overheating ISUZU KB P190 2007 Workshop Owner's Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3576 of 6020

Engine Management – V6 – Service Operations Page 6C1-3–52

Oil Fouled (3)

W et, oily deposits with minor electrode wear possibly due to oil leaking past worn piston rings.

Breaking in a new or recently overhauled engine before the rings are fully seated may also result in this condition.

Deposit Fouling A (4)

Red brown, yellow and white coloured coatings on the insulator tip which are by-products of combustion. They come

from fuel and lubricating oil which generally contain additives. Most powdery deposits have no adverse effect on spark

plug operation, however, they may cause intermittent missing under severe operating conditions.

Deposit Fouling B (5)

Deposits similar to those identified in deposit fouling A (4). These are also by-products of combustion from fuel and

lubricating oil. Excessive valve stem clearances and / or defective intake valve seals allow too much oil to enter the

combustion chamber. The deposits will accumulate on the portion of the spark plug that projects into the chamber and

will be heaviest on the side facing the intake valve. If this condition is only detected in one or two cylinders, check the

valve stem seals.

Deposit Fouling C (6)

Most powdery deposits identified in deposit fouling A (4) have no adverse effect on the operation of the spark plug as

long as they remain powdery.

Under certain conditions of operation however, these deposits melt and form a shiny glaze coating on the insulator.

W hen hot, this acts as a good electrical conductor allowing the current to flow along the deposit instead of sparking

across the gap.

Detonation (7)

Commonly referred to as engine knock or pinging, detonation causes severe shocks inside the combustion chamber

causing damage to parts.

Pre-ignition (8)

Burnt or blistered insulator tip and badly eroded electrodes probably due to the excessive heat.

This is often caused by a cooling system blockage, sticking valves, improperly installed spark plugs or plugs that are the

wrong heat rating (too hot).

Sustained high speed with a heavy load can produce temperatures high enough to cause pre-ignition.

Heat Shock Failure (9)

A rapid increase in spark plug tip temperature under severe operating conditions can cause heat shock and result in

fractured insulators. This is a common cause of broken and cracked insulator tips.

Insufficient Installation Torque (10)

Poor contact between the spark plug and the cylinder head seat.

The lack of proper heat transfer that results from poor seat contact causes overheating of the spark plug. In many cases,

severe damage occurs. Dirty threads in the cylinder head can cause the plug to seize before it is seated.

Ensure the cylinder head and spark plug threads are free of deposits, burrs and scale before installation.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3752 of 6020

Exhaust System – V6 Page 6F – 4

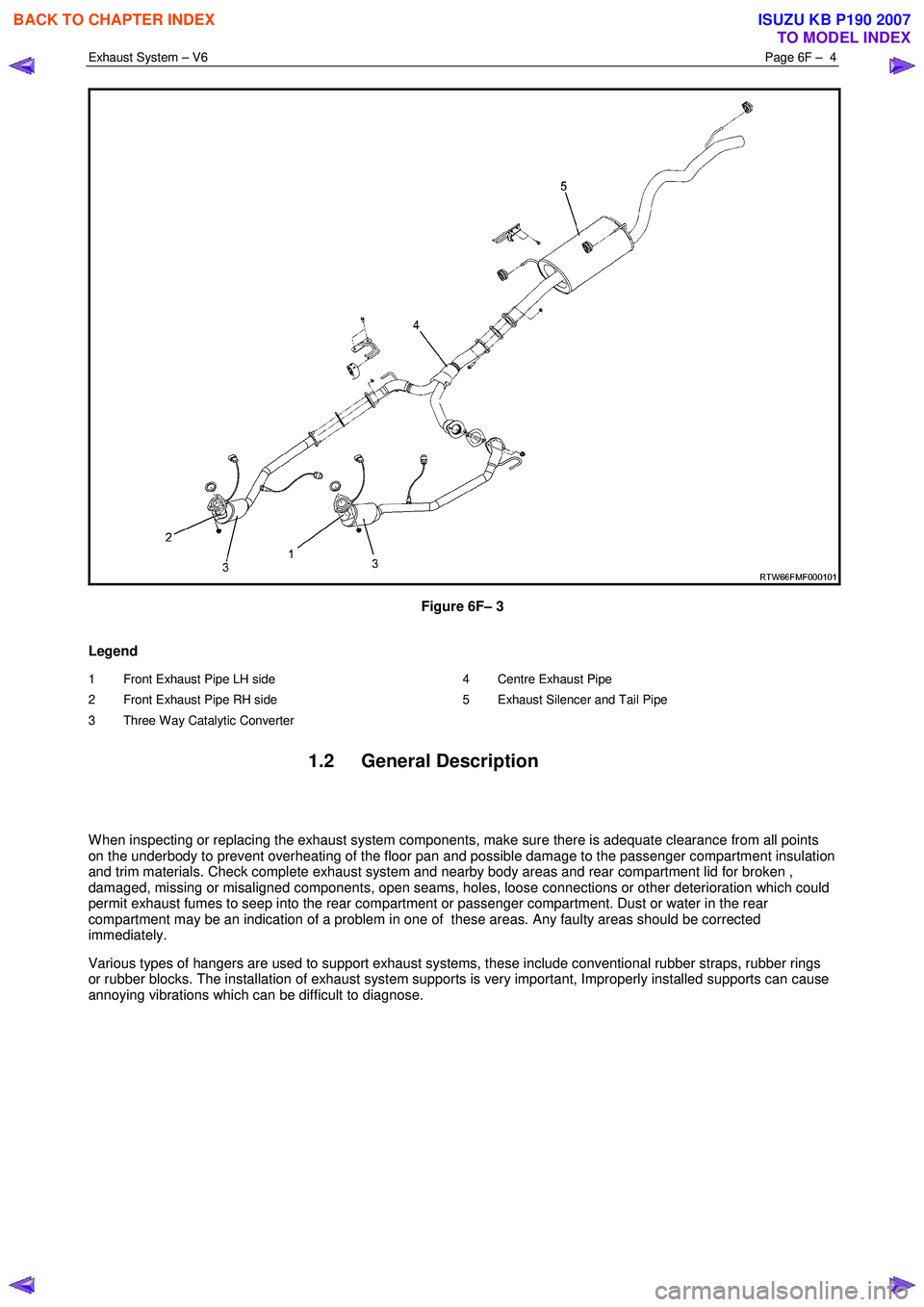

Figure 6F– 3

Legend

1 Front Exhaust Pipe LH side

2 Front Exhaust Pipe RH side

3 Three Way Catalytic Converter 4 Centre Exhaust Pipe

5 Exhaust Silencer and Tail Pipe

1.2 General Description

W hen inspecting or replacing the exhaust system components, make sure there is adequate clearance from all points

on the underbody to prevent overheating of the floor pan and possible damage to the passenger compartment insulation

and trim materials. Check complete exhaust system and nearby body areas and rear compartment lid for broken ,

damaged, missing or misaligned components, open seams, holes, loose connections or other deterioration which could

permit exhaust fumes to seep into the rear compartment or passenger compartment. Dust or water in the rear

compartment may be an indication of a problem in one of these areas. Any faulty areas should be corrected

immediately.

Various types of hangers are used to support exhaust systems, these include conventional rubber straps, rubber rings

or rubber blocks. The installation of exhaust system supports is very important, Improperly installed supports can cause

annoying vibrations which can be difficult to diagnose.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3820 of 6020

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–34

• The TCM records the operating conditions when the conditions for setting the DTC are met. The TCM stores this

information as Failure Records.

• The TCM stores DTC P0218 in TCM history.

Conditions for Clearing the DTC

• Tech 2 can clear the DTC.

• The TCM clears the DTC from TCM history if the vehicle completes 40 warm-up cycles without a non-emission

related diagnostic fault occurring.

• The TCM cancels the DTC default actions when the fault no longer exists and the DTC passes.

Diagnostic Aids

• Tech 2’s Transmission Fluid Temp. should rise steadily to a normal operating temperature, then stabilise.

• Ask about the customer's driving habits, trailer towing, etc. Trailer towing should occur in D3.

• Refer to Symptoms - Automatic Transmission in 7C3 Automatic Transmission – 4L60E – Hydraulic and Mechanical

Diagnosis.

Test Description

The following numbers refer to the step numbers in the diagnostic table:

2 Low transmission fluid can cause the transmission to overheat.

3 This step inspects for airflow restrictions or damage, which may result in the transmission overheating.

4-5 Decreased line pressure will cause the transmission to overheat. The torque converter stator is the pump for the transmission fluid. If the torque converter is damaged, it may not be producing the required pressure.

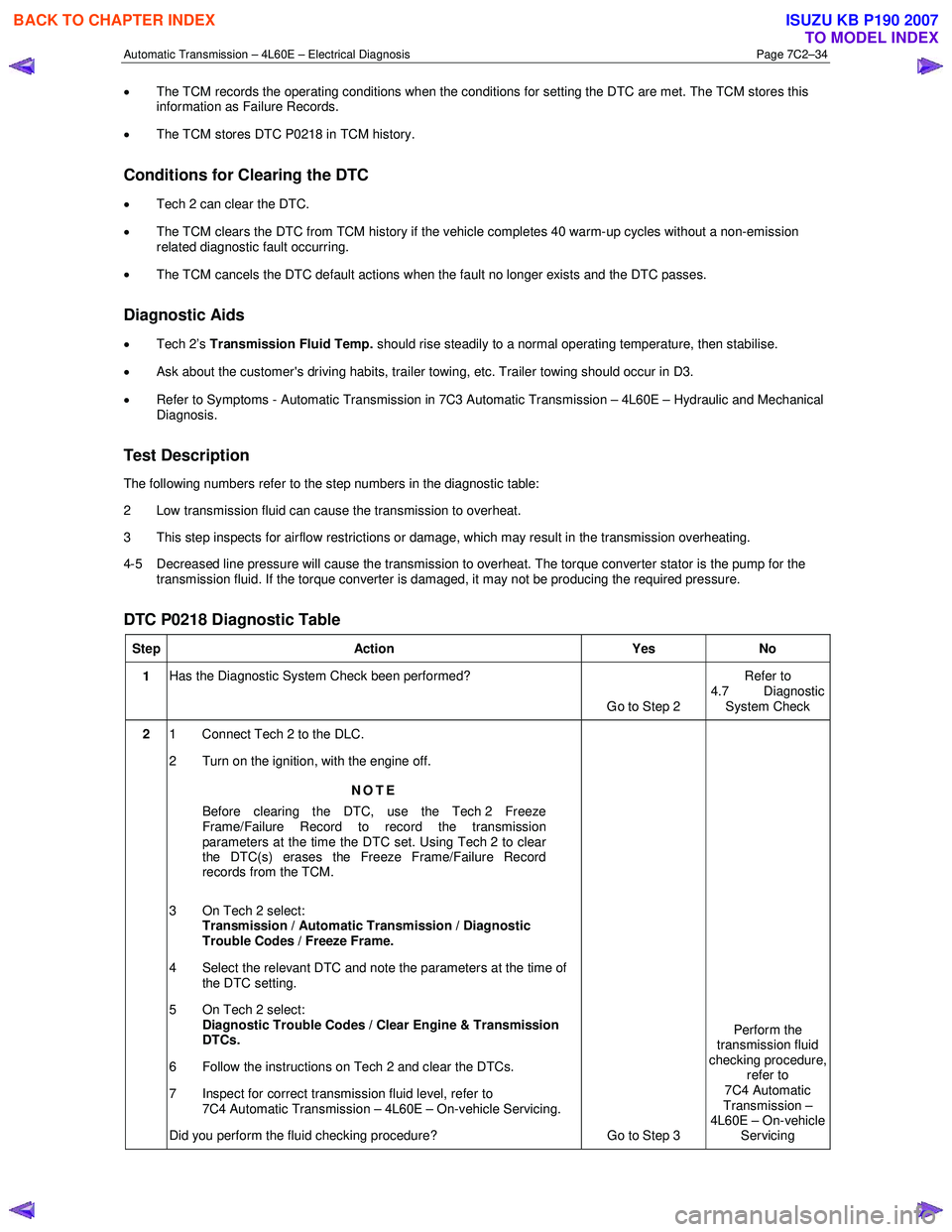

DTC P0218 Diagnostic Table

Step Action Yes No

1 Has the Diagnostic System Check been performed?

Go to Step 2 Refer to

4.7 Diagnostic System Check

2 1 Connect Tech 2 to the DLC.

2 Turn on the ignition, with the engine off.

NOTE

Before clearing the DTC, use the Tech 2 Freeze

Frame/Failure Record to record the transmission

parameters at the time the DTC set. Using Tech 2 to clear

the DTC(s) erases the Freeze Frame/Failure Record

records from the TCM.

3 On Tech 2 select: Transmission / Automatic Transmission / Diagnostic

Trouble Codes / Freeze Frame.

4 Select the relevant DTC and note the parameters at the time of the DTC setting.

5 On Tech 2 select:

Diagnostic Trouble Codes / Clear Engine & Transmission

DTCs.

6 Follow the instructions on Tech 2 and clear the DTCs.

7 Inspect for correct transmission fluid level, refer to 7C4 Automatic Transmission – 4L60E – On-vehicle Servicing.

Did you perform the fluid checking procedure? Go to Step 3 Perform the

transmission fluid

checking procedure, refer to

7C4 Automatic

Transmission –

4L60E – On-vehicle Servicing

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4310 of 6020

7A2-26 TRANSMISSION CONTROL SYSTEM (JR405E)

Low & Reverse Brake Pressure Switch

This parameter displays the input state of the low &

reverse brake transmission fluid pressure (TFP) switch

to the TCM. When the low & reverse brake fluid

pressure is generated, the scan tool displays On.

2-4 Brake Solenoid Command

This parameter displays the 2-4 brake solenoid valve

control duty ratio based on the command from the

TCM. The scan tool will display a lower percentage

when the 2-4 brake is controlled to engage (fluid

pressure is applied to the 2-4 brake hydraulic circuits).

The scan tool will display higher percentage when the

2-4 brake is controlled to disengage (fluid pressure is

drained from the 2-4 brake hydraulic circuits).

2-4 Brake Pressure Switch

This parameter displays the input state of the 2-4 brake

transmission fluid pressure (TFP) switch to the TCM.

When the 2-4 brake fluid pressure is generated, the

scan tool displays On.

High Clutch Solenoid Command

This parameter displays the high clutch solenoid valve

control duty ratio based on the command from the

TCM. The scan tool will display a lower percentage

when the high clutch is controlled to engage (fluid

pressure is applied to the high clutch hydraulic circuits).

The scan tool will display higher percentage when the

high clutch is controlled to disengage (fluid pressure is

drained from the high clutch hydraulic circuits).

High Clutch Pressure Switch

This parameter displays the input state of the high

clutch transmission fluid pressure (TFP) switch to the

TCM. When the high clutch fluid pressure is generated,

the scan tool displays On.

Low Clutch Solenoid Command

This parameter displays the low clutch solenoid valve

control duty ratio based on the command from the

TCM. The scan tool will display a lower percentage

when the low clutch is controlled to engage (fluid

pressure is applied to the low clutch hydraulic circuits).

The scan tool will display higher percentage when the

low clutch is controlled to disengage (fluid pressure is

drained from the low clutch hydraulic circuits).

TCC Solenoid (Torque Converter Clutch)

This parameter displays the torque converter clutch

(TCC) control duty ratio based on the command from

the TCM. The scan tool will display a lower percentage

when the TCC is controlled to disengage (fluid

pressure is drained from the TCC release hydraulic

circuits). The scan tool will display higher percentage

when the TCC is controlled to engage (fluid pressure is

applied to the TCC apply hydraulic circuits). Transmission Fluid Temperature

This parameter displays the temperature of the

automatic transmission fluid (ATF) temperature as

calculated by the TCM using the signal from the

transmission fluid temperature (TFT) sensor. The scan

tool will display a low temperature when the signal

voltage is high, and a high temperature when the signal

voltage is low.

Transmission Oil Temperature Lamp

This parameter displays the commanded state of the

transmission oil temperature lamp control circuit. The

lamp should be On when the scan tool indicates

command On.

TCM Status Temp. (Temperature Transmission

Control Module)

This parameter displays the commanded state of the

high temperature mode shift map. On indicates the

transmission fluid temperature is high and the high

temperature mode is selected to prevent an

overheating.

4 Wheel Drive Low

This parameter displays the input state of the 4WD low

gear signal from the transfer case control module

(TCCM). When the 4L mode is selected, the scan tool

displays On.

TCM Status Transfer (Transmission Control

Module)

This parameter displays the commanded state of the

shift map that is based on the transfer case position.

High indicates the high mode (2H or 4H) is inputted

from the transfer case control module (TCCM). Low

indicates the low mode (4L) is inputted from the TCCM.

TCM Status Down Slope (Transmission Control

Module)

This parameter displays the commanded state of the

down slope mode shift map. On indicates the down

slope mode is selected under certain driving conditions.

TCM Status Up Slope (Transmission Control

Module)

This parameter displays the commanded state of the

up slope mode shift map. On indicates the up slope

mode is selected under certin driving conditions.

3rd Start Switch

This parameter displays the input state of the 3rd start

switch to the TCM. When the switch is pressed, the

scan tool displays On.

3rd Start Lamp

This parameter displays the commanded state of the

3rd start lamp control circuit. The lamp should be On

when the scan tool indicates command On.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007