light ISUZU TROOPER 1998 Service Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 1671 of 3573

FUEL SYSTEM 6C Ð 5

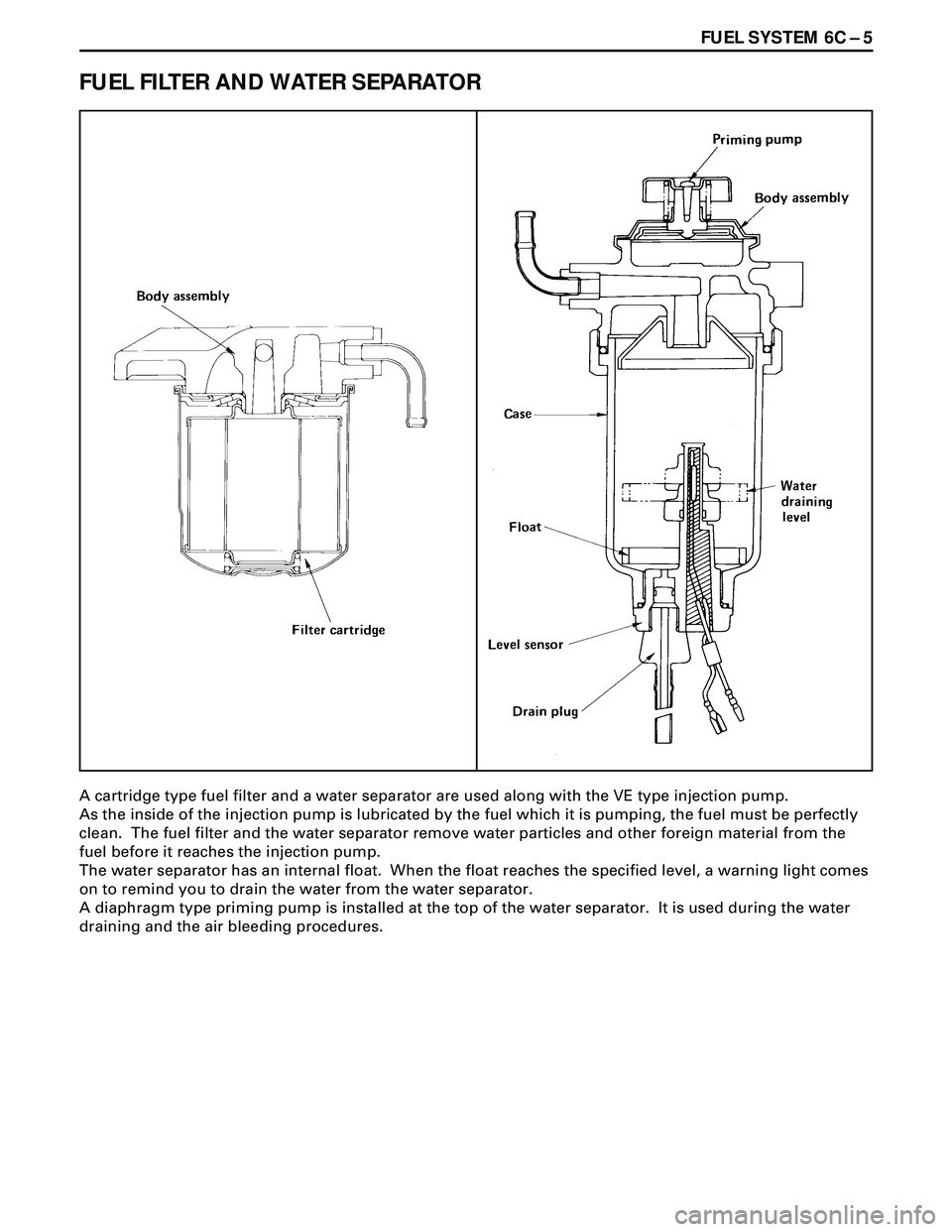

FUEL FILTER AND WATER SEPARATOR

A cartridge type fuel filter and a water separator are used along with the VE type injection pump.

As the inside of the injection pump is lubricated by the fuel which it is pumping, the fuel must be perfectly

clean. The fuel filter and the water separator remove water particles and other foreign material from the

fuel before it reaches the injection pump.

The water separator has an internal float. When the float reaches the specified level, a warning light comes

on to remind you to drain the water from the water separator.

A diaphragm type priming pump is installed at the top of the water separator. It is used during the water

draining and the air bleeding procedures.

Page 1674 of 3573

6C Ð 8 FUEL SYSTEM

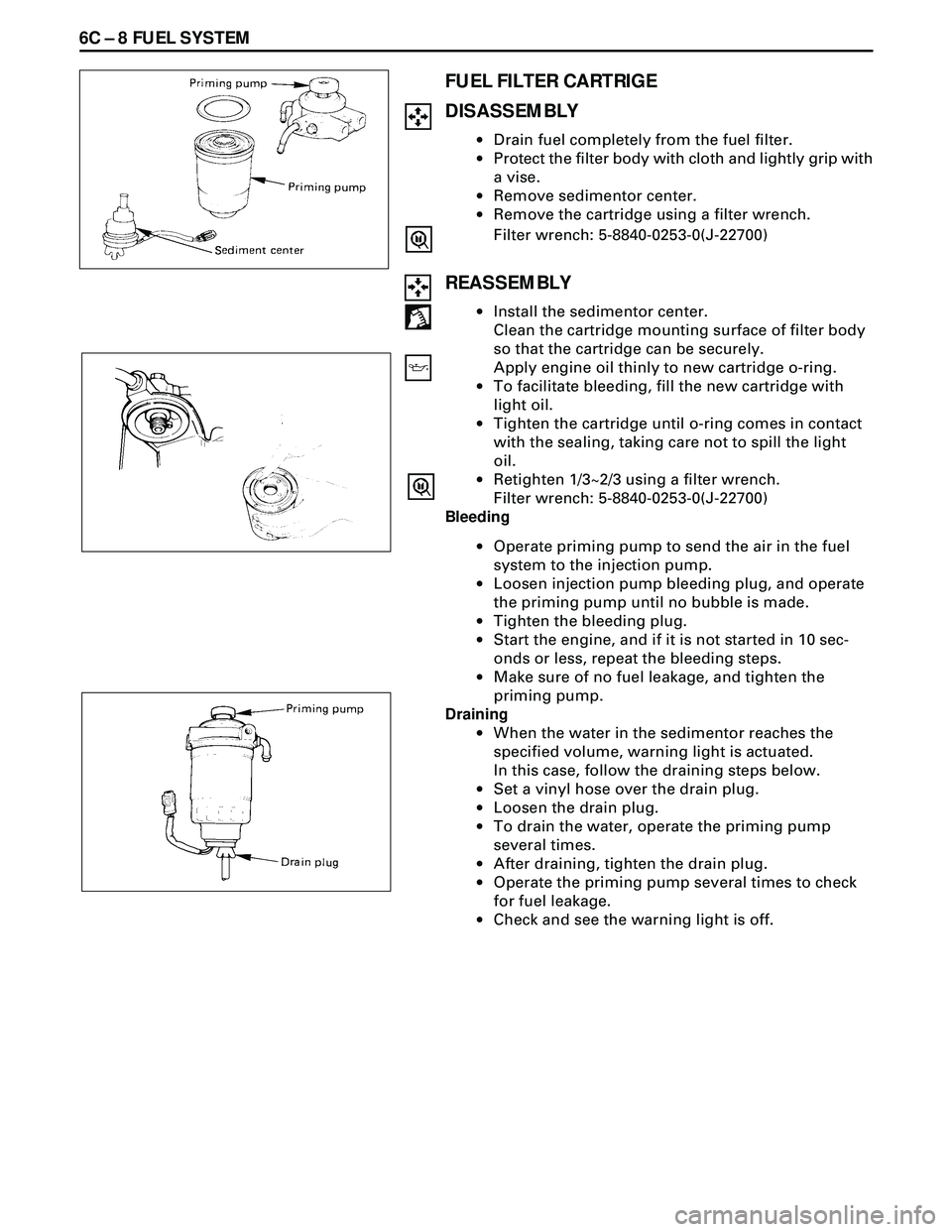

FUEL FILTER CARTRIGE

DISASSEMBLY

·Drain fuel completely from the fuel filter.

·Protect the filter body with cloth and lightly grip with

a vise.

·Remove sedimentor center.

·Remove the cartridge using a filter wrench.

Filter wrench: 5-8840-0253-0(J-22700)

REASSEMBLY

·Install the sedimentor center.

Clean the cartridge mounting surface of filter body

so that the cartridge can be securely.

Apply engine oil thinly to new cartridge o-ring.

·To facilitate bleeding, fill the new cartridge with

light oil.

·Tighten the cartridge until o-ring comes in contact

with the sealing, taking care not to spill the light

oil.

·Retighten 1/3~2/3 using a filter wrench.

Filter wrench: 5-8840-0253-0(J-22700)

Bleeding

·Operate priming pump to send the air in the fuel

system to the injection pump.

·Loosen injection pump bleeding plug, and operate

the priming pump until no bubble is made.

·Tighten the bleeding plug.

·Start the engine, and if it is not started in 10 sec-

onds or less, repeat the bleeding steps.

·Make sure of no fuel leakage, and tighten the

priming pump.

Draining

·When the water in the sedimentor reaches the

specified volume, warning light is actuated.

In this case, follow the draining steps below.

·Set a vinyI hose over the drain plug.

·Loosen the drain plug.

·To drain the water, operate the priming pump

several times.

·After draining, tighten the drain plug.

·Operate the priming pump several times to check

for fuel leakage.

·Check and see the warning light is off.

Page 1676 of 3573

6C Ð 10 FUEL SYSTEM

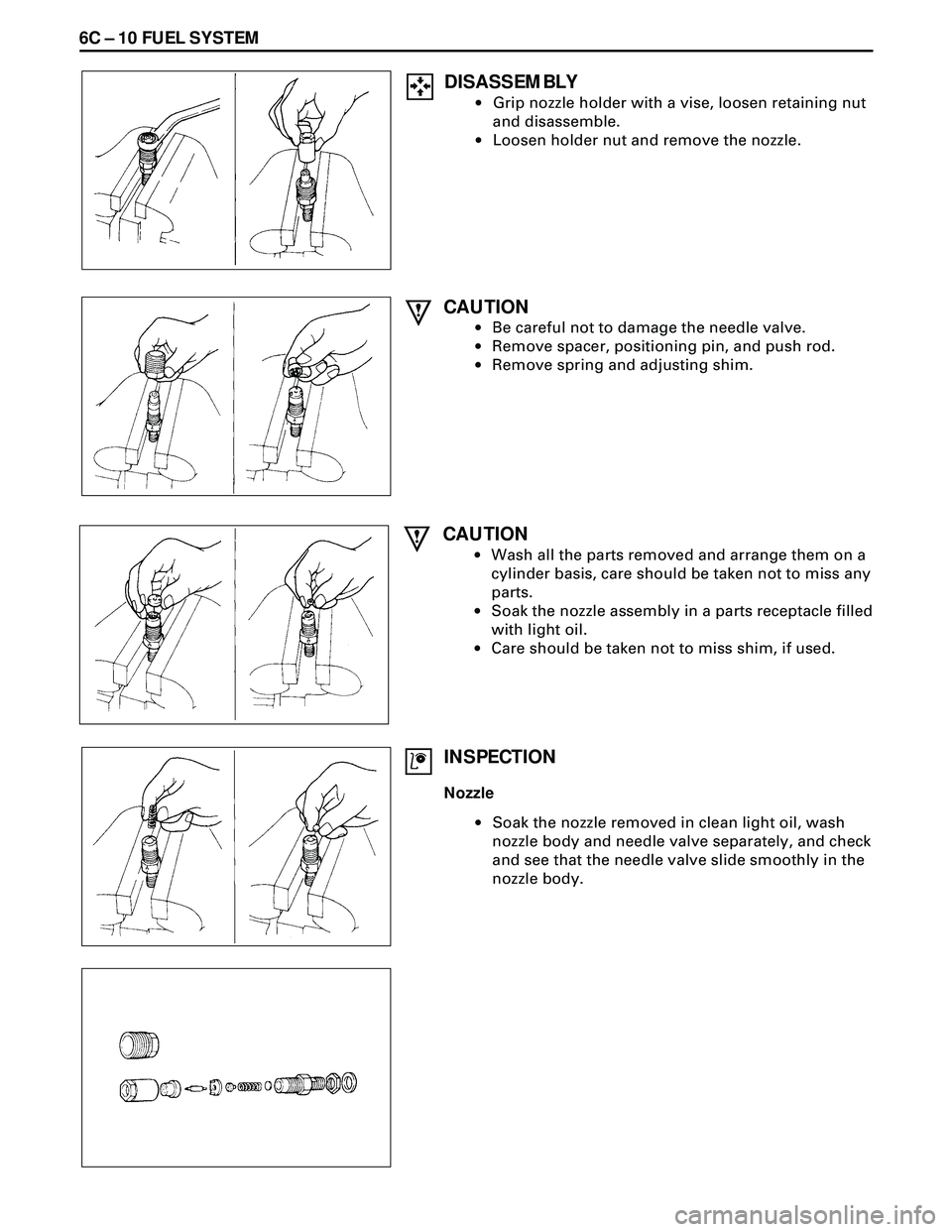

DISASSEMBLY

·Grip nozzle holder with a vise, loosen retaining nut

and disassemble.

·Loosen holder nut and remove the nozzle.

CAUTION

·Be careful not to damage the needle valve.

·Remove spacer, positioning pin, and push rod.

·Remove spring and adjusting shim.

CAUTION

·Wash all the parts removed and arrange them on a

cylinder basis, care should be taken not to miss any

parts.

·Soak the nozzle assembly in a parts receptacle filled

with light oil.

·Care should be taken not to miss shim, if used.

INSPECTION

Nozzle

·Soak the nozzle removed in clean light oil, wash

nozzle body and needle valve separately, and check

and see that the needle valve slide smoothly in the

nozzle body.

Page 1678 of 3573

6C Ð 12 FUEL SYSTEM

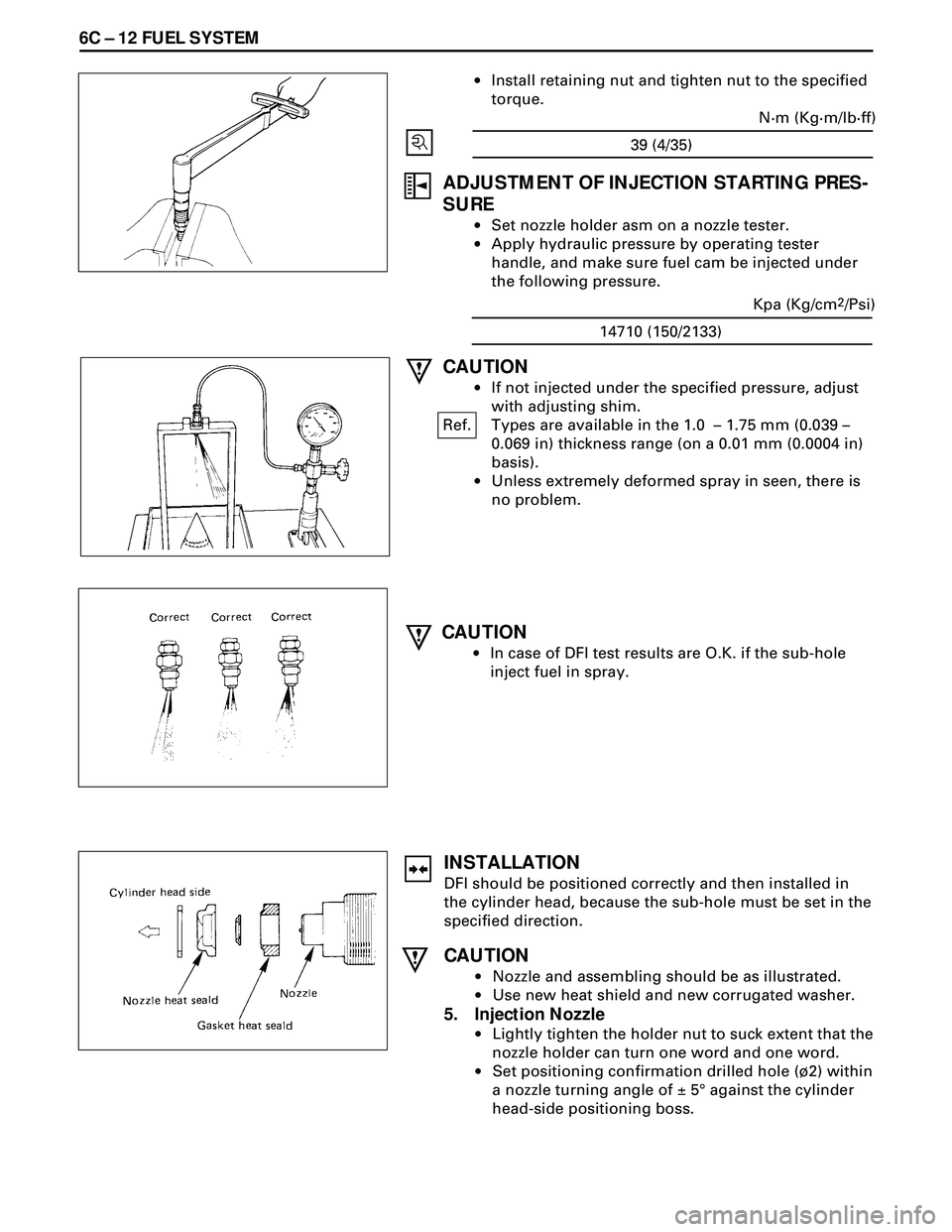

·Install retaining nut and tighten nut to the specified

torque.

ADJUSTMENT OF INJECTION STARTING PRES-

SURE

·Set nozzle holder asm on a nozzle tester.

·Apply hydraulic pressure by operating tester

handle, and make sure fuel cam be injected under

the following pressure.

CAUTION

·In case of DFI test results are O.K. if the sub-hole

inject fuel in spray.

14710 (150/2133)Kpa (Kg/cm

2/Psi)

CAUTION

·If not injected under the specified pressure, adjust

with adjusting shim.

Ref. Types are available in the 1.0 Ð 1.75 mm (0.039 Ð

0.069 in) thickness range (on a 0.01 mm (0.0004 in)

basis).

·Unless extremely deformed spray in seen, there is

no problem.

INSTALLATION

DFI should be positioned correctly and then installed in

the cylinder head, because the sub-hole must be set in the

specified direction.

CAUTION

·Nozzle and assembling should be as illustrated.

·Use new heat shield and new corrugated washer.

5. Injection Nozzle

·Lightly tighten the holder nut to suck extent that the

nozzle holder can turn one word and one word.

·Set positioning confirmation drilled hole (¿2) within

a nozzle turning angle of ± 5¡ against the cylinder

head-side positioning boss.

39 (4/35)N·m (Kg·m/lb·ff)

Page 1691 of 3573

ENGINE ELECTRICAL 6D1 Ð 1

SECTION 6D

ENGINE ELECTRICAL

CONTENTS

Battery................................................................................................................................... Section 6D1

Starting System ................................................................................................................... Section 6D2

Charging System.................................................................................................................. Section 6D3

QOS-IIIPreheating System ................................................................................................. Section 6D6

SECTION 6D1

BATTERY

CONTENTS

General Description ......................................... 6D1Ð1

Diagnosis .......................................................... 6D1Ð1

On-Vehicle Service........................................... 6D1Ð3

Battery Charging .......................................... 6D1Ð3Jump Starting .............................................. 6D1Ð3

Removal and Installation of Battery .......... 6D1Ð4

GENERAL DESCRIPTION

There are six battery fluid caps at the top of the

battery. These are covered by a paper label.

The battery is completely sealed except for the six

small vent holes at the side. These vent holes per-

mit the escape of small amounts of gas generated

by the battery.

This type of battery has the following advantages

over conventional batteries:1. There is no need to add water during the entire

service life of the battery.

2. The battery protects itself against overcharging.

The battery will refuse to accept an excessive

charge.

(A conventional battery will accept an excessive

charge, resulting in gassing and loss of battery

fluid.)

3. The battery is much less vulnerable to self-

discharge than a conventional type battery.

DIAGNOSIS

1. VISUAL INSPECTION

Inspect the battery for obvious physical damage,

such as a cracked or broken case, which would

permit electrolyte loss.

Replace the battery if obvious physical damage is

discovered during inspection.

Check for any other physical damage and correct it

as necessary. If not, proceed to Step 2.

2. HYDROMETER CHECK

There is a built-in hydrometer (Charge test indica-

tor) at the top of the battery. It is designed to be

used during diagnostic procedures.Before trying to read the hydrometer, carefully

clean the upper battery surface.

If your work area is poorly lit, additional light may

be necessary to read the hydrometer.

a. BLUE RING OR DOT VISIBLE Ð Go to Step

4.

b. BLUE RING OR DOT NOT VISIBLE Ð Go to

Step 3.

Page 1693 of 3573

ENGINE ELECTRICAL 6D1 Ð 3

BATTERY CHARGING

Observe the following safety precautions when

charging the battery:

1. Never attempt to charge the battery when the

fluid level is below the lower level line on the

side of the battery. In this case, the battery

must be replaced.

2. Pay close attention to the battery during the

charging procedure.

Battery charging should be discontinued or the

rate of charge reduced if the battery feels hot to

the touch.

Battery charging should be discontinued or the

rate of charge reduced if the battery begins to

gas or spew electrolyte from the vent holes.

3. In order to more easily view the hydrometer

blue dot or ring, it may be necessary to jiggle or

tilt the battery.

4. Battery temperature can have a great effect on

battery charging capacity.

5. The sealed battery used on this vehicle may be

either quick-charged or slow-charged in the

same manner as other batteries.

Whichever method you decide to use, be sure

that you completely charge the battery. Never

partially charge the battery.

JUMP STARTING

JUMP STARTING WITH AN AUXILIARY

(BOOSTER) BATTERY

CAUTION:

Never push or tow the vehicle in an attempt to

start it. Serious damage to the emission system

as well as other vehicle parts will result.

Treat both the discharged battery and the

booster battery with great care when using

jumper cables. Carefully follow the jump

starting procedure, being careful at all times to

avoid sparking.

WARNING:

Failure to carefully follow the jump starting

procedure could result in the following:

1. Serious personal injury, particulaly to

your eyes.

2. Property damage from a battery explo-

sion, battery acid, or an electrical fire.

3. Damage to the electronic components of

one or both vehicles particularly. Never expose the battery to an open flame or elec-

trical spark. Gas generated by the battery may catch

fire or explode.

Remove any rings, watches, or other jewelry before

working around the battery. Protect your eyes by

wearing an approved set of goggles.

Never allow battery fluid to come in contact with

your eyes or skin.

Never allow battery fluid to come in contact with

fabrics or painted surfaces.

Battery fluid is a highly corrosive acid.

Should battery fluid come in contact with your

eyes, skin, fabric, or a painted surface, immediately

and thoroughly rinse the affected area with clean

tap water.

Never allow metal tools or jumper cables to come

in contact with the positive battery terminal, or any

other metal surface of the vehicle. This will protect

against a short circuit.

Always keep batteries out of the reach of young

children.

JUMP STARTING PROCEDURE

1. Set the vehicle parking brake.

If the vehicle is equipped with an automatic

transmission, place the selector lever in the

ÒPARKÓ position.

If the vehicle is equipped with a manual trans-

mission place the shift lever in the ÒNEUTRALÓ

position.

Turn ÒOFFÓ the ignition.

Turn ÒOFFÓ all lights and any other accessory

requiring electrical power.

2. Look at the built-in hydrometer.

If the indication area of the built-in hydrometer

is completely clear, do not try to jump start.

3. Attach the end of one jumper cable to the posi-

tive terminal of the booster battery.

Attach the other end of the same cable to the

positive terminal of the discharged battery.

Do not allow the vehicles to touch each other.

This will cause a ground connection, effectively

neutralizing the charging procedure.

Be sure that the booster battery has a 12 volt

rating.

4. Attach one end of the remaining cable to the

negative terminal of the booster battery.

Attach the other end of the same cable to a

solid engine ground (such as the A/C com-

pressor bracket or the generator mounting

bracket) of the vehicle with the discharged bat-

tery.

This ground connection must be at least 450

mm (18 in) from the battery of the vehicle

whose battery is being charged.

ON-VEHICLE SERVICE

Page 1716 of 3573

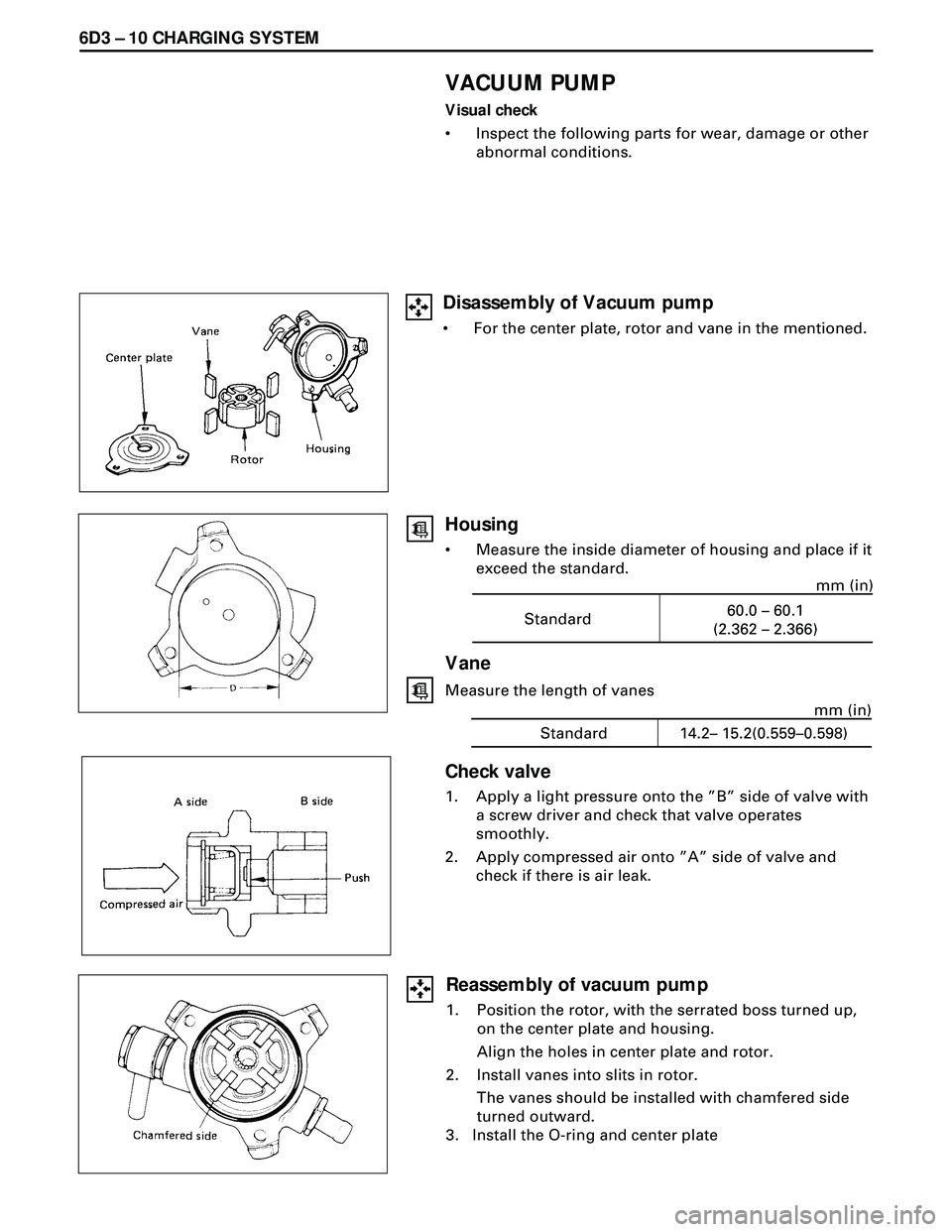

6D3 Ð 10 CHARGING SYSTEM

VACUUM PUMP

Visual check

¥ Inspect the following parts for wear, damage or other

abnormal conditions.

Standard60.0 – 60.1

(2.362 – 2.366)mm (in)

Vane

Measure the length of vanes

Standard 14.2– 15.2(0.559–0.598)mm (in)

Check valve

1. Apply a light pressure onto the ÓBÓ side of valve with

a screw driver and check that valve operates

smoothly.

2. Apply compressed air onto ÓAÓ side of valve and

check if there is air leak.

Housing

¥ Measure the inside diameter of housing and place if it

exceed the standard.

Reassembly of vacuum pump

1. Position the rotor, with the serrated boss turned up,

on the center plate and housing.

Align the holes in center plate and rotor.

2. Install vanes into slits in rotor.

The vanes should be installed with chamfered side

turned outward.

3. Install the O-ring and center plate

Disassembly of Vacuum pump

¥ For the center plate, rotor and vane in the mentioned.

Page 1720 of 3573

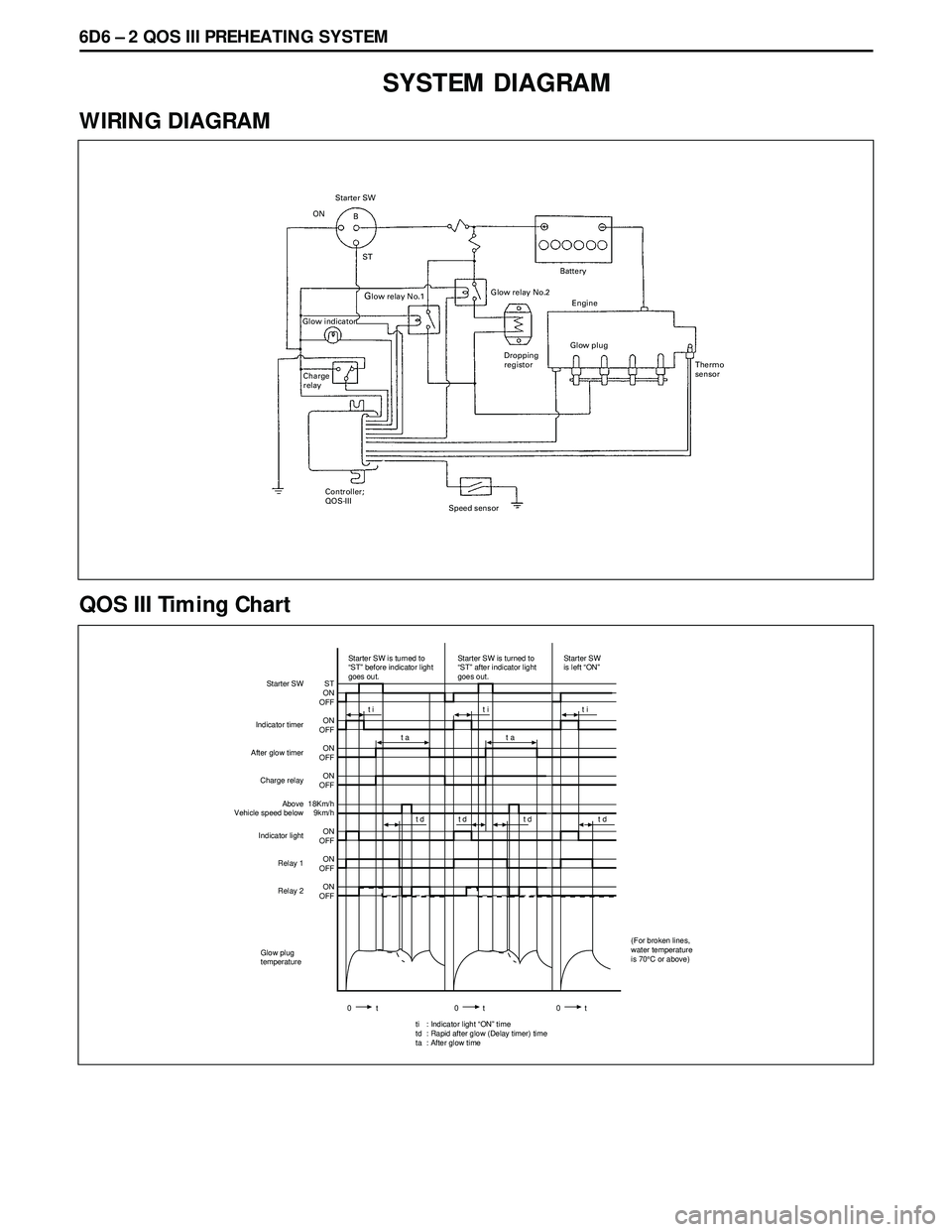

6D6 Ð 2 QOS III PREHEATING SYSTEM

SYSTEM DIAGRAM

WIRING DIAGRAM

ON

B

ST

Glow relay No.1 Starter SW

Battery

Engine Glow relay No.2

Glow indicator

Charge

relayGlow plug

Thermo

sensor

Controller;

QOS-III

Speed sensorDropping

registor

QOS III Timing Chart

ST

ON

OFF

ON

OFF

ON

OFF

ON

OFF

18Km/h

9km/h

ON

OFF

ON

OFF

ON

OFF Starter SW

Starter SW is turned to

“ST” before indicator light

goes out.Starter SW is turned to

“ST” after indicator light

goes out.Starter SW

is left “ON”

Indicator timer

After glow timer

Charge relay

Indicator light

Relay 1

Relay 2Above

Vehicle speed below

t i t i t i

t a t a

t d t d t d t d

Glow plug

temperature

0t 0t 0t

: Indicator light “ON” time

: Rapid after glow (Delay timer) time

: After glow time

ti

td

ta

(For broken lines,

water temperature

is 70¡C or above)

Page 1722 of 3573

6D6 Ð 4 QOS III PREHEATING SYSTEM

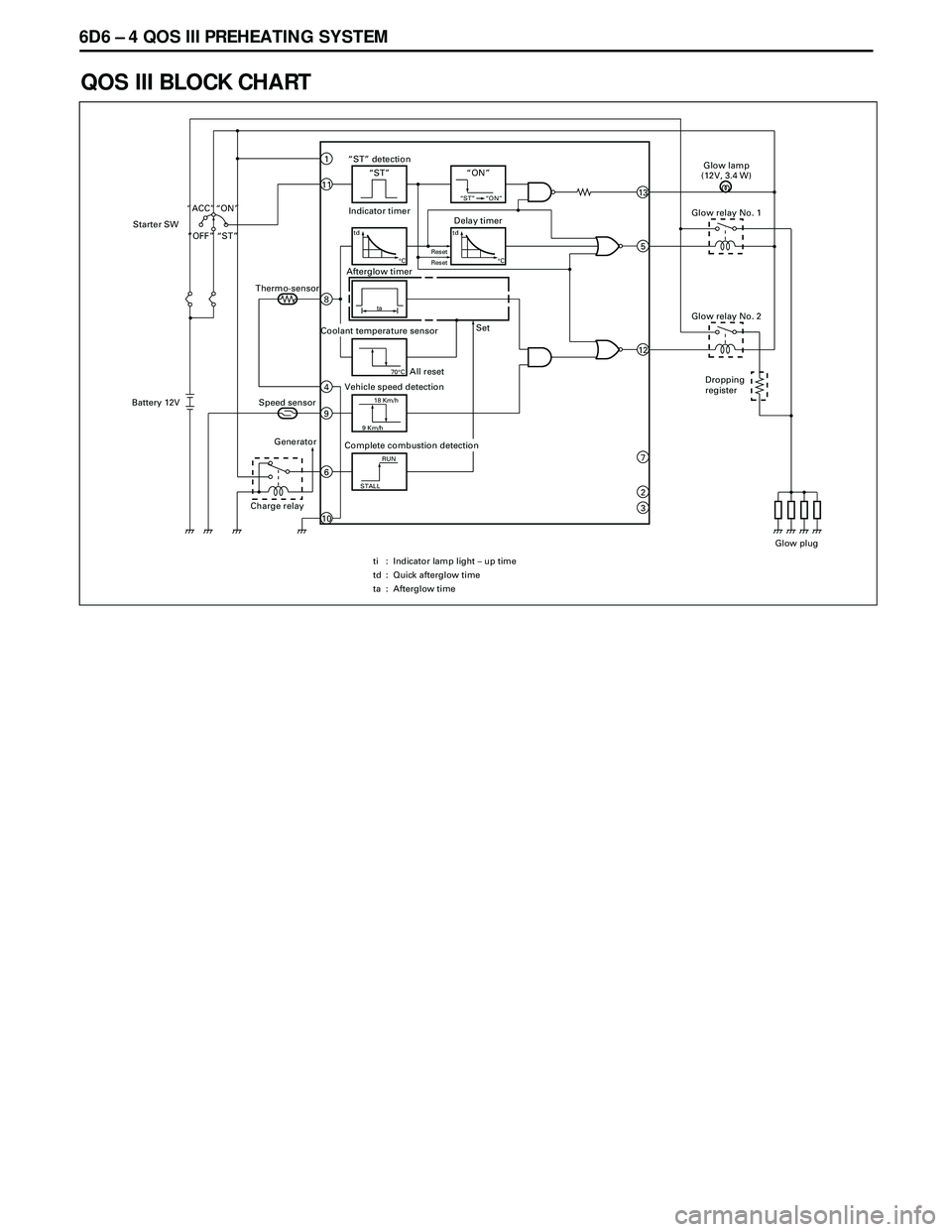

QOS III BLOCK CHART

“ST” detection“ST”

Indicator timer

11

1“ON”

“ST” “ON”13

tdDelay timer

¡C

td

¡CResetReset5

ta

Afterglow timer

Coolant temperature sensor

70¡CAll reset

12

Vehicle speed detection

9 Km/h18 Km/h

Complete combustion detection

STALLRUN

Set 8

4

9

6

10

Thermo-sensor

Speed sensor

Generator

Charge relay

Glow relay No. 1

Glow lamp

(12V, 3.4 W)

Glow relay No. 2

Glow plug

Battery 12VStarter SW

“OFF” “ST” “ACC” “ON”

: Indicator lamp light – up time

: Quick afterglow time

: Afterglow time ti

td

ta7

2

3

Dropping

register

Page 1723 of 3573

QOS III PREHEATING SYSTEM 6D6 Ð 5

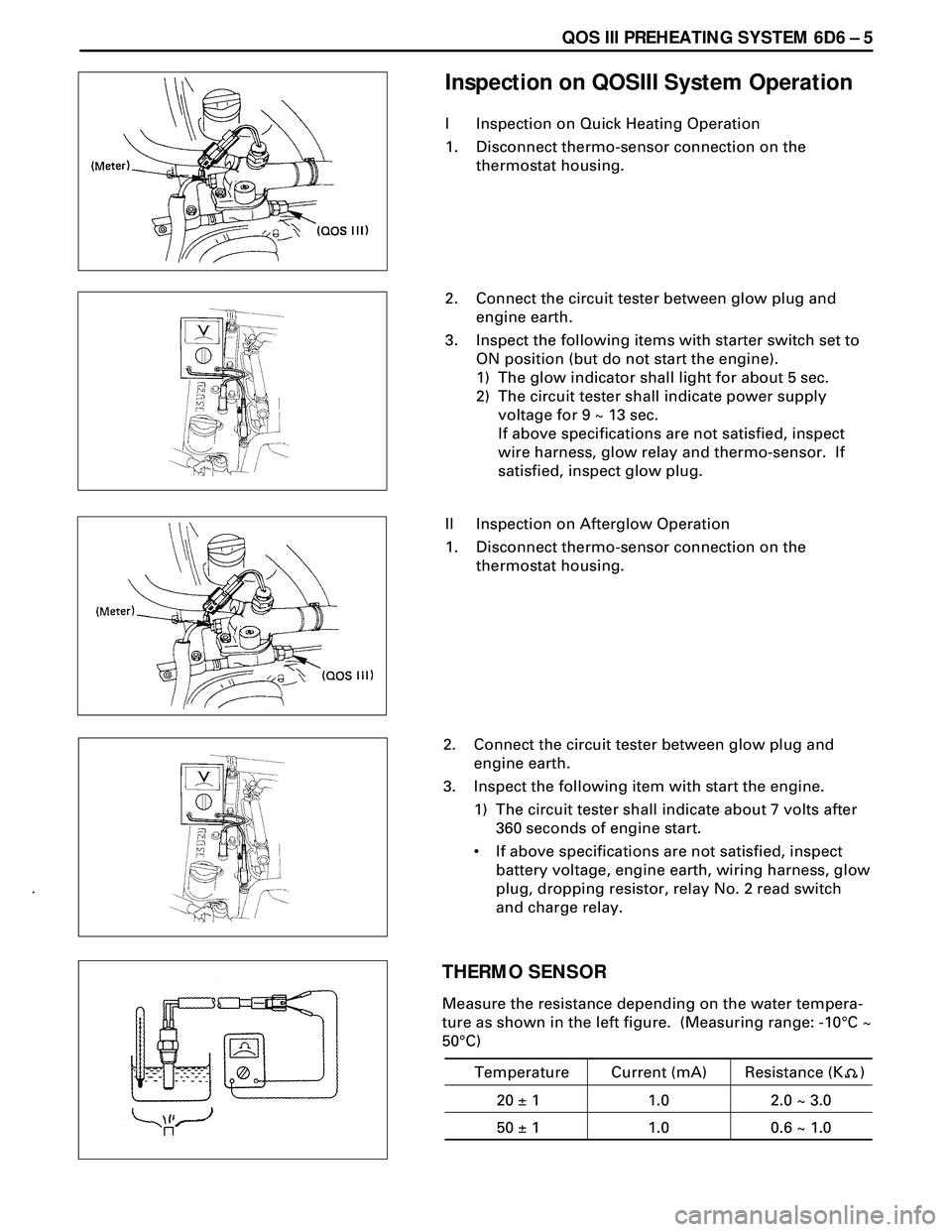

Inspection on QOSIII System Operation

I Inspection on Quick Heating Operation

1. Disconnect thermo-sensor connection on the

thermostat housing.

2. Connect the circuit tester between glow plug and

engine earth.

3. Inspect the following items with starter switch set to

ON position (but do not start the engine).

1) The glow indicator shall light for about 5 sec.

2) The circuit tester shall indicate power supply

voltage for 9 ~ 13 sec.

If above specifications are not satisfied, inspect

wire harness, glow relay and thermo-sensor. If

satisfied, inspect glow plug.

II Inspection on Afterglow Operation

1. Disconnect thermo-sensor connection on the

thermostat housing.

2. Connect the circuit tester between glow plug and

engine earth.

3. Inspect the following item with start the engine.

1) The circuit tester shall indicate about 7 volts after

360 seconds of engine start.

¥ If above specifications are not satisfied, inspect

battery voltage, engine earth, wiring harness, glow

plug, dropping resistor, relay No. 2 read switch

and charge relay.

THERMO SENSOR

Measure the resistance depending on the water tempera-

ture as shown in the left figure. (Measuring range: -10¡C ~

50¡C)

Current (mA)

20 ± 1 1.0

50 ± 1Resistance (K )

1.0

2.0 ~ 3.0

0.6 ~ 1.0 Temperature