light ISUZU TROOPER 1998 Service Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 1529 of 3573

SERVICE INFORMATION 00 Ð 29

FUEL SYSTEM

Fuel Filter

Replacement Procedure

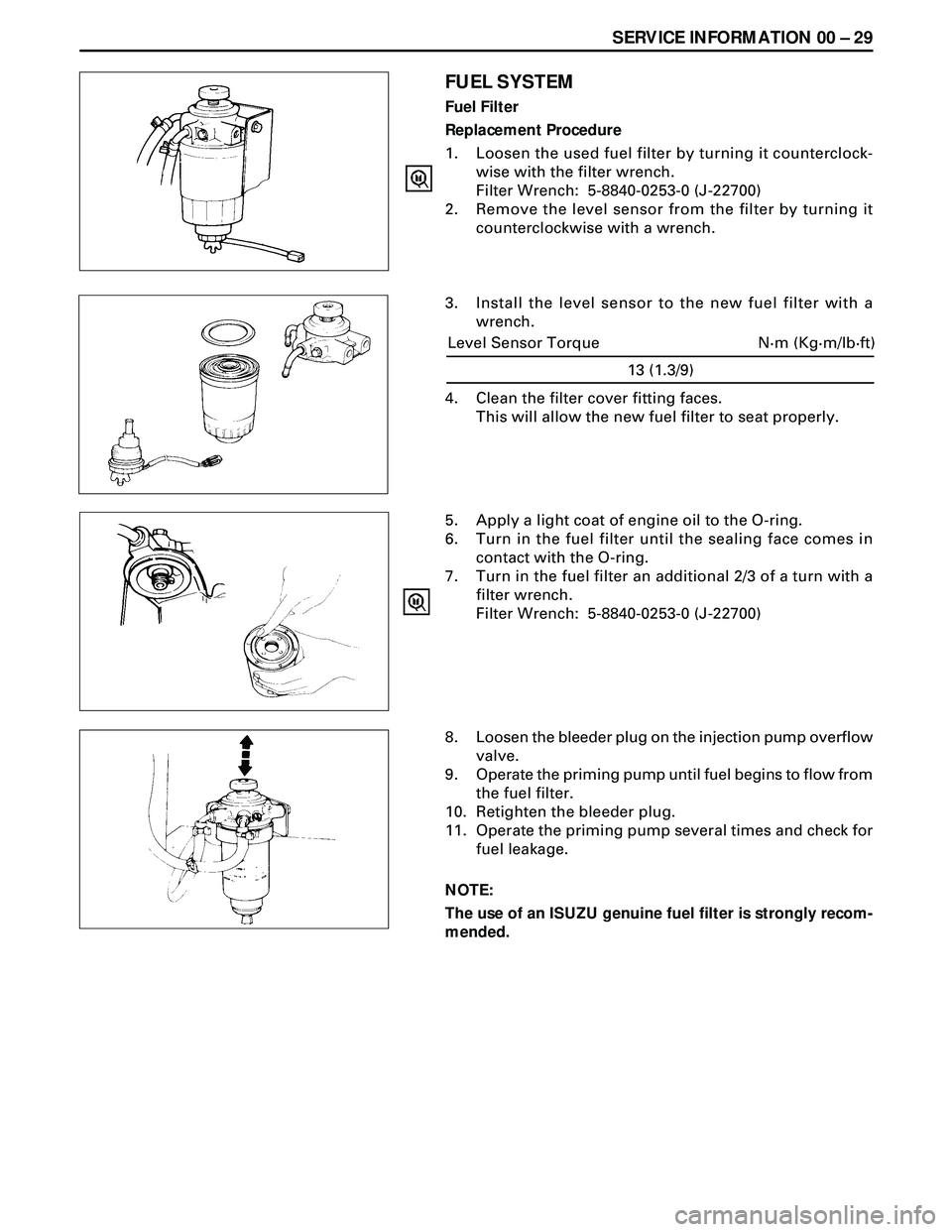

1. Loosen the used fuel filter by turning it counterclock-

wise with the filter wrench.

Filter Wrench: 5-8840-0253-0 (J-22700)

2. Remove the level sensor from the filter by turning it

counterclockwise with a wrench.

3. Install the level sensor to the new fuel filter with a

wrench.

5. Apply a light coat of engine oil to the O-ring.

6. Turn in the fuel filter until the sealing face comes in

contact with the O-ring.

7. Turn in the fuel filter an additional 2/3 of a turn with a

filter wrench.

Filter Wrench: 5-8840-0253-0 (J-22700)

8. Loosen the bleeder plug on the injection pump overflow

valve.

9. Operate the priming pump until fuel begins to flow from

the fuel filter.

10. Retighten the bleeder plug.

11. Operate the priming pump several times and check for

fuel leakage.

NOTE:

The use of an ISUZU genuine fuel filter is strongly recom-

mended.

13 (1.3/9)

N·m (Kg·m/lb·ft) Level Sensor Torque

4. Clean the filter cover fitting faces.

This will allow the new fuel filter to seat properly.

Page 1530 of 3573

00 Ð 30 SERVICE INFORMATION

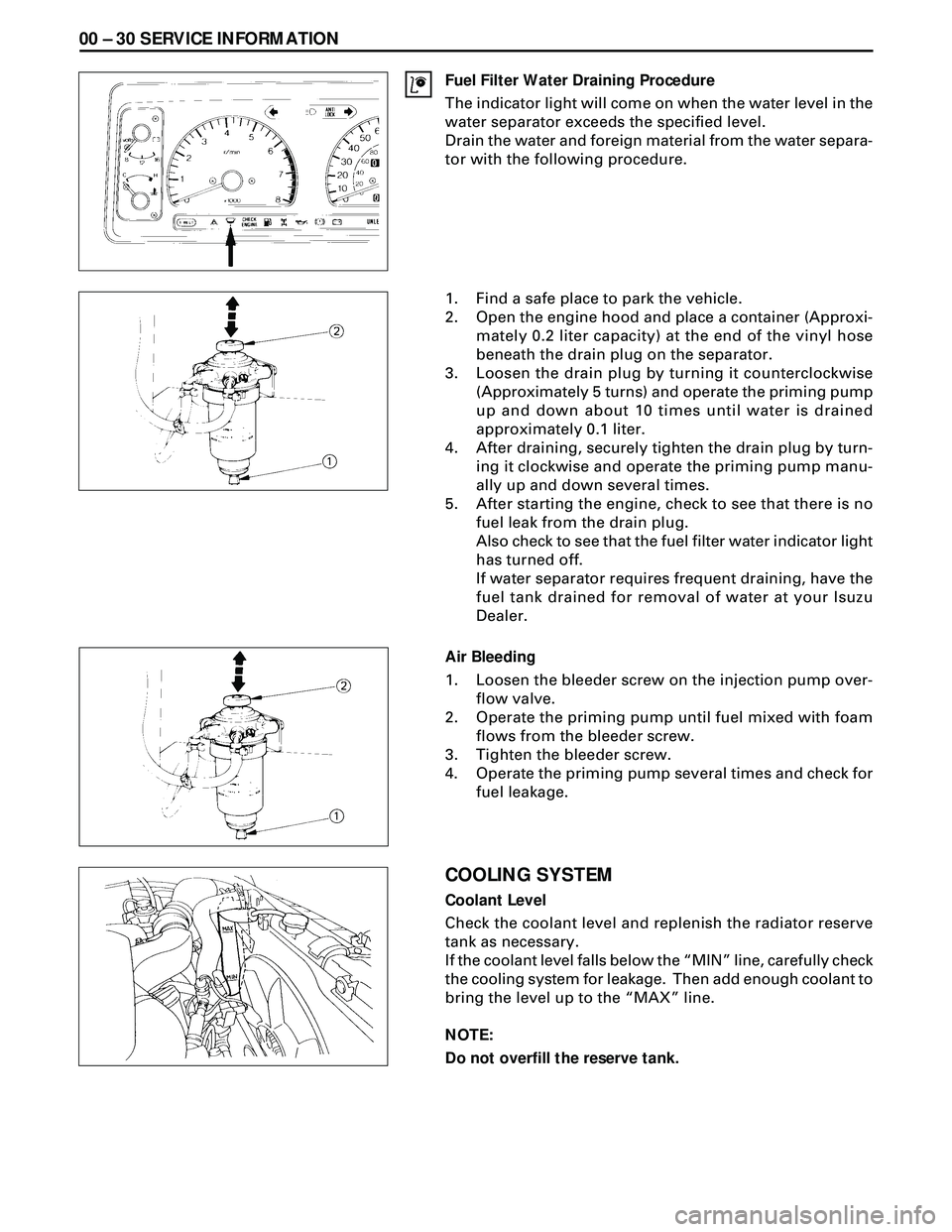

Fuel Filter Water Draining Procedure

The indicator light will come on when the water level in the

water separator exceeds the specified level.

Drain the water and foreign material from the water separa-

tor with the following procedure.

1. Find a safe place to park the vehicle.

2. Open the engine hood and place a container (Approxi-

mately 0.2 liter capacity) at the end of the vinyl hose

beneath the drain plug on the separator.

3. Loosen the drain plug by turning it counterclockwise

(Approximately 5 turns) and operate the priming pump

up and down about 10 times until water is drained

approximately 0.1 liter.

4. After draining, securely tighten the drain plug by turn-

ing it clockwise and operate the priming pump manu-

ally up and down several times.

5. After starting the engine, check to see that there is no

fuel leak from the drain plug.

Also check to see that the fuel filter water indicator light

has turned off.

If water separator requires frequent draining, have the

fuel tank drained for removal of water at your Isuzu

Dealer.

Air Bleeding

1. Loosen the bleeder screw on the injection pump over-

flow valve.

2. Operate the priming pump until fuel mixed with foam

flows from the bleeder screw.

3. Tighten the bleeder screw.

4. Operate the priming pump several times and check for

fuel leakage.

COOLING SYSTEM

Coolant Level

Check the coolant level and replenish the radiator reserve

tank as necessary.

If the coolant level falls below the ÒMINÓ line, carefully check

the cooling system for leakage. Then add enough coolant to

bring the level up to the ÒMAXÓ line.

NOTE:

Do not overfill the reserve tank.

Page 1535 of 3573

SERVICE INFORMATION 00 Ð 35

Adjust the No. 1 or the No. 4 cylinder valve clearances while

their respective cylinders are at TDC on the compression

stroke.

0.4 (0.016)

mm(in) Valve Clearance (At Cold)

4. Loosen each valve clearance adjusting screw as shown

in the ilustration.

5. Insert a feeler gauge of the appropriate thickness be-

tween the rocker arm and the valve stem end.

6. Turn the valve clearance adjusting screw until a slight

drag can be felt on the feeler gauge.

7. Tighten the lock nut securely.

8. Rotate the crankshaft 360°.

9. Realign the crankshaft damper pulley TDC notched line

with the timing pointer.

10. Adjust the clearances for the remaining valves as shown

in the illustration.

INJECTION TIMING ADJUSTMENT

1. Set the No. 1 cylinder to Top Dead Center.

2. Remove injector pump distributor head plug.

3. Cancel Wax CSD with the handle of a screw driver.

4. Fit a dial gauge and set lift to 1 mm.

5. Set crankshaft damper pulley Top Dead Center mark

about 45° before Top Dead Center from the pointer.

6. Set dial gauge in the ÒOÓ position.

Measuring device : 5-8840-0145-0

7. Turn the crankshaft a little rightwise and leftwise and

see it the pointer is stable in the ÒOÓ position.

8. Turn the crankshaft in the normal direction and read the

measuring deviceÕs indication at TDC (4JG2-T) or 1°

ATDC (4JG2-NA).

9. If the injection timing is outside the specified range,

continue with the following steps.

10. Loosen the injection pump fixing nuts and bracket bolts.

11. Adjust the injection pump setting angle.

¥ If injection timing will be advanced, move the injec-

tion pump toward the engine.

¥ If injection timing will be retarded, move the injec-

tion pump away from the engine.

Tighten the pump fixing nut, adjust bolt and pump distribu-

tor head plug to the specified torque.

19(1.9/13)

N·m(Kg·m/lb·ft) Pump Fixing Bolt

0.5 (0.02)

mm(in) Starting Timing

Page 1554 of 3573

6A Ð 4 ENGINE MECHANICAL

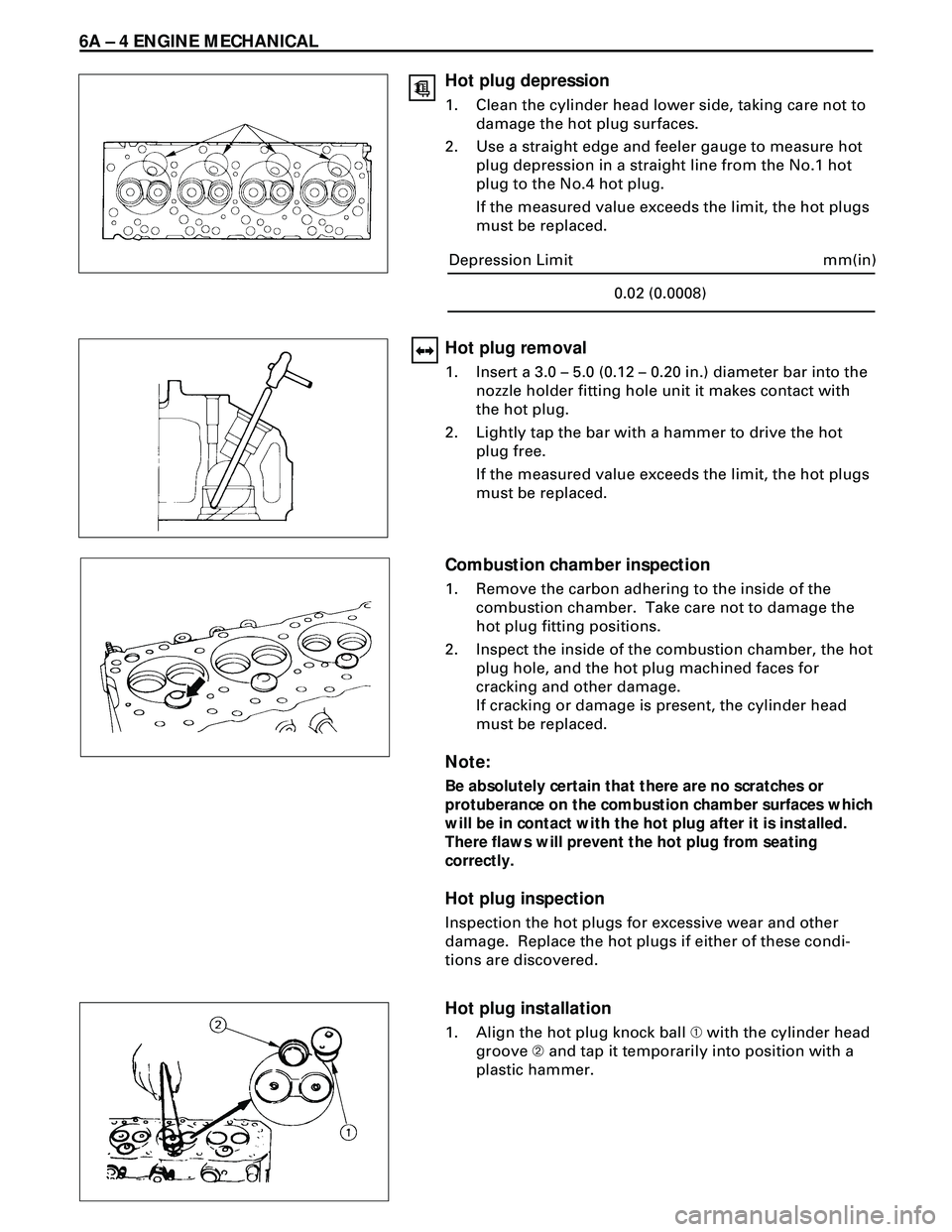

Hot plug depression

1. Clean the cylinder head lower side, taking care not to

damage the hot plug surfaces.

2. Use a straight edge and feeler gauge to measure hot

plug depression in a straight line from the No.1 hot

plug to the No.4 hot plug.

If the measured value exceeds the limit, the hot plugs

must be replaced.

Hot plug removal

1. Insert a 3.0 Ð 5.0 (0.12 Ð 0.20 in.) diameter bar into the

nozzle holder fitting hole unit it makes contact with

the hot plug.

2. Lightly tap the bar with a hammer to drive the hot

plug free.

If the measured value exceeds the limit, the hot plugs

must be replaced.

mm(in)

0.02 (0.0008) Depression Limit

Combustion chamber inspection

1. Remove the carbon adhering to the inside of the

combustion chamber. Take care not to damage the

hot plug fitting positions.

2. Inspect the inside of the combustion chamber, the hot

plug hole, and the hot plug machined faces for

cracking and other damage.

If cracking or damage is present, the cylinder head

must be replaced.

Note:

Be absolutely certain that there are no scratches or

protuberance on the combustion chamber surfaces which

will be in contact with the hot plug after it is installed.

There flaws will prevent the hot plug from seating

correctly.

Hot plug inspection

Inspection the hot plugs for excessive wear and other

damage. Replace the hot plugs if either of these condi-

tions are discovered.

Hot plug installation

1. Align the hot plug knock ball À with the cylinder head

groove Á and tap it temporarily into position with a

plastic hammer.

Page 1555 of 3573

ENGINE MECHANICAL 6A Ð 5

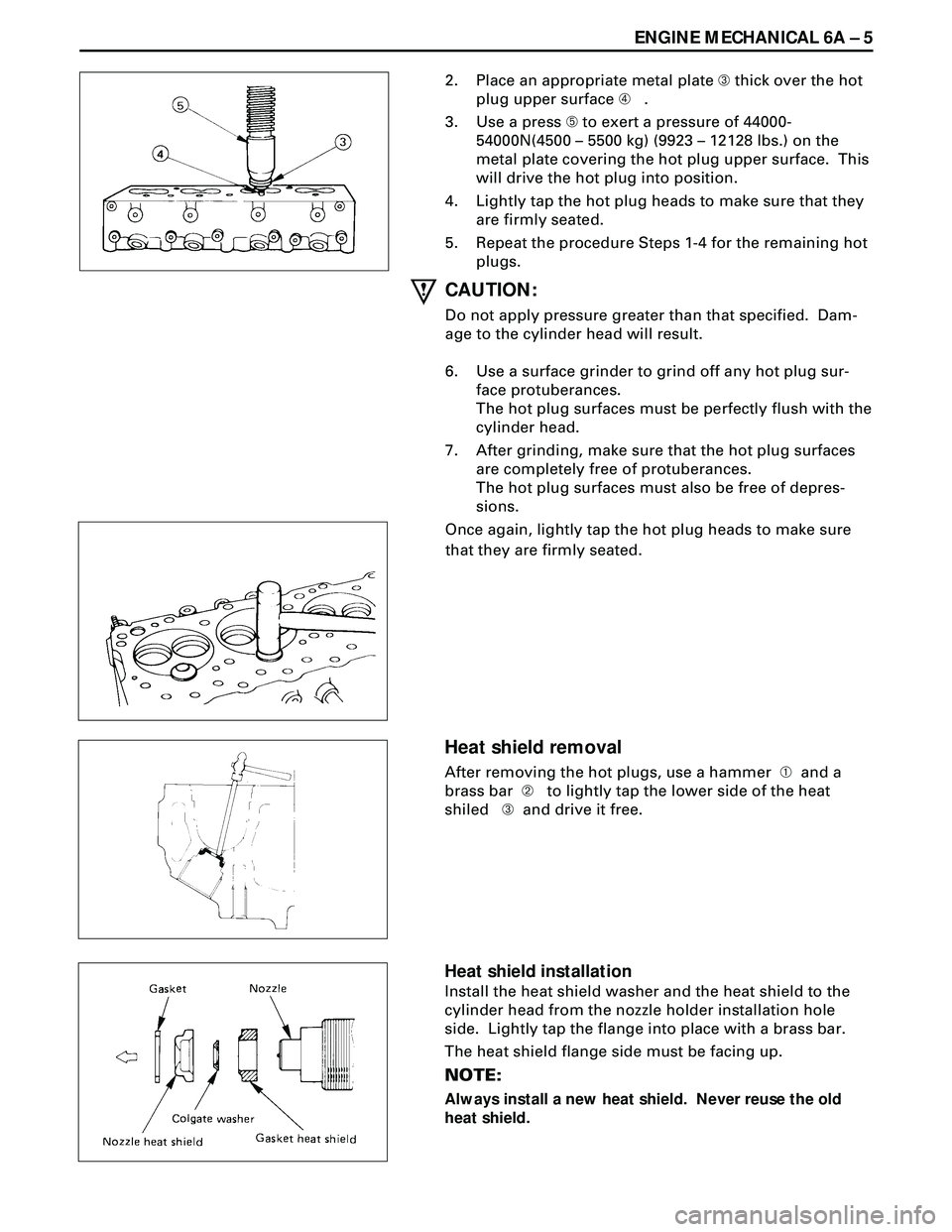

2. Place an appropriate metal plate  thick over the hot

plug upper surface à .

3. Use a press Ä to exert a pressure of 44000-

54000N(4500 Ð 5500 kg) (9923 Ð 12128 lbs.) on the

metal plate covering the hot plug upper surface. This

will drive the hot plug into position.

4. Lightly tap the hot plug heads to make sure that they

are firmly seated.

5. Repeat the procedure Steps 1-4 for the remaining hot

plugs.

CAUTION:

Do not apply pressure greater than that specified. Dam-

age to the cylinder head will result.

6. Use a surface grinder to grind off any hot plug sur-

face protuberances.

The hot plug surfaces must be perfectly flush with the

cylinder head.

7. After grinding, make sure that the hot plug surfaces

are completely free of protuberances.

The hot plug surfaces must also be free of depres-

sions.

Once again, lightly tap the hot plug heads to make sure

that they are firmly seated.

Heat shield removal

After removing the hot plugs, use a hammer À and a

brass bar Á to lightly tap the lower side of the heat

shiled  and drive it free.

Heat shield installation

Install the heat shield washer and the heat shield to the

cylinder head from the nozzle holder installation hole

side. Lightly tap the flange into place with a brass bar.

The heat shield flange side must be facing up.

NOTE:

Always install a new heat shield. Never reuse the old

heat shield.

Page 1563 of 3573

ENGINE MECHANICAL 6A Ð 13

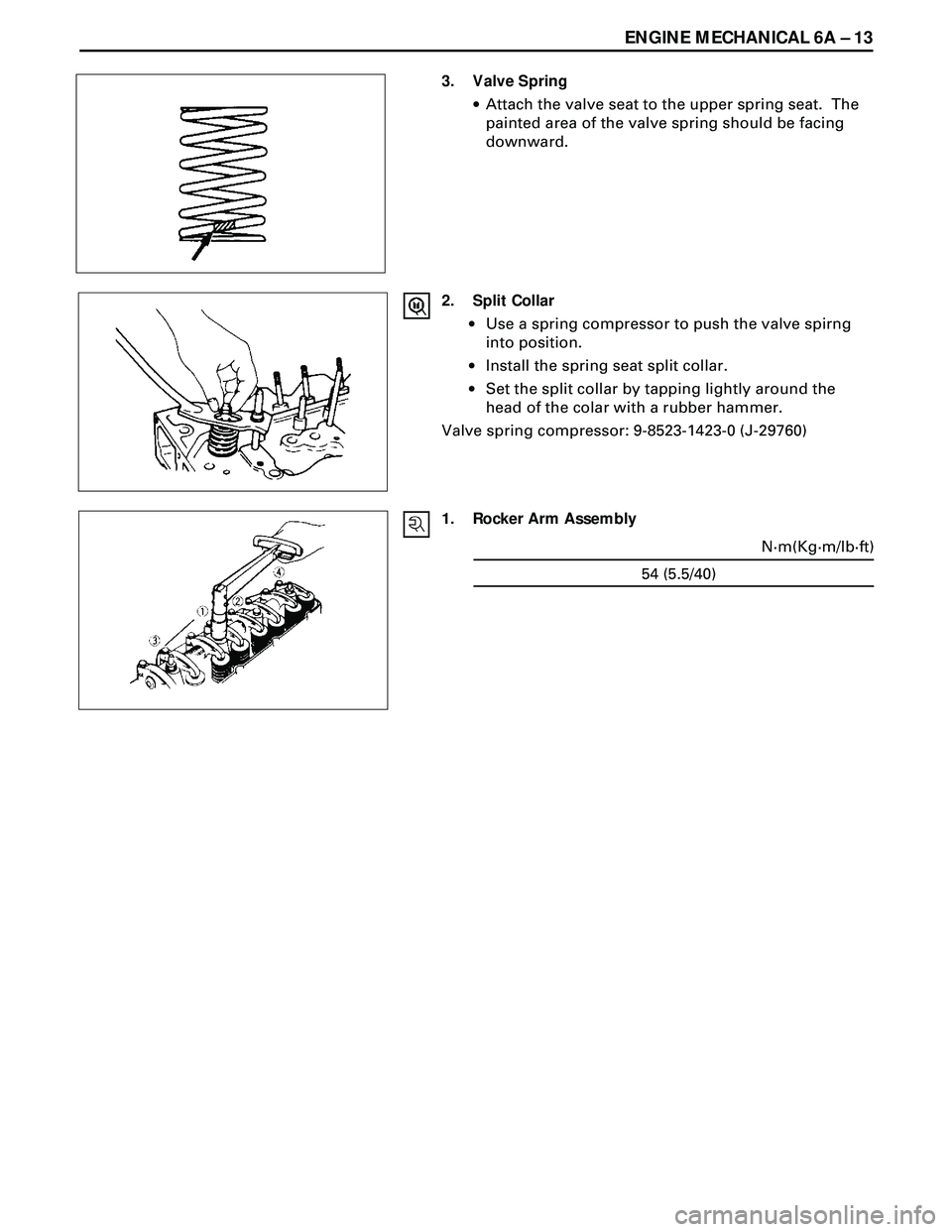

3. Valve Spring

·Attach the valve seat to the upper spring seat. The

painted area of the valve spring should be facing

downward.

2. Split Collar

·Use a spring compressor to push the valve spirng

into position.

·Install the spring seat split collar.

·Set the split collar by tapping lightly around the

head of the colar with a rubber hammer.

Valve spring compressor: 9-8523-1423-0 (J-29760)

1. Rocker Arm Assembly

N·m(Kg·m/lb·ft)

54 (5.5/40)

Page 1570 of 3573

6A Ð 20 ENGINE MECHANICAL

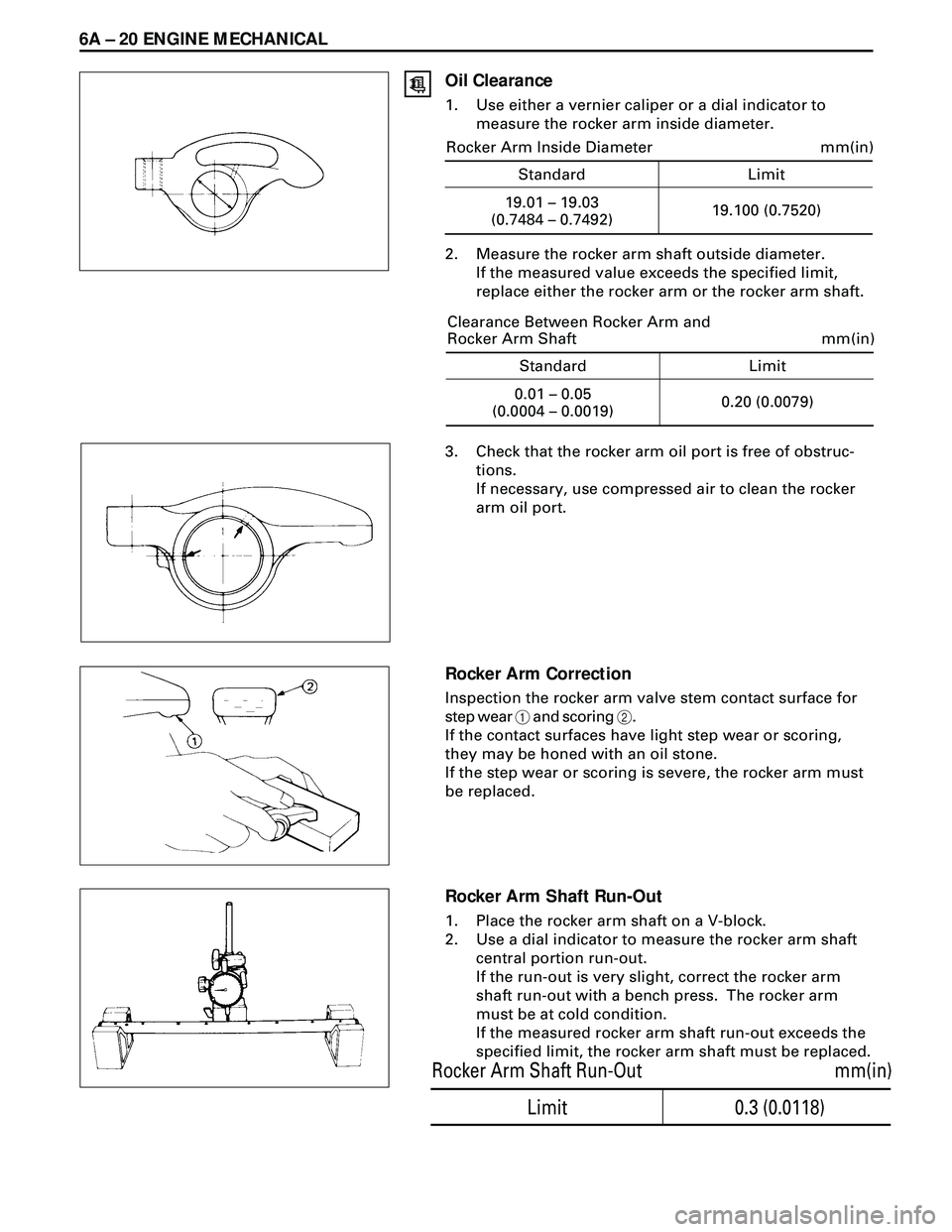

Oil Clearance

1. Use either a vernier caliper or a dial indicator to

measure the rocker arm inside diameter.

2. Measure the rocker arm shaft outside diameter.

If the measured value exceeds the specified limit,

replace either the rocker arm or the rocker arm shaft.

3. Check that the rocker arm oil port is free of obstruc-

tions.

If necessary, use compressed air to clean the rocker

arm oil port.

Rocker Arm Correction

Inspection the rocker arm valve stem contact surface for

step wear 1 and scoring 2.

If the contact surfaces have light step wear or scoring,

they may be honed with an oil stone.

If the step wear or scoring is severe, the rocker arm must

be replaced.

Rocker Arm Shaft Run-Out

1. Place the rocker arm shaft on a V-block.

2. Use a dial indicator to measure the rocker arm shaft

central portion run-out.

If the run-out is very slight, correct the rocker arm

shaft run-out with a bench press. The rocker arm

must be at cold condition.

If the measured rocker arm shaft run-out exceeds the

specified limit, the rocker arm shaft must be replaced.

0.3 (0.0118)

mm(in) Rocker Arm Shaft Run-Out

Limit

Standard Limit

mm(in)

19.01 – 19.03

(0.7484 – 0.7492)19.100 (0.7520) Rocker Arm Inside Diameter

Standard Limit

mm(in)

0.01 – 0.05

(0.0004 – 0.0019)0.20 (0.0079) Clearance Between Rocker Arm and

Rocker Arm Shaft

Page 1571 of 3573

ENGINE MECHANICAL 6A Ð 21

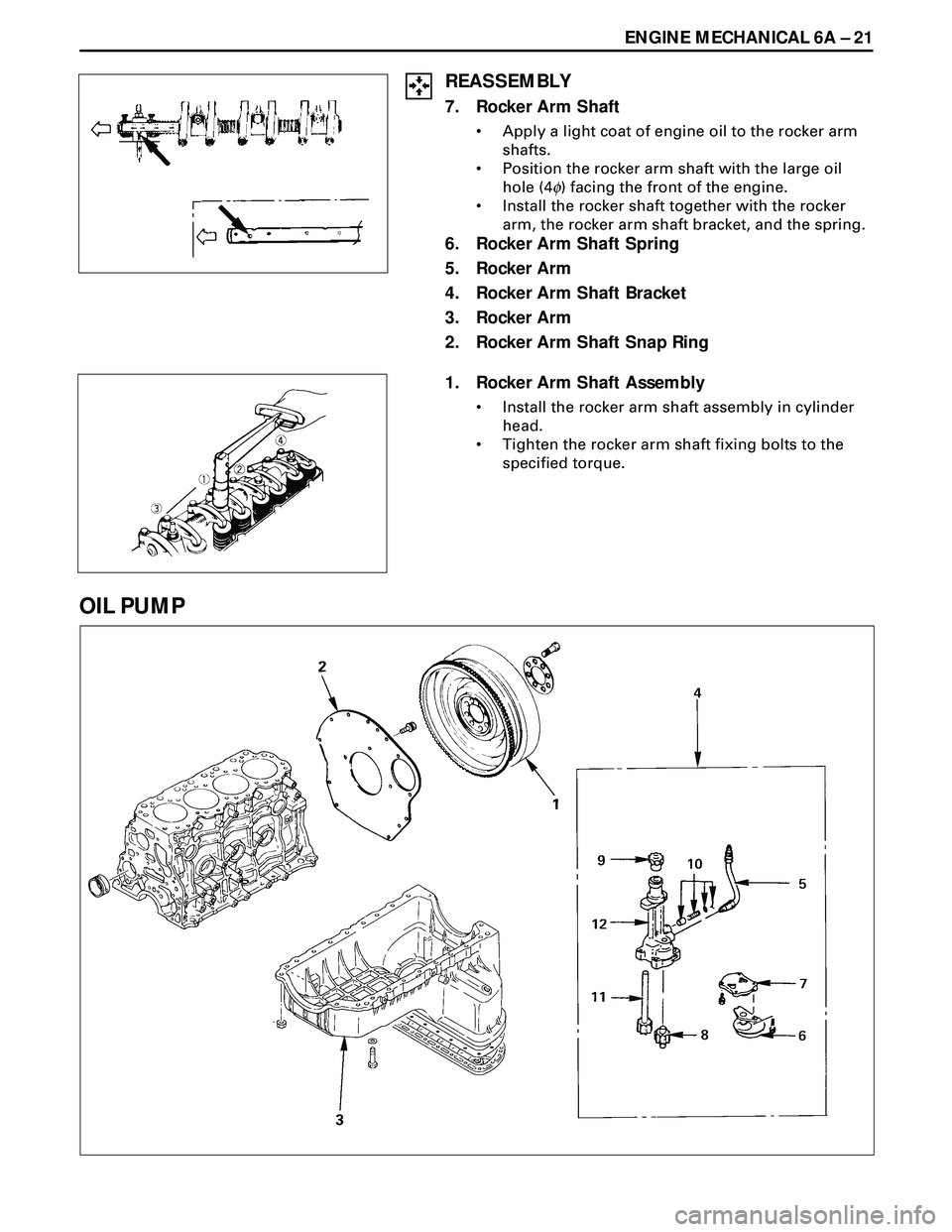

REASSEMBLY

7. Rocker Arm Shaft

¥ Apply a light coat of engine oil to the rocker arm

shafts.

¥ Position the rocker arm shaft with the large oil

hole (4

f) facing the front of the engine.

¥ Install the rocker shaft together with the rocker

arm, the rocker arm shaft bracket, and the spring.

6. Rocker Arm Shaft Spring

5. Rocker Arm

4. Rocker Arm Shaft Bracket

3. Rocker Arm

2. Rocker Arm Shaft Snap Ring

1. Rocker Arm Shaft Assembly

¥ Install the rocker arm shaft assembly in cylinder

head.

¥ Tighten the rocker arm shaft fixing bolts to the

specified torque.

OIL PUMP

Page 1635 of 3573

4JG2-NA/4JG2-TURBO ENGINE 6A2 Ð 33

OIL FILTER CARTRIDGE

REMOVAL

·Place a receptacle beneath the oil filter to contain the

drained oil.

·Remove the oil filter cartridge using filter wrench.

Filter wrench: 5-8840-0200-0

INSTALLATION

·Lightly oil the o-ring of oil filter cartridge.

·Turn in the new oil filter cartridge by hand until the

sealing face is fiffted again the o-ring.

·Use the filter wrench to turn in the oil filter and

additional one and 1á1/8 turns.

·Start the engine and check for oil leakage from oil filter.

Page 1670 of 3573

6C Ð 4 FUEL SYSTEM

INJECTION PUMP

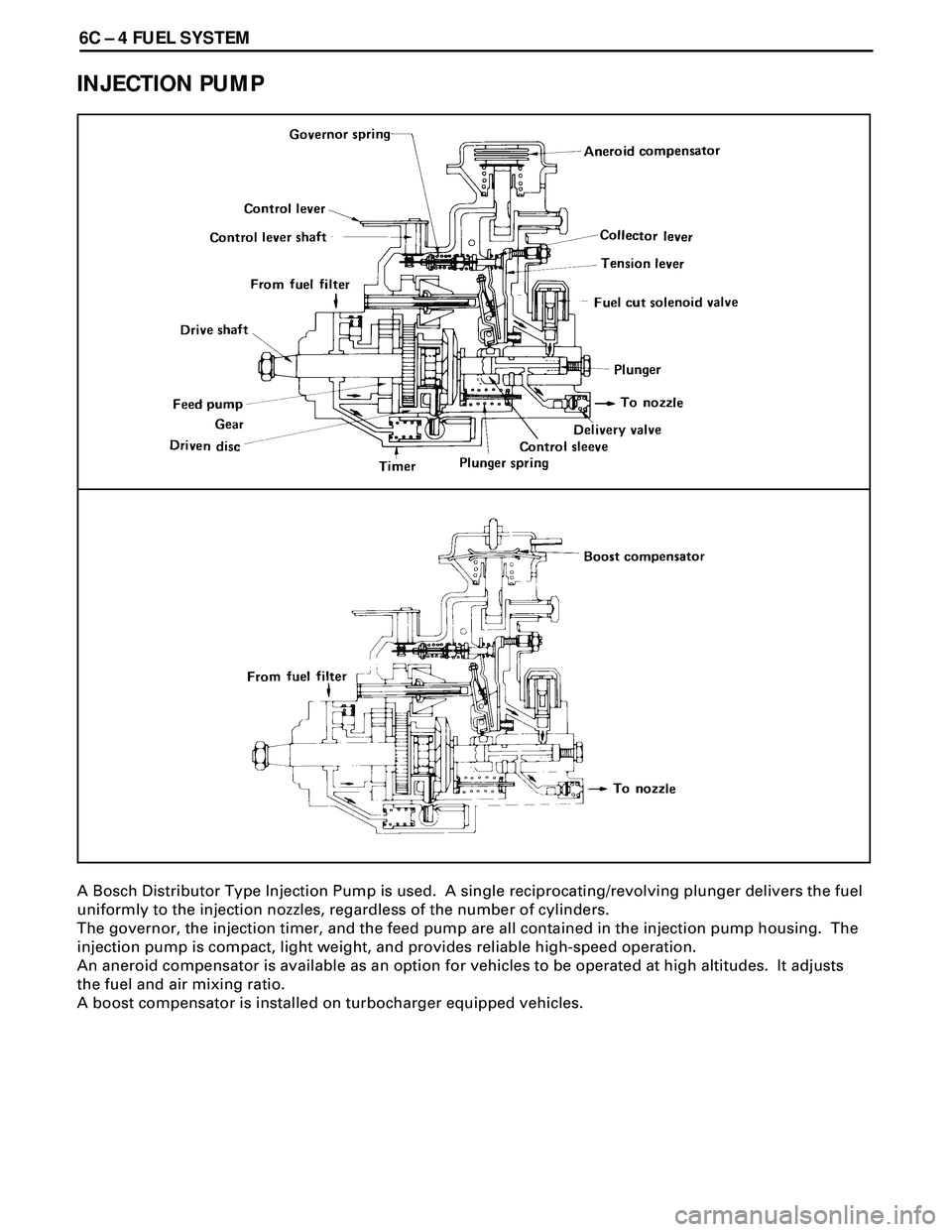

A Bosch Distributor Type Injection Pump is used. A single reciprocating/revolving plunger delivers the fuel

uniformly to the injection nozzles, regardless of the number of cylinders.

The governor, the injection timer, and the feed pump are all contained in the injection pump housing. The

injection pump is compact, light weight, and provides reliable high-speed operation.

An aneroid compensator is available as an option for vehicles to be operated at high altitudes. It adjusts

the fuel and air mixing ratio.

A boost compensator is installed on turbocharger equipped vehicles.