switch ISUZU TF SERIES 2004 Workshop Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2004, Model line: TF SERIES, Model: ISUZU TF SERIES 2004Pages: 4264, PDF Size: 72.63 MB

Page 1425 of 4264

4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS 6E–53

ECM CONNECTOR PIN ASSIGNMENT & OUTPUT SIGNAL

4JA1-TC ECM CONNECTOR PIN ASSIGNMENT & OUTPUT SIGNA L

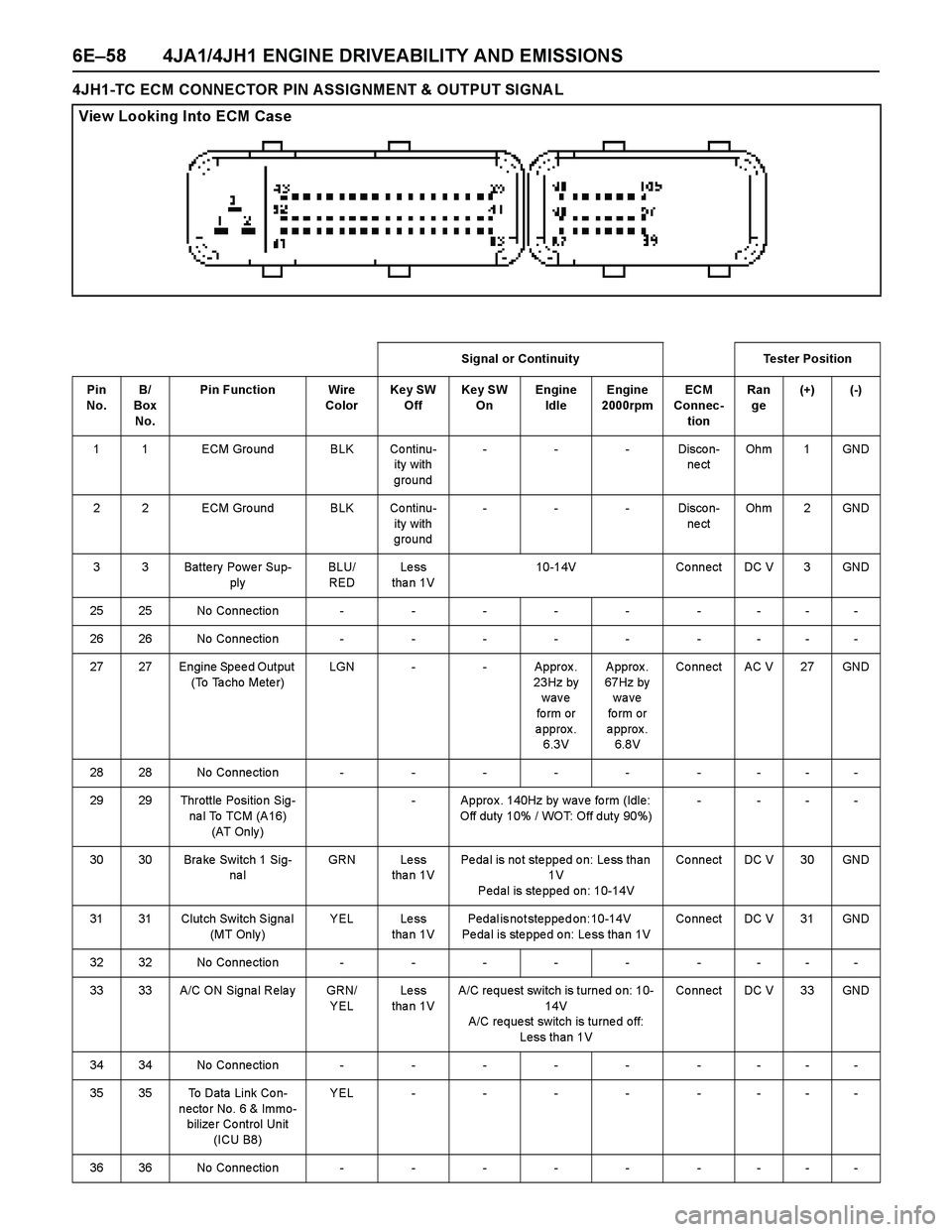

View Looking Into ECM Case

Signal or Continuity Tester Position

Pin

No. B/Box

No.Pin Function Wire

ColorKey SW

OffKey SW

OnEngine

IdleEngine

2000rpmECM

Connec-

tionRange (+) (-)

1 1 ECM Gro und BLK Continuity

with

gro und---Discon-

ne ctOhm 1 GND

2 2 ECM Gro und BLK Continuity

with

gro und---Discon-

ne ctOhm 2 GND

3 3 Batte ry Powe r Supply BLU/

REDLess than

1V10-14V Connect DC V 3 GND

25 25 No Conne ctio n - - - - - - - - -

26 26 No Conne ctio n - - - - - - - - -

27 27 Engine Spee d Output

(To Ta cho Me te r)LGN - - Approx.

23Hz by

w a v e fo rm

or approx.

6.3V Approx.

67Hz by

wave form

or approx.

6.8V Co nnect AC V 27 GND

28 28 No Conne ctio n - - - - - - - - -

29 29 No Conne ctio n - - - - - - - - -

30 30 Brake Switch 1 Signal GRN Less than

1VPedal is not stepped on: Less than 1V

Pedal is stepped on: 10-14VCo nnect DC V 30 GND

31 31 Clutch Switch Signal

(MT Only )YEL Less than

1VPedal is not stepped on: 10-14V

Pedal is stepped on: Less than 1VCo nnect DC V 31 GND

32 32 No Conne ctio n - - - - - - - - -

33 33 A/C ON Signa l Re la y GRN/

YELLess than

1VA/C re que st switch is turne d on: 10-

14V

A/C request switch is turned off: Less

than 1VCo nnect DC V 33 GND

34 34 No Conne ctio n - - - - - - - - -

35 35 To Da ta Link Co nnec-

tor No. 6 & Immobi-

lize r Contro l Unit (ICU

B8)YEL--------

36 36 No Conne ctio n - - - - - - - - -

37 37 No Conne ctio n - - - - - - - - -

38 38 Throttle Po sitio n Sen-

so r (TPS) Output Sig-

na lGRN/

ORGLess than

1VLess than 1V Approx.

0.5VCo nnect DC V 38 49

39 39 Key Sw itch Input Sig-

nal Via Engine FuseWHT Less than

1V10-14V Co nnect DC V 39 GND

40 40 No Conne ctio n - - - - - - - - -

Page 1426 of 4264

6E–54 4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS

41 41 A/C Compresso r

Re la yWH T/

GRNLess than

1V10-14V A/C comp. is operated:

L e s s t h a n 1 V

A/C comp. is not oper-

ated: 10 - 14VCo nnect DC V 41 GND

42 42 Che ck Engine La mp GRN/

YELLess than

1VLamp is turned on: Less than 1V

Lamp is turned off: 10-14VCo nnect DC V 42 GND

43 43 Glow La mp ORG/

BLULess than

1VLamp is turned on: Less than 1V

Lamp is turned off: 10-14VCo nnect DC V 43 GND

44 44 No Conne ctio n - - - - - - - - -

45 45 To Da ta Link Co nnec-

to r No . 6BLU Less than

1V10-14V Co nnect DC V 45 GND

46 46 No Conne ctio n - - - - - - - - -

47 47 No Conne ctio n - - - - - - - - -

48 48 No Conne ctio n - - - - - - - - -

49 49 Throttle Po sitio n Sen-

so r (TPS) Gro undBLK/

GRNIdle :

Approx.

0.4K ohm /

WOT:

Approx.

4.0K ohm---Discon-

ne ctOhm 38 49

50 50 No Conne ctio n - - - - - - - - -

51 51 No Conne ctio n - - - - - - - - -

52 52 No Conne ctio n - - - - - - - - -

53 53 No Conne ctio n - - - - - - - - -

54 54 No Conne ctio n - - - - - - - - -

55 55 No Conne ctio n - - - - - - - - -

56 56 No Conne ctio n - - - - - - - - -

57 57 Throttle Po sitio n Sen-

sor (TPS) Po wer Sup-

plyRED/

GRNLess than

1VAppro x . 5V Co nnect DC V 57 49

58 58 ECM Re lay BLU/

BLK10-14V Less than 1V Connect DC V 58 GND

59 59 No Conne ctio n - - - - - - - - -

60 60 No Conne ctio n - - - - - - - - -

61 61 No Conne ctio n - - - - - - - - -

62 62 No Conne ctio n - - - - - - - - -

63 63 ECM Power Supply Less than

1V10-14V - DC V 63 GND

64 64 No Conne ctio n - - - - - - - - -

65 65 Bra ke Switch 2 Signa l WHT/

BLKLess than

1VPedal is not stepped on: 10-14V

Pedal is stepped on: Less than 1VCo nnect DC V 65 GND

66 66 No Conne ctio n - - - - - - - - -

67 67 No Conne ctio n - - - - - - - - -

68 68 Vehicle Spe ed Se n-

so r (VSS)YEL/

GRN- Approx . 14.5Hz by wav e fo rm or

approx. 6.0V at vehicle speed 20km/hCo nnect AC V 68 GND

69 69 Idle Switch GRN/

BLKLess than

1VPedal is not stepped on: Less than 1V

Pedal is stepped on: Approx. 5VCo nnect DC V 69 GND

70 70 No Conne ctio n - - - - - - - - -

71 71 No Conne ctio n - - - - - - - - -

72 72 No Conne ctio n - - - - - - - - -

73 73 No Conne ctio n - - - - - - - - -

74 74 No Conne ctio n - - - - - - - - -Signal or Continuity Tester Position

Pin

No. B/Box

No.Pin Function Wire

ColorKey SW

OffKey SW

OnEngine

IdleEngine

2000rpmECM

Connec-

tionRange (+) (-)

Page 1427 of 4264

4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS 6E–55

75 75 No Conne ctio n - - - - - - - - -

76 76 No Conne ctio n - - - - - - - - -

77 77 No Conne ctio n - - - - - - - - -

78 78 No Conne ctio n - - - - - - - - -

79 79 No Conne ctio n - - - - - - - - -

80 80 No Conne ctio n - - - - - - - - -

81 81 No Conne ctio n - - - - - - - - -

82 82 No Conne ctio n - - - - - - - - -

83 83 Ma ss Air Flo w (MAF)

Se nso r Po wer SupplyWH T/

REDLess than

1VAppro x . 5V Co nnect DC V 83 92

84 84 Intake Air Tempera-

ture (IAT) Sensor Sig-

na lBLK/

BLULess than

1V0 deg. C: Approx. 3.6V / 20 deg. C:

Approx. 2.6V / 40 deg. C: Approx.

1.7V / 60 deg. C: 1.1V / 80 deg. C:

0.7VCo nnect DC V 84 92

85 85 No Conne ctio n - - - - - - - - -

86 86 No Conne ctio n - - - - - - - - -

87 87 Neutral Switch BLK/

WH TLess than

1VIn neutral: Less than 1V

Other than neutral: 10-14VCo nnect DC V 87 GND

88 88 Ma ss Air Flo w (MAF)

Se nso r SignalGRN/

REDLess than

1VAppro x . 1V Appro x .

1.8VApprox.

2.5VCo nnect DC V 88 92

89 89 Engine Coolant Tem-

perature (ECT) Sen-

so r S ig na lGRY Less than

1V0 deg. C: Approx. 4.4V / 20 deg. C:

Approx. 3.8V / 40 deg. C: Approx.

2.9V / 60 deg. C: 2.1V / 80 deg. C:

1.4VCo nnect DC V 89 93

90 90 CKP Se nso r Signal RED - - Appro x .

47Hz by

w a v e fo rm Approx.

134Hz by

wave form

or approx.

1.1VCo nnect AC V 90 98

91 91 CKP Senso r Output

To Pump Co ntrol Unit

(PSG) No.8PNK - - Appro x .

47Hz by

w a v e fo rm Approx.

134Hz by

wave form

or approx.

0.7VCo nnect AC V 91 GND

92 92 Ma ss Air Flo w (MAF)

Se nsor GroundBLK/

REDContinuity

with

gro und- - - Connect Ohm 92 GND

93 93 Engine Coolant Tem-

perature (ECT) Sen-

so r Gro undBLK/

PNKContinuity

with

gro und- - - Connect Ohm 93 GND

94 94 Glo w Relay BLK/

REDLess than

1VGlow system is operated: Less than

1 V

Glow system is not operated: 10 - 14VCo nnect DC V 94 GND

95 95 No Conne ctio n - - - - - - - - -

96 96 No Conne ctio n - - - - - - - - -

97 97 EGR EVRV BLK/

ORG- - Approx. 140Hz by wave

fo rm whe n EVRV is

operated----

98 98 CKP Se nsor Ground WHT Continuity

with

gro und- - - Connect Ohm 98 GND

99 99 CAN (Contro ller Are a

Ne two rk) to PSG No .1BLU--------

100 100 CAN (Contro ller Are a

Ne two rk) to PSG No .2YEL--------Signal or Continuity Tester Position

Pin

No. B/Box

No.Pin Function Wire

ColorKey SW

OffKey SW

OnEngine

IdleEngine

2000rpmECM

Connec-

tionRange (+) (-)

Page 1430 of 4264

6E–58 4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS

4JH1-TC ECM CONNECTOR PIN ASSIGNMENT & OUTPUT SIGNA L

View Looking Into ECM Case

Signal or Continuity Tester Position

Pin

No. B/

Box

No.Pin Function Wire

ColorKey SW

OffKey SW

OnEngine

IdleEngine

2000rpmECM

Connec-

tionRan

ge(+) (-)

1 1 ECM Gro und BLK Co ntinu-

ity with

ground---Discon-

ne ctOh m 1 GND

2 2 ECM Gro und BLK Co ntinu-

ity with

ground---Discon-

ne ctOh m 2 GND

3 3 Batte ry Powe r Sup-

plyBLU/

REDLe ss

tha n 1V10-14V Co nnect DC V 3 GND

2525No Connection---------

2626No Connection---------

27 27 Engine Spee d Output

(To Ta cho Mete r)LGN - - Approx .

23Hz by

wave

fo rm or

approx.

6.3V Approx.

67Hz by

wave

fo rm or

approx.

6.8V Co nnect AC V 27 GND

2828No Connection---------

29 29 Throttle Positio n Sig-

na l To TCM (A16)

(AT Only )- Appro x . 140Hz by wav e fo rm (Idle:

Off duty 10% / WOT: Off duty 90%)- ---

30 30 Bra ke Switch 1 Sig-

na lGRN Le ss

tha n 1VPedal is not stepped on: Less than

1V

Pedal is stepped on: 10-14VCo nnect DC V 30 GND

31 31 Clutch Switch Signa l

(MT Only )YEL Less

tha n 1VPedal is not stepped on: 10-14V

Pe da l is ste ppe d o n: Le ss tha n 1VCo nnect DC V 31 GND

3232No Connection---------

33 33 A/C ON Signa l Rela y GRN/

YELLe ss

tha n 1VA/C request switch is turned on: 10-

14V

A/C reque st switch is turne d off:

Less than 1VCo nnect DC V 33 GND

3434No Connection---------

35 35 To Data Link Co n-

necto r No. 6 & Immo-

bilize r Co ntrol Unit

(ICU B8)YEL--------

3636No Connection---------

Page 1431 of 4264

4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS 6E–59

3737No Connection---------

38 38 Throttle Po sitio n

Se nso r (TPS) Out-

put Signa lGRN/

ORGLe ss

tha n 1VLess than 1V Approx.

0.5VCo nnect DC V 38 49

39 39 Ke y Switch Input Sig-

nal Via Engine FuseWH T L e s s

tha n 1V10-14V Co nnect DC V 39 GND

4040No Connection---------

41 41 A/C Compressor

RelayWH T/

GRNLe ss

tha n 1V10-14V A/C comp. is o pe r-

ated: Less than 1V

A/C comp. is no t o pe r-

ate d: 10 - 14VCo nnect DC V 41 GND

42 42 Check Engine La mp GRN/

YELLe ss

tha n 1VLamp is turned on: Less than 1V

Lamp is turned off: 10-14VCo nnect DC V 42 GND

43 43 Glo w Lamp ORG/

BLULe ss

tha n 1VLamp is turned on: Less than 1V

Lamp is turned off: 10-14VCo nnect DC V 43 GND

4444No Connection---------

45 45 To Data Link Co n-

necto r No . 6BLU Less

tha n 1V10-14V Co nnect DC V 45 GND

4646No Connection---------

4747No Connection---------

4848No Connection---------

49 49 Throttle Po sitio n

Se nso r (TPS)

GroundBLK/

GRNIdle:

Appro x.

0.4K

ohm /

WO T:

Appro x.

4.0K

ohm---Discon-

ne ctOh m 3 8 4 9

5050No Connection---------

5151No Connection---------

5252No Connection---------

5353No Connection---------

5454No Connection---------

5555No Connection---------

5656No Connection---------

57 57 Throttle Po sitio n

Senso r (TPS) Po wer

SupplyRED/

GRNLe ss

tha n 1VApprox. 5V Connect DC V 57 49

58 58 ECM Re la y BLU/

BLK10-14V Less than 1V Connect DC V 58 GND

5959No Connection---------

6060No Connection---------

6161No Connection---------

6262No Connection---------Signal or Continuity Tester Position

Pin

No. B/

Box

No.Pin Function Wire

ColorKey SW

OffKey SW

OnEngine

IdleEngine

2000rpmECM

Connec-

tionRan

ge(+) (-)

Page 1432 of 4264

6E–60 4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS

63 63 ECM Po wer Supply - Le ss

tha n 1V10-14V - DC V 63 GND

6464No Connection---------

65 65 Bra ke Switch 2 Sig-

na lWH T/

BLKLe ss

tha n 1VPedal is not stepped on: 10-14V

Pe da l is ste ppe d o n: Le ss tha n 1VCo nnect DC V 65 GND

6666No Connection---------

6767No Connection---------

68 68 Ve hicle Spe ed Sen-

sor (VSS)YEL/

GRN- Appro x. 14.5Hz by wa ve fo rm or

approx. 6.0V at vehicle speed

20km/hCo nnect AC V 68 GND

69 69 Idle Switch GRN/

BLKLe ss

tha n 1VPedal is not stepped on: Less than

1V

Pedal is stepped on: Approx. 5VCo nnect DC V 69 GND

7070No Connection---------

7171No Connection---------

7272No Connection---------

7373No Connection---------

7474No Connection---------

7575No Connection---------

7676No Connection---------

7777No Connection---------

7878No Connection---------

7979No Connection---------

8080No Connection---------

8181No Connection---------

82 82 Boo st Pre ssure Sen-

so r (High Altitude

Spe c. Onl y )WH T/

BLULe ss

tha n 1VApprox. 5V Connect DC V 82 93

83 83 Ma ss Air Flow (MAF)

Se nso r Po wer Sup-

plyWH T/

REDLe ss

tha n 1VApprox. 5V Connect DC V 83 92

84 84 Intake Air Tempera-

ture (IAT) Se nso r

SignalBLK/

BLULe ss

tha n 1V0 deg. C: Approx. 3.6V / 20 deg. C:

Approx. 2.6V / 40 deg. C: Approx.

1.7V / 60 deg. C: 1.1V / 80 deg. C:

0.7VCo nnect DC V 84 92

85 85 Manifo ld Pre ssure

Se nsor (High Alti-

tude Spe c. Only)RED/

BLULe ss

tha n 1V- - - Co nnect DC V 85 93

8686No Connection---------

87 87 Neutra l Switch BLK/

WH TLe ss

tha n 1VIn neutral (A/T: P or N): Less than

1 V

Othe r tha n neutra l (A/T: o ther tha n

P o r N): 10-14VCo nnect DC V 87 GND

88 88 Ma ss Air Flow (MAF)

Sensor SignalGRN/

REDLe ss

tha n 1VAppro x.

1V Approx .

1.8VApprox.

2.5VCo nnect DC V 88 92 Signal or Continuity Tester Position

Pin

No. B/

Box

No.Pin Function Wire

ColorKey SW

OffKey SW

OnEngine

IdleEngine

2000rpmECM

Connec-

tionRan

ge(+) (-)

Page 1438 of 4264

6E–66 4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS

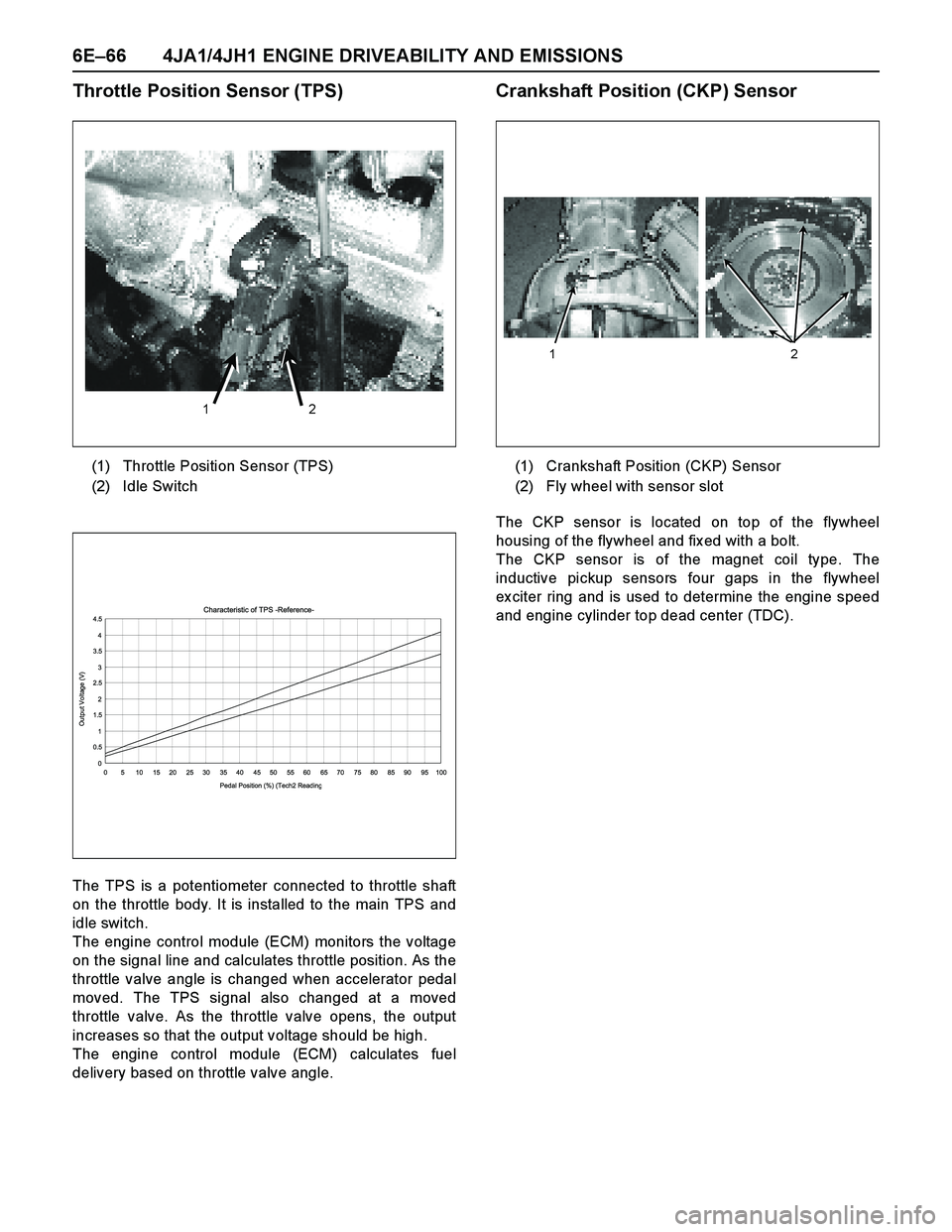

Throttle Position Sensor (TPS)

The TPS is a potentiometer connected to throttle shaft

on the throttle body. It is installed to the main TPS and

idle switch.

The engine control module (ECM) monitors the voltage

on the signal line and calculates throttle position. As the

throttle valve angle is changed when accelerator pedal

moved. The TPS signal also changed at a moved

throttle valve. As the throttle valve opens, the output

increases so that the output voltage should be high.

The engine control module (ECM) calculates fuel

delivery based on throttle valve angle.

Crankshaft Position (CKP) Sensor

The CKP sensor is located on top of the flywheel

housing of the flywheel and fix ed with a bolt.

The CKP sensor is of the magnet coil type. The

inductive pickup sensors four gaps in the flywheel

ex citer ring and is used to determine the engine speed

and engine cylinder top dead center (TDC). (1) Throttle Position Sensor (TPS)

(2) Idle Switch

1 2

Characteristic of TPS -Reference-

0 0.51 1.52 2.53 3.54 4.5

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Pedal Position (%) (Tech2 Readin

g

Output Voltage (V)

(1) Crankshaft Position (CKP) Sensor

(2) Fly wheel with sensor slot

1 2

Page 1450 of 4264

6E–78 4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS

3. Check Bulletins and

Troubleshooting Hints

NOTE: As estimated 30 percent of successful vehicle

repairs are diagnosed with this step!

What you should do

You should have enough information gained from

preliminary checks to accurately search for a bulletin

and other related service information. Some service

manual sections provide troubleshooting hints that

match symptoms with specific complaints.

What resources you should use

You should use the following resources for assistance in

checking for bulletins and troubleshooting hints:

Printed bulletins

Access ISUZU Bulletin Web site.

Videotapes

Service manual

4. Perform Service Manual

Diagnostic Checks

What you should do

The “System Checks” in most service manual sections

and in most cells of section 8A (electrical) provide you

with:

A systematic approach to narrowing down the

possible causes of a system fault

Direction to specific diagnostic procedures in the

service manual

Assistance to identify what systems work correctly

What resources you should use

Whenever possible, you should use the following

resources to perform service manual checks:

Service manual

Technical equipment (for viewing DTCs and

analyzing data)

Digital multimeter and circuit testing tools

Other tools as needed

5a and 5b. Perform Service Manual

Diagnostic Procedures

NOTE: An estimated 40 percent of successful vehicle

repairs are diagnosed with these steps!

What you should do

When directed by service manual diagnostic checks,

you must then carefully and accurately perform the

steps of diagnostic procedures to locate the fault relatedto the customer complaint.

What resources you should use

Whenever appropriate, you should use the following

resources to perform service manual diagnostic

procedures:

Service manual

Technical equipment (for analyzing diagnostic data)

Digital multimeter and circuit testing tools

Essential and special tools

5c. Technician Self Diagnoses

When there is no DTC stored and no matching

symptom for the condition identified in the service

manual, you must begin with a thorough understanding

of how the system(s) operates. Efficient use of the

service manual combined with you ex perience and a

good process of elimination will result in accurate

diagnosis of the condition.

What you should do

Step 1: Identify and understand the suspect

circuit(s)

Having completed steps 1 through 4 of the Strategy

Based Diagnostics chart, you should have enough

information to identify the system(s) or sub-system(s)

involved. Using the service manual, you should

determine and investigate the following circuit

characteristics:

Electrical:

–How is the circuit powered (power distribution

charts and/or fuse block details)?

–How is the circuit grounded (ground distribution

charts)?

–How is the circuit controlled or sensed (theory of

operation):

–If it is a switched circuit, is it normally open or

normally closed?

–Is the power switched or is the ground

switched?

–Is it a variable resistance circuit (ECT sensor

or TP sensor, for ex ample)?

–Is it a signal generating device (MAF sensor of

VSS, for example)?

–Does it rely on some mechanical/vacuum

device to operate?

Physical:

–Where are the circuit components (component

locators and wire harness routing diagrams):

–Are there areas where wires could be chafed

or pinched (brackets or frames)?

–Are there areas subjected to ex treme

temperatures?

Page 1451 of 4264

4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS 6E–79

–Are there areas subjected to vibration or

movement (engine, transmission or

suspension)?

–Are there areas ex posed to moisture, road salt

or other corrosives (battery acid, oil or other

fluids)?

–Are there common mounting areas with other

systems/components?

–Have previous repairs been performed to wiring,

connectors, components or mounting areas

(causing pinched wires between panels and

drivetrain or suspension components without

causing and immediate problem)?

–Does the vehicle have aftermarket or dealer-

installed equipment (radios, telephone, etc.)

Step 2: Isolate the problem

At this point, you should have a good idea of what could

cause the present condition, as well as could not cause

the condition. Actions to take include the following:

Divide (and separate, where possible) the system or

circuit into smaller sections

Confine the problem to a smaller area of the vehicle

(start with main harness connections while removing

panels and trim as necessary in order to eliminate

large vehicle sections from further investigation)

For two or more circuits that do not share a common

power or ground, concentrate on areas where

harnesses are routed together or connectors are

shared (refer to the following hints)

Hints

Though the symptoms may vary, basic electrical failures

are generally caused by:

Loose connections:

–Open/high resistance in terminals, splices,

connectors or grounds

Incorrect connector/harness routing (usually in new

vehicles or after a repair has been made):

–Open/high resistance in terminals, splices,

connectors of grounds

Corrosion and wire damage:

–Open/high resistance in terminals, splices,

connectors of grounds

Component failure:

–Opens/short and high resistance in relays,

modules, switches or loads

Aftermarket equipment affecting normal operation of

other systems

You may isolate circuits by:

Unplugging connectors or removing a fuse to

separate one part of the circuit from another part

Operating shared circuits and eliminating those that

function normally from the suspect circuit

If only one component fails to operate, begin testingat the component

If a number of components do no operate, begin tests

at the area of commonality (such as power sources,

ground circuits, switches or major connectors)

What resources you should use

Whenever appropriate, you should use the following

resources to assist in the diagnostic process:

Service manual

Technical equipment (for data analysis)

Ex perience

Technical Assistance

Circuit testing tools

5d. Intermittent Diagnosis

By definition, an intermittent problem is one that does

not occur continuously and will occur when certain

conditions are met. All these conditions, however, may

not be obvious or currently known. Generally,

intermittents are caused by:

Faulty electrical connections and wiring

Malfunctioning components (such as sticking relays,

solenoids, etc.)

EMI/RFI (Electromagnetic/radio frequency

interference)

Aftermarket equipment

Intermittent diagnosis requires careful analysis of

suspected systems to help prevent replacing good

parts. This may involve using creativity and ingenuity to

interpret customer complaints and simulating all

ex ternal and internal system conditions to duplicate the

problem.

What you should do

Step 1: A cquire information

A thorough and comprehensive customer check sheet

is critical to intermittent problem diagnosis. You should

require this, since it will dictate the diagnostic starting

point. The vehicle service history file is another

source for accumulating information about the

complaint.

Step 2: A nalyze the intermittent problem

Analyze the customer check sheet and service history

file to determine conditions relevant to the suspect

system(s).

Using service manual information, you must identify,

trace and locate all electrical circuits related to the

malfunctioning system(s). If there is more than one

system failure, you should identify, trace and locate

areas of commonality shared by the suspect circuits.

Page 1452 of 4264

6E–80 4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS

Step 3: Simulate the symptom and isolate the

problem

Simulate the symptom and isolate the system by

reproducing all possible conditions suggested in Step 1

while monitoring suspected circuits/components/

systems to isolate the problem symptom. Begin with the

most logical circuit/component.

Isolate the circuit by dividing the suspect system into

simpler circuits. Nex t, confine the problem into a smaller

area of the system. Begin at the most logical point (or

point of easiest access) and thoroughly check the

isolated circuit for the fault, using basic circuit tests.

Hints

You can isolate a circuit by:

Unplugging connectors or removing a fuse to

separate one part of the circuit from another

If only component fails to operate, begin testing the

component

If a number of components do not operate, begin test

at areas of commonality (such as power sources,

ground circuits, switches, main connectors or major

components)

Substitute a known good part from the parts

department or the vehicle system

Try the suspect part in a known good vehicle

See Symptom Simulation Tests on the nex t page for

problem simulation procedures. Refer to service manual

sections 6E and 8A for information about intermittent

diagnosis. Follow procedures for basic circuit testing in

service manual section 8A.

What resources you should use

Whenever appropriate, you should use the following

resources to assist in the diagnostic process:

Service manual

Bulletins

Digital multimeter (with a MIN/MAX feature)

Tech II and Tech II upload function

Circuit testing tools (including connector kits/

harnesses and jumper wires)

Ex perience

Intermittent problem solving simulation methods

Customer complaint check sheet

Symptom Simulation Tests

1. Vibration

This method is useful when the customer complaint

analysis indicates that the problem occurs when the

vehicle/system undergoes some form of vibration.

For connectors and wire harness, slightly shake

vertically and horizontally. Inspect the connector joint

and body for damage. Also, tapping lightly along a

suspected circuit may be helpful.For parts and sensors, apply slight vibration to the part

with a light tap of the finger while monitoring the system

for a malfunction.

2. Heat

This method is important when the complaint suggests

that the problem occurs in a heated environment. Apply

moderate heat to the component with a hair drier or

similar tool while monitoring the system for a

malfunction.

CA UTION: Care must be take to avoid overheating

the component.

3. Water and Moisture

This method may be used when the complaint suggests

that the malfunction occurs on a rainy day or under

conditions of high humidity. In this case, apply water in a

light spray on the vehicle to duplicate the problem.

CA UTION: Care must be take to avoid directly

exposing electrical connections to water.

4. Electrical loads

This method involves turning systems ON (such as the

blower, lights or rear window defogger) to create a load

on the vehicle electrical system at the same time you

are monitoring the suspect circuit/component.

5e. Vehicle Operates as Designed

This condition refers to instances where a system

operating as designed is perceived to be unsatisfactory

or undesirable. In general, this is due to:

A lack of understanding by the customer

A conflict between customer ex pectations and

vehicle design intent

A system performance that is unacceptable to the

customer

What you should do

You can verify that a system is operating as designed

by:

Reviewing service manual functional/diagnostic

checks

Ex amining bulletins and other service information for

supplementary information

Compare system operation to an identical vehicle

If the condition is due to a customer misunderstanding

or a conflict between customer ex pectation and system

operation, you should ex plain the system operation to

the customer.

If the complaint is due to a case of unsatisfactory

system performance, you should contact Technical

Assistance for the latest information.

What resources you should use

Whenever possible, you should use the following

resources to facilitate the diagnostic process: