identification

• Maintenance schedules

• Recommended Iubricants

• Recommended fuels

• Oil viscosity charts

3. Individual sections of this W orkshop Manual are divided into the following categories: • Main data and specifications

• Torque specifications

• Recommended liquid gasket

• Loctite application procedure

• Servicing

• Removal and installation

• Disassembly

• Inspection and repair

• Reassembly

• Troubleshooting

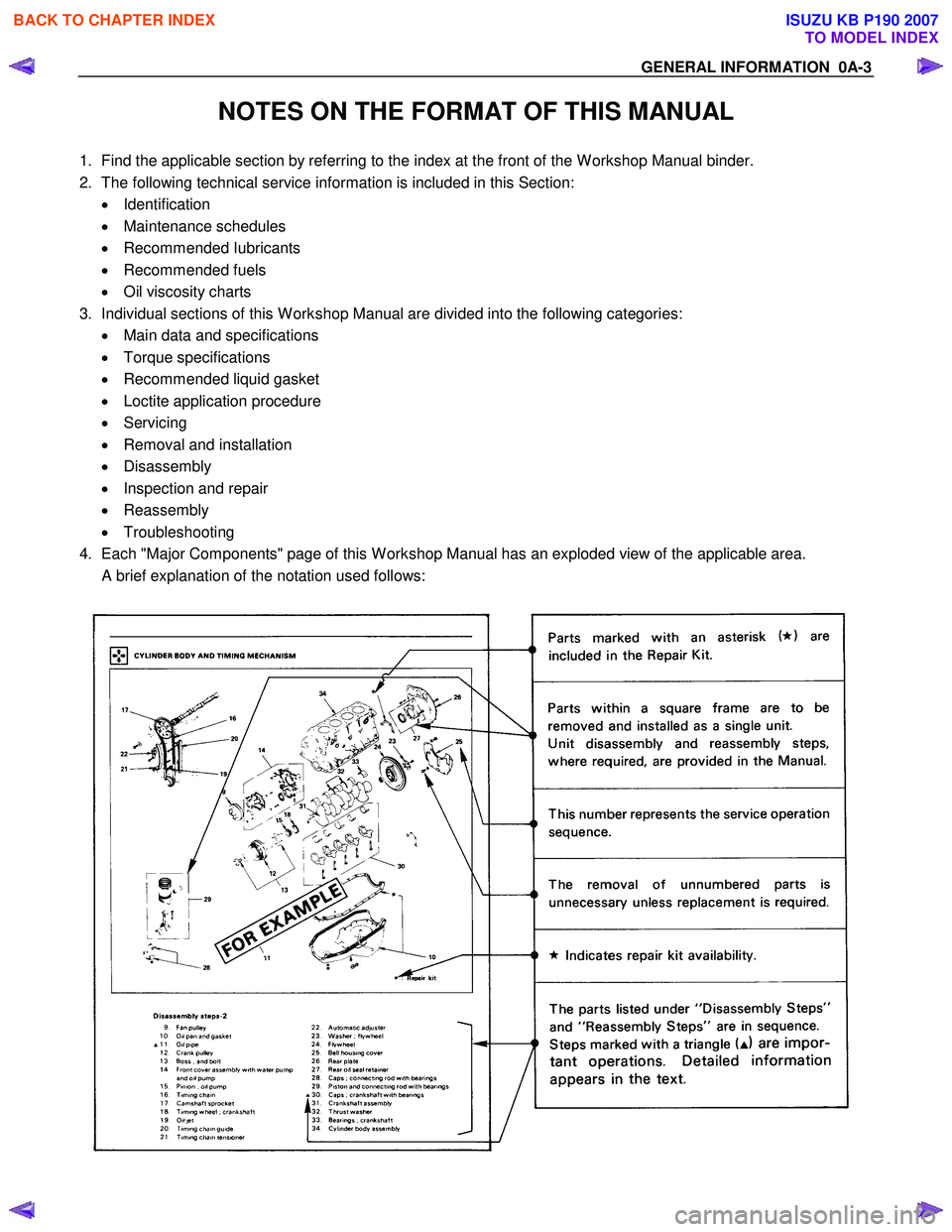

4. Each "Major Components" page of this W orkshop Manual has an exploded view of the applicable area.

A brief explanation of the notation used follows:

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 6 of 6020

0A-4 GENERAL INFORMATION

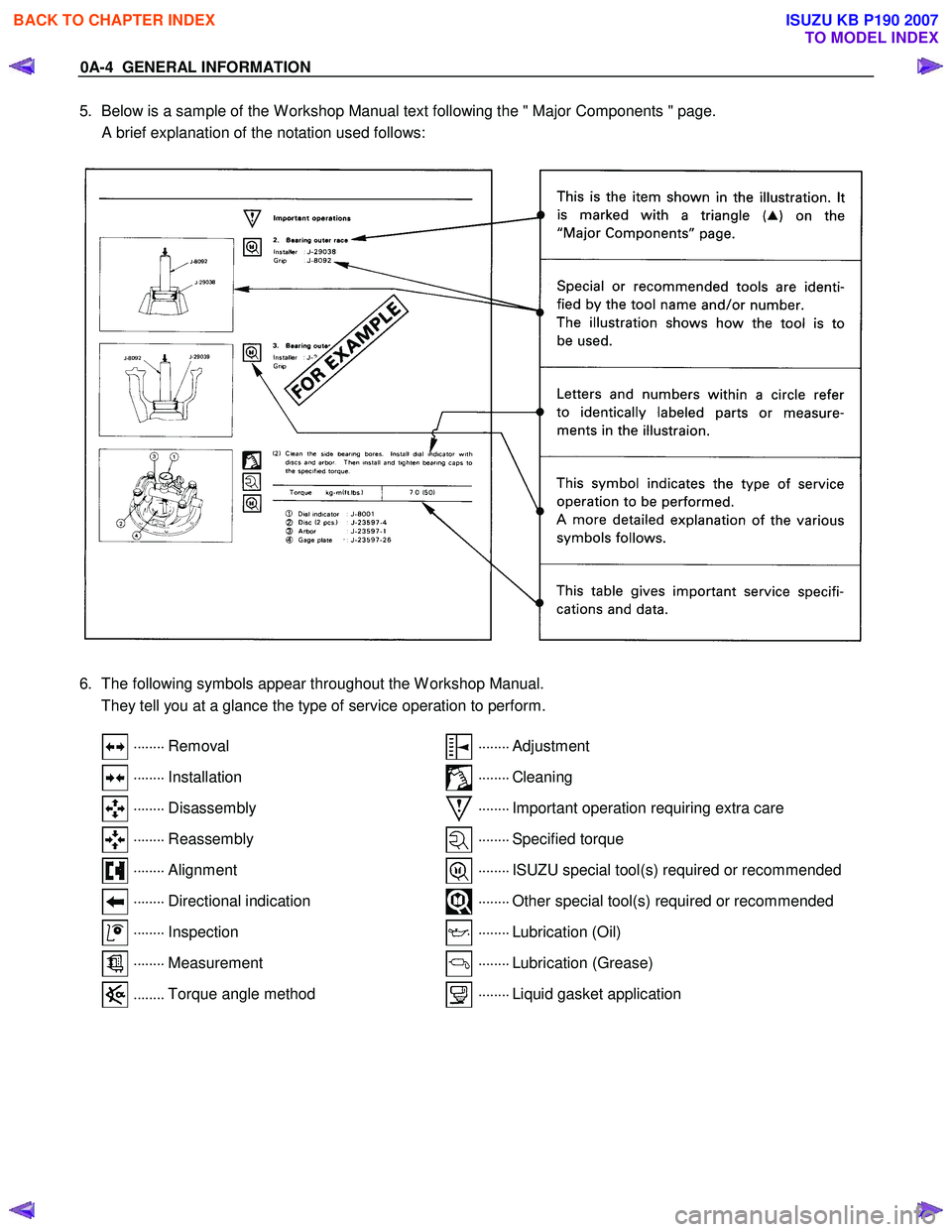

5. Below is a sample of the W orkshop Manual text following the " Major Components " page.

A brief explanation of the notation used follows:

6. The following symbols appear throughout the W orkshop Manual.

They tell you at a glance the type of service operation to perform.

........

Removal ........

Adjustment

........

Installation ........

Cleaning

........

Disassembly ........

Important operation requiring extra care

........

Reassembly ........

Specified torque

........

Alignment ........

ISUZU special tool(s) required or recommended

........

Directional indication ........

Other special tool(s) required or recommended

........

Inspection ........

Lubrication (Oil)

........

Measurement ........

Lubrication (Grease)

........

Torque angle method ........

Liquid gasket application

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 7 of 6020

GENERAL INFORMATION 0A-5

7. Measurement criteria are defined by the terms "standard" and "limit".

A measurement falling within the "standard" range indicates that the applicable part or parts are serviceable.

"Limit" is an absolute value.

A measurement falling outside the "limit" indicates that the applicable part or parts must be repaired or replaced.

8. Components and parts are listed in the singular form throughout the W orkshop Manual.

9. The following directional criteria are used throughout the W orkshop Manual:

Front:

The cooling fan side of the engine.

Right:

The right-hand side of the engine viewed from the flywheel.

Left:

The left-hand side of the engine viewed from the flywheel.

Rear:

The flywheel side of the engine.

Cylinder numbers are counted from the front of the engine towards the rear.

The engine's rotation is clockwise viewed from the front of the engine.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 8 of 6020

0A-6 GENERAL INFORMATION

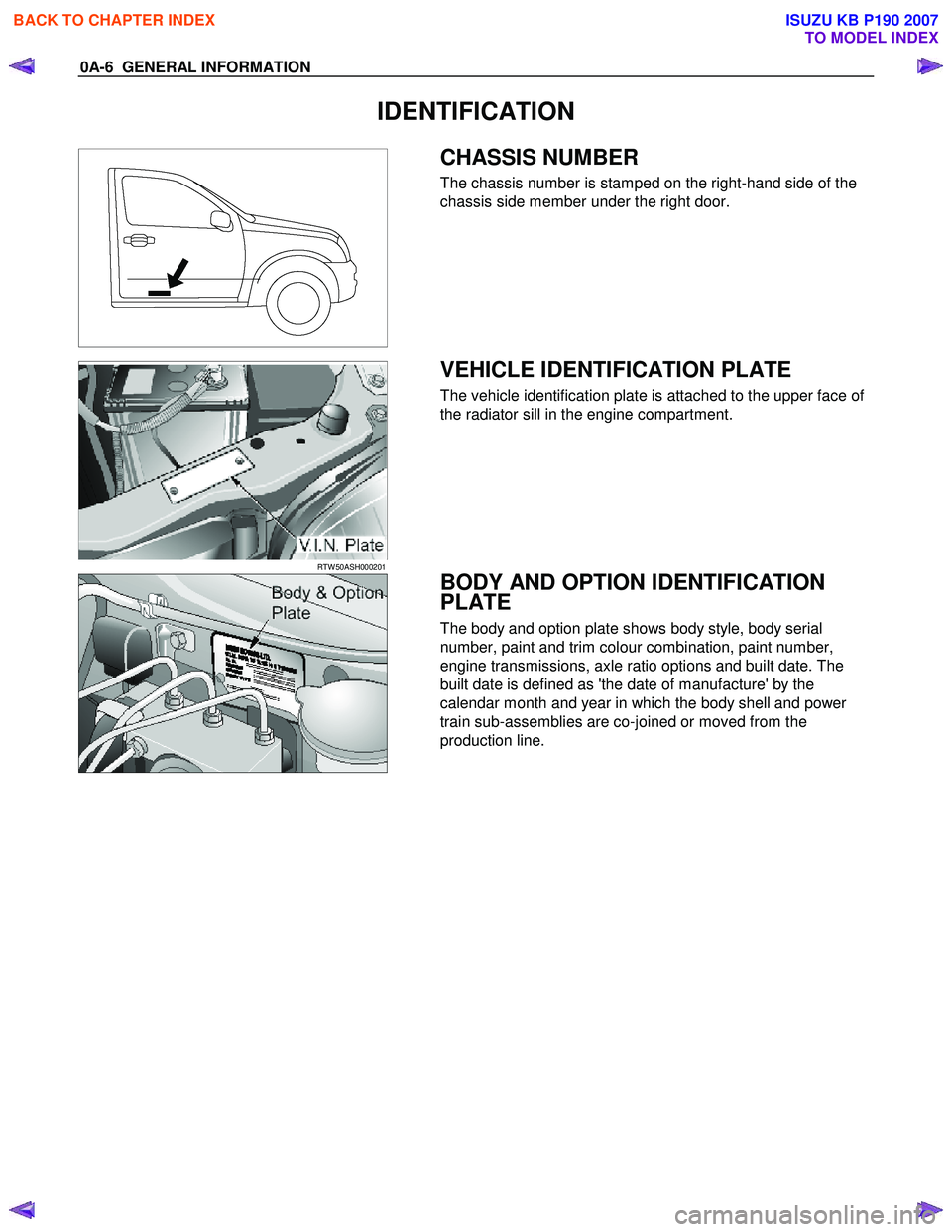

IDENTIFICATION

CHASSIS NUMBER

The chassis number is stamped on the right-hand side of the

chassis side member under the right door.

RTW 50ASH000201

VEHICLE IDENTIFICATION PLATE

The vehicle identification plate is attached to the upper face of

the radiator sill in the engine compartment.

BODY AND OPTION IDENTIFICATION

PLATE

The body and option plate shows body style, body serial

number, paint and trim colour combination, paint number,

engine transmissions, axle ratio options and built date. The

built date is defined as 'the date of manufacture' by the

calendar month and year in which the body shell and power

train sub-assemblies are co-joined or moved from the

production line.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 9 of 6020

GENERAL INFORMATION 0A-7

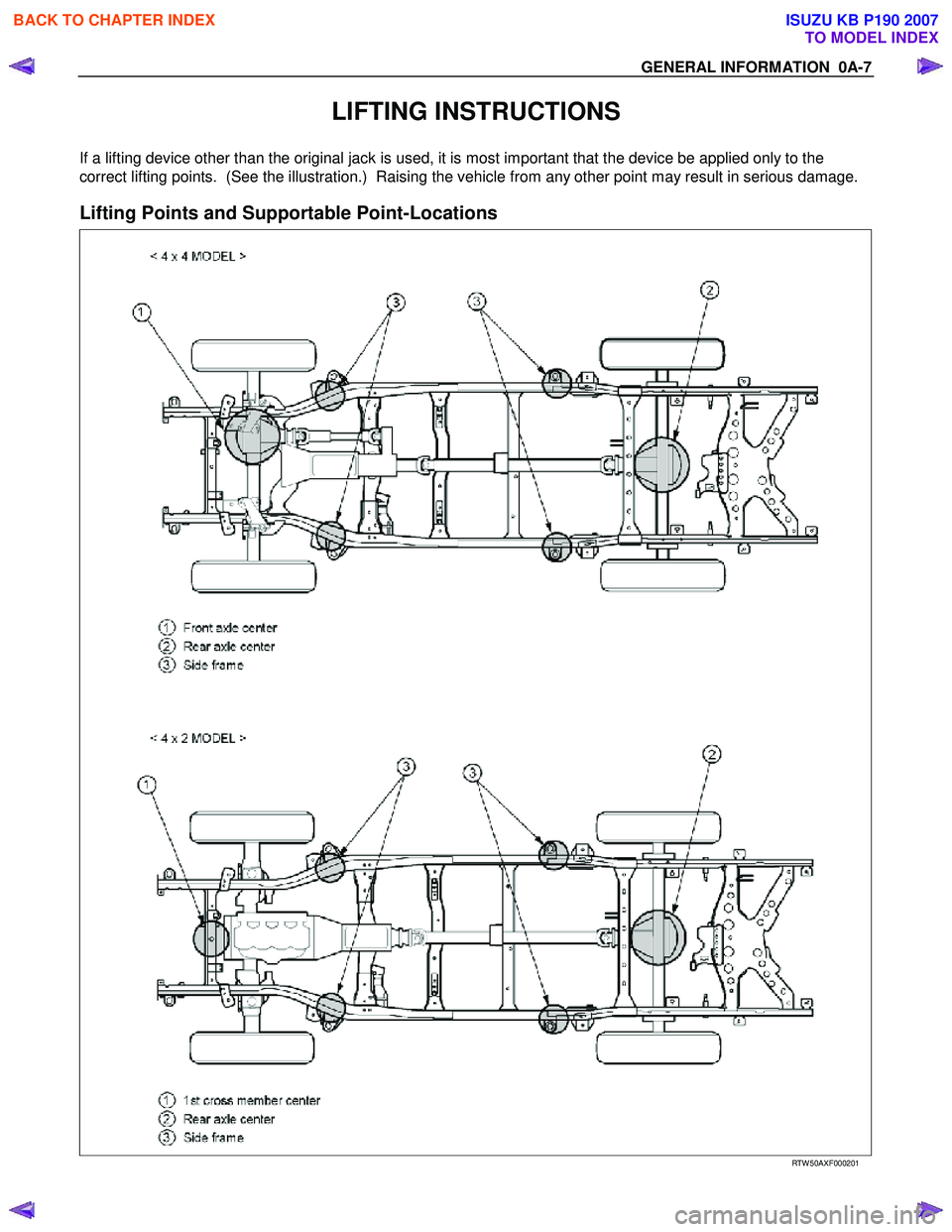

LIFTING INSTRUCTIONS

If a lifting device other than the original jack is used, it is most important that the device be applied only to the

correct lifting points. (See the illustration.) Raising the vehicle from any other point may result in serious damage.

Lifting Points and Supportable Point-Locations

RTW 50AXF000201

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 10 of 6020

0A-8 GENERAL INFORMATION

RUW 50ASH000101

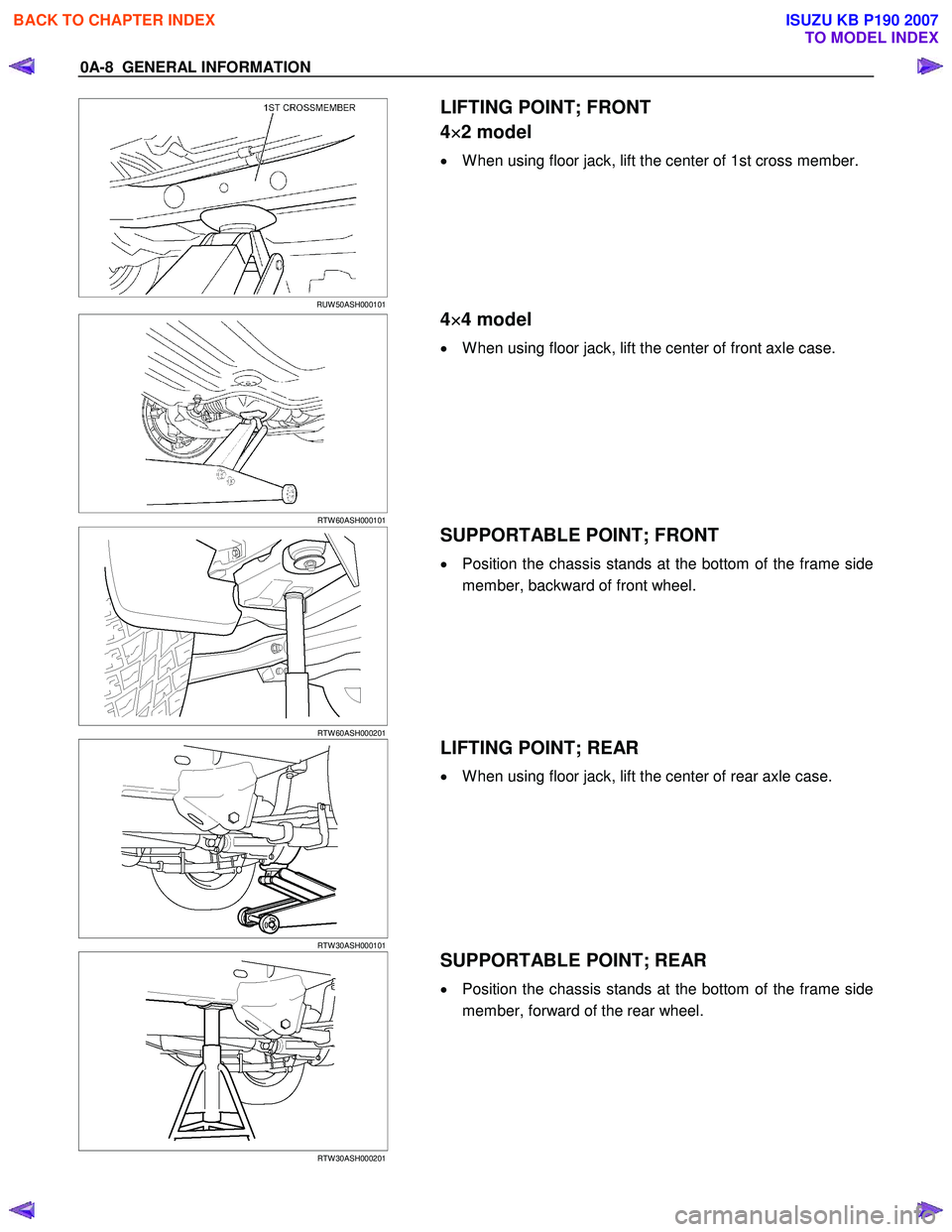

LIFTING POINT; FRONT

4 ×

××

×

2 model

• W hen using floor jack, lift the center of 1st cross member.

RTW 60ASH000101

4 ×

××

×

4 model

• W hen using floor jack, lift the center of front axle case.

RTW 60ASH000201

SUPPORTABLE POINT; FRONT

• Position the chassis stands at the bottom of the frame side

member, backward of front wheel.

RTW 30ASH000101

LIFTING POINT; REAR

• W hen using floor jack, lift the center of rear axle case.

RTW 30ASH000201

SUPPORTABLE POINT; REAR

• Position the chassis stands at the bottom of the frame side

member, forward of the rear wheel.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007