UBS ISUZU TROOPER 1998 Service Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 1 of 3573

W O R K S H O P M A N U A L

US VERSION

RIGHT HAND MODEL

EXP UBS

PubNo. RV99_02-01.E

Page 2 of 3573

W O R K S H O P M A N U A L

1998/1999

U B S

2000

UBS

2002

UBS

Page 17 of 3573

GENERAL INFORMATION 0AÐ3

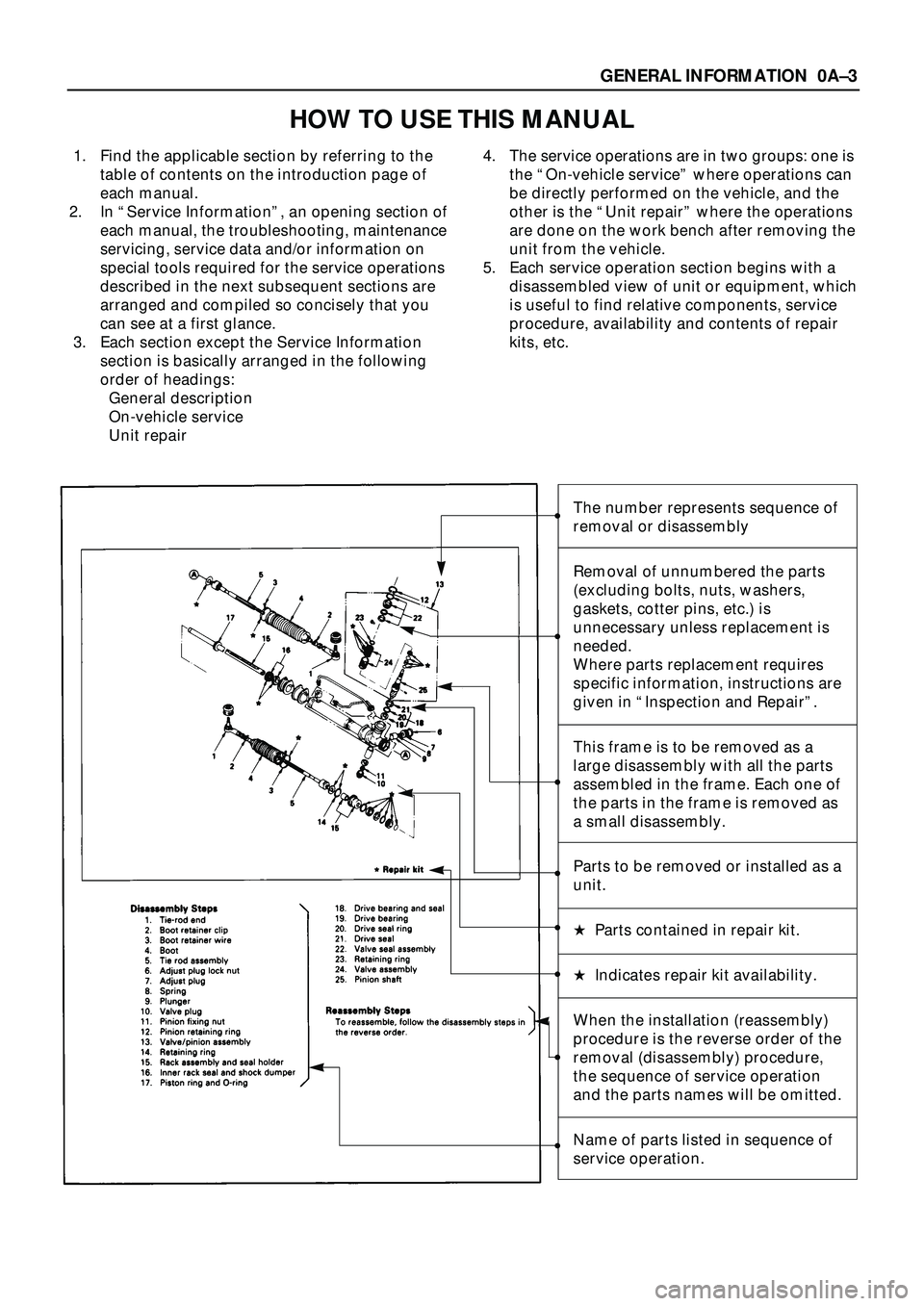

HOW TO USE THIS MANUAL

1. Find the applicable section by referring to the

table of contents on the introduction page of

each manual.

2. In ÒService InformationÓ, an opening section of

each manual, the troubleshooting, maintenance

servicing, service data and/or information on

special tools required for the service operations

described in the next subsequent sections are

arranged and compiled so concisely that you

can see at a first glance.

3. Each section except the Service Information

section is basically arranged in the following

order of headings:

General description

On-vehicle service

Unit repair4. The service operations are in two groups: one is

the ÒOn-vehicle serviceÓ where operations can

be directly performed on the vehicle, and the

other is the ÒUnit repairÓ where the operations

are done on the work bench after removing the

unit from the vehicle.

5. Each service operation section begins with a

disassembled view of unit or equipment, which

is useful to find relative components, service

procedure, availability and contents of repair

kits, etc.

The number represents sequence of

removal or disassembly

Removal of unnumbered the parts

(excluding bolts, nuts, washers,

gaskets, cotter pins, etc.) is

unnecessary unless replacement is

needed.

Where parts replacement requires

specific information, instructions are

given in ÒInspection and RepairÓ.

This frame is to be removed as a

large disassembly with all the parts

assembled in the frame. Each one of

the parts in the frame is removed as

a small disassembly.

Parts to be removed or installed as a

unit.

H Parts contained in repair kit.

H Indicates repair kit availability.

When the installation (reassembly)

procedure is the reverse order of the

removal (disassembly) procedure,

the sequence of service operation

and the parts names will be omitted.

Name of parts listed in sequence of

service operation.

Page 20 of 3573

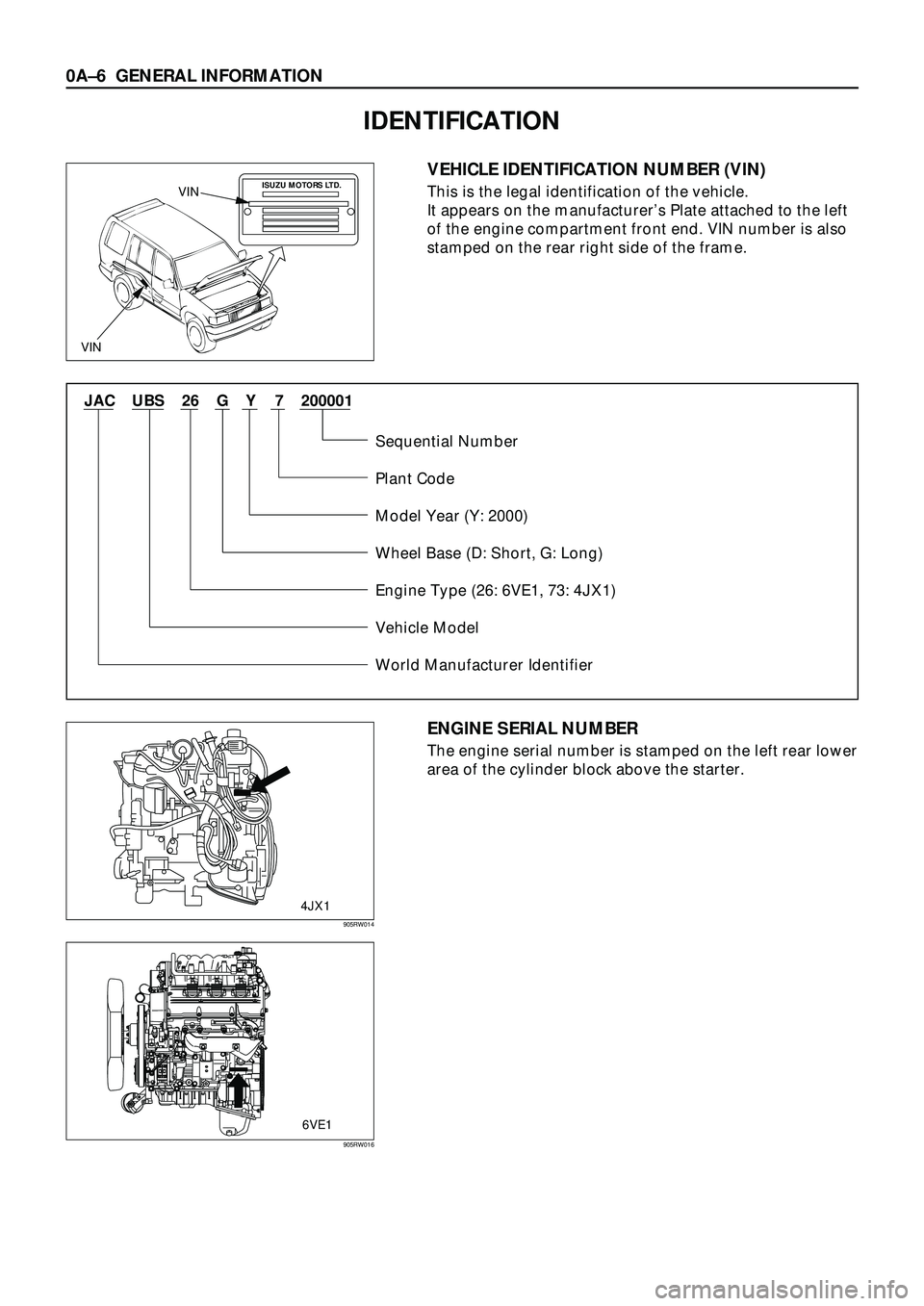

VEHICLE IDENTIFICATION NUMBER (VIN)

This is the legal identification of the vehicle.

It appears on the manufacturerÕs Plate attached to the left

of the engine compartment front end. VIN number is also

stamped on the rear right side of the frame.VIN

VINISUZU MOTORS LTD.

JAC UBS 26 G Y 7 200001

Sequential Number

Plant Code

Model Year (Y: 2000)

Wheel Base (D: Short, G: Long)

Engine Type (26: 6VE1, 73: 4JX1)

Vehicle Model

World Manufacturer Identifier

ENGINE SERIAL NUMBER

The engine serial number is stamped on the left rear lower

area of the cylinder block above the starter.

4JX1

6VE1

0AÐ6 GENERAL INFORMATION

IDENTIFICATION

905RW014

905RW016

Page 30 of 3573

MAINTENANCE AND LUBRICATION 0BÐ3

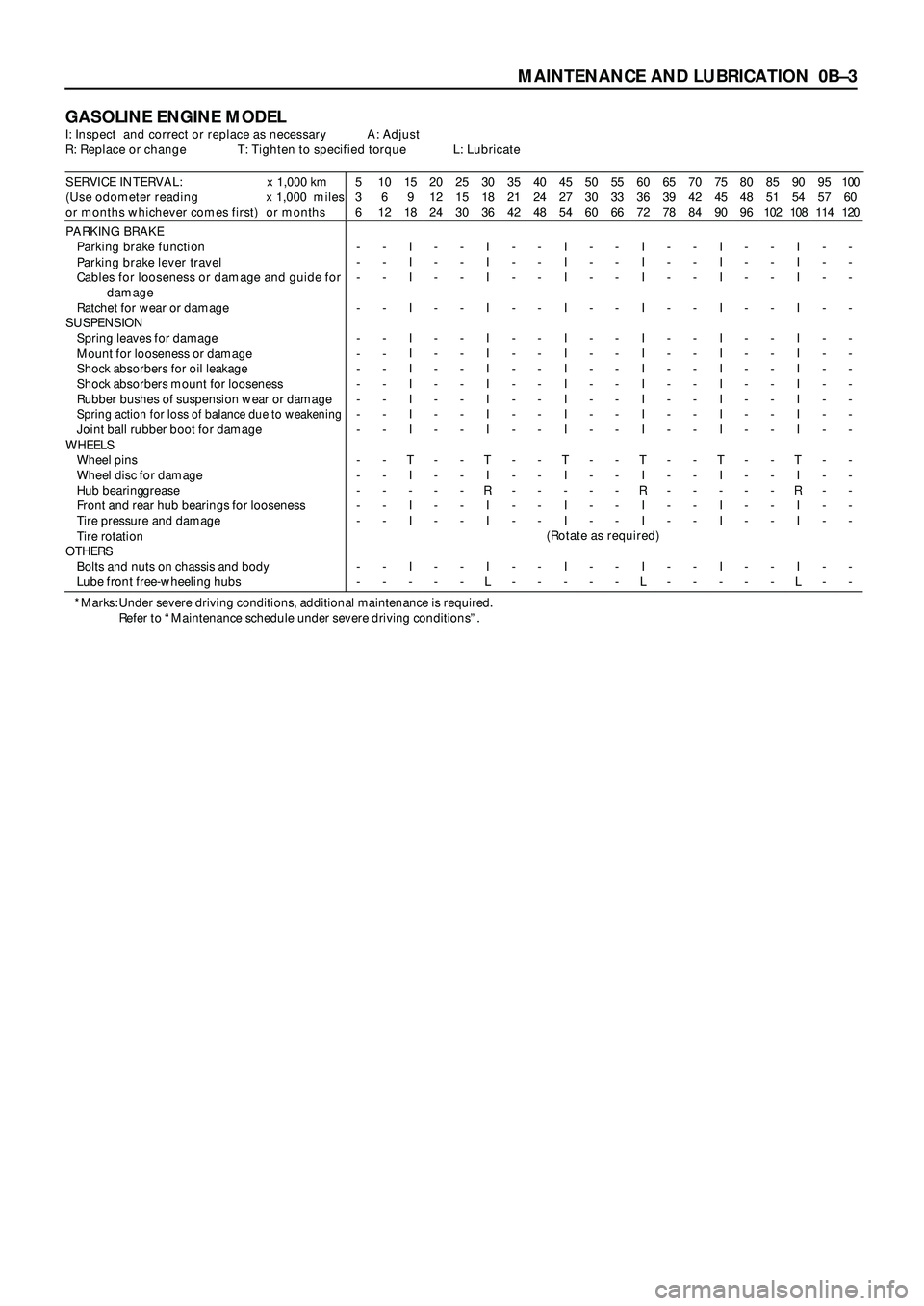

GASOLINE ENGINE MODELI: Inspect and correct or replace as necessary A: Adjust

R: Replace or change T: Tighten to specified torque L: Lubricate

SERVICE INTERVAL: x 1,000 km

(Use odometer reading x 1,000 miles

or months whichever comes first) or months5

3

610

6

1215

9

1820

12

2425

15

3030

18

3635

21

4240

24

4845

27

5450

30

6055

33

6660

36

7265

39

7870

42

8475

45

9080

48

9685

51

10290

54

10895

57

114100

60

120

PARKING BRAKE

Parking brake function

Parking brake lever travel

Cables for looseness or damage and guide for

damage

Ratchet for wear or damage

SUSPENSION

Spring leaves for damage

Mount for looseness or damage

Shock absorbers for oil leakage

Shock absorbers mount for looseness

Rubber bushes of suspension wear or damage

Spring action for loss of balance due to weakeningJoint ball rubber boot for damage

WHEELS

Wheel pins

Wheel disc for damage

Hub bearing grease

Front and rear hub bearings for looseness

Tire pressure and damage

Tire rotation

OTHERS

Bolts and nuts on chassis and body

Lube front free-wheeling hubs-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

I

I

I

I

I

I

I

T

I

-

I

I

I

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

I

I

I

I

I

I

I

T

I

R

I

I

I

L-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

I

I

I

I

I

I

I

T

I

-

I

I

I

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

I

I

I

I

I

I

I

T

I

R

I

I

I

L-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

I

I

I

I

I

I

I

T

I

-

I

I

I

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

I

I

I

I

I

I

I

T

I

R

I

I

I

L-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

(Rotate as required)

*Marks: Under severe driving conditions, additional maintenance is required.

Refer to “Maintenance schedule under severe driving conditions”.

Page 32 of 3573

MAINTENANCE AND LUBRICATION 0BÐ5

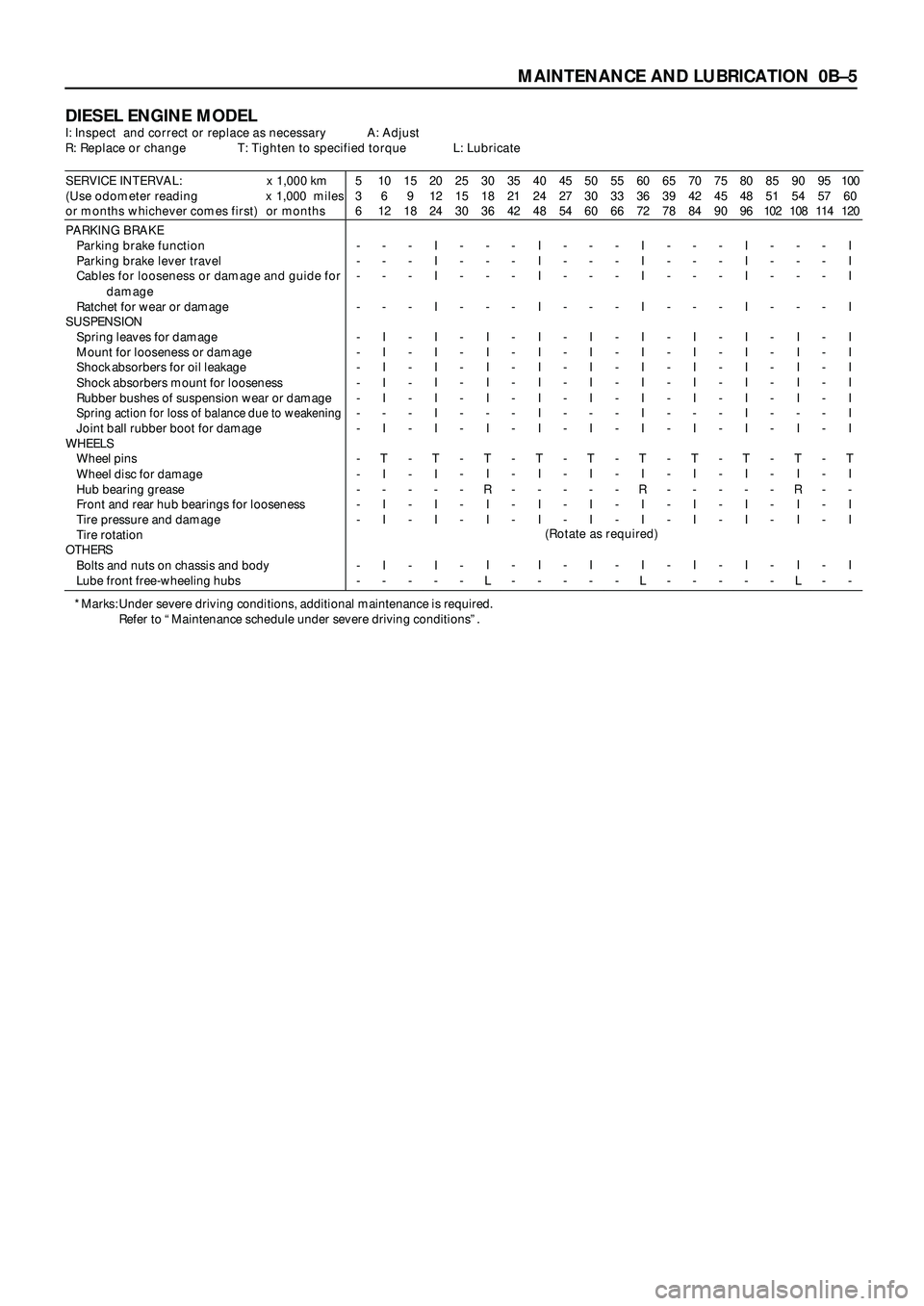

DIESEL ENGINE MODELI: Inspect and correct or replace as necessary A: Adjust

R: Replace or change T: Tighten to specified torque L: Lubricate

SERVICE INTERVAL: x 1,000 km

(Use odometer reading x 1,000 miles

or months whichever comes first) or months5

3

610

6

1215

9

1820

12

2425

15

3030

18

3635

21

4240

24

4845

27

5450

30

6055

33

6660

36

7265

39

7870

42

8475

45

9080

48

9685

51

10290

54

10895

57

114100

60

120

PARKING BRAKE

Parking brake function

Parking brake lever travel

Cables for looseness or damage and guide for

damage

Ratchet for wear or damage

SUSPENSION

Spring leaves for damage

Mount for looseness or damage

Shock absorbers for oil leakage

Shock absorbers mount for looseness

Rubber bushes of suspension wear or damage

Spring action for loss of balance due to weakeningJoint ball rubber boot for damage

WHEELS

Wheel pins

Wheel disc for damage

Hub bearing grease

Front and rear hub bearings for looseness

Tire pressure and damage

Tire rotation

OTHERS

Bolts and nuts on chassis and body

Lube front free-wheeling hubs-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

I

I

I

I

I

-

I

T

I

-

I

I

I

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

I

I

I

I

I

I

I

T

I

-

I

I

I

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

I

I

I

I

I

-

I

T

I

R

I

I

I

L-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

I

I

I

I

I

I

I

T

I

-

I

I

I

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

I

I

I

I

I

-

I

T

I

-

I

I

I

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

I

I

I

I

I

I

I

T

I

R

I

I

I

L-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

I

I

I

I

I

-

I

T

I

-

I

I

I

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

I

I

I

I

I

I

I

T

I

-

I

I

I

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

I

I

I

I

I

-

I

T

I

R

I

I

I

L-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

I

I

I

I

I

I

I

T

I

-

I

I

I

-

(Rotate as required)

*Marks: Under severe driving conditions, additional maintenance is required.

Refer to “Maintenance schedule under severe driving conditions”.

Page 62 of 3573

SERVICE INFORMATION 00 Ð 23

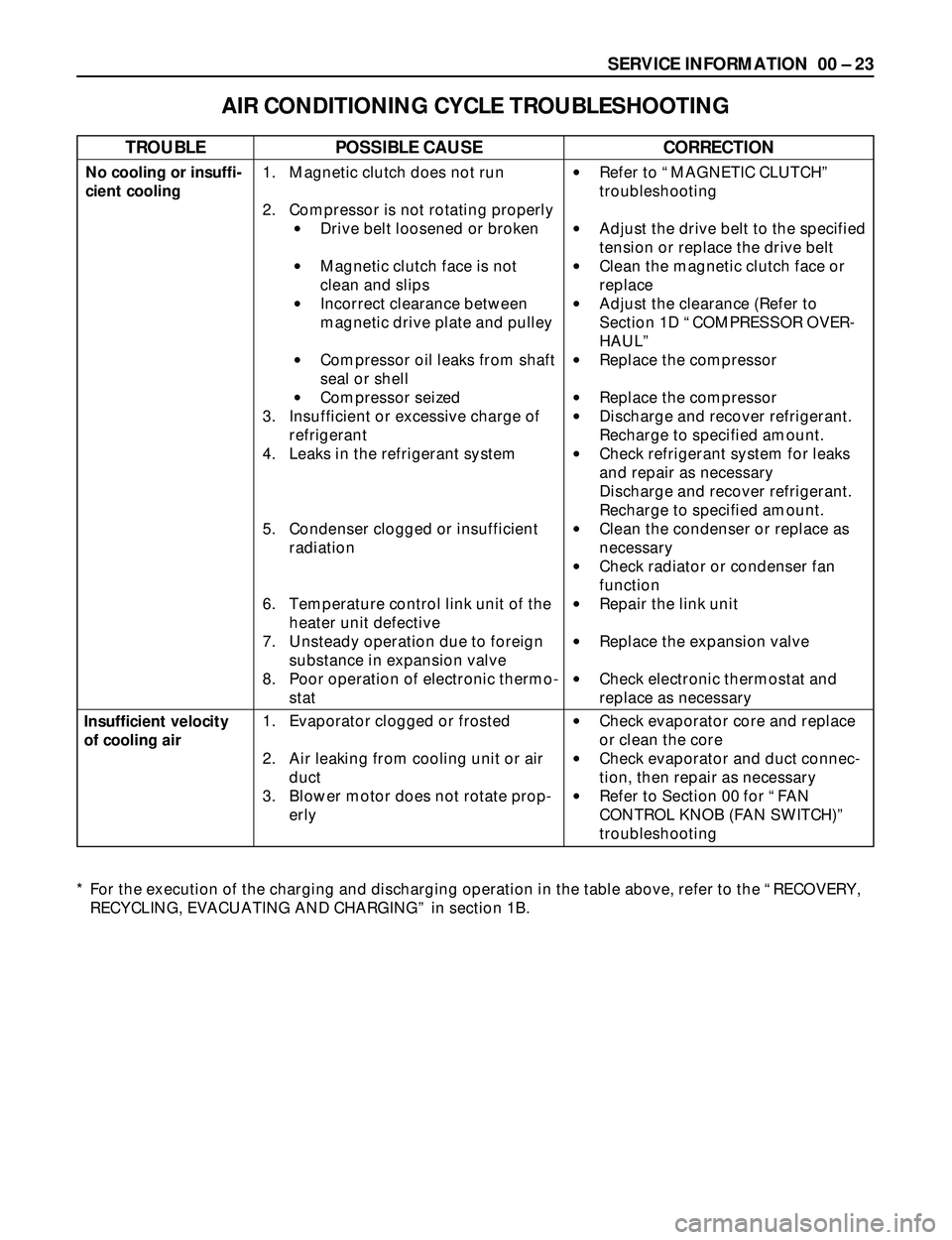

AIR CONDITIONING CYCLE TROUBLESHOOTING

No cooling or insuffi-

cient cooling

Insufficient velocity

of cooling air1. Magnetic clutch does not run

2. Compressor is not rotating properly

·Drive belt loosened or broken

·Magnetic clutch face is not

clean and slips

·Incorrect clearance between

magnetic drive plate and pulley

·Compressor oil leaks from shaft

seal or shell

·Compressor seized

3. Insufficient or excessive charge of

refrigerant

4. Leaks in the refrigerant system

5. Condenser clogged or insufficient

radiation

6. Temperature control link unit of the

heater unit defective

7. Unsteady operation due to foreign

substance in expansion valve

8. Poor operation of electronic thermo-

stat

1. Evaporator clogged or frosted

2. Air leaking from cooling unit or air

duct

3. Blower motor does not rotate prop-

erly·Refer to ÒMAGNETIC CLUTCHÓ

troubleshooting

·Adjust the drive belt to the specified

tension or replace the drive belt

·Clean the magnetic clutch face or

replace

·Adjust the clearance (Refer to

Section 1D ÒCOMPRESSOR OVER-

HAULÓ

·Replace the compressor

·Replace the compressor

·Discharge and recover refrigerant.

Recharge to specified amount.

·Check refrigerant system for leaks

and repair as necessary

Discharge and recover refrigerant.

Recharge to specified amount.

·Clean the condenser or replace as

necessary

·Check radiator or condenser fan

function

·Repair the link unit

·Replace the expansion valve

·Check electronic thermostat and

replace as necessary

·Check evaporator core and replace

or clean the core

·Check evaporator and duct connec-

tion, then repair as necessary

·Refer to Section 00 for ÒFAN

CONTROL KNOB (FAN SWITCH)Ó

troubleshooting

* For the execution of the charging and discharging operation in the table above, refer to the ÒRECOVERY,

RECYCLING, EVACUATING AND CHARGINGÓ in section 1B.

TROUBLEPOSSIBLE CAUSECORRECTION

Page 261 of 3573

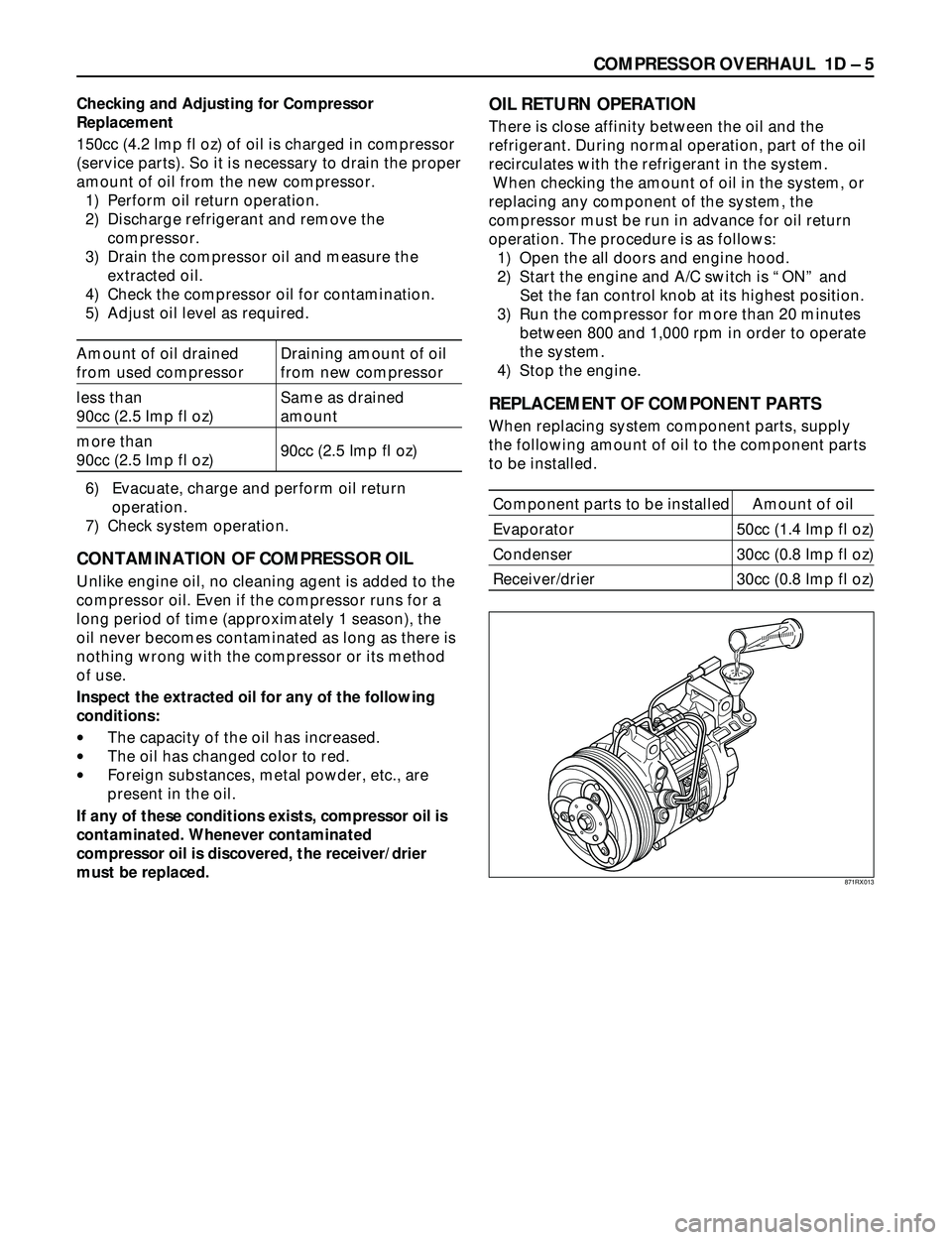

COMPRESSOR OVERHAUL 1D Ð 5

Checking and Adjusting for Compressor

Replacement

150cc (4.2 Imp fl oz) of oil is charged in compressor

(service parts). So it is necessary to drain the proper

amount of oil from the new compressor.

1) Perform oil return operation.

2) Discharge refrigerant and remove the

compressor.

3) Drain the compressor oil and measure the

extracted oil.

4) Check the compressor oil for contamination.

5) Adjust oil level as required.

Amount of oil drained Draining amount of oil

from used compressor from new compressor

less than Same as drained

90cc (2.5 Imp fl oz) amount

more than

90cc (2.5 Imp fl oz)

90cc (2.5 Imp fl oz)

6) Evacuate, charge and perform oil return

operation.

7) Check system operation.

CONTAMINATION OF COMPRESSOR OIL

Unlike engine oil, no cleaning agent is added to the

compressor oil. Even if the compressor runs for a

long period of time (approximately 1 season), the

oil never becomes contaminated as long as there is

nothing wrong with the compressor or its method

of use.

Inspect the extracted oil for any of the following

conditions:

·The capacity of the oil has increased.

·The oil has changed color to red.

·Foreign substances, metal powder, etc., are

present in the oil.

If any of these conditions exists, compressor oil is

contaminated. Whenever contaminated

compressor oil is discovered, the receiver/drier

must be replaced.

OIL RETURN OPERATION

There is close affinity between the oil and the

refrigerant. During normal operation, part of the oil

recirculates with the refrigerant in the system.

When checking the amount of oil in the system, or

replacing any component of the system, the

compressor must be run in advance for oil return

operation. The procedure is as follows:

1) Open the all doors and engine hood.

2) Start the engine and A/C switch is ÒONÓ and

Set the fan control knob at its highest position.

3) Run the compressor for more than 20 minutes

between 800 and 1,000 rpm in order to operate

the system.

4) Stop the engine.

REPLACEMENT OF COMPONENT PARTS

When replacing system component parts, supply

the following amount of oil to the component parts

to be installed.

Component parts to be installed Amount of oil

Evaporator 50cc (1.4 Imp fl oz)

Condenser 30cc (0.8 Imp fl oz)

Receiver/drier 30cc (0.8 Imp fl oz)

871RX013

Page 281 of 3573

COMPRESSOR OVERHAUL 1D Ð 25

1. Perform oil return operation.

2. Discharge and recover the refrigerant and remove

the compressor.

3. Drain the compressor oil and measure the extracted

oil.

4. Check the compressor oil for contamination.

5. Adjust the oil level as required.

6. Evacuate, charge and perform the oil return

operation.

7. Check the system operation.

Contamination of Compressor Oil

Unlike engine oil, no cleaning agent is added to the

compressor oil. Even if the compressor runs for a long

period of time (approximately one season), the oil never

becomes contaminated as long as there is nothing

wrong with the compressor or its method of use.

Inspect the extracted oil for any of the following

conditions:

·The capacity of the oil has increased.

·The oil has changed to red.

·Foreign substances, metal powder, etc., are present

in the oil.

If any of these conditions exists, the compressor

oil is contaminated. Whenever contaminated

compressor oil is discovered, the receiver/drier

must be replaced.

Oil Return Operation

There is close affinity between the oil and the

refrigerant. During normal operation, part of the oil

recirculates with the refrigerant in the system. When

checking the amount of oil in the system, or replacing

any component of the system, the compressor must be

run in advance for oil return operation. The procedure

is as follows:

1. Open all the doors and the engine hood.

2. Start the engine and air conditioning switch to "ON"

and set the fan control knob at its highest position.

3. Run the compressor for more than 20 minutes

between 800 and 1,000 rpm in order to operate the

system.

4. Stop the engine.

Replacement of Component Parts

When replacing the system component parts, supply

the following amount of oil to the component parts to be

installed.

Compressor Leak Testing (External and

Internal)

Bench-Check Procedure

1. Install test plate J-39893 on rear head of compressor.

2. Using Refrigerant Recovery System, attach center

hose of manifold gage set on charging station to a

refrigerant drum standing in an upright drum.

3. Connect charging station high and low pressure

lines to corresponding fittings on test plate J-39893.

Suction port (low-side) of compressor has large

internal opening. Discharge port (high-side) has

smaller internal opening into compressor and

deeper recess.

4. Open low pressure control, high pressure control

and refrigerant control on charging station to allow

refrigerant vapor to flow into compressor.

5. Using a leak detector, check for leaks at pressure

relief valve, rear head switch location, compressor

front and rear head seals, center cylinder seal,

through bolt head gaskets and compressor shaft

seal. After checking, shut off low pressure control

and high-pressure control on charging station.

6. If an external leak is present, perform the necessary

corrective measures and recheck for leaks to make

certain the leak has been connected.

7. Recover the refrigerant.

8. Disconnect both hoses from the test plate J-39893.

9. Add 90 ml (3 oz.) new PAG lubricant to the

compressor assembly. Rotate the complete

compressor assembly (not the crankshaft or drive

plate hub) slowly several turns to distribute oil to all

cylinder and piston areas.

10. Install a M9 ´1.25 threaded nut on the compressor

crankshaft if the drive plate and clutch assembly are

not installed.

11. Using a box-end wrench or socket and handle,

rotate the compressor crankshaft or clutch drive

plate on the crankshaft several turns to insure

piston assembly to cylinder wall lubrication.

12. Using Refrigerant Recovery System, connect the

charging station high-pressure line to the test plate

J-39893 high-side connector.

13. Using Refrigerant Recovery System, connect the

charging station low-pressure line to the low

pressure port of the test plate J-39893. Oil will drain

out of the compressor suction port if the compressor

is positioned with the suction port downward. (Component parts to be (Amount of Oil)

installed)

Evaporator 50 cc (1.7 fl. oz.)

Condenser 30 cc (1.0 fl. oz.)

Receiver/dryer 30 cc (1.0 fl. oz.)

Refrigerant line (one 10 cc (0.3 fl. oz.)

piece)

(Amount of oil drained (Charging amount of oil

from used compressor) to new compressor)

more than 90 cc same as drained amount

(3.0 fl.oz)

less than 90 cc (3.0 fl.oz) 90 cc (3.0 fl.oz)

Page 357 of 3573

SUPPLEMENTAL RESTRAINT SYSTEM STEERING WHEEL & COLUMN 2A Ð 55

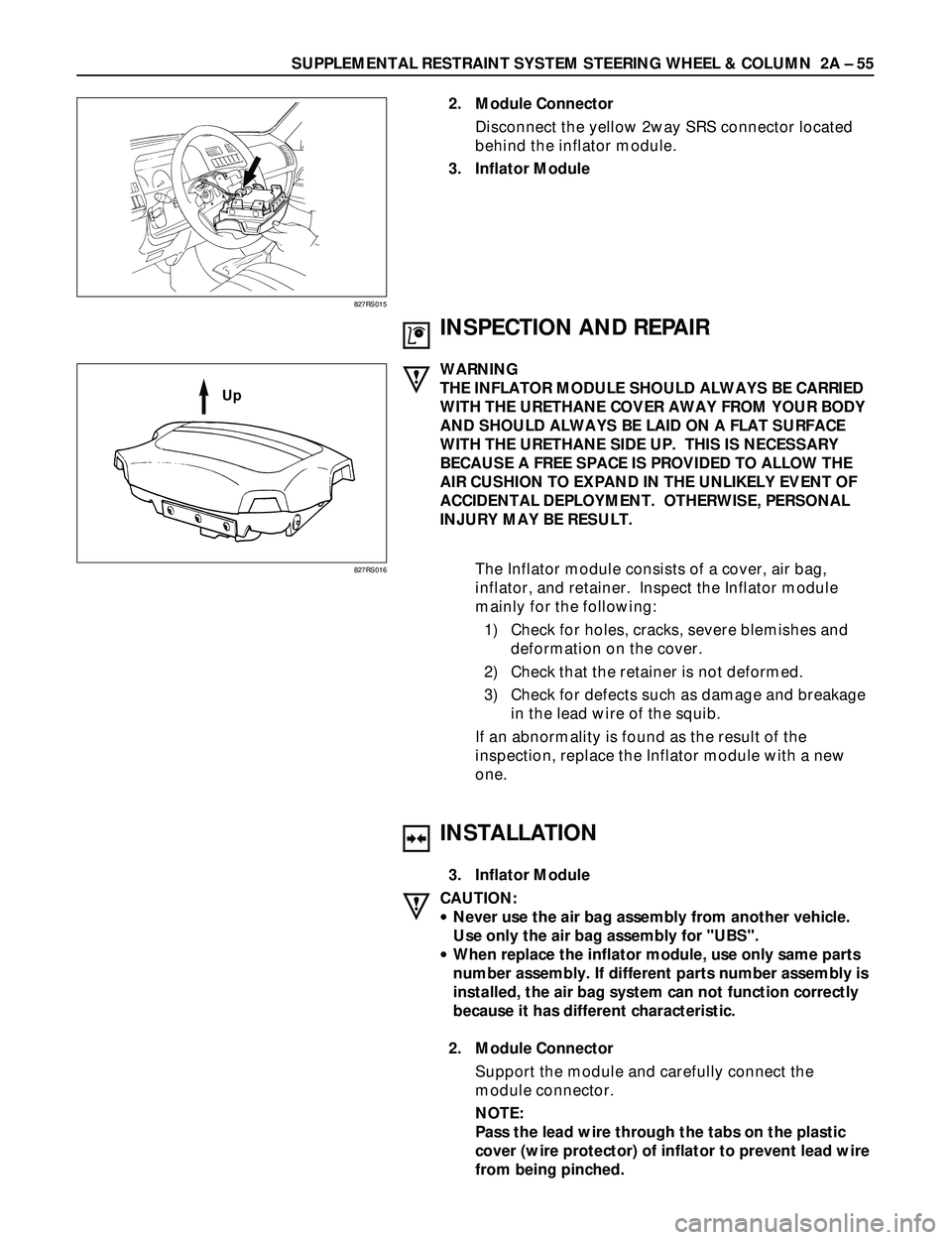

2. Module Connector

Disconnect the yellow 2way SRS connector located

behind the inflator module.

3. Inflator Module

827RS015

827RS016

INSPECTION AND REPAIR

WARNING

THE INFLATOR MODULE SHOULD ALWAYS BE CARRIED

WITH THE URETHANE COVER AWAY FROM YOUR BODY

AND SHOULD ALWAYS BE LAID ON A FLAT SURFACE

WITH THE URETHANE SIDE UP. THIS IS NECESSARY

BECAUSE A FREE SPACE IS PROVIDED TO ALLOW THE

AIR CUSHION TO EXPAND IN THE UNLIKELY EVENT OF

ACCIDENTAL DEPLOYMENT. OTHERWISE, PERSONAL

INJURY MAY BE RESULT.

INSTALLATION

3. Inflator Module

CAUTION:

·Never use the air bag assembly from another vehicle.

Use only the air bag assembly for "UBS".

·When replace the inflator module, use only same parts

number assembly. If different parts number assembly is

installed, the air bag system can not function correctly

because it has different characteristic.

2. Module Connector

Support the module and carefully connect the

module connector.

NOTE:

Pass the lead wire through the tabs on the plastic

cover (wire protector) of inflator to prevent lead wire

from being pinched.

The Inflator module consists of a cover, air bag,

inflator, and retainer. Inspect the Inflator module

mainly for the following:

1) Check for holes, cracks, severe blemishes and

deformation on the cover.

2) Check that the retainer is not deformed.

3) Check for defects such as damage and breakage

in the lead wire of the squib.

If an abnormality is found as the result of the

inspection, replace the Inflator module with a new

one.

Up