Remove engine ISUZU TROOPER 1998 Service Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 1537 of 3573

SERVICE INFORMATION 00 Ð 37

3. Measure the glow plug terminal voltage with a circuit

tester immediately after turning the starter switch to the

ÒONÓ position.

8 – 9

V Glow Plug Terminal Voltage

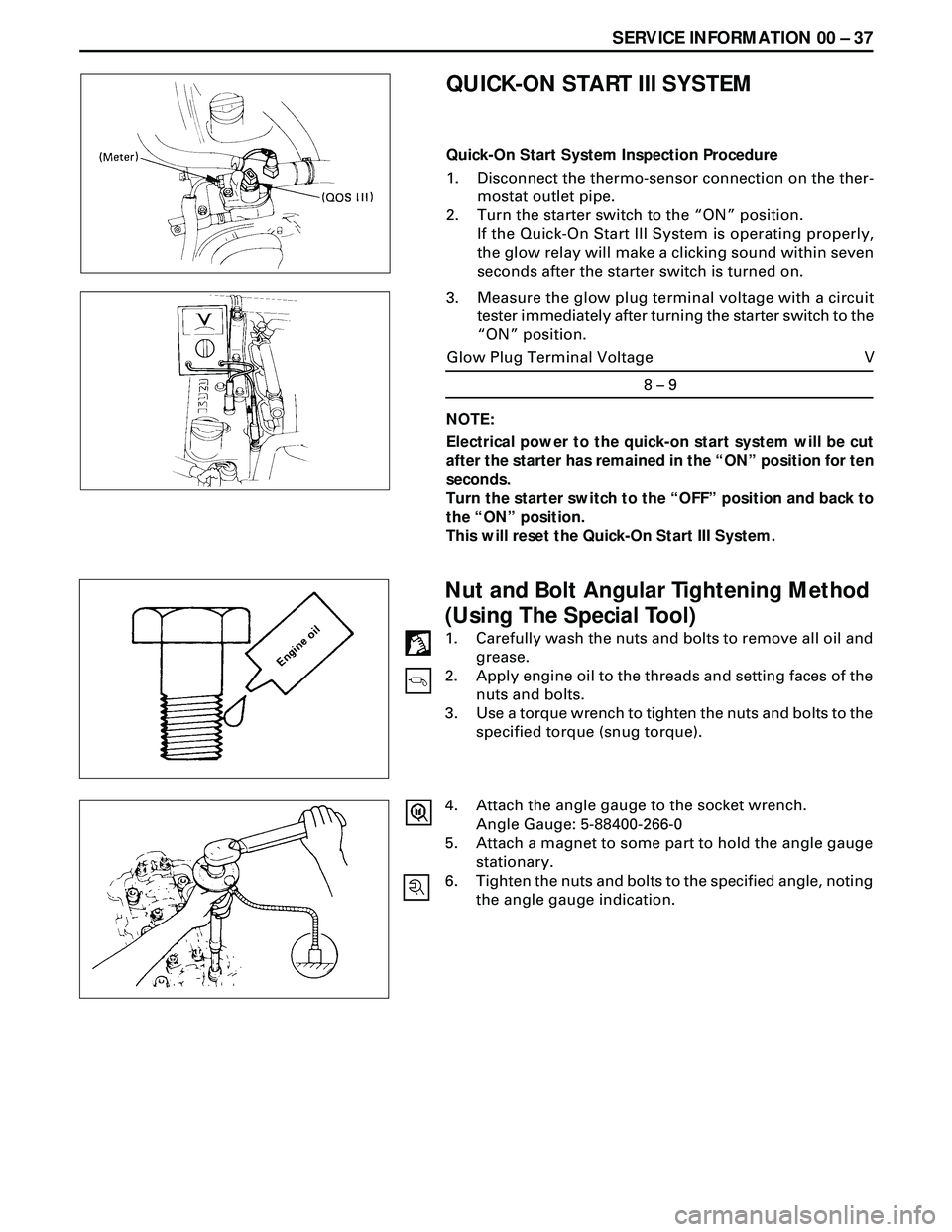

QUICK-ON START III SYSTEM

Quick-On Start System Inspection Procedure

1. Disconnect the thermo-sensor connection on the ther-

mostat outlet pipe.

2. Turn the starter switch to the ÒONÓ position.

If the Quick-On Start III System is operating properly,

the glow relay will make a clicking sound within seven

seconds after the starter switch is turned on.

NOTE:

Electrical power to the quick-on start system will be cut

after the starter has remained in the ÒONÓ position for ten

seconds.

Turn the starter switch to the ÒOFFÓ position and back to

the ÒONÓ position.

This will reset the Quick-On Start III System.

Nut and Bolt Angular Tightening Method

(Using The Special Tool)

1. Carefully wash the nuts and bolts to remove all oil and

grease.

2. Apply engine oil to the threads and setting faces of the

nuts and bolts.

3. Use a torque wrench to tighten the nuts and bolts to the

specified torque (snug torque).

4. Attach the angle gauge to the socket wrench.

Angle Gauge: 5-88400-266-0

5. Attach a magnet to some part to hold the angle gauge

stationary.

6. Tighten the nuts and bolts to the specified angle, noting

the angle gauge indication.

Page 1548 of 3573

00 Ð 48 SERVICE INFORMATION

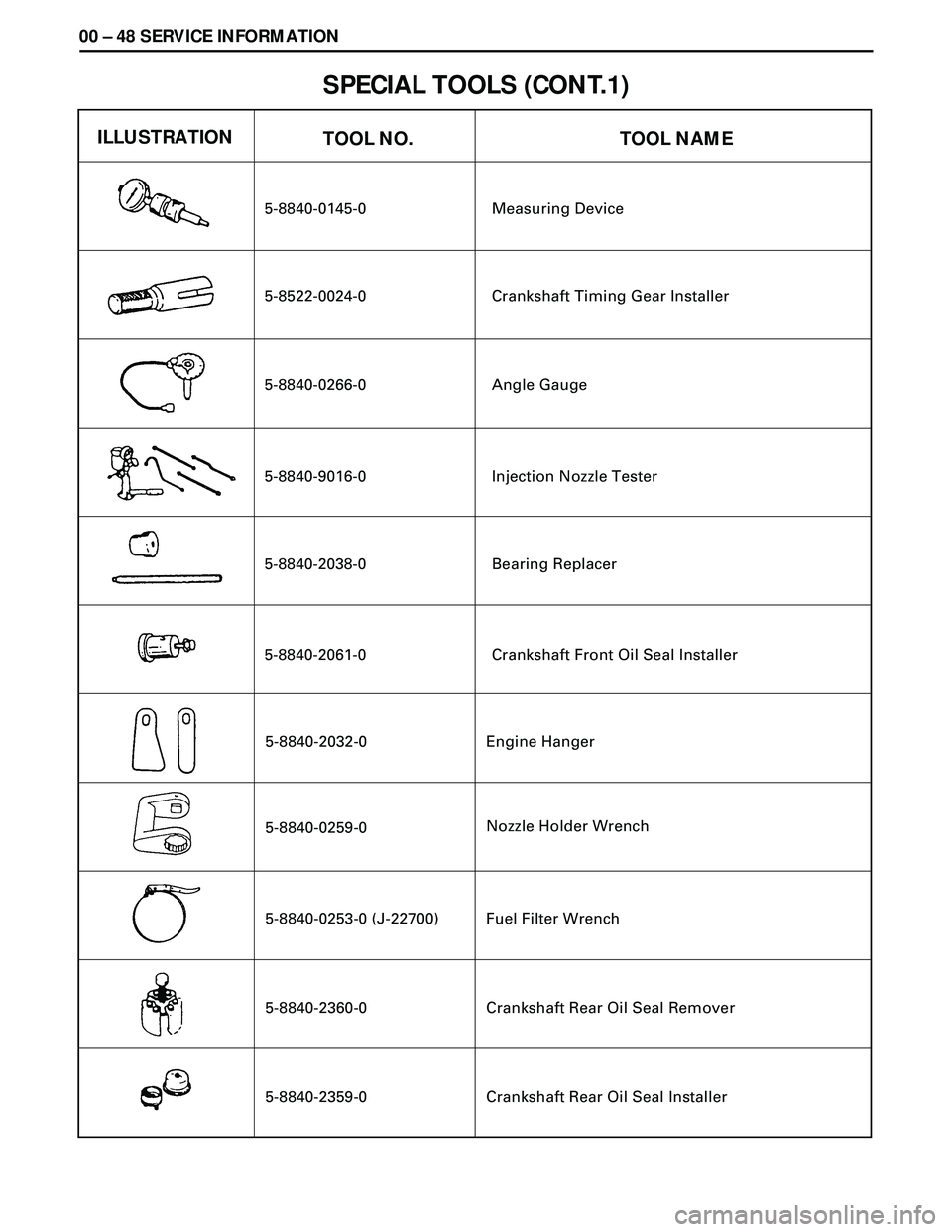

SPECIAL TOOLS (CONT.1)

5-8840-0145-0

5-8522-0024-0

5-8840-0266-0

5-8840-9016-0

5-8840-2038-0

5-8840-2061-0

ILLUSTRATION

TOOL NAME TOOL NO.

Measuring Device

Crankshaft Timing Gear Installer

Angle Gauge

Injection Nozzle Tester

Bearing Replacer

Crankshaft Front Oil Seal Installer

5-8840-2032-0

5-8840-0259-0

5-8840-0253-0 (J-22700)Engine Hanger

Nozzle Holder Wrench

Fuel Filter Wrench

5-8840-2360-0 Crankshaft Rear Oil Seal Remover

5-8840-2359-0 Crankshaft Rear Oil Seal Installer

Page 1552 of 3573

6A Ð 2 ENGINE MECHANICAL

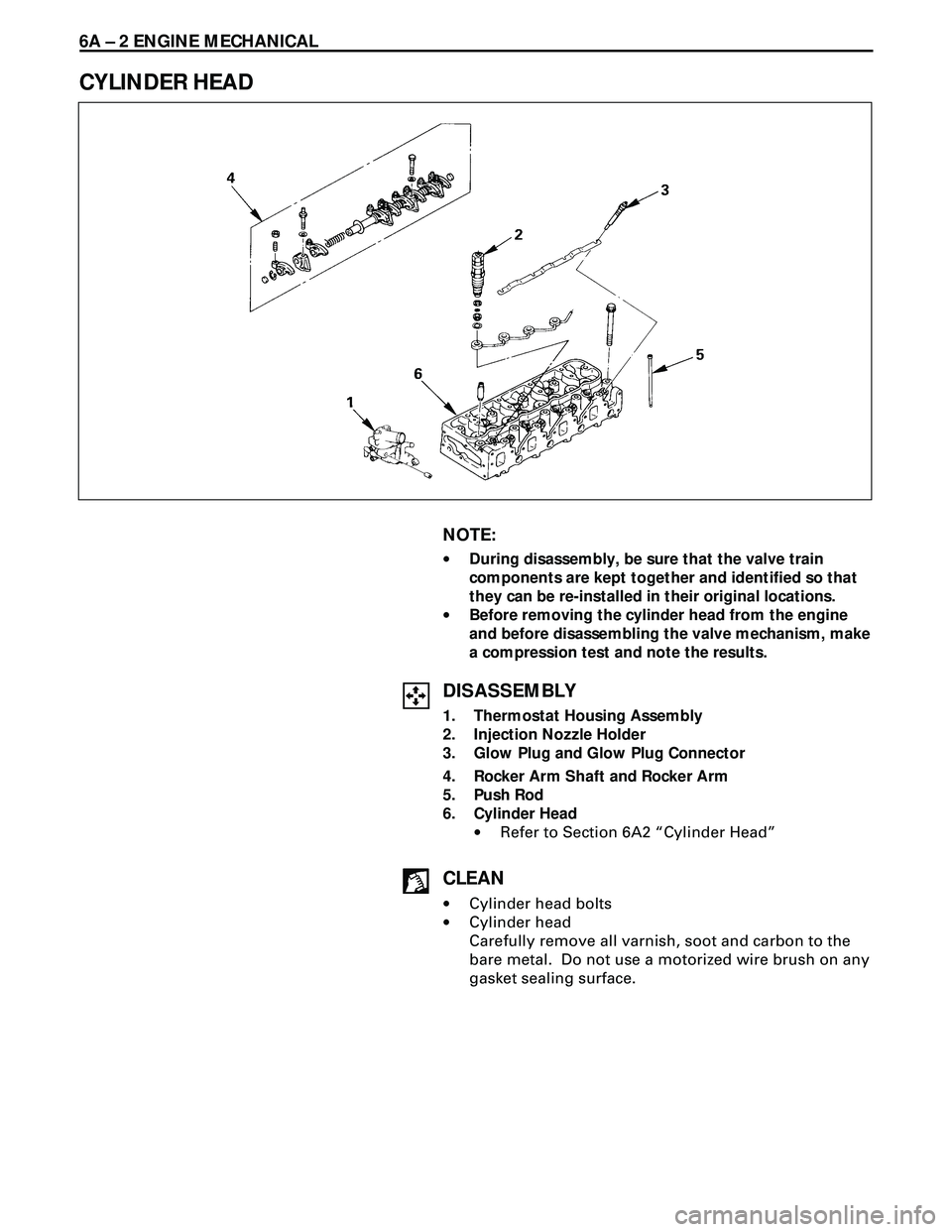

CYLINDER HEAD

NOTE:

·During disassembly, be sure that the valve train

components are kept together and identified so that

they can be re-installed in their original locations.

·Before removing the cylinder head from the engine

and before disassembling the valve mechanism, make

a compression test and note the results.

DISASSEMBLY

1. Thermostat Housing Assembly

2. Injection Nozzle Holder

3. Glow Plug and Glow Plug Connector

4. Rocker Arm Shaft and Rocker Arm

5. Push Rod

6. Cylinder Head

·Refer to Section 6A2 ÒCylinder HeadÓ

CLEAN

·Cylinder head bolts

·Cylinder head

Carefully remove all varnish, soot and carbon to the

bare metal. Do not use a motorized wire brush on any

gasket sealing surface.

Page 1554 of 3573

6A Ð 4 ENGINE MECHANICAL

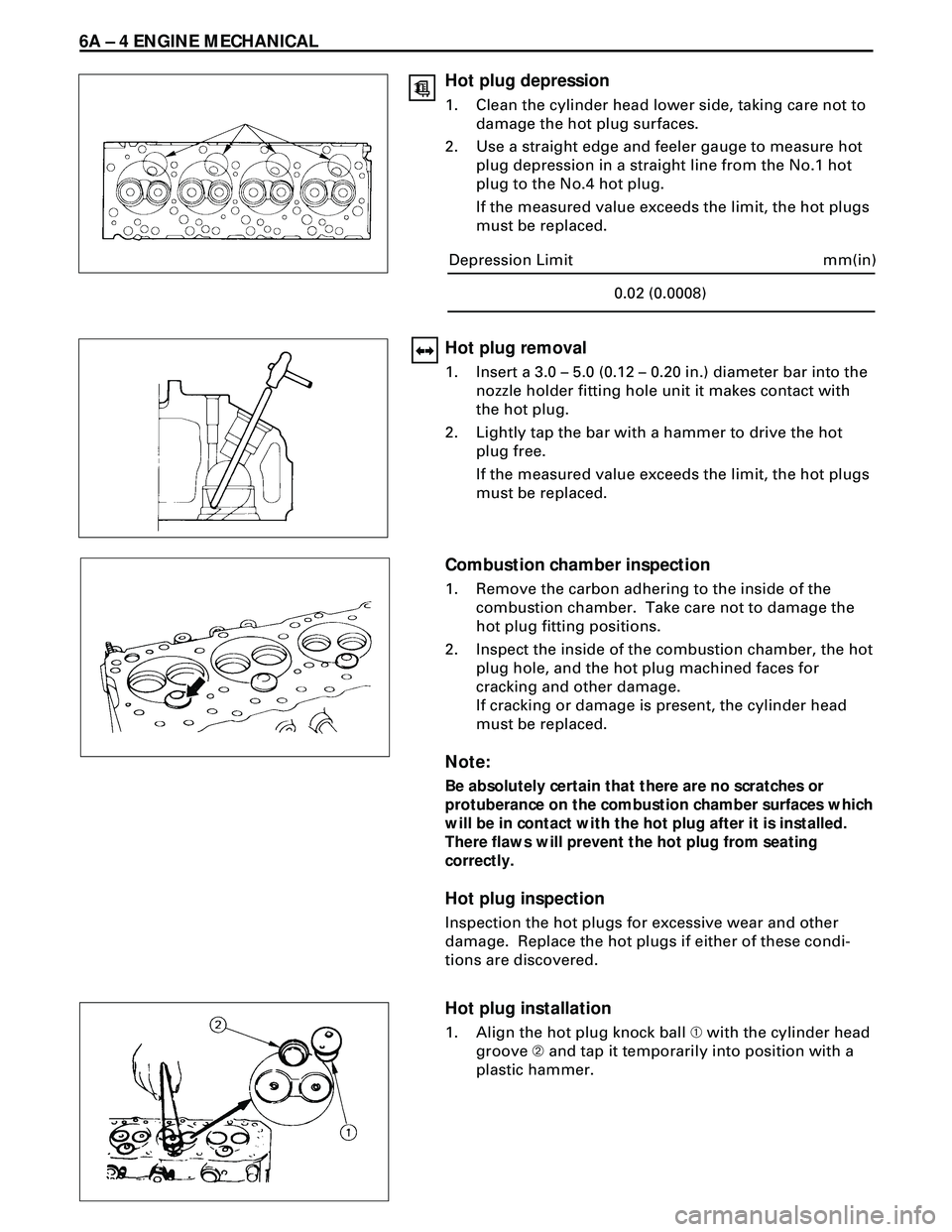

Hot plug depression

1. Clean the cylinder head lower side, taking care not to

damage the hot plug surfaces.

2. Use a straight edge and feeler gauge to measure hot

plug depression in a straight line from the No.1 hot

plug to the No.4 hot plug.

If the measured value exceeds the limit, the hot plugs

must be replaced.

Hot plug removal

1. Insert a 3.0 Ð 5.0 (0.12 Ð 0.20 in.) diameter bar into the

nozzle holder fitting hole unit it makes contact with

the hot plug.

2. Lightly tap the bar with a hammer to drive the hot

plug free.

If the measured value exceeds the limit, the hot plugs

must be replaced.

mm(in)

0.02 (0.0008) Depression Limit

Combustion chamber inspection

1. Remove the carbon adhering to the inside of the

combustion chamber. Take care not to damage the

hot plug fitting positions.

2. Inspect the inside of the combustion chamber, the hot

plug hole, and the hot plug machined faces for

cracking and other damage.

If cracking or damage is present, the cylinder head

must be replaced.

Note:

Be absolutely certain that there are no scratches or

protuberance on the combustion chamber surfaces which

will be in contact with the hot plug after it is installed.

There flaws will prevent the hot plug from seating

correctly.

Hot plug inspection

Inspection the hot plugs for excessive wear and other

damage. Replace the hot plugs if either of these condi-

tions are discovered.

Hot plug installation

1. Align the hot plug knock ball À with the cylinder head

groove Á and tap it temporarily into position with a

plastic hammer.

Page 1560 of 3573

6A Ð 10 ENGINE MECHANICAL

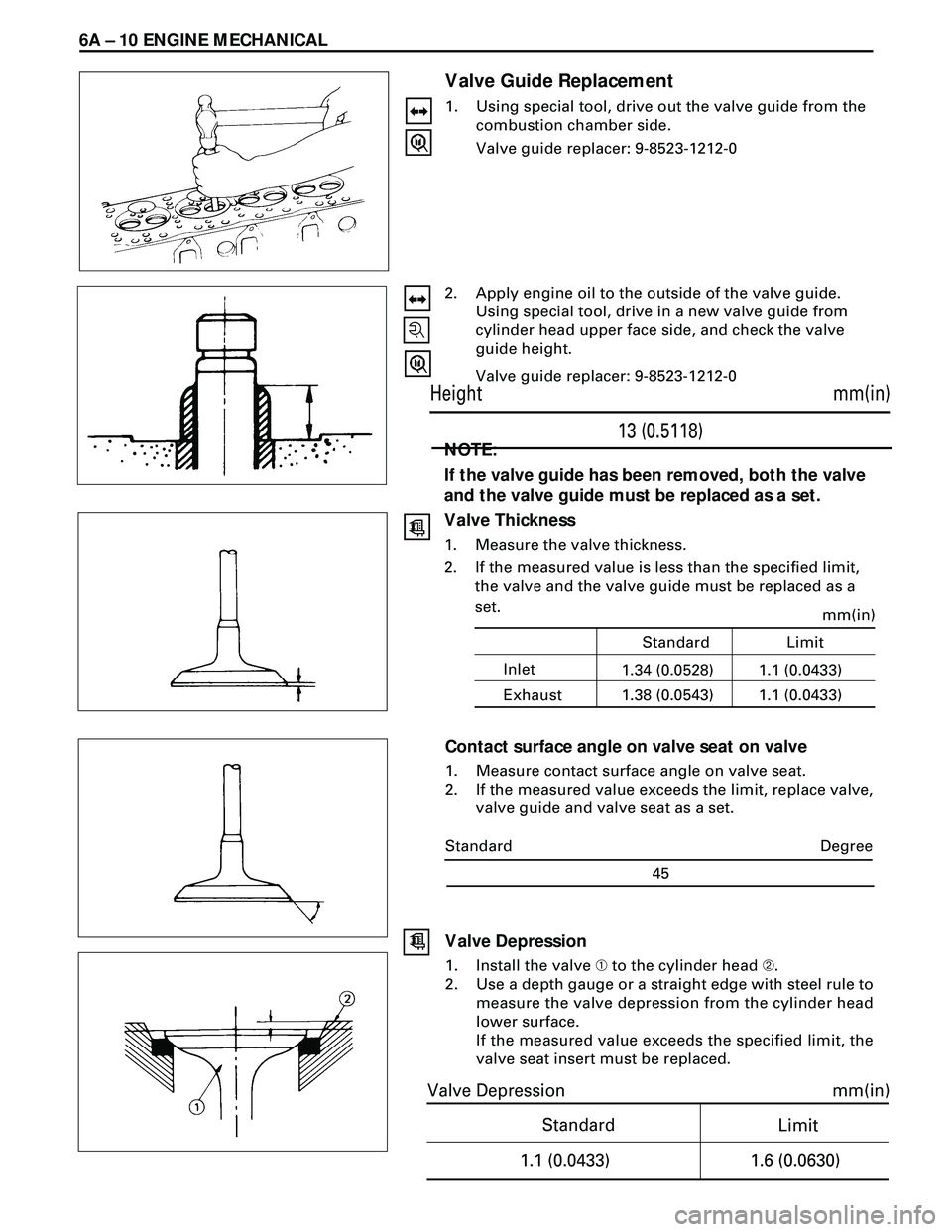

Valve Guide Replacement

1. Using special tool, drive out the valve guide from the

combustion chamber side.

Valve guide replacer: 9-8523-1212-0

2. Apply engine oil to the outside of the valve guide.

Using special tool, drive in a new valve guide from

cylinder head upper face side, and check the valve

guide height.

Valve guide replacer: 9-8523-1212-0

NOTE:

If the valve guide has been removed, both the valve

and the valve guide must be replaced as a set.

Valve Thickness

1. Measure the valve thickness.

2. If the measured value is less than the specified limit,

the valve and the valve guide must be replaced as a

set.

Contact surface angle on valve seat on valve

1. Measure contact surface angle on valve seat.

2. If the measured value exceeds the limit, replace valve,

valve guide and valve seat as a set.

mm(in)

13 (0.5118) Height

Standard

mm(in)

Limit

1.1 (0.0433)

1.6 (0.0630)

Valve Depression

Degree

45 Standard

Valve Depression

1. Install the valve À to the cylinder head Á.

2. Use a depth gauge or a straight edge with steel rule to

measure the valve depression from the cylinder head

lower surface.

If the measured value exceeds the specified limit, the

valve seat insert must be replaced.

Inletmm(in)1.1 (0.0433) Standard Limit

Exhaust1.34 (0.0528)

1.1 (0.0433) 1.38 (0.0543)

Page 1561 of 3573

ENGINE MECHANICAL 6A Ð 11

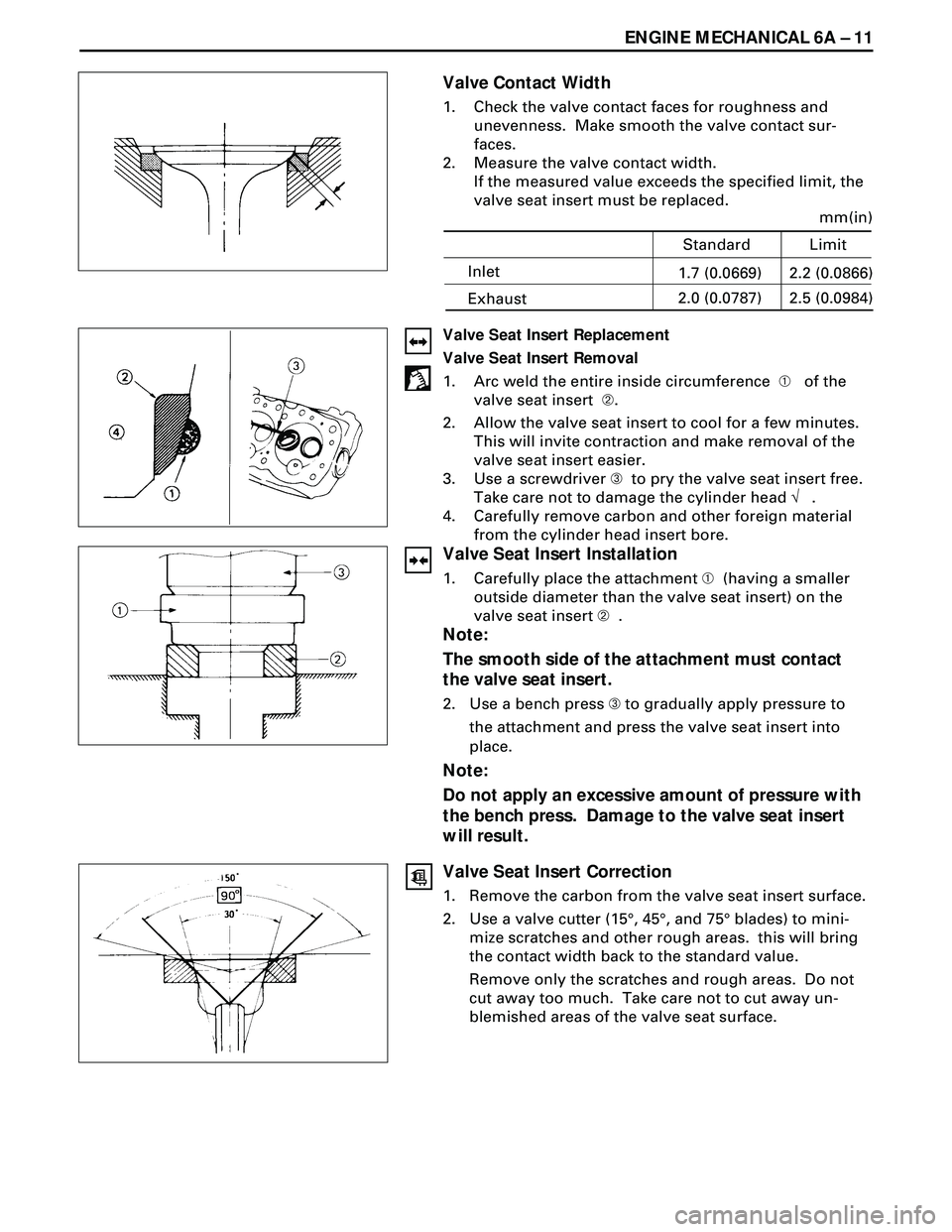

Valve Contact Width

1. Check the valve contact faces for roughness and

unevenness. Make smooth the valve contact sur-

faces.

2. Measure the valve contact width.

If the measured value exceeds the specified limit, the

valve seat insert must be replaced.

Valve Seat Insert Replacement

Valve Seat Insert Removal

1. Arc weld the entire inside circumference À of the

valve seat insert Á.

2. Allow the valve seat insert to cool for a few minutes.

This will invite contraction and make removal of the

valve seat insert easier.

3. Use a screwdriver  to pry the valve seat insert free.

Take care not to damage the cylinder head Ö .

4. Carefully remove carbon and other foreign material

from the cylinder head insert bore.

Valve Seat Insert Installation

1. Carefully place the attachment À (having a smaller

outside diameter than the valve seat insert) on the

valve seat insert Á .

Note:

The smooth side of the attachment must contact

the valve seat insert.

2. Use a bench press  to gradually apply pressure to

the attachment and press the valve seat insert into

place.

Note:

Do not apply an excessive amount of pressure with

the bench press. Damage to the valve seat insert

will result.

Valve Seat Insert Correction

1. Remove the carbon from the valve seat insert surface.

2. Use a valve cutter (15°, 45°, and 75° blades) to mini-

mize scratches and other rough areas. this will bring

the contact width back to the standard value.

Remove only the scratches and rough areas. Do not

cut away too much. Take care not to cut away un-

blemished areas of the valve seat surface.

Inlet

mm(in)

2.2 (0.0866)

Standard Limit

Exhaust1.7 (0.0669)

2.5 (0.0984) 2.0 (0.0787)

Page 1564 of 3573

6A Ð 14 ENGINE MECHANICAL

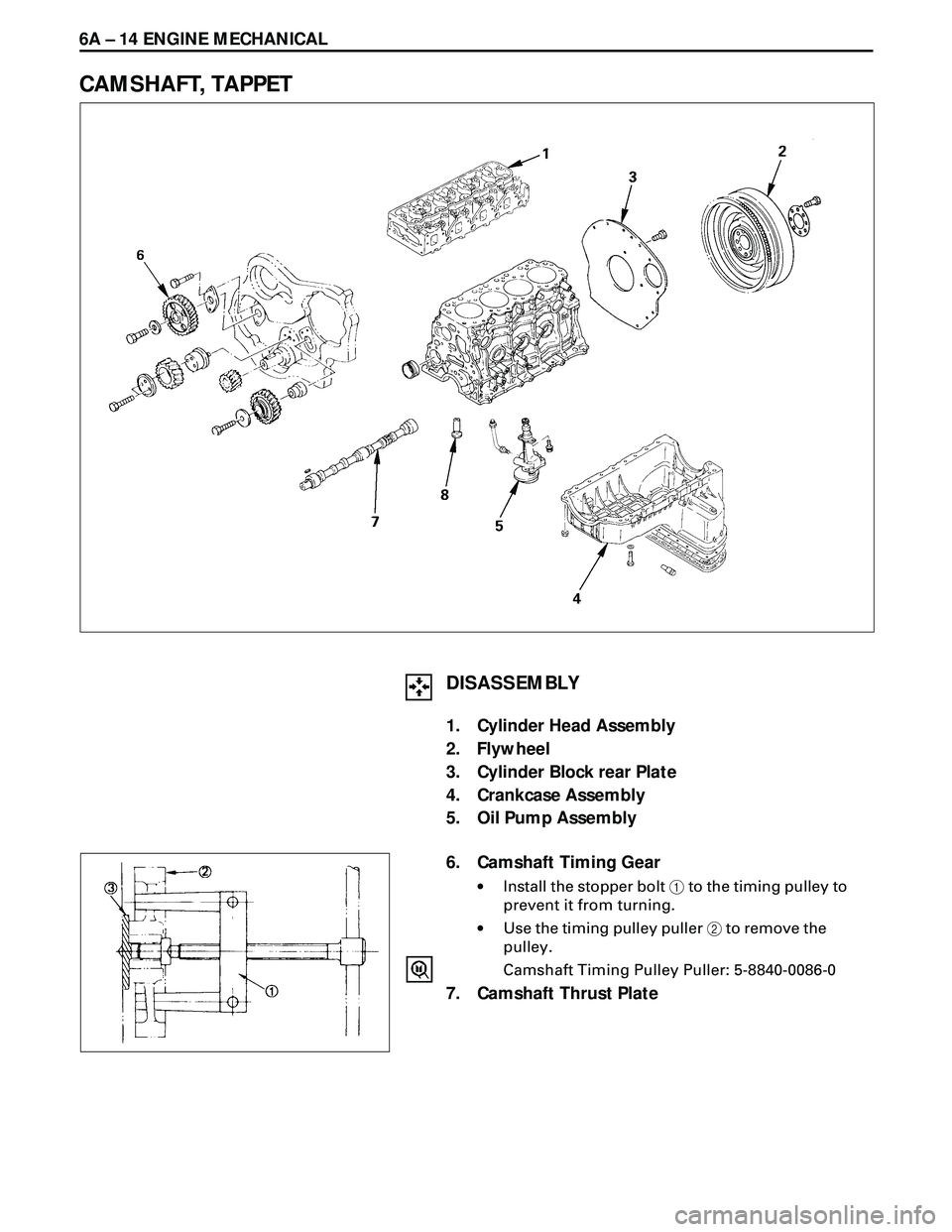

CAMSHAFT, TAPPET

6. Camshaft Timing Gear

·Install the stopper bolt 1 to the timing pulley to

prevent it from turning.

·Use the timing pulley puller 2 to remove the

pulley.

Camshaft Timing Pulley Puller: 5-8840-0086-0

7. Camshaft Thrust Plate

DISASSEMBLY

1. Cylinder Head Assembly

2. Flywheel

3. Cylinder Block rear Plate

4. Crankcase Assembly

5. Oil Pump Assembly

Page 1566 of 3573

6A Ð 16 ENGINE MECHANICAL

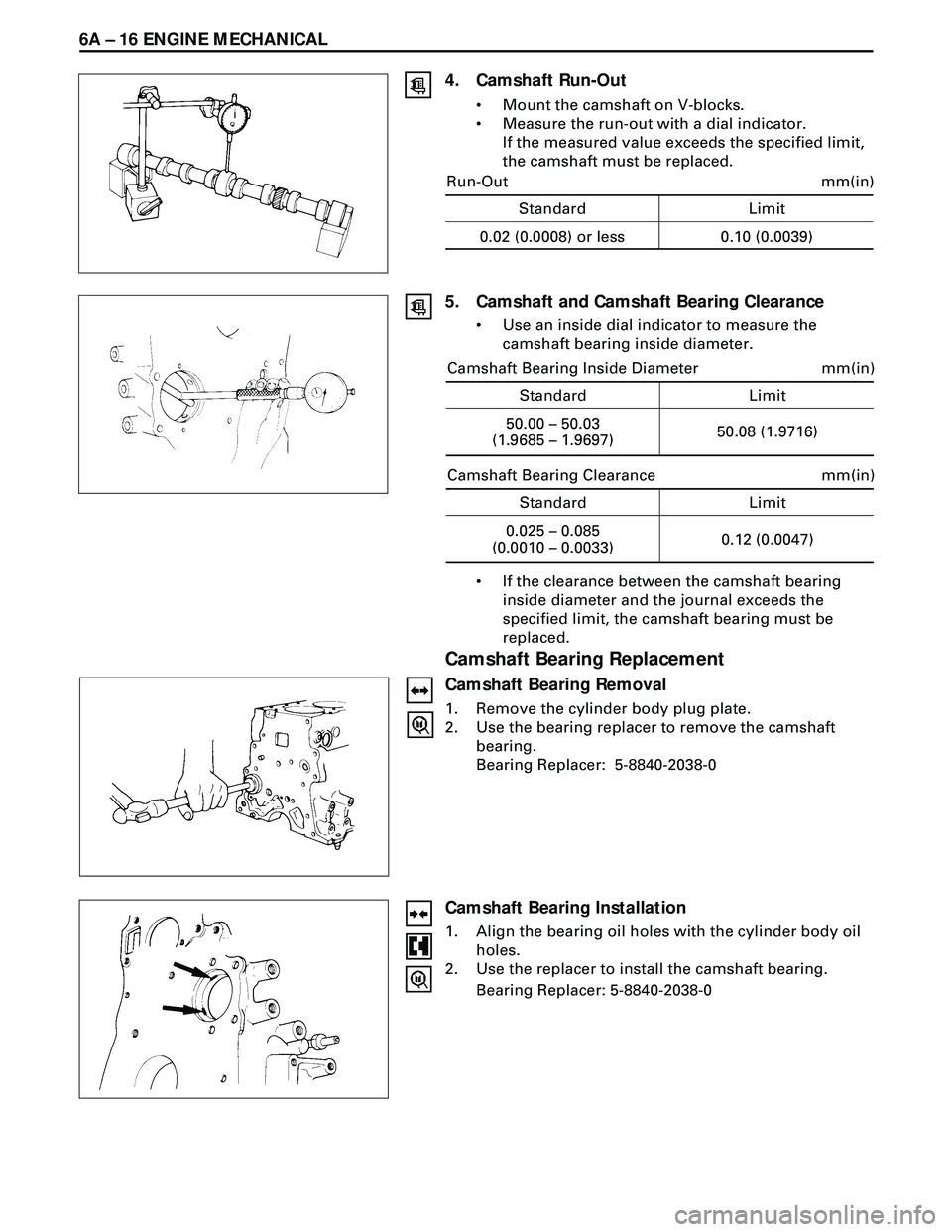

4. Camshaft Run-Out

¥ Mount the camshaft on V-blocks.

¥ Measure the run-out with a dial indicator.

If the measured value exceeds the specified limit,

the camshaft must be replaced.

5. Camshaft and Camshaft Bearing Clearance

¥ Use an inside dial indicator to measure the

camshaft bearing inside diameter.

Standard Limit

mm(in)

0.02 (0.0008) or less 0.10 (0.0039) Run-Out

¥ If the clearance between the camshaft bearing

inside diameter and the journal exceeds the

specified limit, the camshaft bearing must be

replaced.

Camshaft Bearing Replacement

Camshaft Bearing Removal

1. Remove the cylinder body plug plate.

2. Use the bearing replacer to remove the camshaft

bearing.

Bearing Replacer: 5-8840-2038-0

Camshaft Bearing Installation

1. Align the bearing oil holes with the cylinder body oil

holes.

2. Use the replacer to install the camshaft bearing.

Bearing Replacer: 5-8840-2038-0

Standard Limit

mm(in)

50.00 – 50.03

(1.9685 – 1.9697)50.08 (1.9716) Camshaft Bearing Inside Diameter

Standard Limit

mm(in)

0.025 – 0.085

(0.0010 – 0.0033)0.12 (0.0047) Camshaft Bearing Clearance

Page 1576 of 3573

6A Ð 26 ENGINE MECHANICAL

8. Crankshaft Rear Oil Seal

·With the oil seal pushed in deep, install the special

tool as shown in the illustration and remove the oil

seal.

Oil Seal Remover : 5-8840-2362-0

9. Crankcase Assembly

·Refer to ÒCrankcaseÓ in Section 6A2.

10. Oil Pump Assembly

11. Piston Cooling Oil Pipe

12. Piston and Connecting Rod Assembly

13. Main Bearing Cap

14. Crankshaft

INSPECTION AND REPAIR

Make the necessary adjustments, repairs, and part replacements if excessive wear or damage is discovered

during inspection.

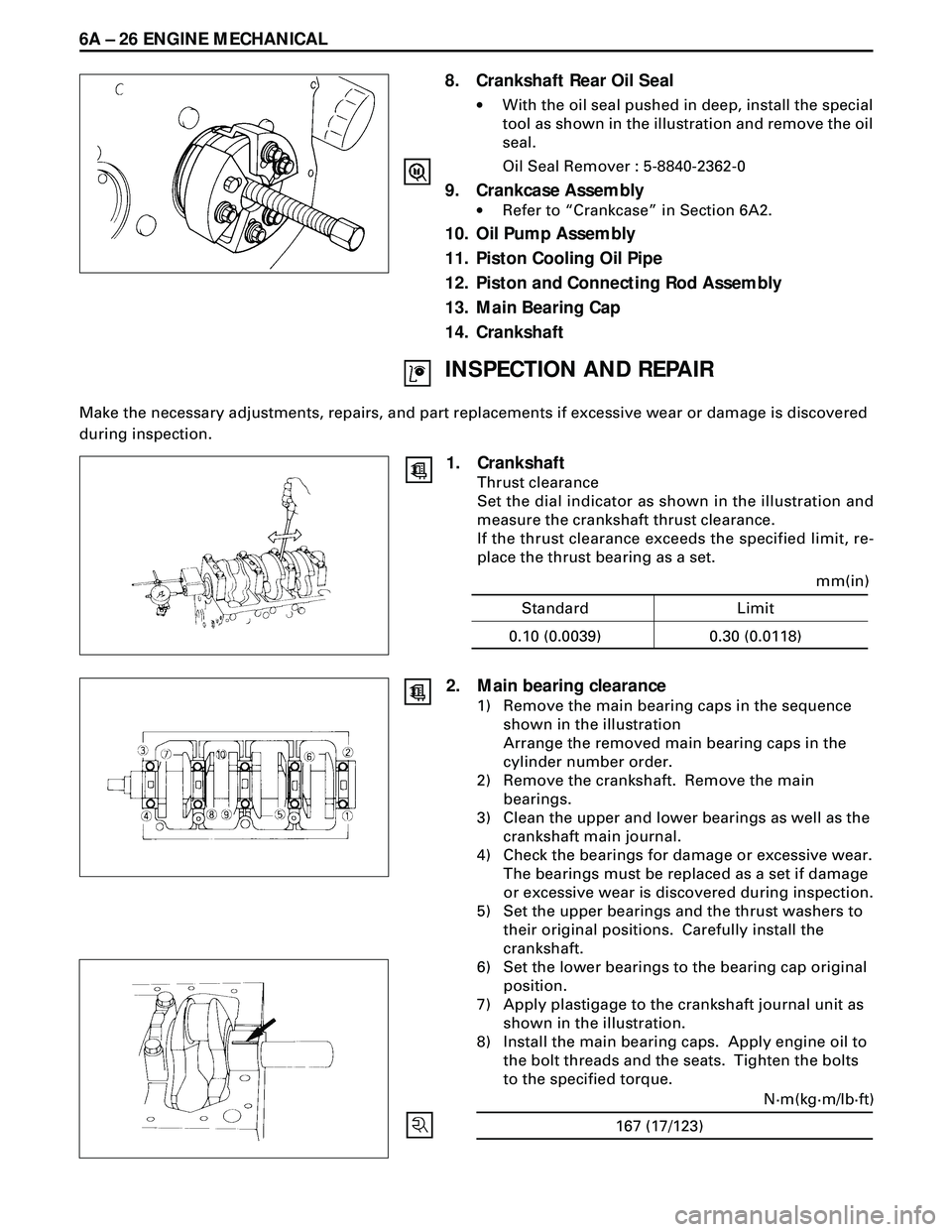

1. Crankshaft

Thrust clearance

Set the dial indicator as shown in the illustration and

measure the crankshaft thrust clearance.

If the thrust clearance exceeds the specified limit, re-

place the thrust bearing as a set.

Standard Limit

mm(in)

0.10 (0.0039) 0.30 (0.0118)

167 (17/123)N·m(kg·m/lb·ft)

2. Main bearing clearance

1) Remove the main bearing caps in the sequence

shown in the illustration

Arrange the removed main bearing caps in the

cylinder number order.

2) Remove the crankshaft. Remove the main

bearings.

3) Clean the upper and lower bearings as well as the

crankshaft main journal.

4) Check the bearings for damage or excessive wear.

The bearings must be replaced as a set if damage

or excessive wear is discovered during inspection.

5) Set the upper bearings and the thrust washers to

their original positions. Carefully install the

crankshaft.

6) Set the lower bearings to the bearing cap original

position.

7) Apply plastigage to the crankshaft journal unit as

shown in the illustration.

8) Install the main bearing caps. Apply engine oil to

the bolt threads and the seats. Tighten the bolts

to the specified torque.

Page 1577 of 3573

ENGINE MECHANICAL 6A Ð 27

NOTE:

Do not allow the crankshaft to rotate.

9) Remove the main bearing caps.

10) Measure the plastigage width and determine the

oil clearance. If the oil clearance exceeds the

specified limit, replace the main bearings as a set

and/or replace the crankshaft.

11) Clean the plastigage from the bearings and the

crankshaft.

Remove the crankshaft and the bearings.

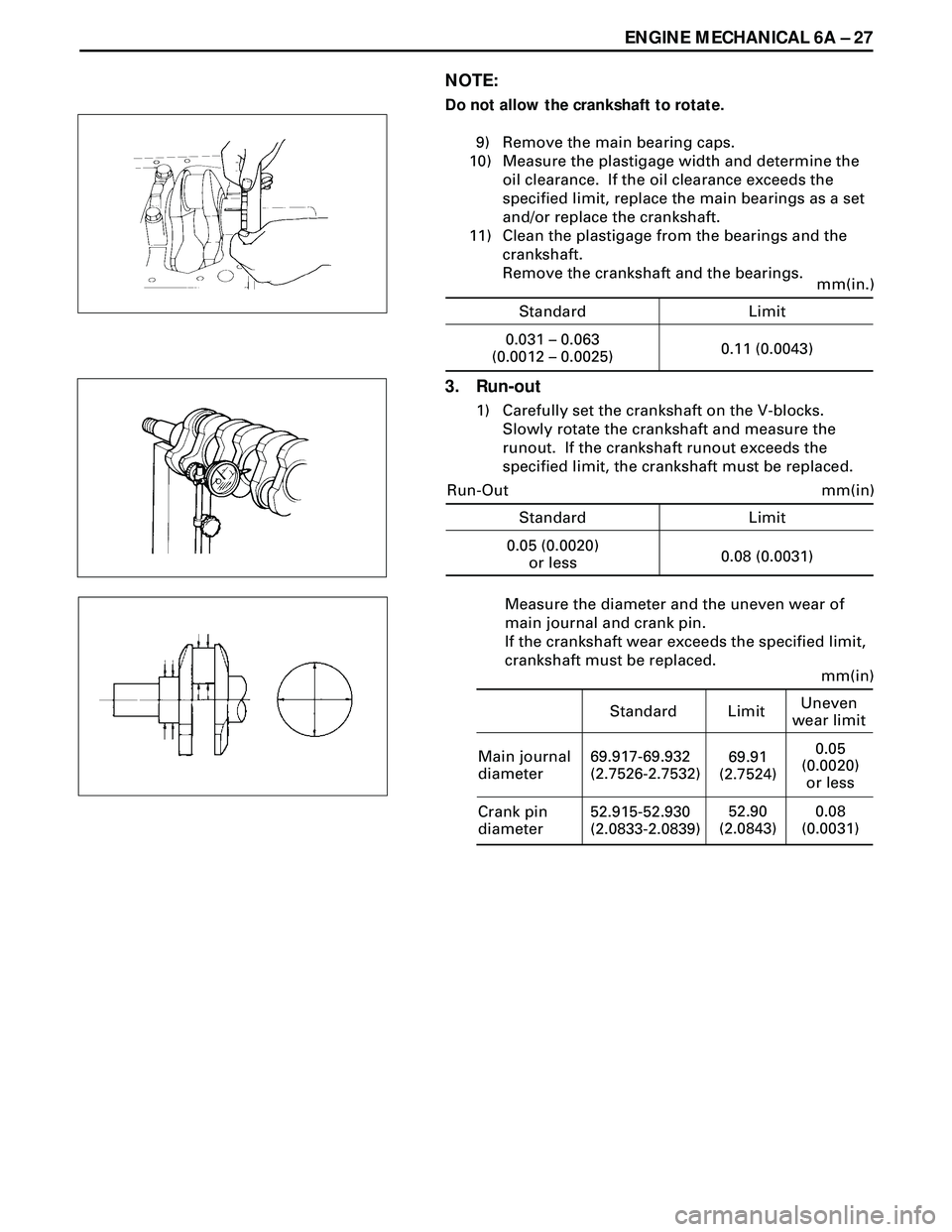

3. Run-out

1) Carefully set the crankshaft on the V-blocks.

Slowly rotate the crankshaft and measure the

runout. If the crankshaft runout exceeds the

specified limit, the crankshaft must be replaced.

Measure the diameter and the uneven wear of

main journal and crank pin.

If the crankshaft wear exceeds the specified limit,

crankshaft must be replaced.

Standard Limit

mm(in.)

0.031 – 0.063

(0.0012 – 0.0025)0.11 (0.0043)

Standard Limit

mm(in)

0.05 (0.0020)

or less0.08 (0.0031) Run-Out

Standard Limitmm(in)

Main journal

diameter69.91

(2.7524)

69.917-69.932

(2.7526-2.7532)

Crank pin

diameter52.90

(2.0843) 52.915-52.930

(2.0833-2.0839)

Uneven

wear limit

0.05

(0.0020)

or less

0.08

(0.0031)