Remove engine ISUZU TROOPER 1998 Service Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 25 of 3573

GENERAL INFORMATION 0AÐ11

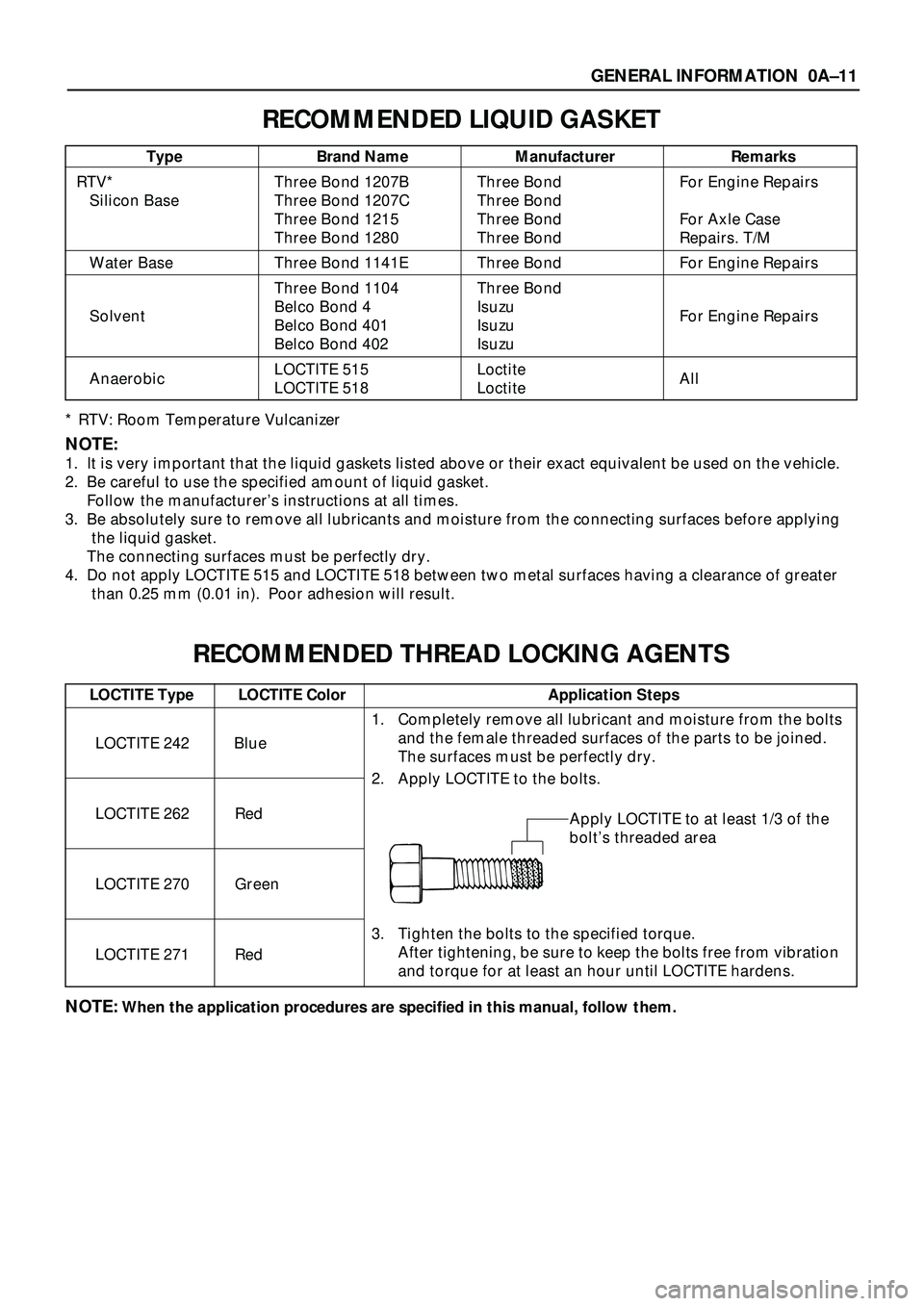

RECOMMENDED LIQUID GASKET

* RTV: Room Temperature Vulcanizer

NOTE:

1. It is very important that the liquid gaskets listed above or their exact equivalent be used on the vehicle.

2. Be careful to use the specified amount of liquid gasket.

Follow the manufacturerÕs instructions at all times.

3. Be absolutely sure to remove all lubricants and moisture from the connecting surfaces before applying

the liquid gasket.

The connecting surfaces must be perfectly dry.

4. Do not apply LOCTITE 515 and LOCTITE 518 between two metal surfaces having a clearance of greater

than 0.25 mm (0.01 in). Poor adhesion will result.

RECOMMENDED THREAD LOCKING AGENTS

NOTE:When the application procedures are specified in this manual, follow them.

Type Brand Name Manufacturer Remarks

RTV* Three Bond 1207B Three Bond For Engine Repairs

Silicon Base Three Bond 1207C Three Bond

Three Bond 1215 Three Bond For Axle Case

Three Bond 1280 Three Bond Repairs. T/M

Water Base Three Bond 1141E Three Bond For Engine Repairs

Three Bond 1104 Three Bond

Belco Bond 4 Isuzu

Solvent

Belco Bond 401 Isuzu For Engine Repairs

Belco Bond 402 Isuzu

LOCTITE 515 Loctite

Anaerobic

LOCTITE 518 Loctite All

LOCTITE Type LOCTITE Color Application Steps

LOCTITE 242 Blue

LOCTITE 262 Red

LOCTITE 270 Green

LOCTITE 271 Red

1. Completely remove all lubricant and moisture from the bolts

and the female threaded surfaces of the parts to be joined.

The surfaces must be perfectly dry.

2. Apply LOCTITE to the bolts.

Apply LOCTITE to at least 1/3 of the

boltÕs threaded area

3. Tighten the bolts to the specified torque.

After tightening, be sure to keep the bolts free from vibration

and torque for at least an hour until LOCTITE hardens.

Page 67 of 3573

00 Ð 28 SERVICE INFORMATION

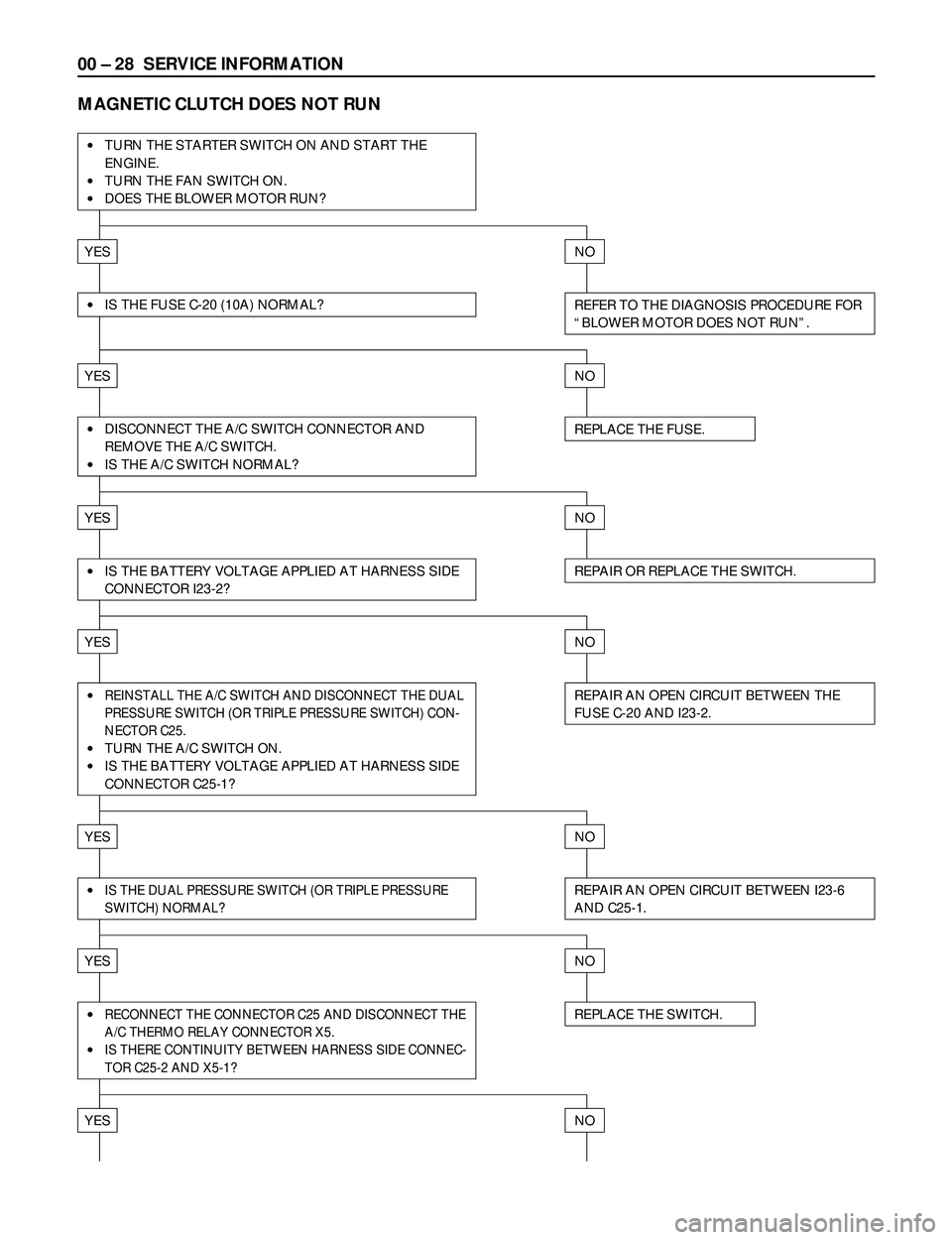

MAGNETIC CLUTCH DOES NOT RUN

·TURN THE STARTER SWITCH ON AND START THE

ENGINE.

·TURN THE FAN SWITCH ON.

·DOES THE BLOWER MOTOR RUN?

YESNO

REFER TO THE DIAGNOSIS PROCEDURE FOR

ÒBLOWER MOTOR DOES NOT RUNÓ.·IS THE FUSE C-20 (10A) NORMAL?

YESNO

REPLACE THE FUSE.·DISCONNECT THE A/C SWITCH CONNECTOR AND

REMOVE THE A/C SWITCH.

·IS THE A/C SWITCH NORMAL?

YESNO

YESNO

REPAIR AN OPEN CIRCUIT BETWEEN THE

FUSE C-20 AND I23-2.·REINSTALL THE A/C SWITCH AND DISCONNECT THE DUAL

PRESSURE SWITCH (OR TRIPLE PRESSURE SWITCH) CON-

NECTOR C25.

·TURN THE A/C SWITCH ON.

·IS THE BATTERY VOLTAGE APPLIED AT HARNESS SIDE

CONNECTOR C25-1?

YESNO

REPLACE THE SWITCH.·RECONNECT THE CONNECTOR C25 AND DISCONNECT THE

A/C THERMO RELAY CONNECTOR X5.

·IS THERE CONTINUITY BETWEEN HARNESS SIDE CONNEC-

TOR C25-2 AND X5-1?

YESNO

REPAIR AN OPEN CIRCUIT BETWEEN I23-6

AND C25-1.·IS THE DUAL PRESSURE SWITCH (OR TRIPLE PRESSURE

SWITCH) NORMAL?

YESNO

REPAIR OR REPLACE THE SWITCH.·IS THE BATTERY VOLTAGE APPLIED AT HARNESS SIDE

CONNECTOR I23-2?

Page 74 of 3573

SERVICE INFORMATION 00 Ð 35

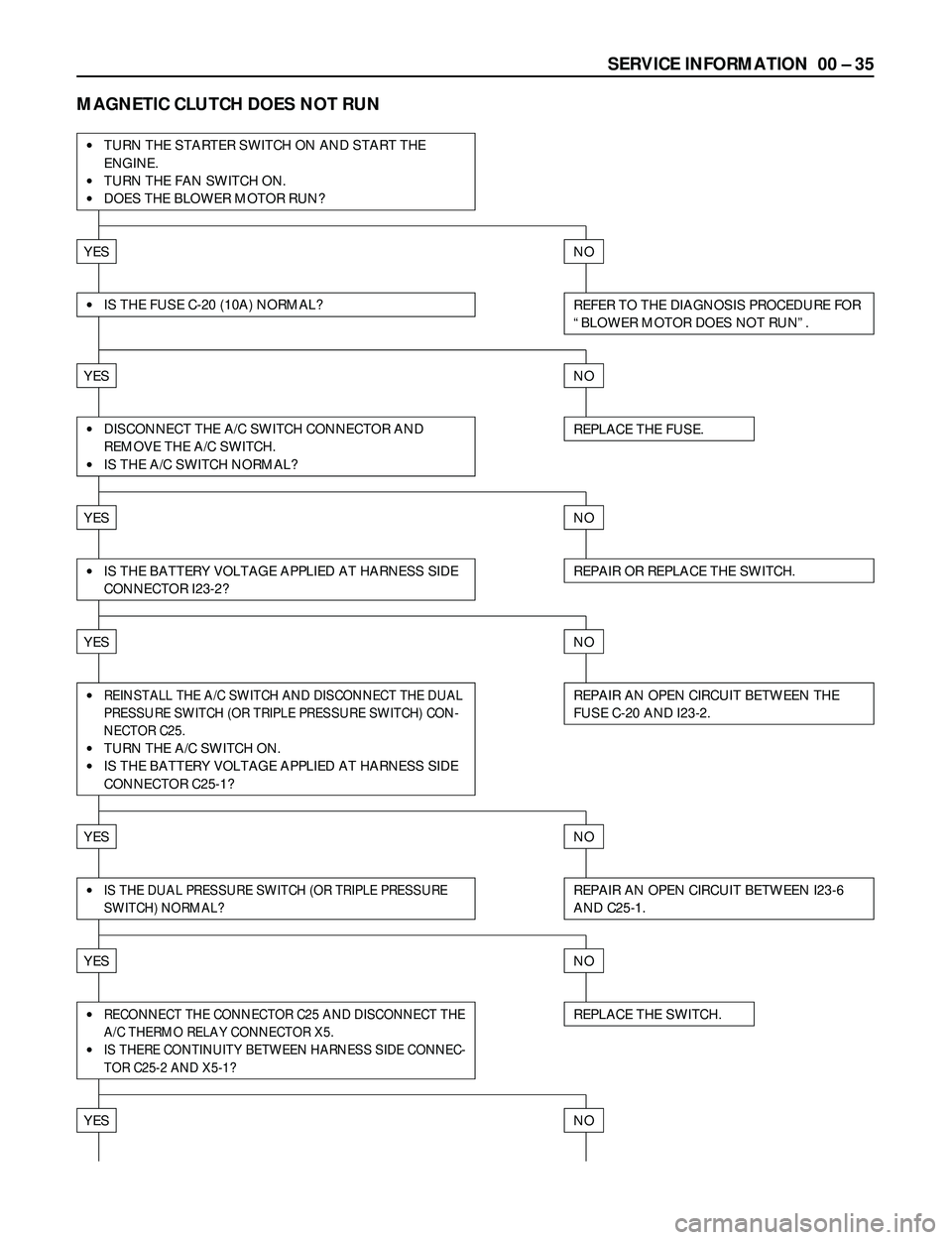

MAGNETIC CLUTCH DOES NOT RUN

·TURN THE STARTER SWITCH ON AND START THE

ENGINE.

·TURN THE FAN SWITCH ON.

·DOES THE BLOWER MOTOR RUN?

YESNO

REFER TO THE DIAGNOSIS PROCEDURE FOR

ÒBLOWER MOTOR DOES NOT RUNÓ.·IS THE FUSE C-20 (10A) NORMAL?

YESNO

REPLACE THE FUSE.·DISCONNECT THE A/C SWITCH CONNECTOR AND

REMOVE THE A/C SWITCH.

·IS THE A/C SWITCH NORMAL?

YESNO

YESNO

REPAIR AN OPEN CIRCUIT BETWEEN THE

FUSE C-20 AND I23-2.·REINSTALL THE A/C SWITCH AND DISCONNECT THE DUAL

PRESSURE SWITCH (OR TRIPLE PRESSURE SWITCH) CON-

NECTOR C25.

·TURN THE A/C SWITCH ON.

·IS THE BATTERY VOLTAGE APPLIED AT HARNESS SIDE

CONNECTOR C25-1?

YESNO

REPLACE THE SWITCH.·RECONNECT THE CONNECTOR C25 AND DISCONNECT THE

A/C THERMO RELAY CONNECTOR X5.

·IS THERE CONTINUITY BETWEEN HARNESS SIDE CONNEC-

TOR C25-2 AND X5-1?

YESNO

REPAIR AN OPEN CIRCUIT BETWEEN I23-6

AND C25-1.·IS THE DUAL PRESSURE SWITCH (OR TRIPLE PRESSURE

SWITCH) NORMAL?

YESNO

REPAIR OR REPLACE THE SWITCH.·IS THE BATTERY VOLTAGE APPLIED AT HARNESS SIDE

CONNECTOR I23-2?

Page 104 of 3573

HEATING AND VENTILATION 1A Ð 9

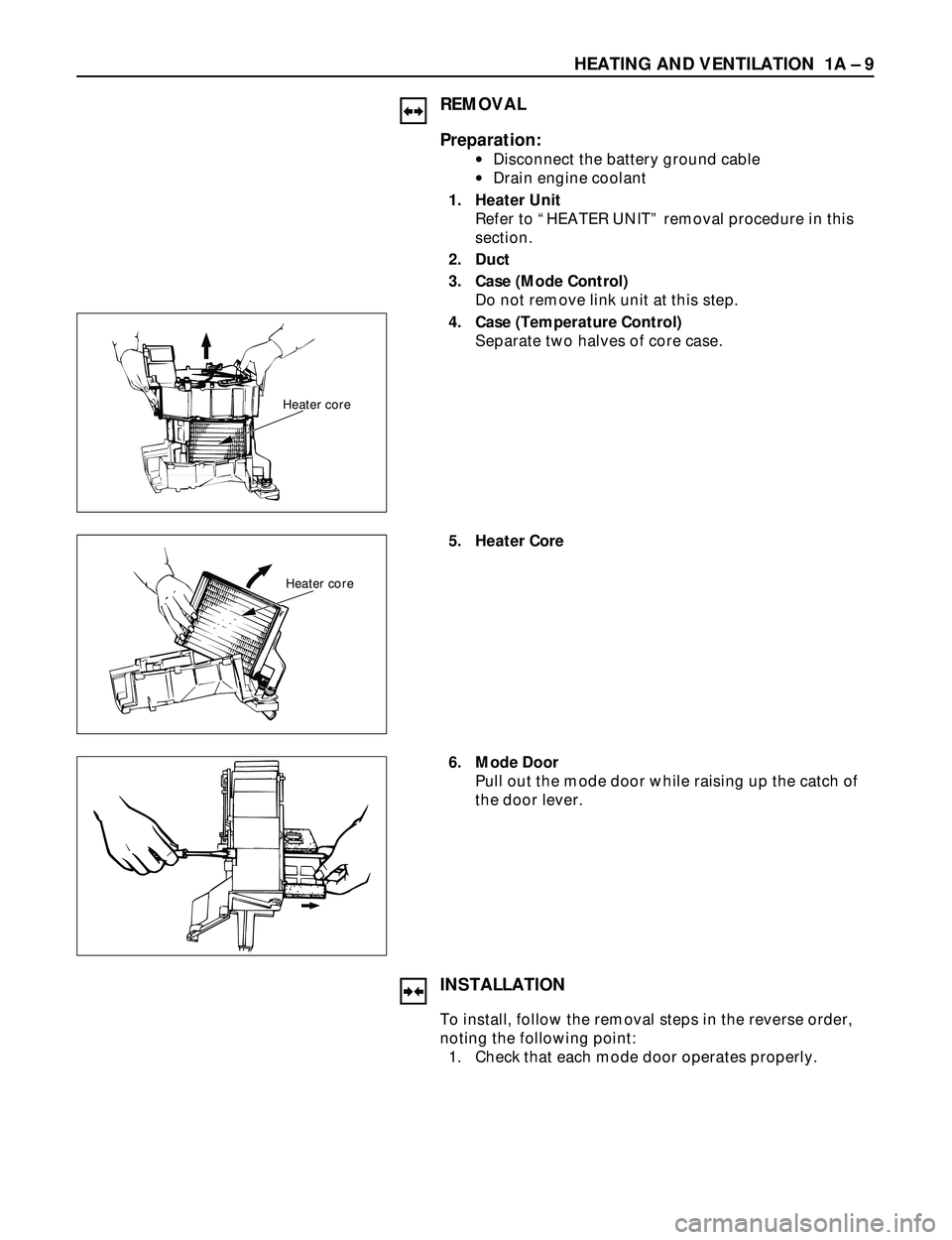

REMOVAL

Preparation:

·Disconnect the battery ground cable

·Drain engine coolant

1. Heater Unit

Refer to ÒHEATER UNITÓ removal procedure in this

section.

2. Duct

3. Case (Mode Control)

Do not remove link unit at this step.

4. Case (Temperature Control)

Separate two halves of core case.

Heater core

5. Heater Core

Heater core

6. Mode Door

Pull out the mode door while raising up the catch of

the door lever.

INSTALLATION

To install, follow the removal steps in the reverse order,

noting the following point:

1. Check that each mode door operates properly.

Page 106 of 3573

HEATING AND VENTILATION 1A Ð 11

REMOVAL

Preparation:

·Disconnect the battery ground cable

·Drain engine coolant

1. Heater Unit

Refer to ÒHEATER UNITÓ removal procedure in this

section.

2. Case (Mode Control)

Remove the case (Mode control) from heater unit.

3. Washer and Mode Main Lever

4. Rod

5. Mode Sub-Lever

Press the tab of the sub-lever inward, and take out the

sub-lever.

6. Door Lever

Pull out the door lever while raising up the catch of

the door lever.

INSTALLATION

To install, follow the removal steps in the reverse order,

noting the following points:

1. Apply grease to mode sub-lever and to the abrasive

surface of the heater unit.

2. After installing the link unit, check to see if the link

unit operates correctly.

Page 108 of 3573

HEATING AND VENTILATION 1A Ð 13

REMOVAL

Preparation:

·Disconnect the battery ground cable

·Drain engine coolant

1. Heater Unit

Refer to ÒHEATER UNITÓ removal procedure in this

section.

2. Case (Temperature Control)

Remove the case (Temperature control) from the

heater unit.

3. Rod

4. Sub-Lever

5. Door Lever

Pull out the door lever while raising up the catch of

the door lever.

6. Clip

INSTALLATION

To install, follow the removal steps in the reverse order,

noting the following points:

1. Apply grease to sub-lever and to the abrasive surface

of the heater unit.

2. After installing the link unit, check to see if the link

unit operates correctly.

Page 130 of 3573

1B Ð 4 AIR CONDITIONING

The refrigeration cycle includes the following four

processes as the refrigerant changes repeatedly

from liquid to gas and back to liquid while

circulating.

EVAPORATION

The refrigerant is changed from a liquid to a gas

inside the evaporator. The refrigerant mist that

enters the evaporator vaporizes readily. The liquid

refrigerant removes the required quantity of heat

(latent heat of vaporization) from the air around the

evaporator core cooling fins and rapidly vaporizes.

Removing the heat cools the air, which is then

radiated from the fins and lowers the temperature

of the air inside the vehicle.

The refrigerant liquid sent from the expansion valve

and the vaporized refrigerant gas are both present

inside the evaporator and the liquid is converted to

gas.

With this change from liquid to gas, the pressure

inside the evaporator must be kept low enough for

vaporization to occur at a lower temperature.

Because of that, the vaporized refrigerant is sucked

into the compressor.

COMPRESSION

The refrigerant is compressed by the compressor

until it is easily liquefied at normal temperature.

The vaporized refrigerant in the evaporator is

sucked into the compressor. This action maintains

the refrigerant inside the evaporator at a low

pressure so that it can easily vaporize, even at low

temperatures close to 0¡C (32¡F).

Also, the refrigerant sucked into the compressor is

compressed inside the cylinder to increase the

pressure and temperature to values such that the

refrigerant can easily liquefy at normal ambient

temperatures.

CONDENSATION

The refrigerant inside the condenser is cooled by

the outside air and changes from gas to liquid.

The high temperature, high pressure gas coming

from the compressor is cooled and liquefied by the

condenser with outside air and accumulated in the

receiver/drier. The heat radiated to the outside air

by the high temperature, high pressure gas in the

compressor is called heat of condensation. This is

the total quantity of heat (heat of vaporization) the

refrigerant removes from the vehicle interior via the

evaporator and the work (calculated as the quantity

of heat) performed for compression.

EXPANSION

The expansion valve lowers the pressure of the

refrigerant liquid so that it can easily vaporize.

The process of lowering the pressure to encourage

vaporization before the liquefied refrigerant is sent

to the evaporator is called expansion. In addition,

the expansion valve controls the flow rate of the

refrigerant liquid while decreasing the pressure.

That is, the quantity of refrigerant liquid vaporized

inside the evaporator is determined by the quantity

of heat which must be removed at a prescribed

vaporization temperature. It is important that the

quantity of refrigerant be controlled to exactly the

right value.

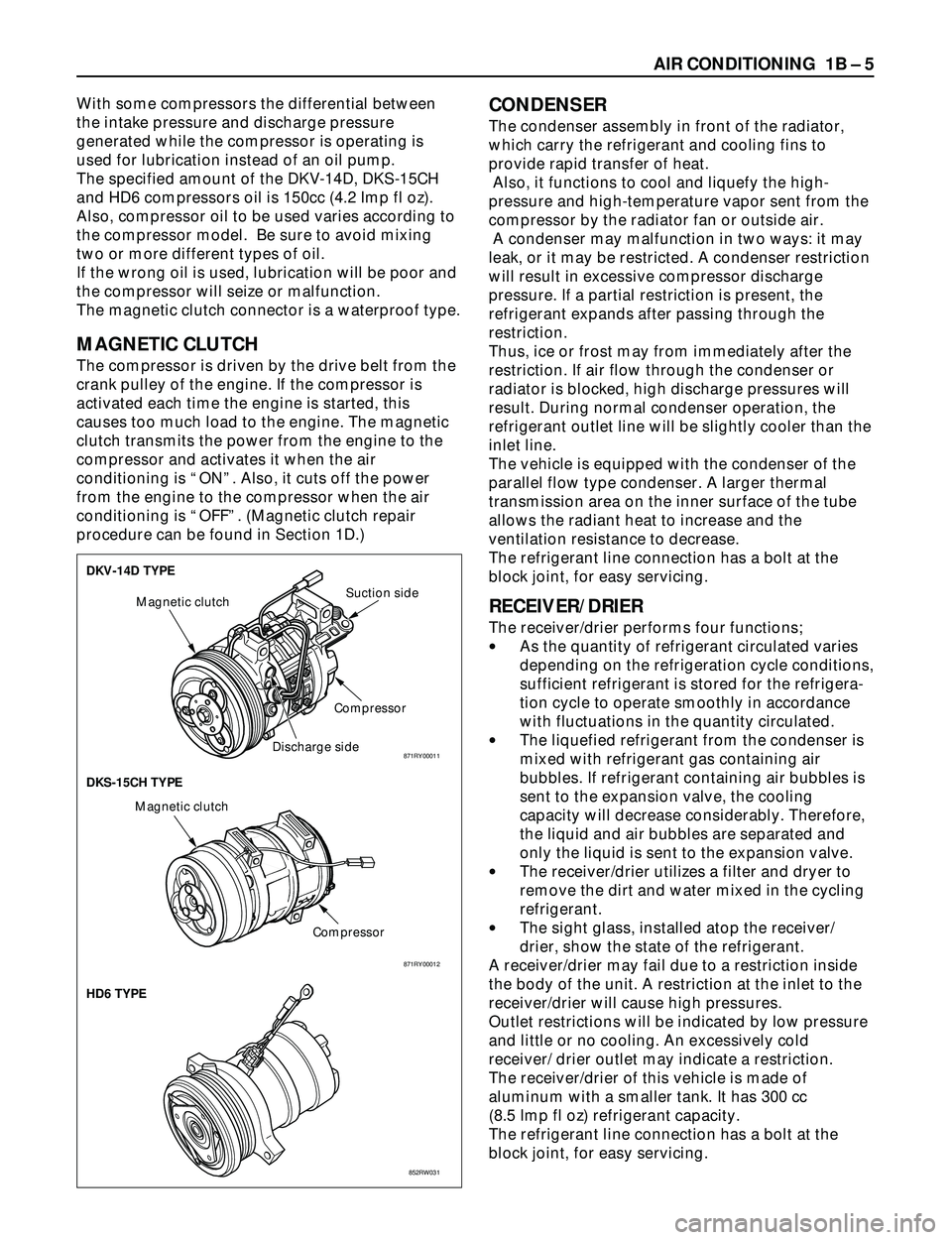

COMPRESSOR

The compressor performs two main functions:

It compresses low-pressure and low-temperature

refrigerant vapor from the evaporator into high-

pressure and high-temperature refrigerant vapor to

the condenser. And it pumps refrigerant and

refrigerant oil through the A/C system.

6VD1/6VE1 engine on RHD model is equipped with

an invariable capacity five-vane rotary compressor

(DKV-14D Type).

The compressor sucks and compresses refrigerant

by the rotation of the vane installed to the shaft,

and always discharges a fixed amount of refrigerant

independent of the load of refrigerant.

The thermo sensor is installed to the front head of

the compressor to protect it by stopping its

operation when the refrigerant gas is insufficient or

when the temperature is abnormally high.

·OFF ....... 160 ±5¡C (320.0 ±41¡F)

·ON ........ 135 ±5¡C (275.0 ±41¡F)

Diesel Engine models and 6VD1/6VE1 engine on

LHD model are equipped with a swash plate type

compressor

Swash plate compressors have a swash (slanted)

plate mounted on the shaft. When the shaft turns,

the rotation of the swash plate is converted to

reciprocating piston motion which sucks in and

compresses the refrigerant gas.

Shaft seal (Lip type) is installed between the valve

plate and shaft & cylinder head to prevent

refrigerant gas leaks. A specified amount of

compressor oil is contained in the oil pan.

This oil is supplied to the cylinders, bearings, etc.,

by an oil pump which is connected to the swash

plate shaft.

Page 131 of 3573

AIR CONDITIONING 1B Ð 5

With some compressors the differential between

the intake pressure and discharge pressure

generated while the compressor is operating is

used for lubrication instead of an oil pump.

The specified amount of the DKV-14D, DKS-15CH

and HD6 compressors oil is 150cc (4.2 Imp fl oz).

Also, compressor oil to be used varies according to

the compressor model. Be sure to avoid mixing

two or more different types of oil.

If the wrong oil is used, lubrication will be poor and

the compressor will seize or malfunction.

The magnetic clutch connector is a waterproof type.

MAGNETIC CLUTCH

The compressor is driven by the drive belt from the

crank pulley of the engine. If the compressor is

activated each time the engine is started, this

causes too much load to the engine. The magnetic

clutch transmits the power from the engine to the

compressor and activates it when the air

conditioning is ÒONÓ. Also, it cuts off the power

from the engine to the compressor when the air

conditioning is ÒOFFÓ. (Magnetic clutch repair

procedure can be found in Section 1D.)

CONDENSER

The condenser assembly in front of the radiator,

which carry the refrigerant and cooling fins to

provide rapid transfer of heat.

Also, it functions to cool and liquefy the high-

pressure and high-temperature vapor sent from the

compressor by the radiator fan or outside air.

A condenser may malfunction in two ways: it may

leak, or it may be restricted. A condenser restriction

will result in excessive compressor discharge

pressure. If a partial restriction is present, the

refrigerant expands after passing through the

restriction.

Thus, ice or frost may from immediately after the

restriction. If air flow through the condenser or

radiator is blocked, high discharge pressures will

result. During normal condenser operation, the

refrigerant outlet line will be slightly cooler than the

inlet line.

The vehicle is equipped with the condenser of the

parallel flow type condenser. A larger thermal

transmission area on the inner surface of the tube

allows the radiant heat to increase and the

ventilation resistance to decrease.

The refrigerant line connection has a bolt at the

block joint, for easy servicing.

RECEIVER/DRIER

The receiver/drier performs four functions;

·As the quantity of refrigerant circulated varies

depending on the refrigeration cycle conditions,

sufficient refrigerant is stored for the refrigera-

tion cycle to operate smoothly in accordance

with fluctuations in the quantity circulated.

·The liquefied refrigerant from the condenser is

mixed with refrigerant gas containing air

bubbles. If refrigerant containing air bubbles is

sent to the expansion valve, the cooling

capacity will decrease considerably. Therefore,

the liquid and air bubbles are separated and

only the liquid is sent to the expansion valve.

·The receiver/drier utilizes a filter and dryer to

remove the dirt and water mixed in the cycling

refrigerant.

·The sight glass, installed atop the receiver/

drier, show the state of the refrigerant.

A receiver/drier may fail due to a restriction inside

the body of the unit. A restriction at the inlet to the

receiver/drier will cause high pressures.

Outlet restrictions will be indicated by low pressure

and little or no cooling. An excessively cold

receiver/ drier outlet may indicate a restriction.

The receiver/drier of this vehicle is made of

aluminum with a smaller tank. It has 300 cc

(8.5 Imp fl oz) refrigerant capacity.

The refrigerant line connection has a bolt at the

block joint, for easy servicing.

DKV-14D TYPE

DKS-15CH TYPE

HD6 TYPE

Magnetic clutch

CompressorSuction side

Discharge side

Compressor Magnetic clutch

852RW031 871RY00012

871RY00011

Page 139 of 3573

AIR CONDITIONING 1B Ð 13

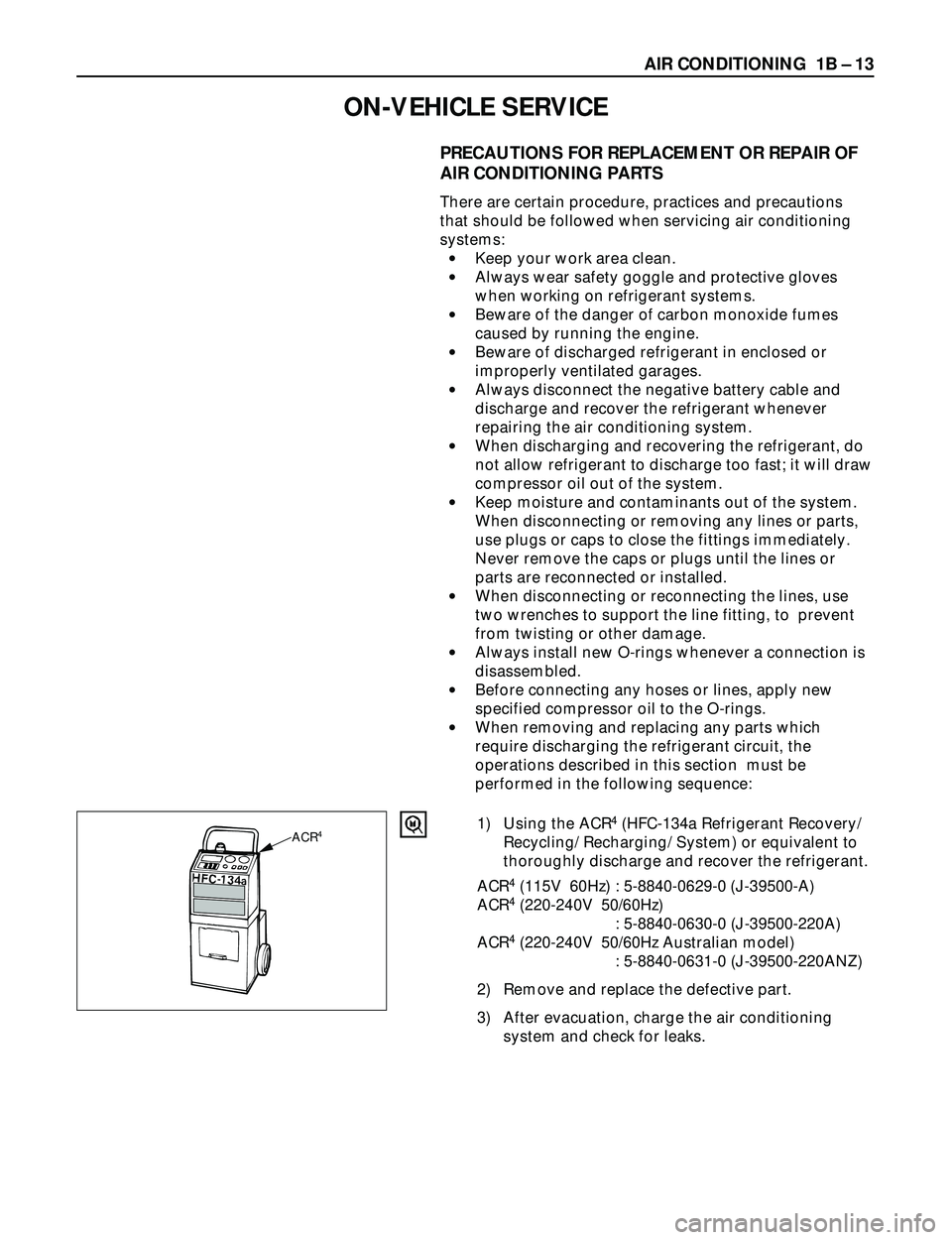

ACR41) Using the ACR4(HFC-134a Refrigerant Recovery/

Recycling/ Recharging/ System) or equivalent to

thoroughly discharge and recover the refrigerant.

ACR

4(115V 60Hz) : 5-8840-0629-0 (J-39500-A)

ACR4(220-240V 50/60Hz)

: 5-8840-0630-0 (J-39500-220A)

ACR

4(220-240V 50/60Hz Australian model)

: 5-8840-0631-0 (J-39500-220ANZ)

2) Remove and replace the defective part.

3) After evacuation, charge the air conditioning

system and check for leaks.

PRECAUTIONS FOR REPLACEMENT OR REPAIR OF

AIR CONDITIONING PARTS

There are certain procedure, practices and precautions

that should be followed when servicing air conditioning

systems:

·Keep your work area clean.

·Always wear safety goggle and protective gloves

when working on refrigerant systems.

·Beware of the danger of carbon monoxide fumes

caused by running the engine.

·Beware of discharged refrigerant in enclosed or

improperly ventilated garages.

·Always disconnect the negative battery cable and

discharge and recover the refrigerant whenever

repairing the air conditioning system.

·When discharging and recovering the refrigerant, do

not allow refrigerant to discharge too fast; it will draw

compressor oil out of the system.

·Keep moisture and contaminants out of the system.

When disconnecting or removing any lines or parts,

use plugs or caps to close the fittings immediately.

Never remove the caps or plugs until the lines or

parts are reconnected or installed.

·When disconnecting or reconnecting the lines, use

two wrenches to support the line fitting, to prevent

from twisting or other damage.

·Always install new O-rings whenever a connection is

disassembled.

·Before connecting any hoses or lines, apply new

specified compressor oil to the O-rings.

·When removing and replacing any parts which

require discharging the refrigerant circuit, the

operations described in this section must be

performed in the following sequence:

ON-VEHICLE SERVICE

Page 146 of 3573

1B Ð 20 AIR CONDITIONING

1) Make sure the evacuation process is correctly

completed.

2) Connect the center-hose of the manifold gauge to the

refrigerant container.

·Turn the charge valve handle counterclockwise to

purge the charging line and purge any air existing

in the center-hose of the manifold gauge.

3) Open the low-pressure hand valve and charge the

refrigerant about 200 g(0.44 lbs.).

·Make sure the high-pressure hand valve is closed.

·Avoid charging the refrigerant by turning the

refrigerant container upside down.

4) Close the low-pressure hand valve of the manifold

gauge.

·Check to ensure that the degree of pressure does

not charge.

5) Check the refrigerant leaks by using a HFC-134a leak

detector.

·If a leak occurs, repair the leak connection, and

start all over again from the first step of

evacuation.

6) If no leaks are found, open the low-pressure hand

valve of the manifold gauge.Then continue charging

refrigerant to the system.

·When charging the system becomes difficult:

(1) Run the engine at Idling and close the all

vehicle doors.

(2) A/C switch is ÒONÓ.

(3) Set the fan control knob (fan switch) to its

highest position.

WARNING

BE ABSOLUTELY SURE NOT TO OPEN THE HIGH-

PRESSURE HAND VALVE. SHOULD THE HIGH-

PRESSURE HAND VALVE BE OPENED, THE HIGH-

PRESSURE REFRIGERANT GAS WOULD FLOW

BACKWARD, AND THIS MAY CAUSE THE

REFRIGERANT CONTAINER TO BURST.

7) When the refrigerant container is emptied, use the

following procedure to replace it with a new

refrigerant container.

(1) Close the low pressure hand valve.

(2) Raise the needle upward and remove the charge

valve.

(3) Reinstall the charge valve to the new refrigerant

container.

(4) Purge any air existing in the center hose of the

manifold gauge.