heater ISUZU TROOPER 1998 Service User Guide

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 59 of 3573

00 Ð 20 SERVICE INFORMATION

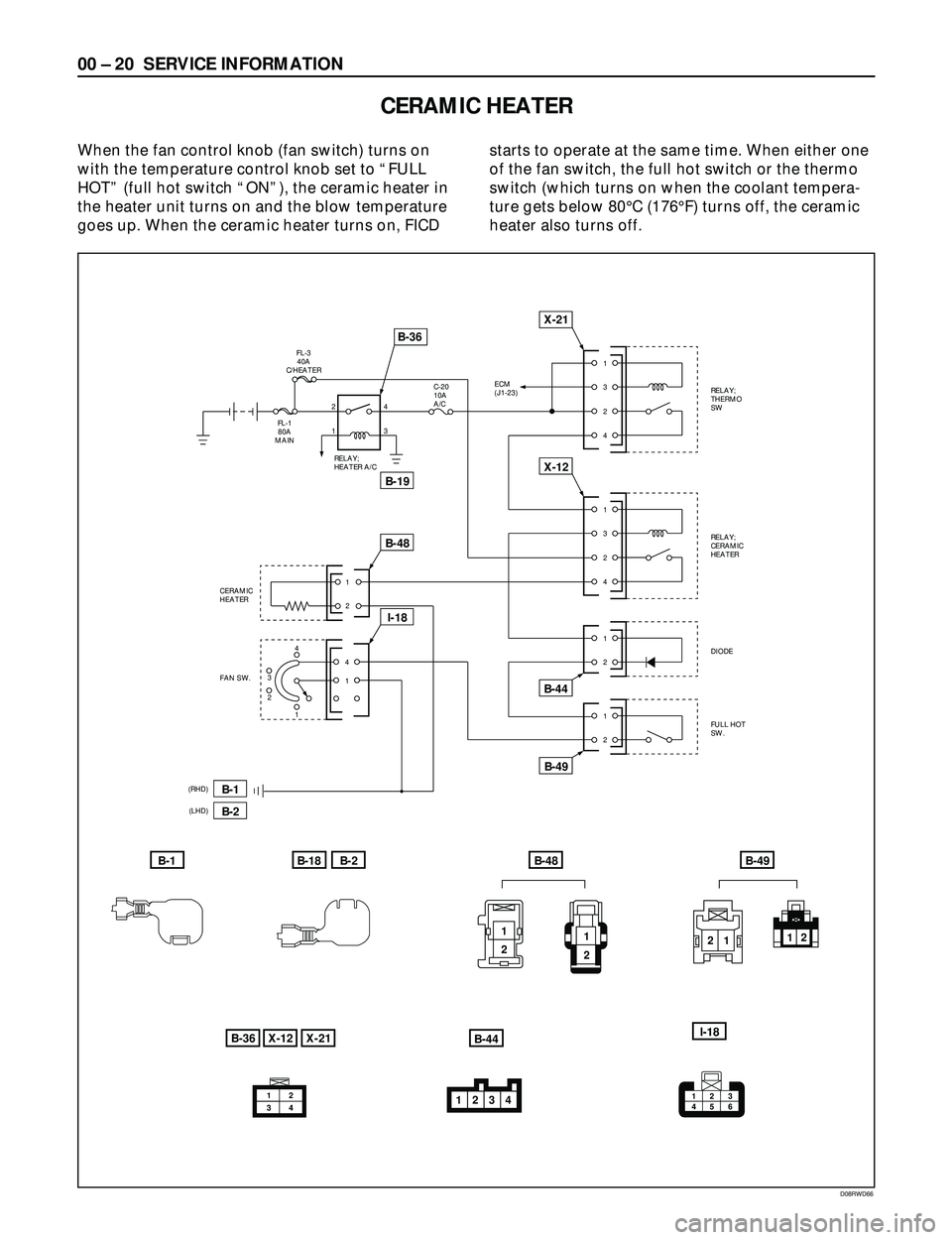

CERAMIC HEATER

When the fan control knob (fan switch) turns on

with the temperature control knob set to ÒFULL

HOTÓ (full hot switch ÒONÓ), the ceramic heater in

the heater unit turns on and the blow temperature

goes up. When the ceramic heater turns on, FICDstarts to operate at the same time. When either one

of the fan switch, the full hot switch or the thermo

switch (which turns on when the coolant tempera-

ture gets below 80°C (176°F) turns off, the ceramic

heater also turns off.

FL-3

40A

C/HEATER

RELAY;

HEATER A/CECM

(J1-23)

24

13

C-20

10A

A/C

FL-1

80A

MAIN

B-18B-1

B-36

1

3

X-12

2

4

1

3

X-21

2

4

1

2

1

2

4

13

24

1

1

2CERAMIC

HEATER

FAN SW.

B-19

B-48

I-18

B-44

B-49

RELAY;

THERMO

SW

RELAY;

CERAMIC

HEATER

DIODE

FULL HOT

SW.

B-1

B-48

1

21

22112

B-49

I-18

213

5 4612

34

B-36X-12X-21

1234

B-44

(RHD)

B-2(LHD)

B-2

D08RWD66

Page 60 of 3573

SERVICE INFORMATION 00 Ð 21

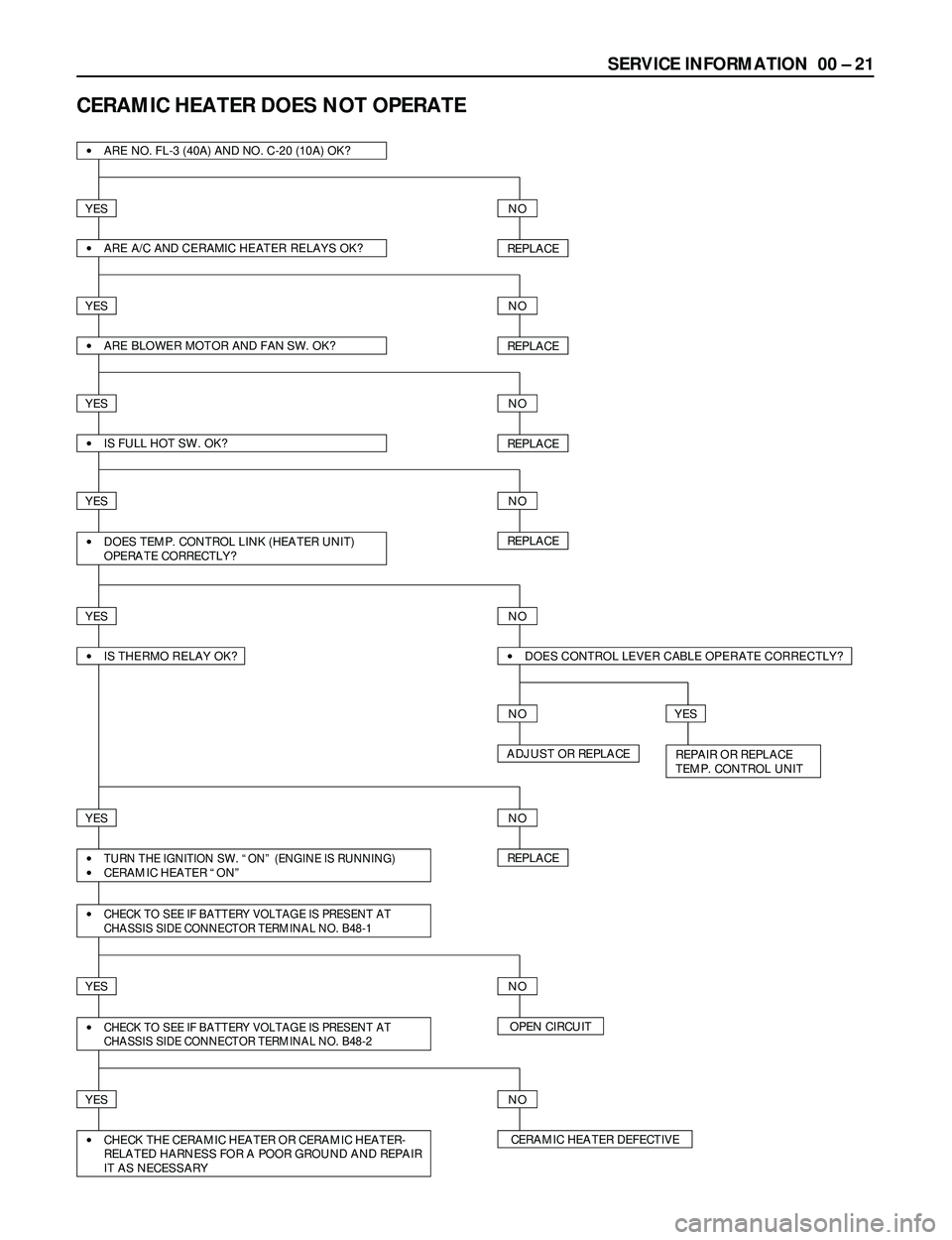

CERAMIC HEATER DOES NOT OPERATE

·ARE NO. FL-3 (40A) AND NO. C-20 (10A) OK?

YESNO

REPLACE

REPLACE

REPLACE

REPLACE

·ARE A/C AND CERAMIC HEATER RELAYS OK?

YESNO

·ARE BLOWER MOTOR AND FAN SW. OK?

YESNO

·IS FULL HOT SW. OK?

·DOES TEMP. CONTROL LINK (HEATER UNIT)

OPERATE CORRECTLY?

YESNO

REPLACE·TURN THE IGNITION SW. ÒONÓ (ENGINE IS RUNNING)·CERAMIC HEATER ÒONÓ

·CHECK TO SEE IF BATTERY VOLTAGE IS PRESENT AT

CHASSIS SIDE CONNECTOR TERMINAL NO. B48-1

YESNO

OPEN CIRCUIT·CHECK TO SEE IF BATTERY VOLTAGE IS PRESENT AT

CHASSIS SIDE CONNECTOR TERMINAL NO. B48-2

YESNO

CERAMIC HEATER DEFECTIVE·CHECK THE CERAMIC HEATER OR CERAMIC HEATER-

RELATED HARNESS FOR A POOR GROUND AND REPAIR

IT AS NECESSARY

YESNO

·DOES CONTROL LEVER CABLE OPERATE CORRECTLY?·IS THERMO RELAY OK?

YESNO

NOYES

ADJUST OR REPLACEREPAIR OR REPLACE

TEMP. CONTROL UNIT

Page 61 of 3573

00 Ð 22 SERVICE INFORMATION

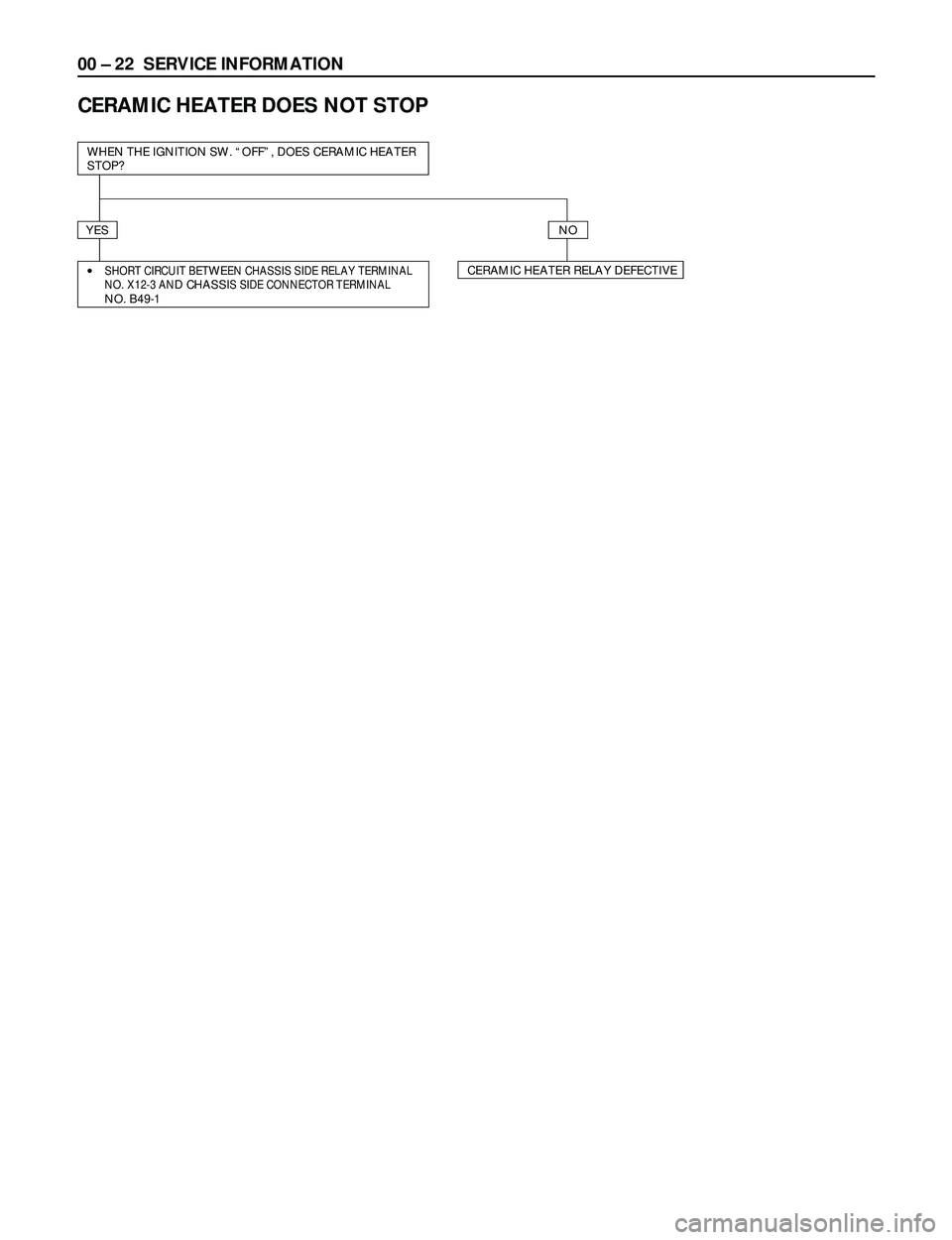

CERAMIC HEATER DOES NOT STOP

WHEN THE IGNITION SW. ÒOFFÓ, DOES CERAMIC HEATER

STOP?

YESNO

CERAMIC HEATER RELAY DEFECTIVE·SHORT CIRCUIT BETWEEN CHASSIS SIDE RELAY TERMINAL

NO. X12-3 AND CHASSIS SIDE CONNECTOR TERMINALNO. B49-1

Page 62 of 3573

SERVICE INFORMATION 00 Ð 23

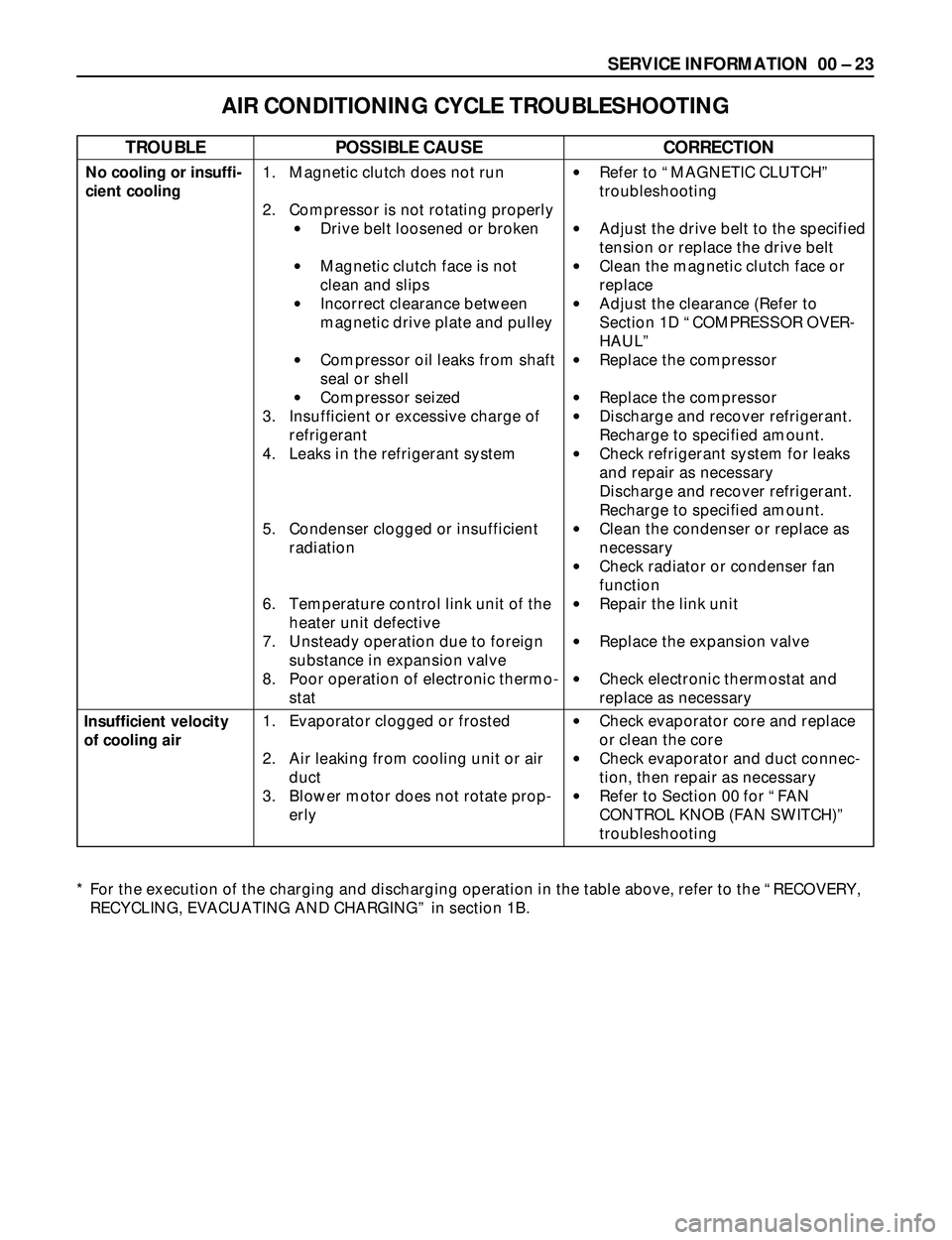

AIR CONDITIONING CYCLE TROUBLESHOOTING

No cooling or insuffi-

cient cooling

Insufficient velocity

of cooling air1. Magnetic clutch does not run

2. Compressor is not rotating properly

·Drive belt loosened or broken

·Magnetic clutch face is not

clean and slips

·Incorrect clearance between

magnetic drive plate and pulley

·Compressor oil leaks from shaft

seal or shell

·Compressor seized

3. Insufficient or excessive charge of

refrigerant

4. Leaks in the refrigerant system

5. Condenser clogged or insufficient

radiation

6. Temperature control link unit of the

heater unit defective

7. Unsteady operation due to foreign

substance in expansion valve

8. Poor operation of electronic thermo-

stat

1. Evaporator clogged or frosted

2. Air leaking from cooling unit or air

duct

3. Blower motor does not rotate prop-

erly·Refer to ÒMAGNETIC CLUTCHÓ

troubleshooting

·Adjust the drive belt to the specified

tension or replace the drive belt

·Clean the magnetic clutch face or

replace

·Adjust the clearance (Refer to

Section 1D ÒCOMPRESSOR OVER-

HAULÓ

·Replace the compressor

·Replace the compressor

·Discharge and recover refrigerant.

Recharge to specified amount.

·Check refrigerant system for leaks

and repair as necessary

Discharge and recover refrigerant.

Recharge to specified amount.

·Clean the condenser or replace as

necessary

·Check radiator or condenser fan

function

·Repair the link unit

·Replace the expansion valve

·Check electronic thermostat and

replace as necessary

·Check evaporator core and replace

or clean the core

·Check evaporator and duct connec-

tion, then repair as necessary

·Refer to Section 00 for ÒFAN

CONTROL KNOB (FAN SWITCH)Ó

troubleshooting

* For the execution of the charging and discharging operation in the table above, refer to the ÒRECOVERY,

RECYCLING, EVACUATING AND CHARGINGÓ in section 1B.

TROUBLEPOSSIBLE CAUSECORRECTION

Page 71 of 3573

00 Ð 32 SERVICE INFORMATION

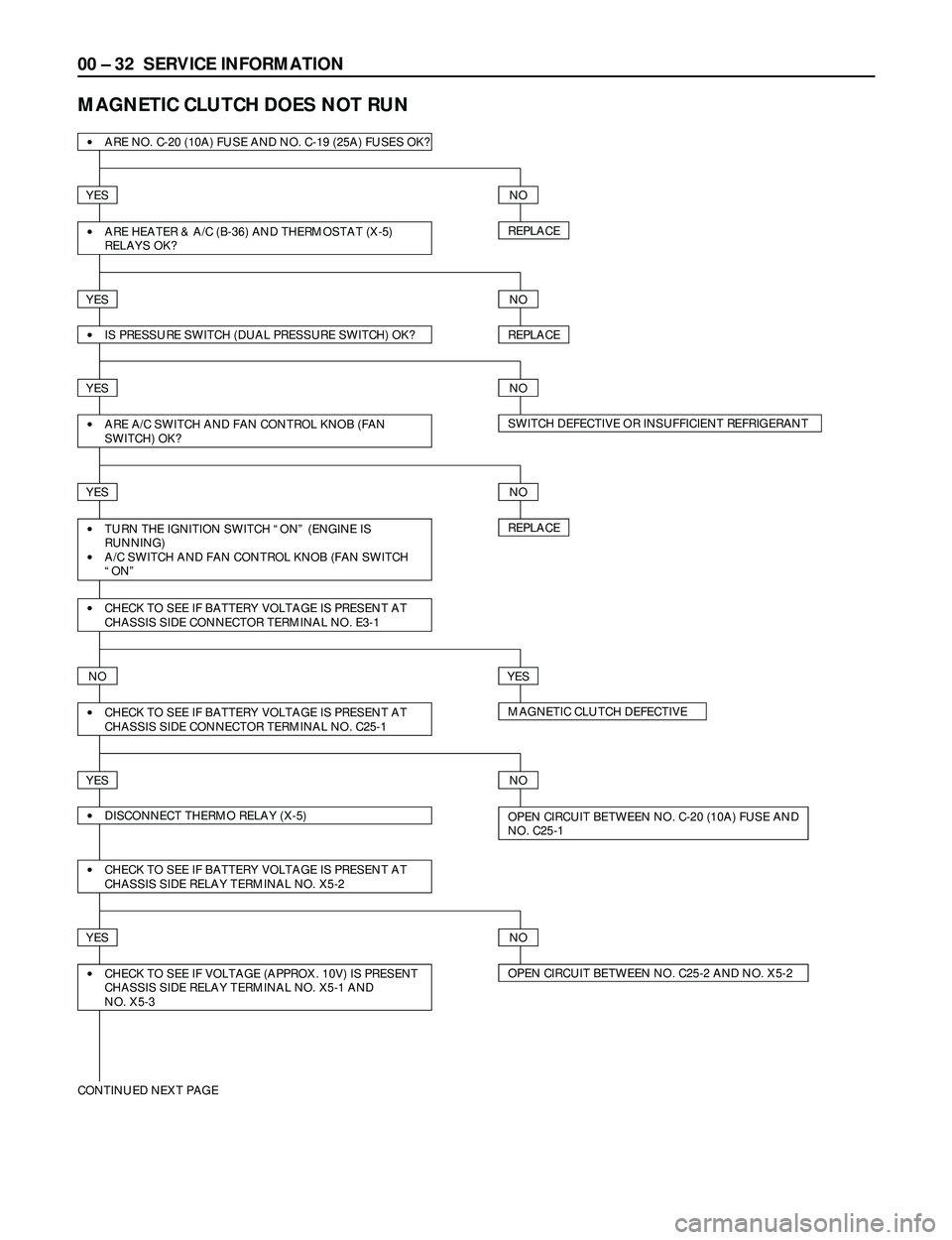

MAGNETIC CLUTCH DOES NOT RUN

·ARE NO. C-20 (10A) FUSE AND NO. C-19 (25A) FUSES OK?

YESNO

REPLACE·ARE HEATER & A/C (B-36) AND THERMOSTAT (X-5)

RELAYS OK?

YESNO

REPLACE·IS PRESSURE SWITCH (DUAL PRESSURE SWITCH) OK?

YESNO

SWITCH DEFECTIVE OR INSUFFICIENT REFRIGERANT·ARE A/C SWITCH AND FAN CONTROL KNOB (FAN

SWITCH) OK?

YESNO

REPLACE·TURN THE IGNITION SWITCH ÒONÓ (ENGINE IS

RUNNING)

·A/C SWITCH AND FAN CONTROL KNOB (FAN SWITCH

ÒONÓ

·CHECK TO SEE IF BATTERY VOLTAGE IS PRESENT AT

CHASSIS SIDE CONNECTOR TERMINAL NO. E3-1

NOYES

MAGNETIC CLUTCH DEFECTIVE ·CHECK TO SEE IF BATTERY VOLTAGE IS PRESENT AT

CHASSIS SIDE CONNECTOR TERMINAL NO. C25-1

YESNO

OPEN CIRCUIT BETWEEN NO. C-20 (10A) FUSE AND

NO. C25-1·DISCONNECT THERMO RELAY (X-5)

·CHECK TO SEE IF BATTERY VOLTAGE IS PRESENT AT

CHASSIS SIDE RELAY TERMINAL NO. X5-2

YESNO

OPEN CIRCUIT BETWEEN NO. C25-2 AND NO. X5-2 ·CHECK TO SEE IF VOLTAGE (APPROX. 10V) IS PRESENT

CHASSIS SIDE RELAY TERMINAL NO. X5-1 AND

NO. X5-3

CONTINUED NEXT PAGE

Page 80 of 3573

SERVICE INFORMATION 00 Ð 41

I-18 I-23

123456126

OFF

1

FAN SW. 2

3

4

OFF

A/C SW.

ON

FAN CONTROL KNOB (FAN SWITCH) AND A/C

SWITCH

INDIVIDUAL INSPECTION

Check for continuity between fan switch and A/C switch

side connector terminals.

2

65 4 31362

51

4

I-23I-18

I-23I-18

5

A/C SW. BEZEL

ILLUMI-

NATION

FAN SW. OFF1

2

3

4 32 6 1253641

HEATER & A/C, THERMOSTAT, COMPRESSOR,

CONDENSER FAN AND CERAMIC HEATER RELAY

Check for continuity between the relay terminals.

2Ð 4..... No continuity

(When battery voltage is applied between 1Ð 3)

2Ð 4..... Continuity

2

2

1

144

3

3

Terminal

No. SW.

position

DUAL PRESSURE SWITCH

21

Disconnect pressure switch connector and check for

continuity between pressure switch side connector

terminals.

Page 82 of 3573

SERVICE INFORMATION 00 Ð 43

CONDENSER FAN

1 2

THERMO SWITCH (ENGINE)

1 2

1) Disconnect the condenser fan connector (C-75).

2) Connect the battery positive terminal to the No. 1

terminal and negative to No. 2.

3) Be sure to check to see if condenser fan operates

correctly.

With the environmental temperature of the switch set to

the following conditions, check to see if there is any

continuity between the switch side connector terminals.

Ambient Terminal

Continuity

Temperature No.

Above 77 Ð 83°C

1Ð 2No Continuity

(170.6Ð181.4°F)

CERAMIC HEATER

1

2

Ceramic heater

Disconnect the ceramic heater connector and check for

continuity between ceramic heater side connector

terminals.

Connector No. B-48

Terminal 1 2

Continuity

Page 83 of 3573

00 Ð 44 SERVICE INFORMATION

FULL HOT SWITCH

21

Temperature

control link

Full hot switch

1) With the temperature control knob set to the full hot

position, check to see visually if the temperature

control link of the heater unit operate correctly and if

the link contacts securely with the full hot switch.

2) Disconnect the full hot switch connector.

3) With the full hot switch contacted, check to see if

there is any continuity between the switch side

connector terminals.

B-49

Terminal

Full No. 1 2

hot switch

FREE

CONTACT

Page 84 of 3573

SERVICE INFORMATION 00 Ð 45

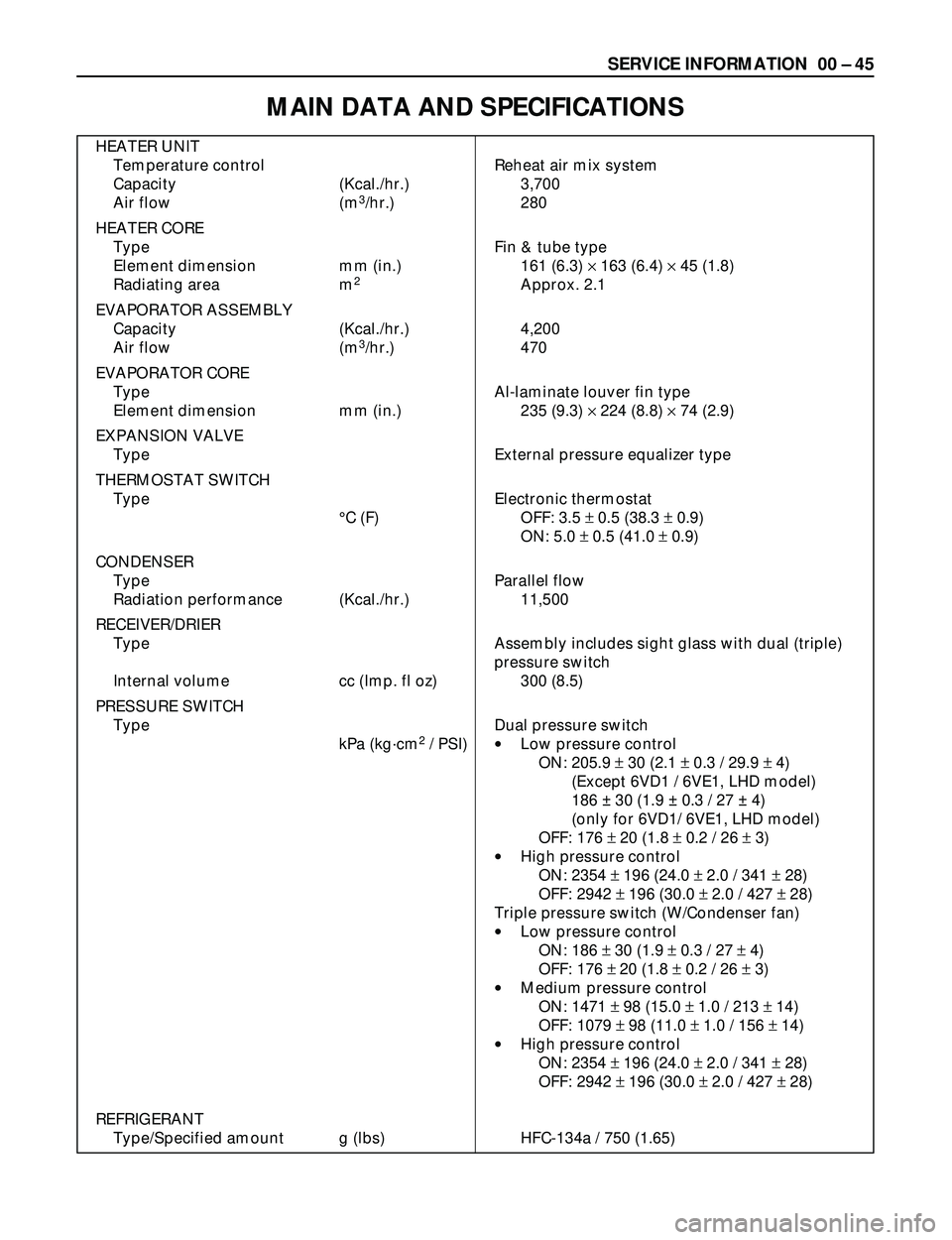

HEATER UNIT

Temperature control Reheat air mix system

Capacity (Kcal./hr.) 3,700

Air flow (m

3/hr.) 280

HEATER CORE

Type Fin & tube type

Element dimension mm (in.) 161 (6.3) ´163 (6.4) ´45 (1.8)

Radiating area m

2Approx. 2.1

EVAPORATOR ASSEMBLY

Capacity (Kcal./hr.) 4,200

Air flow (m

3/hr.) 470

EVAPORATOR CORE

Type Al-laminate louver fin type

Element dimension mm (in.) 235 (9.3) ´224 (8.8) ´74 (2.9)

EXPANSION VALVE

Type External pressure equalizer type

THERMOSTAT SWITCH

Type Electronic thermostat

°C (F) OFF: 3.5 ±0.5 (38.3 ±0.9)

ON: 5.0 ±0.5 (41.0 ±0.9)

CONDENSER

Type Parallel flow

Radiation performance (Kcal./hr.) 11,500

RECEIVER/DRIER

Type Assembly includes sight glass with dual (triple)

pressure switch

Internal volume cc (Imp. fl oz) 300 (8.5)

PRESSURE SWITCH

Type Dual pressure switch

kPa (kgácm

2/ PSI)·Low pressure control

ON: 205.9 ±30 (2.1 ±0.3 / 29.9 ±4)

(Except 6VD1 / 6VE1, LHD model)

186 ± 30 (1.9 ± 0.3 / 27 ± 4)

(only for 6VD1/ 6VE1, LHD model)

OFF: 176 ±20 (1.8 ±0.2 / 26 ±3)

·High pressure control

ON: 2354 ±196 (24.0 ±2.0 / 341 ±28)

OFF: 2942 ±196 (30.0 ±2.0 / 427 ±28)

Triple pressure switch (W/Condenser fan)

·Low pressure control

ON: 186 ±30 (1.9 ±0.3 / 27 ±4)

OFF: 176 ± 20 (1.8 ±0.2 / 26 ±3)

·Medium pressure control

ON: 1471 ±98 (15.0 ±1.0 / 213 ±14)

OFF: 1079 ±98 (11.0 ±1.0 / 156 ±14)

·High pressure control

ON: 2354 ±196 (24.0 ±2.0 / 341 ±28)

OFF: 2942 ±196 (30.0 ±2.0 / 427 ±28)

REFRIGERANT

Type/Specified amount g (lbs) HFC-134a / 750 (1.65)

MAIN DATA AND SPECIFICATIONS

Page 96 of 3573

CAUTION

When fasteners are removed, always

reinstall them at the same location from

which they were removed. If a fastener

needs to be replaced, use the correct part

number fastener for that application. If the

correct part number fastener is not available,

a fastener of equal size and strength (or

stronger) may be used. Fasteners that are not reused, and those

requiring thread locking compound, will be

called out. The correct torque values must

be used when installing fasteners that

require it. If the above conditions are not

followed, parts or system damage could

result.

HEATING AND VENTILATION 1A Ð 1

SECTION 1A

HEATING AND VENTILATION

CONTENTS

PAGE

General Description.....................................................1AÐ 2

Heater...............................................................1AÐ 2

Control Lever Assembly................................................1AÐ 3

Ventilation...........................................................1AÐ 3

Air Select Knob.......................................................1AÐ 4

Air Source Select Lever................................................1AÐ 4

Fan Control Knob.....................................................1AÐ 4

Temperature Control Knob.............................................1AÐ 4

Ceramic Heater.......................................................1AÐ 5

On-Vehicle Service......................................................1AÐ 6

Heater Unit..........................................................1AÐ 6

Heater Core and/or Mode Door..........................................1AÐ 8

Heater Mode Control Link Unit..........................................1AÐ10

Heater Temperature Control Link Unit....................................1AÐ12

Blower Assembly.....................................................1AÐ14

Blower Link Unit and/or Mode Door......................................1AÐ16

Blower Motor........................................................1AÐ18

Rear Heater Duct, Defroster Nozzle and Ventilation Duct....................1AÐ20

Center and/or Side Vent...............................................1AÐ22

Control Lever Assembly and/or Control Cables............................1AÐ24

Control Panel Illumination Bulb..........................................1AÐ27

Resistor.............................................................1AÐ28

Ceramic Heater and/or Full Hot Switch...................................1AÐ30