Remove engine ISUZU TROOPER 1998 Service Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 1643 of 3573

4JG2-NA/4JG2-TURBO ENGINE 6A2 Ð 41

19 (1.9/14)N·m(Kg·m/lb·ft)

·After tightening the bolts, make sure that the

crankshaft rotates smoothly.

167 (17.0/123)N·m(Kg·m/lb·ft)

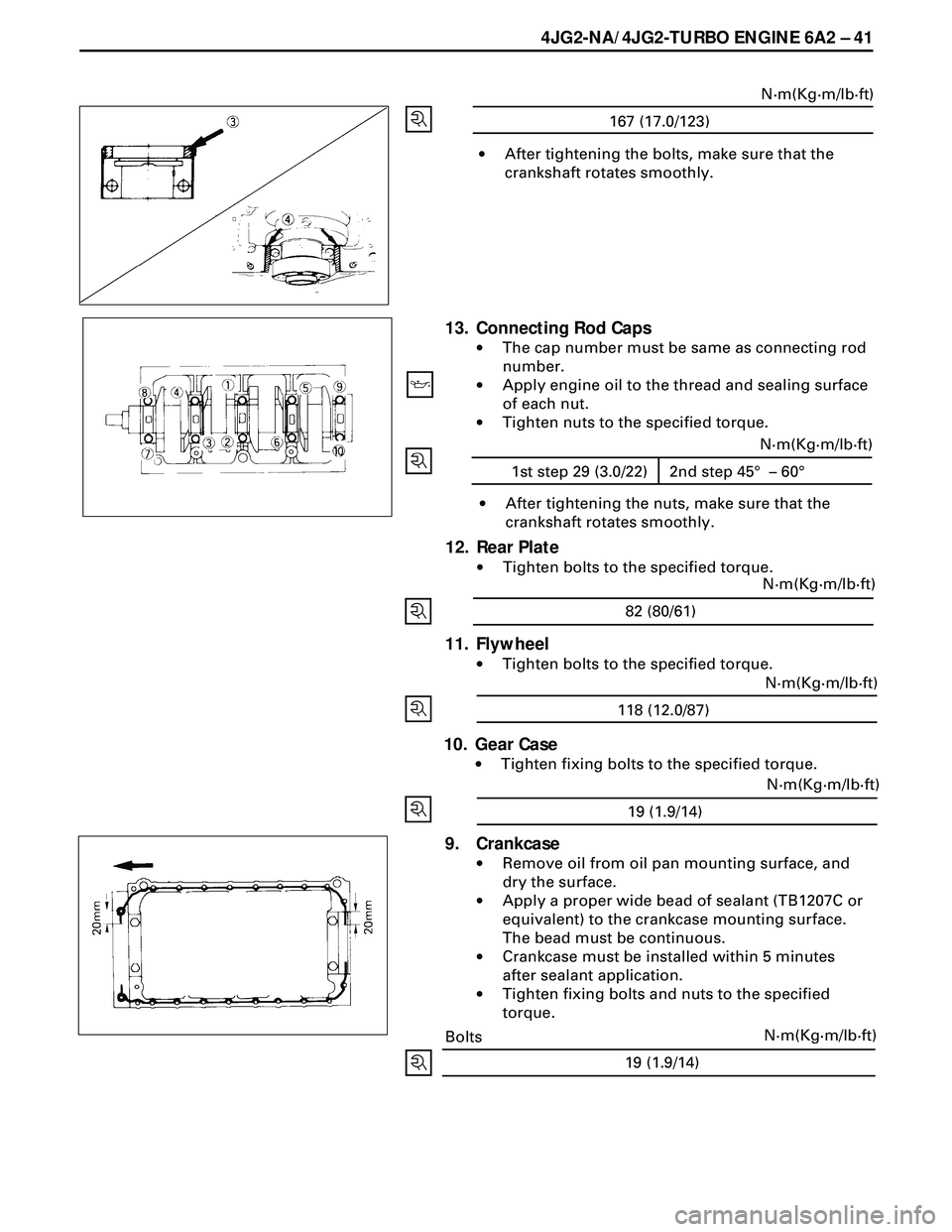

13. Connecting Rod Caps

·The cap number must be same as connecting rod

number.

·Apply engine oil to the thread and sealing surface

of each nut.

·Tighten nuts to the specified torque.

·After tightening the nuts, make sure that the

crankshaft rotates smoothly.

12. Rear Plate

·Tighten bolts to the specified torque.

82 (80/61)N·m(Kg·m/lb·ft)

11. Flywheel

·Tighten bolts to the specified torque.

118 (12.0/87)N·m(Kg·m/lb·ft)

10. Gear Case

·Tighten fixing bolts to the specified torque.

19 (1.9/14)N·m(Kg·m/lb·ft)

9. Crankcase

·Remove oil from oil pan mounting surface, and

dry the surface.

·Apply a proper wide bead of sealant (TB1207C or

equivalent) to the crankcase mounting surface.

The bead must be continuous.

·Crankcase must be installed within 5 minutes

after sealant application.

·Tighten fixing bolts and nuts to the specified

torque.

Bolts

1st step 29 (3.0/22) 2nd step 45° – 60°N·m(Kg·m/lb·ft)

Page 1647 of 3573

4JG2-NA/4JG2-TURBO ENGINE 6A2 Ð 45

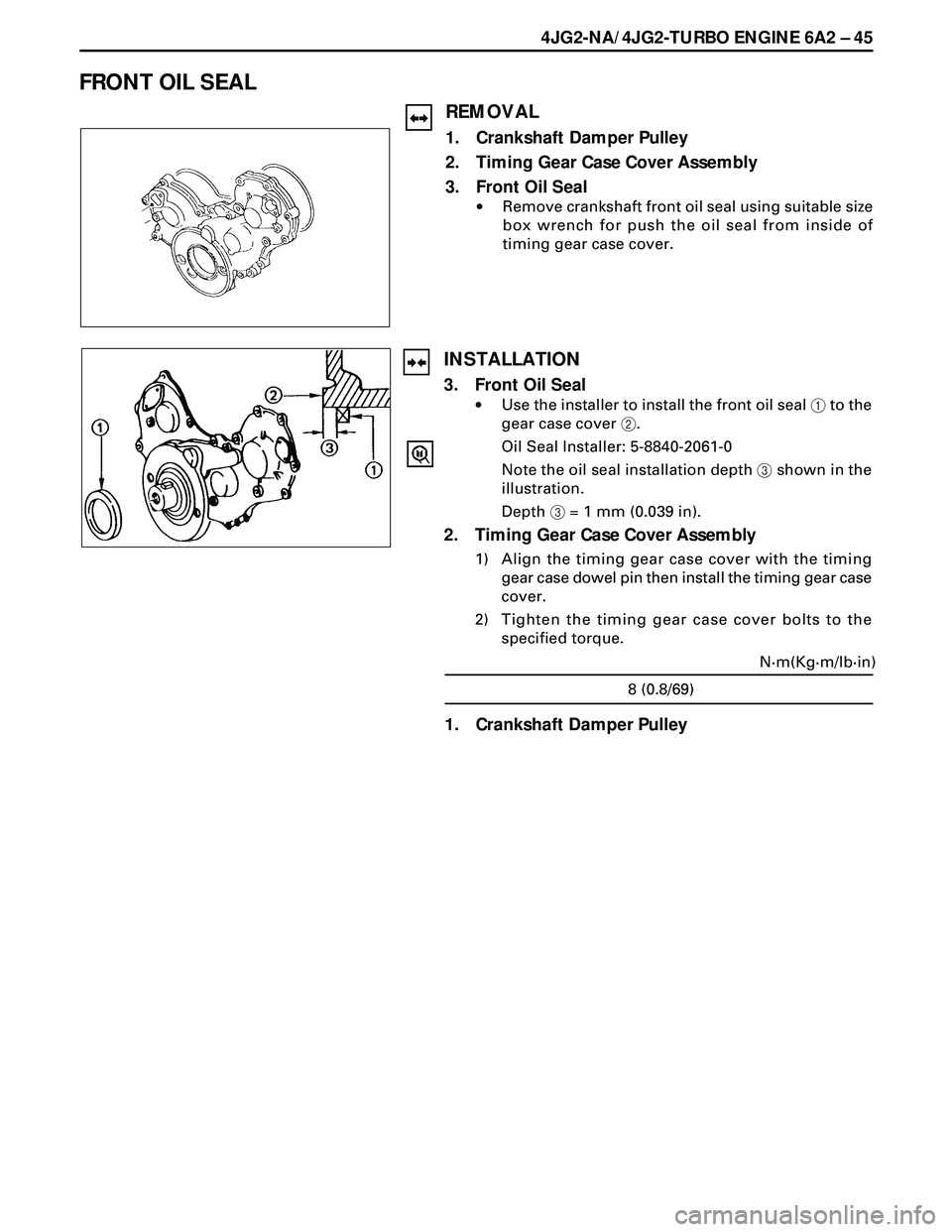

FRONT OIL SEAL

REMOVAL

1. Crankshaft Damper Pulley

2. Timing Gear Case Cover Assembly

3. Front Oil Seal

·Remove crankshaft front oil seal using suitable size

box wrench for push the oil seal from inside of

timing gear case cover.

INSTALLATION

3. Front Oil Seal

·Use the installer to install the front oil seal 1 to the

gear case cover 2.

Oil Seal Installer: 5-8840-2061-0

Note the oil seal installation depth 3 shown in the

illustration.

Depth 3 = 1 mm (0.039 in).

2. Timing Gear Case Cover Assembly

1) Align the timing gear case cover with the timing

gear case dowel pin then install the timing gear case

cover.

2) Tighten the timing gear case cover bolts to the

specified torque.

8 (0.8/69)N·m(Kg·m/lb·in)

1. Crankshaft Damper Pulley

Page 1648 of 3573

6A2 Ð 46 4JG2-NA/4JG2-TURBO ENGINE

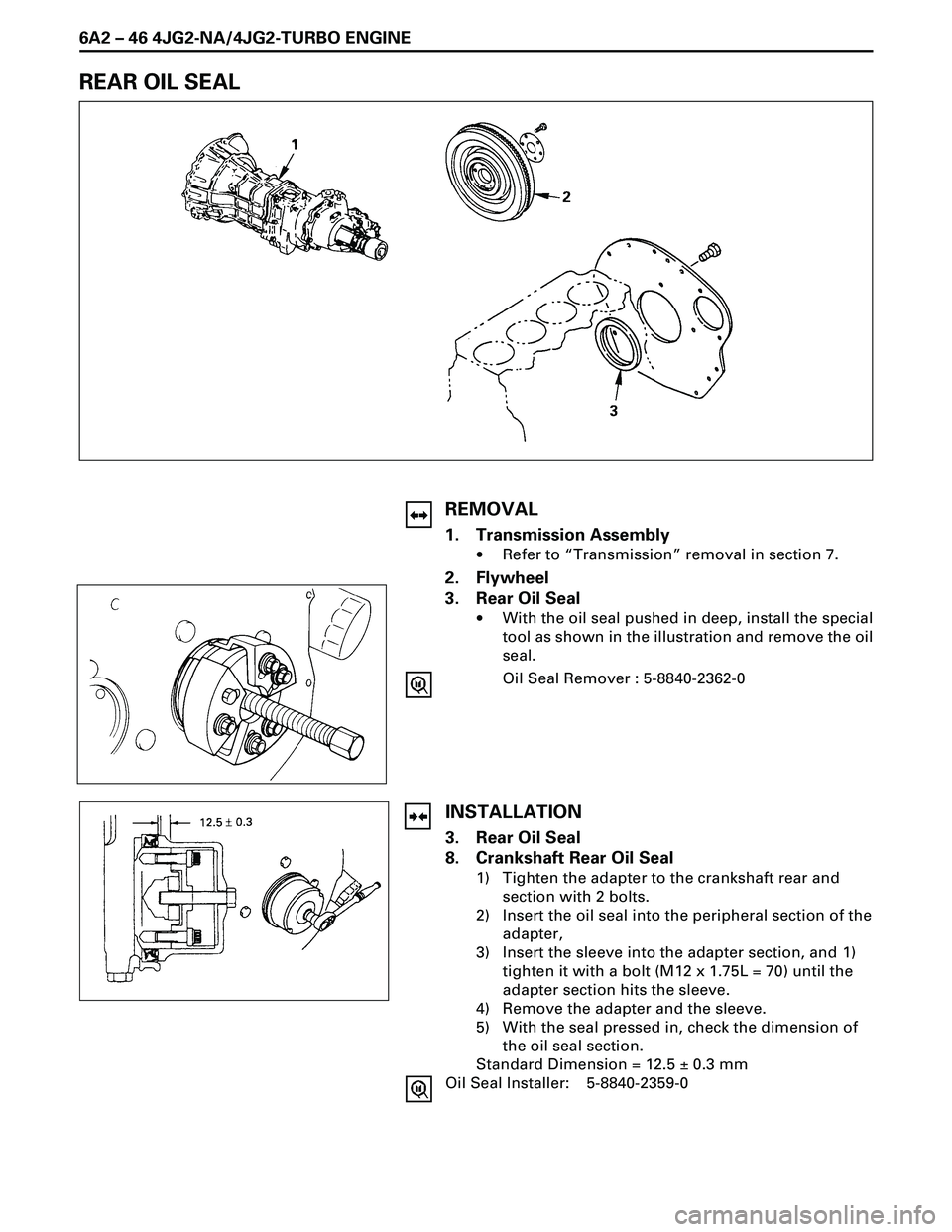

REAR OIL SEAL

REMOVAL

1. Transmission Assembly

·Refer to ÒTransmissionÓ removal in section 7.

2. Flywheel

3. Rear Oil Seal

·With the oil seal pushed in deep, install the special

tool as shown in the illustration and remove the oil

seal.

Oil Seal Remover : 5-8840-2362-0

INSTALLATION

3. Rear Oil Seal

8. Crankshaft Rear Oil Seal

1) Tighten the adapter to the crankshaft rear and

section with 2 bolts.

2) Insert the oil seal into the peripheral section of the

adapter,

3) Insert the sleeve into the adapter section, and 1)

tighten it with a bolt (M12 x 1.75L = 70) until the

adapter section hits the sleeve.

4) Remove the adapter and the sleeve.

5) With the seal pressed in, check the dimension of

the oil seal section.

Standard Dimension = 12.5 ± 0.3 mm

Oil Seal Installer: 5-8840-2359-0

Page 1650 of 3573

6A2 Ð 48 4JG2-NA/4JG2-TURBO ENGINE

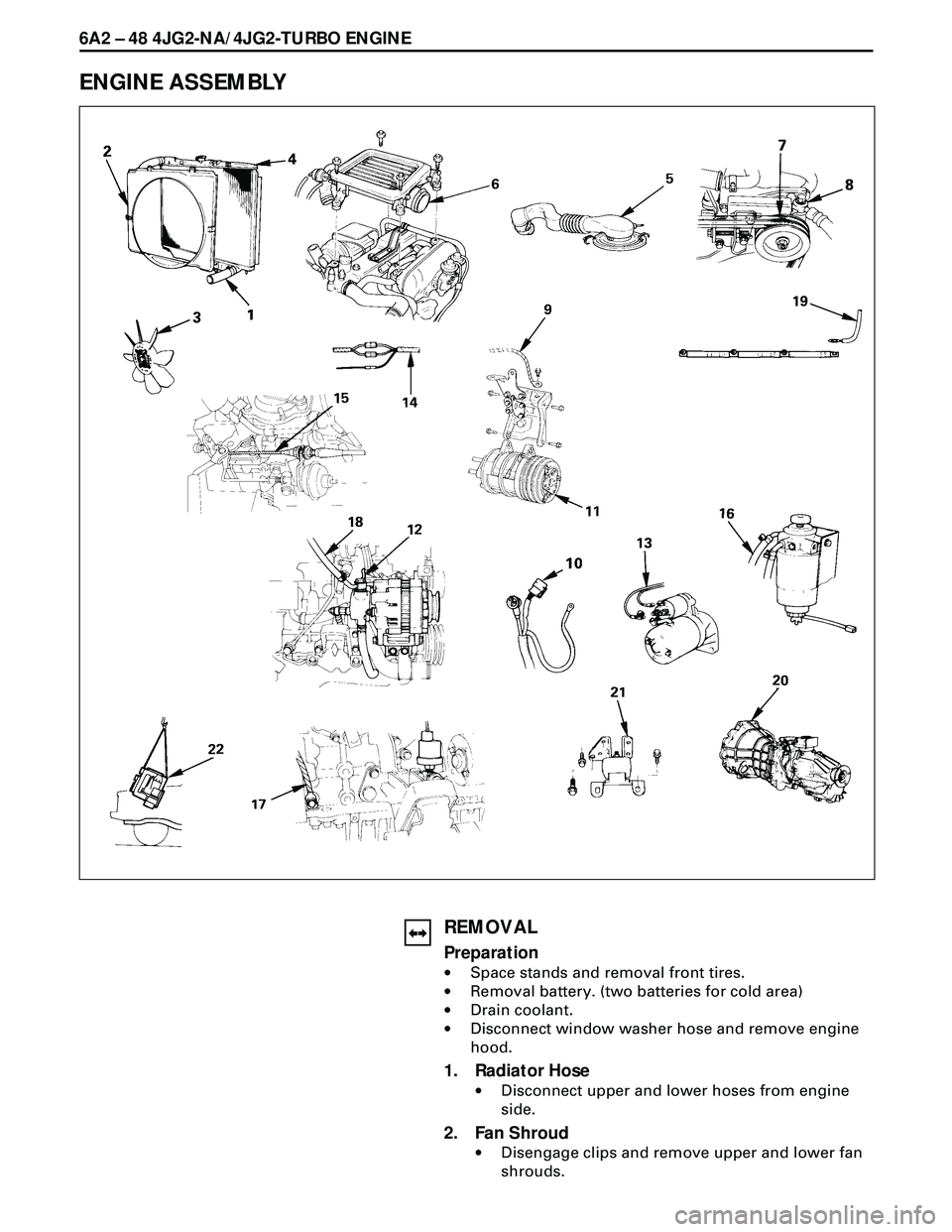

ENGINE ASSEMBLY

REMOVAL

Preparation

·Space stands and removal front tires.

·Removal battery. (two batteries for cold area)

·Drain coolant.

·Disconnect window washer hose and remove engine

hood.

1. Radiator Hose

·Disconnect upper and lower hoses from engine

side.

2. Fan Shroud

·Disengage clips and remove upper and lower fan

shrouds.

Page 1651 of 3573

4JG2-NA/4JG2-TURBO ENGINE 6A2 Ð 49

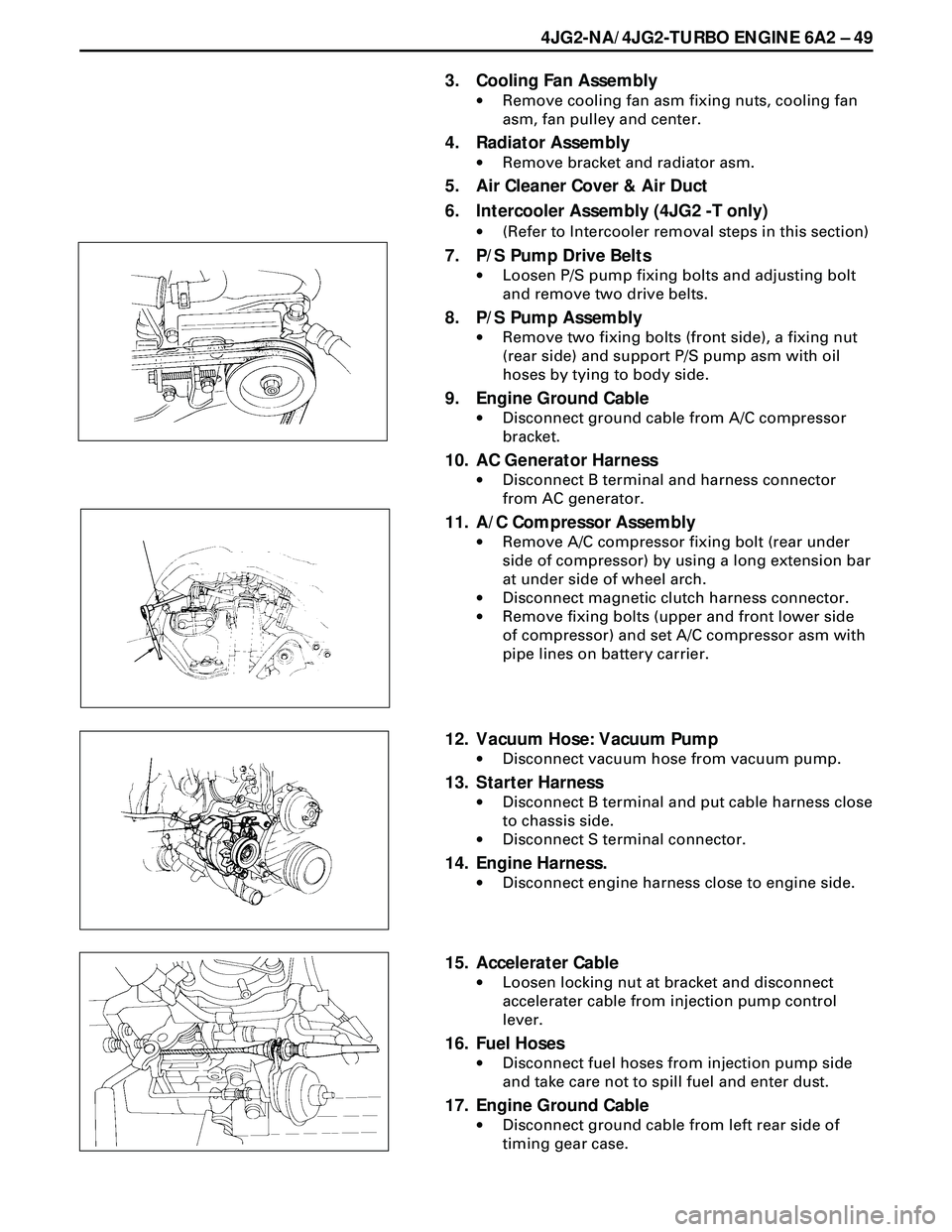

3. Cooling Fan Assembly

·Remove cooling fan asm fixing nuts, cooling fan

asm, fan pulley and center.

4. Radiator Assembly

·Remove bracket and radiator asm.

5. Air Cleaner Cover & Air Duct

6. Intercooler Assembly (4JG2 -T only)

·(Refer to Intercooler removal steps in this section)

7. P/S Pump Drive Belts

·Loosen P/S pump fixing bolts and adjusting bolt

and remove two drive belts.

8. P/S Pump Assembly

·Remove two fixing bolts (front side), a fixing nut

(rear side) and support P/S pump asm with oil

hoses by tying to body side.

9. Engine Ground Cable

·Disconnect ground cable from A/C compressor

bracket.

10. AC Generator Harness

·Disconnect B terminal and harness connector

from AC generator.

11. A/C Compressor Assembly

·Remove A/C compressor fixing bolt (rear under

side of compressor) by using a long extension bar

at under side of wheel arch.

·Disconnect magnetic clutch harness connector.

·Remove fixing bolts (upper and front lower side

of compressor) and set A/C compressor asm with

pipe lines on battery carrier.

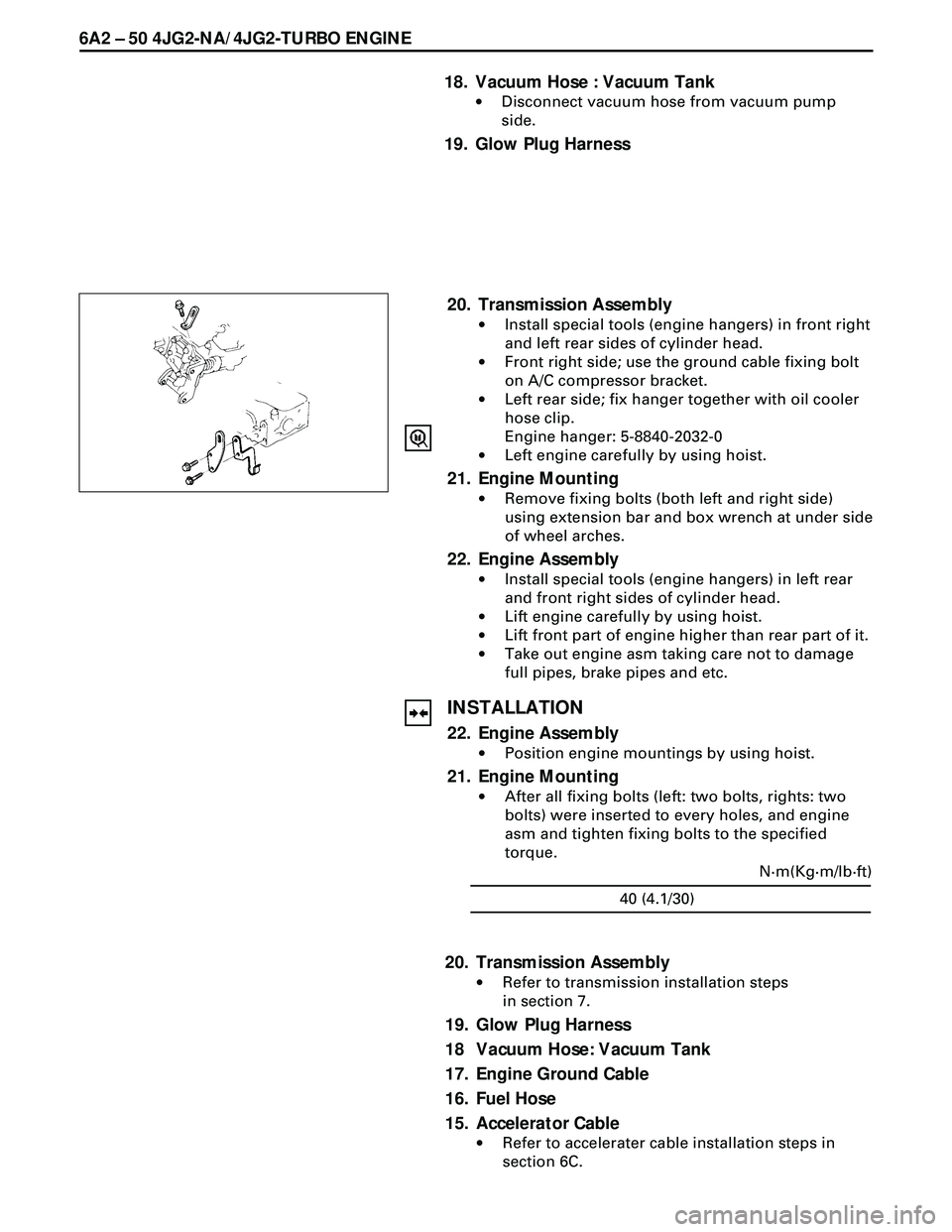

12. Vacuum Hose: Vacuum Pump

·Disconnect vacuum hose from vacuum pump.

13. Starter Harness

·Disconnect B terminal and put cable harness close

to chassis side.

·Disconnect S terminal connector.

14. Engine Harness.

·Disconnect engine harness close to engine side.

15. Accelerater Cable

·Loosen locking nut at bracket and disconnect

accelerater cable from injection pump control

lever.

16. Fuel Hoses

·Disconnect fuel hoses from injection pump side

and take care not to spill fuel and enter dust.

17. Engine Ground Cable

·Disconnect ground cable from left rear side of

timing gear case.

Page 1652 of 3573

6A2 Ð 50 4JG2-NA/4JG2-TURBO ENGINE

18. Vacuum Hose : Vacuum Tank

·Disconnect vacuum hose from vacuum pump

side.

19. Glow Plug Harness

20. Transmission Assembly

·Install special tools (engine hangers) in front right

and left rear sides of cylinder head.

·Front right side; use the ground cable fixing bolt

on A/C compressor bracket.

·Left rear side; fix hanger together with oil cooler

hose clip.

Engine hanger: 5-8840-2032-0

·Left engine carefully by using hoist.

21. Engine Mounting

·Remove fixing bolts (both left and right side)

using extension bar and box wrench at under side

of wheel arches.

22. Engine Assembly

·Install special tools (engine hangers) in left rear

and front right sides of cylinder head.

·Lift engine carefully by using hoist.

·Lift front part of engine higher than rear part of it.

·Take out engine asm taking care not to damage

full pipes, brake pipes and etc.

INSTALLATION

22. Engine Assembly

·Position engine mountings by using hoist.

21. Engine Mounting

·After all fixing bolts (left: two bolts, rights: two

bolts) were inserted to every holes, and engine

asm and tighten fixing bolts to the specified

torque.

40 (4.1/30)N·m(Kg·m/lb·ft)

20. Transmission Assembly

·Refer to transmission installation steps

in section 7.

19. Glow Plug Harness

18 Vacuum Hose: Vacuum Tank

17. Engine Ground Cable

16. Fuel Hose

15. Accelerator Cable

·Refer to accelerater cable installation steps in

section 6C.

Page 1659 of 3573

ENGINE COOLING 6B Ð 5

ON-VEHICLE SERVICE

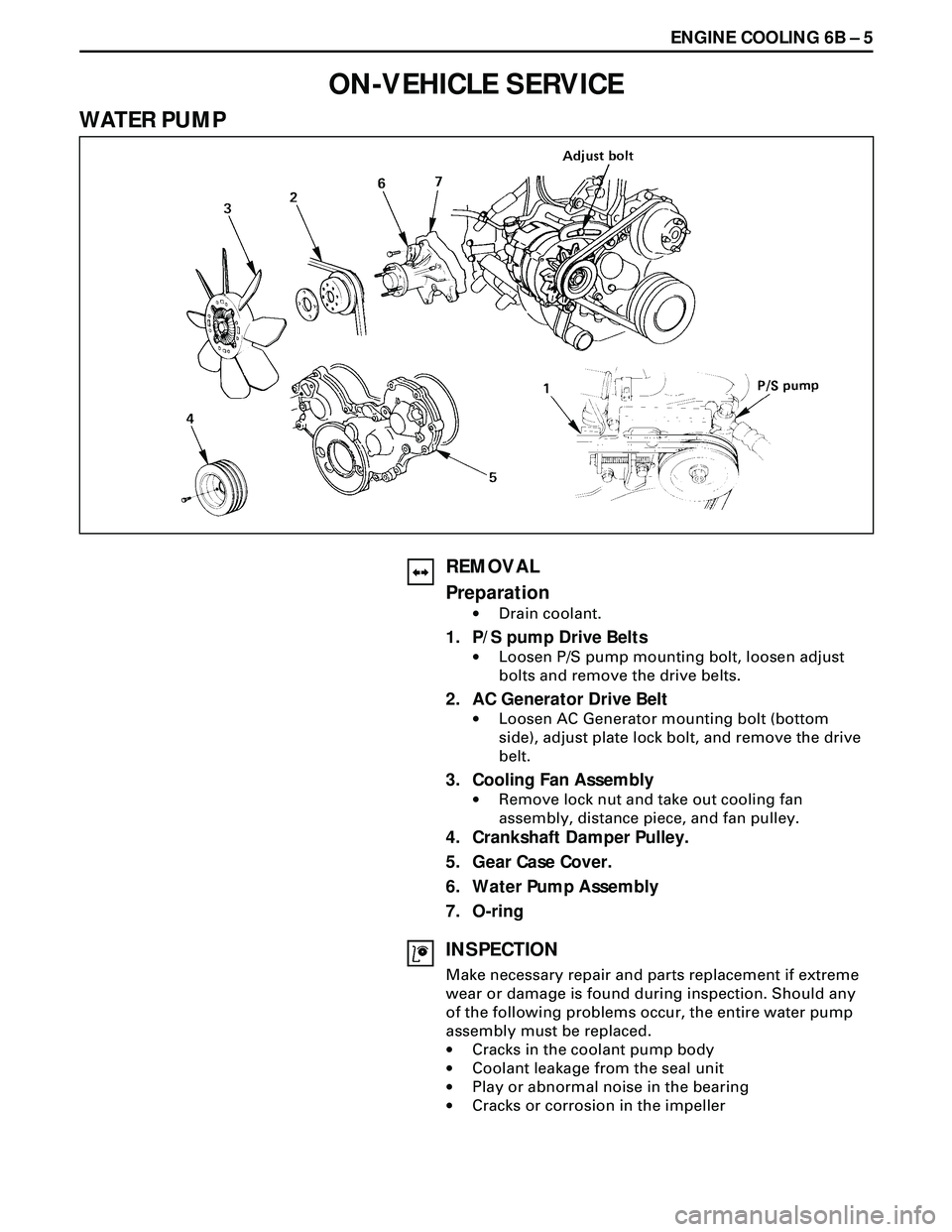

WATER PUMP

REMOVAL

Preparation

·Drain coolant.

1. P/S pump Drive Belts

·Loosen P/S pump mounting bolt, loosen adjust

bolts and remove the drive belts.

2. AC Generator Drive Belt

·Loosen AC Generator mounting bolt (bottom

side), adjust plate lock bolt, and remove the drive

belt.

3. Cooling Fan Assembly

·Remove lock nut and take out cooling fan

assembly, distance piece, and fan pulley.

4. Crankshaft Damper Pulley.

5. Gear Case Cover.

6. Water Pump Assembly

7. O-ring

INSPECTION

Make necessary repair and parts replacement if extreme

wear or damage is found during inspection. Should any

of the following problems occur, the entire water pump

assembly must be replaced.

·Cracks in the coolant pump body

·Coolant leakage from the seal unit

·Play or abnormal noise in the bearing

·Cracks or corrosion in the impeller

Page 1661 of 3573

ENGINE COOLING 6B Ð 7

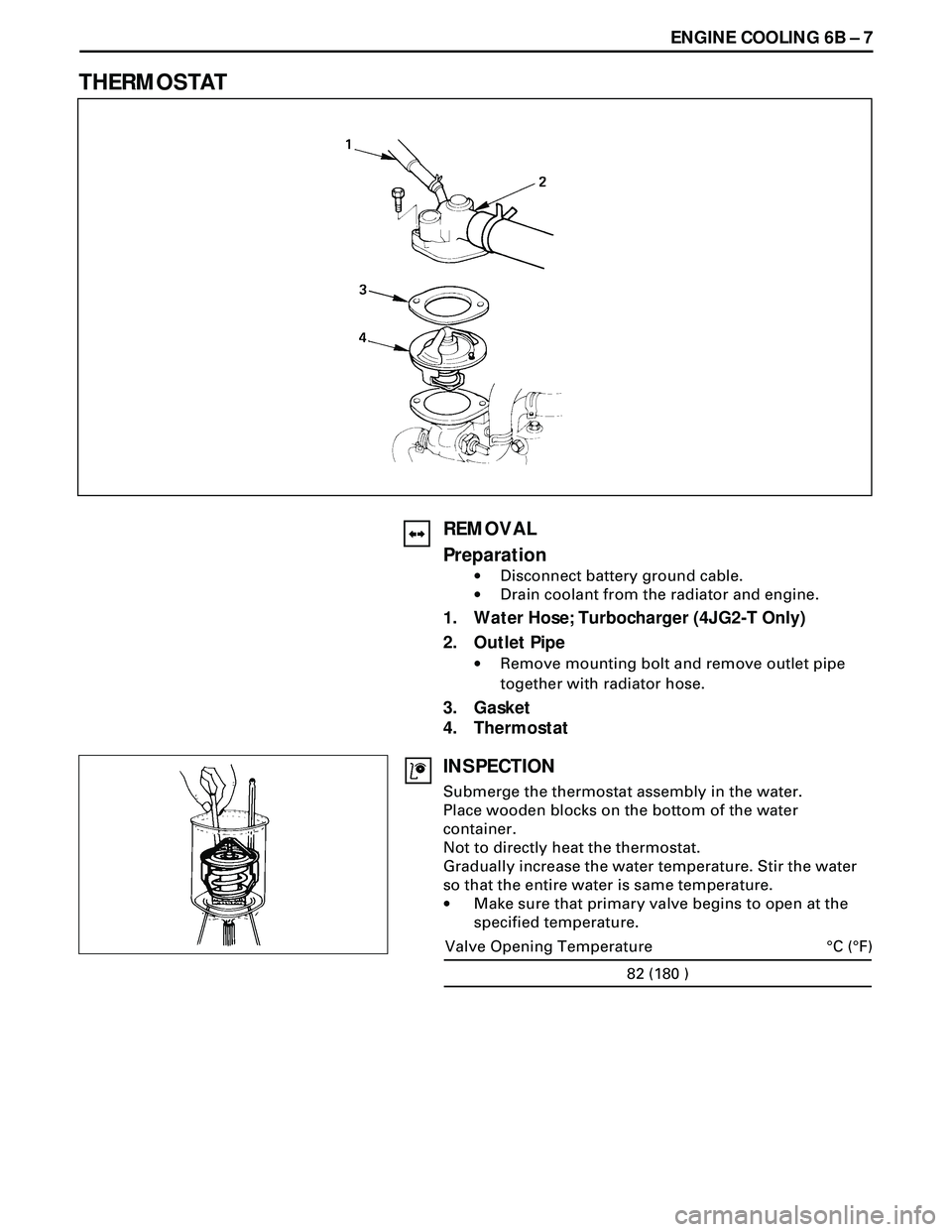

THERMOSTAT

REMOVAL

Preparation

·Disconnect battery ground cable.

·Drain coolant from the radiator and engine.

1. Water Hose; Turbocharger (4JG2-T Only)

2. Outlet Pipe

·Remove mounting bolt and remove outlet pipe

together with radiator hose.

3. Gasket

4. Thermostat

INSPECTION

Submerge the thermostat assembly in the water.

Place wooden blocks on the bottom of the water

container.

Not to directly heat the thermostat.

Gradually increase the water temperature. Stir the water

so that the entire water is same temperature.

·Make sure that primary valve begins to open at the

specified temperature.

82 (180 )

°C (°F) Valve Opening Temperature

Page 1663 of 3573

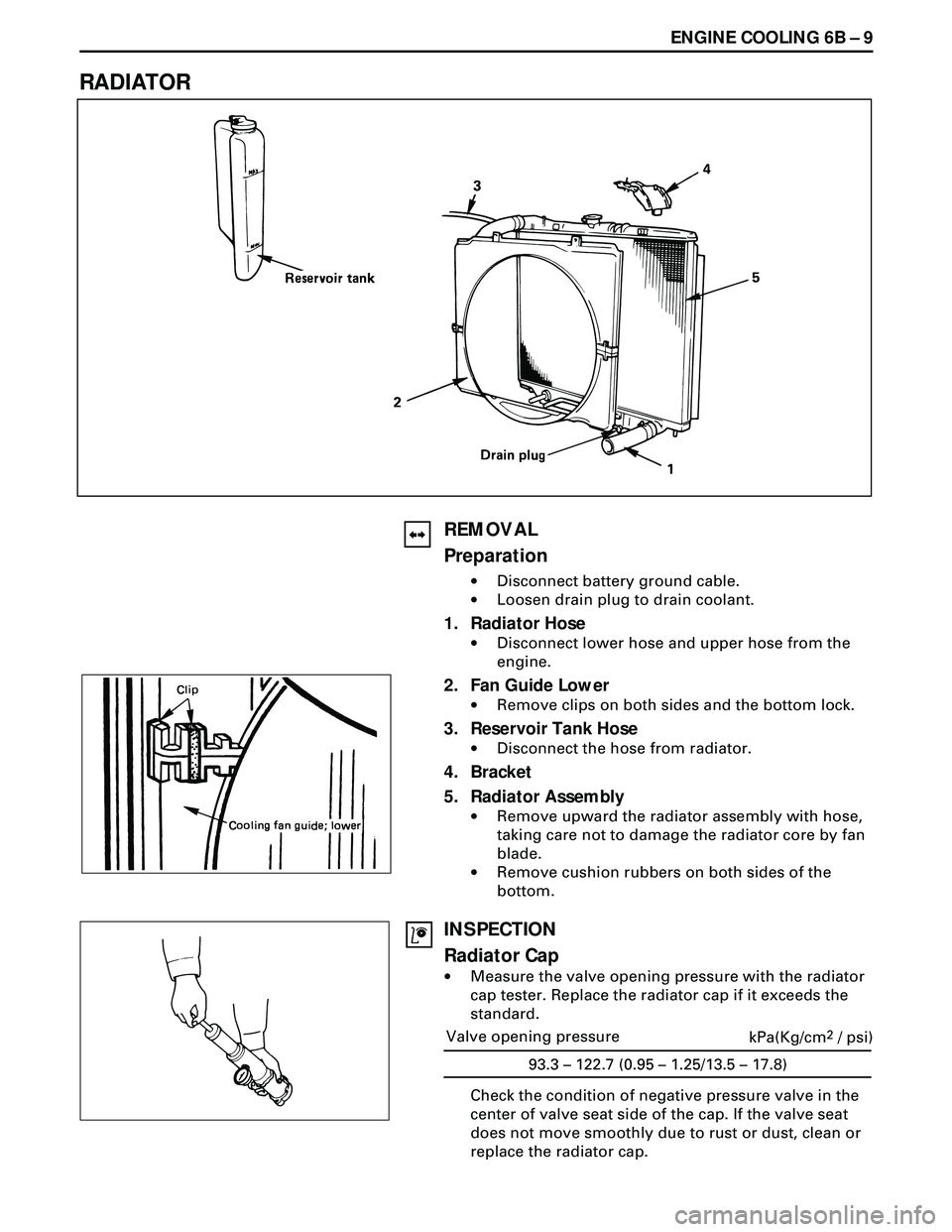

ENGINE COOLING 6B Ð 9

RADIATOR

REMOVAL

Preparation

·Disconnect battery ground cable.

·Loosen drain plug to drain coolant.

1. Radiator Hose

·Disconnect lower hose and upper hose from the

engine.

2. Fan Guide Lower

·Remove clips on both sides and the bottom lock.

3. Reservoir Tank Hose

·Disconnect the hose from radiator.

4. Bracket

5. Radiator Assembly

·Remove upward the radiator assembly with hose,

taking care not to damage the radiator core by fan

blade.

·Remove cushion rubbers on both sides of the

bottom.

INSPECTION

Radiator Cap

·Measure the valve opening pressure with the radiator

cap tester. Replace the radiator cap if it exceeds the

standard.

Check the condition of negative pressure valve in the

center of valve seat side of the cap. If the valve seat

does not move smoothly due to rust or dust, clean or

replace the radiator cap.

Valve opening pressure

93.3 – 122.7 (0.95 – 1.25/13.5 – 17.8)kPa(Kg/cm2 / psi)

Page 1664 of 3573

6B Ð 10 ENGINE COOLING

Radiator Core

·Deformed radiator fins could reduce radiation effects,

resulting in overheat. Straighten the fins. In such a

case, take care not to damage the fin roots.

·Remove dust and other foreign materials.

Flushing the Radiator

·Wash the inside of radiator and the coolant passage

with water and neutral detergent. Remove all scales

and rust.

Checking for Coolant Leakage

·Check the cooling system for leakage with the radiator

cap tester by applying 196.0kPa (28.4 psi) air pressure

from filler neck to inside the radiator.

INSTALLATION

5. Radiator Assembly

·Install cushion rubbers on both sides of radiator

bottom.

·Install radiator assembly with hose, taking care not

to damage the radiator core by a fan blade.

4. Bracket

·Support the radiator upper tank with the bracket

and fix the radiator.

3. Reserve Tank Hose

2. Fan Guide, Lower

1. Radiator Hose

·Connect inlet hose and outlet hose to the engine.

·Connect battery ground cable.

·Pour coolant

·Pour coolant up to filler neck of radiator, and up to

MAX mark of reserve tank.

·Start engine to warm up, and check for coolant

level. Replenish coolant if it does not reach the

radiator filler neck, and tighten the cap completely.