compression ratio ISUZU TFS SERIES 1997 Workshop Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1997, Model line: TFS SERIES, Model: ISUZU TFS SERIES 1997Pages: 1600, PDF Size: 40.98 MB

Page 133 of 1600

4C1-70 FRONT WHEEL DRIVE

Important Operations

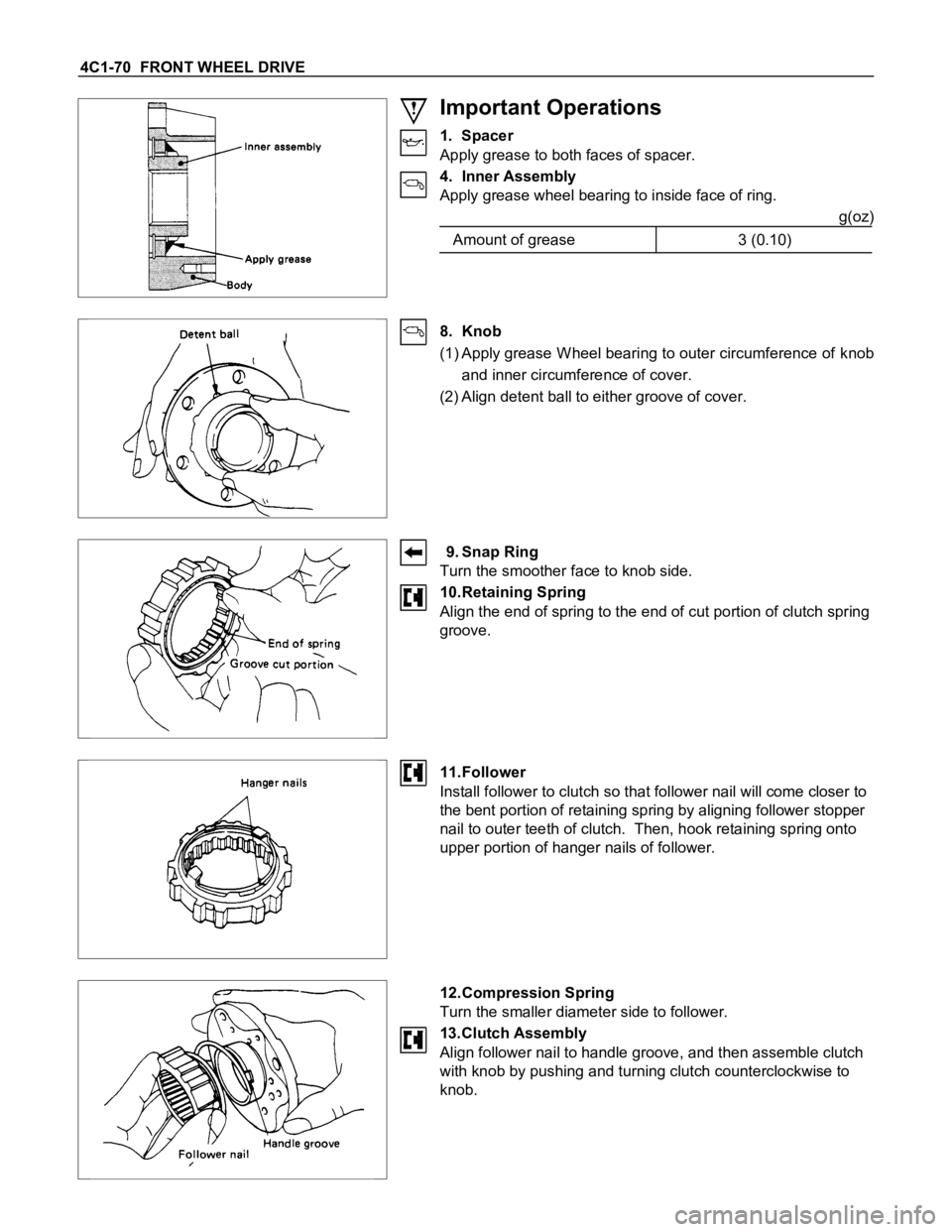

1. Spacer

Apply grease to both faces of spacer.

4. Inner Assembly

Apply grease wheel bearing to inside face of ring.

g(oz)

Amount of grease 3 (0.10)

8. Knob

(1) Apply grease W heel bearing to outer circumference of knob

and inner circumference of cover.

(2) Align detent ball to either groove of cover.

9. Snap Ring

Turn the smoother face to knob side.

10.Retaining Spring

Align the end of spring to the end of cut portion of clutch spring

groove.

11.Follower

Install follower to clutch so that follower nail will come closer to

the bent portion of retaining spring by aligning follower stopper

nail to outer teeth of clutch. Then, hook retaining spring onto

upper portion of hanger nails of follower.

12.Compression Spring

Turn the smaller diameter side to follower.

13.Clutch Assembly

Align follower nail to handle groove, and then assemble clutch

with knob by pushing and turning clutch counterclockwise to

knob.

Page 344 of 1600

5-16 BRAKES

From

primary

master cylinder From

Secondary

master cylinder

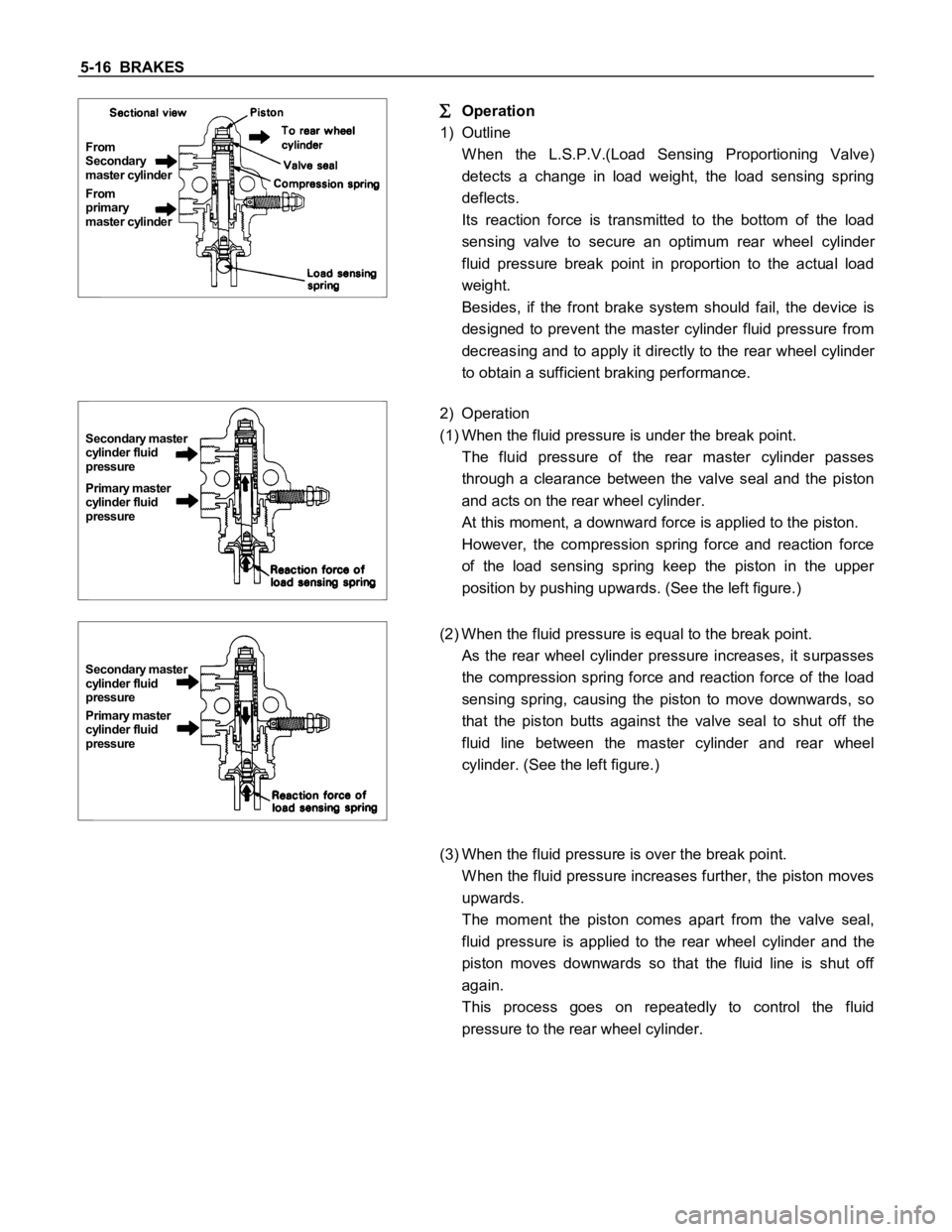

Operation

1) Outline

W hen the L.S.P.V.(Load Sensing Proportioning Valve)

detects a change in load weight, the load sensing spring

deflects.

Its reaction force is transmitted to the bottom of the load

sensing valve to secure an optimum rear wheel cylinder

fluid pressure break point in proportion to the actual load

weight.

Besides, if the front brake system should fail, the device is

designed to prevent the master cylinder fluid pressure from

decreasing and to apply it directly to the rear wheel cylinder

to obtain a sufficient braking performance.

Primary master

cylinder fluid

pressure Secondary master

cylinder fluid

pressure

2) Operation

(1) When the fluid pressure is under the break point.

The fluid pressure of the rear master cylinder passes

through a clearance between the valve seal and the piston

and acts on the rear wheel cylinder.

At this moment, a downward force is applied to the piston.

However, the compression spring force and reaction force

of the load sensing spring keep the piston in the upper

position by pushing upwards. (See the left figure.)

Primary master

cylinder fluid

pressure Secondary master

cylinder fluid

pressure

(2) When the fluid pressure is equal to the break point.

As the rear wheel cylinder pressure increases, it surpasses

the compression spring force and reaction force of the load

sensing spring, causing the piston to move downwards, so

that the piston butts against the valve seal to shut off the

fluid line between the master cylinder and rear wheel

cylinder. (See the left figure.)

(3) When the fluid pressure is over the break point.

W hen the fluid pressure increases further, the piston moves

upwards.

The moment the piston comes apart from the valve seal,

fluid pressure is applied to the rear wheel cylinder and the

piston moves downwards so that the fluid line is shut off

again.

This process goes on repeatedly to control the fluid

pressure to the rear wheel cylinder.