jack points ISUZU TROOPER 1998 Service Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 16 of 3573

GENERAL REPAIR INSTRUCTIONS

1. Park the vehicle on level ground and chock the

front or rear wheels before lifting the vehicle.

2. Use covers on the vehicle body, seats, and

floor to prevent damage and/or

contaminations.

3. Disconnect the grounding cable from the

battery before performing service operations.

This will prevent cable damage or burning due

to shortcircuiting.

4. Raise the vehicle with a jack set against the

recommended lifting points (see ÒLifting

instructionsÓ in this section).

5. Support the vehicle on chassis stands.

6. Handle brake fluid and antifreeze solution with

great care.

Spilling these liquids on painted surfaces will

damage the paint.

7. The use of the proper tool(s) and special tool(s)

where specified is essential to efficient,

reliable, and safe service operations.

8. Always use genuine ISUZU replacement parts.

9. Discard used cotter pins, gasket, plastic clips,

O-rings, oil seals, lock washers, and self-

locking nuts at disassembly.

Normal function of these parts cannot be

guaranteed if they are reused.

10. Keep the disassembled parts neatly in groups.

This will facilitate smooth and correct

reassembly.11. Keep fixing nuts and bolts separate.

Fixing nuts and bolts vary in hardness and

design according to installation positions.

12. Clean all parts before inspection or

reassembly.

13. Clean the oil ports and other openings with

compressed air to make certain that they are

free of dirt and obstructions.

14. Lubricate the rotating and sliding faces of all

moving parts with oil or grease before

installation.

15. Use the recommended liquid gasket to prevent

leakage.

16. Carefully observe all nut and bolt torque

specifications.

17. When service operation is completed, make a

final check to be sure service has been done

properly and problem has been corrected.

18. When removing or replacing parts that require

refrigerant to be discharged from the air

conditioning system, be sure to use the

following tools to recover and recycle the

Refrigerant-134a (R-134a).

For 134a:

Use the R-134a Refrigerant Recovery/Recovery/

Recycling/Recharging/System (ACR

4) or its

equivalent to prevent the discharge of

refrigerant into the air.

0AÐ2 GENERAL INFORMATION

Page 22 of 3573

0AÐ8 GENERAL INFORMATION

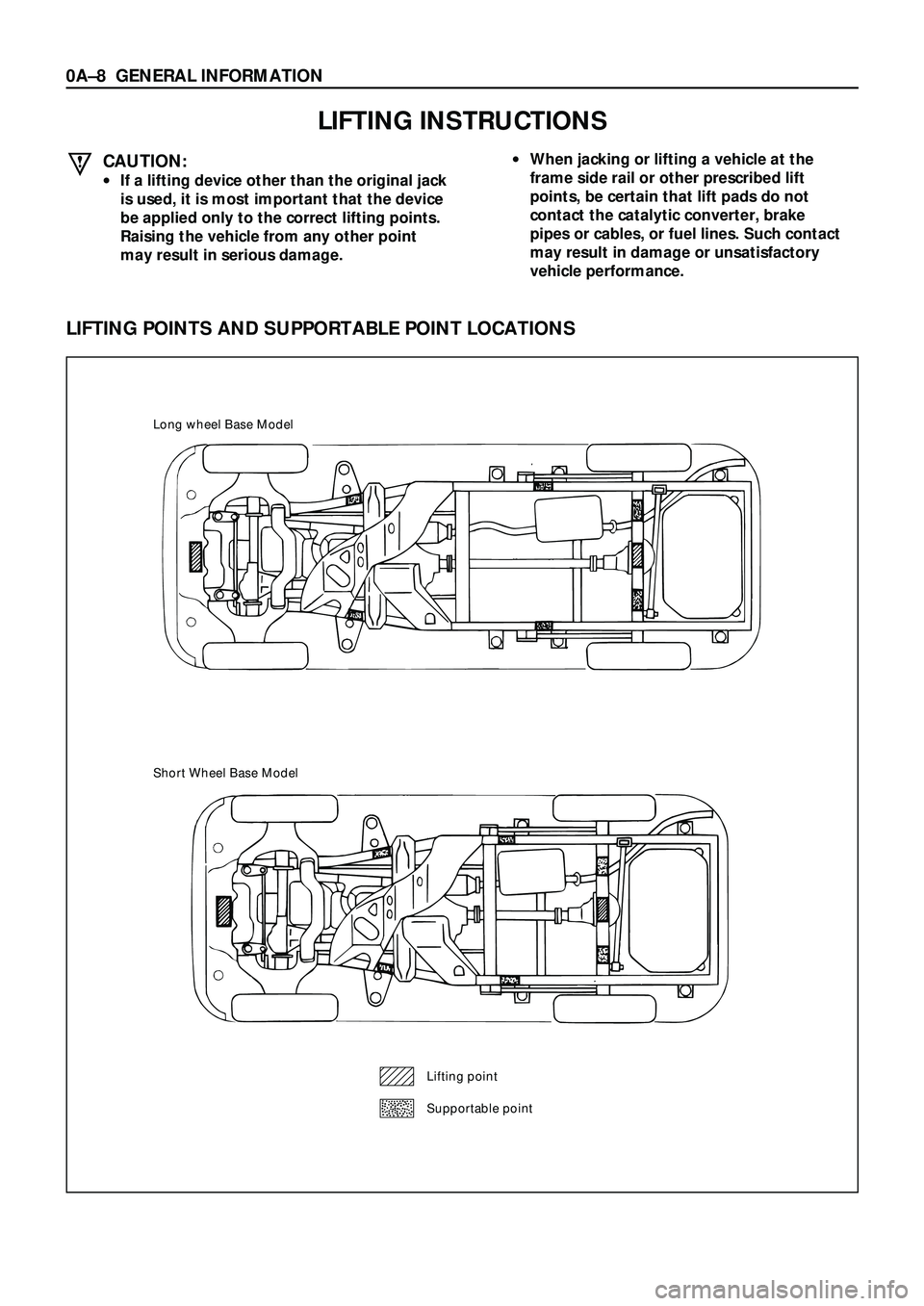

LIFTING INSTRUCTIONS

CAUTION:

·If a lifting device other than the original jack

is used, it is most important that the device

be applied only to the correct lifting points.

Raising the vehicle from any other point

may result in serious damage.

·When jacking or lifting a vehicle at the

frame side rail or other prescribed lift

points, be certain that lift pads do not

contact the catalytic converter, brake

pipes or cables, or fuel lines. Such contact

may result in damage or unsatisfactory

vehicle performance.

LIFTING POINTS AND SUPPORTABLE POINT LOCATIONS

Long wheel Base Model

Short Wheel Base Model

Lifting point

Supportable point

Page 770 of 3573

4D2±3 TRANSFER CASE (TOD)

6. Disconnect the wiring harness connector and shift

lock cable and then remove the front console.

7. Remove the selector lever assembly and put it aside.

8. Remove the transfer control lever.

9. Disconnect the breather hose.

10. Remove the left front exhaust pipe fixing bolts and

nuts, and put the exhaust pipe aside.

11. Remove the left seat belt tension rod and put the rear

proper shaft aside.

260RW006

12. Remove the silencer.

13. Disconnect the transfer connector from the top of the

transfer case.

14. Disconnect the speed sensor harness connector.

15. Remove the fuel pipe clip fixing bolt on the transfer

case.

16. Support the transmission with a jack.

17. Remove the seven bolts from the transfer case.

18. Remove transfer case assembly.

Installation

To install, follow the removal steps in the reverse order,

nothing the following points:

1. Apply a thin coat of grease (Besco L2) or equivalent to

the input shaft spline.

261RW024

2. Mount the transfer case.

Page 2442 of 3573

MUA MODEL 7B1 – 51

REMOVAL AND INSTALLATION

Read this Section carefully before performing any removal and installation procedure. This Section gives

you important points as well as the order of operation. Be sure that you understand everything in this

Section before you begin.

Important Operations – Removal

Battery Cable

Disconnect the negative (–) cable from the battery

terminal.

Engine Hood

Apply setting marks to the engine hood and the engine

hood hinges before removing the engine hood.

Gear Shift Lever and Transfer Change Lever

1. Place the gear shift lever in the neutral position.

2. Place the transfer change lever in the “H” position.

3. Remove the gear shift lever knob and transfer

change lever konb.

4. Remove the center console assembly and front

console assembly.

5. Remove the grommet and dust cover.

6. Remove the gear shift lever cover bolt.

7. Remove the gear shift lever.

8. Remove the transfer change lever retainer bolts.

9. Remove the transfer change lever and O-ring.

Note:

Cover the shift lever and change lever holes to prevent

the entry of foreign material into the transmission.

Lifting the Vehicle

1. Jack up the vehicle.

2. Place chassis stands at the front and the rear of the

vehicle.

Transfer Case Protector (Except 00 Year or Subsequent

ones)

Remove the transfer case protector from the transmission

mounting member and the side member.

235RT004