low beam ISUZU TROOPER 1998 Service Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 115 of 3573

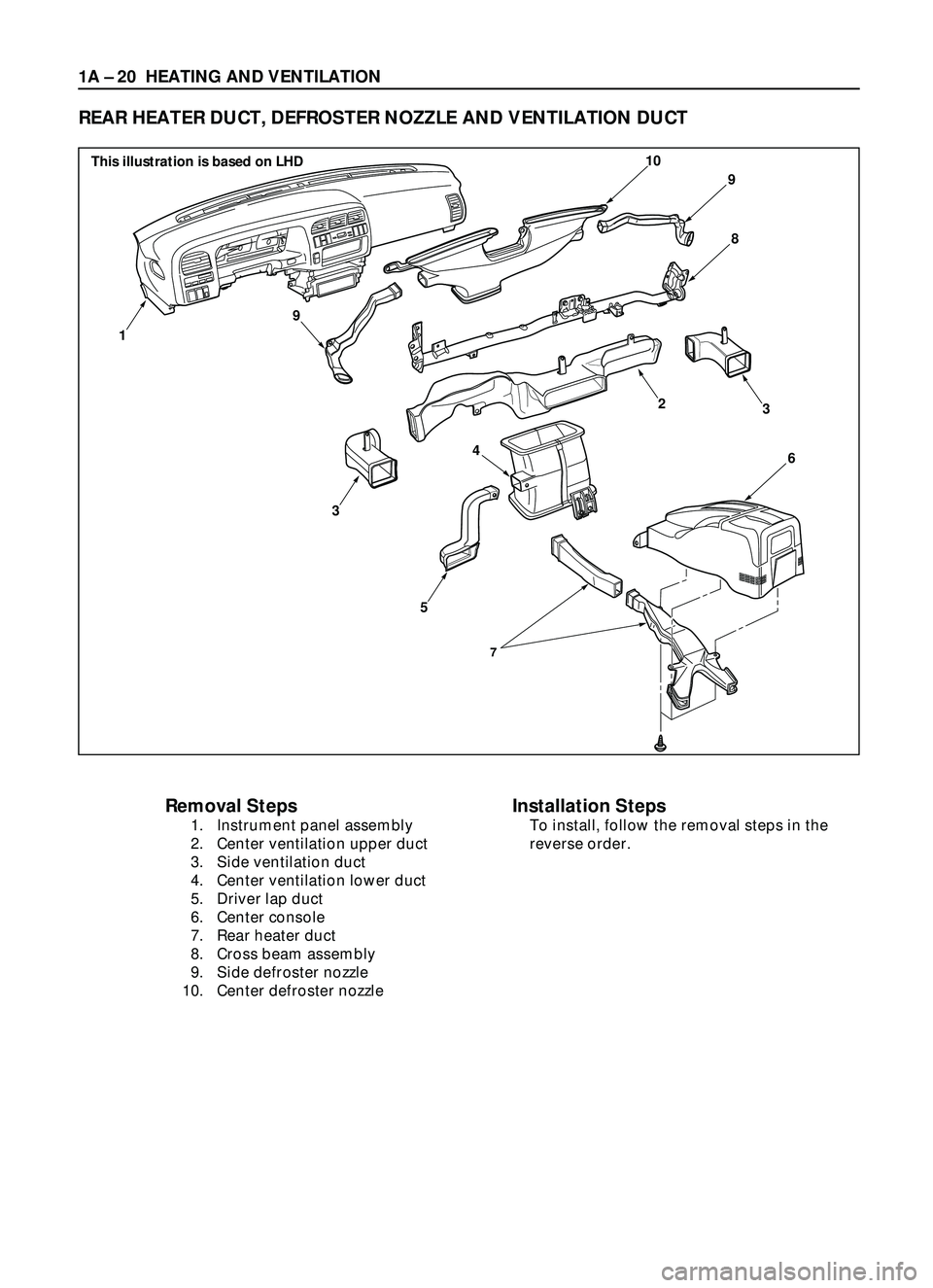

1A Ð 20 HEATING AND VENTILATION

REAR HEATER DUCT, DEFROSTER NOZZLE AND VENTILATION DUCT

Removal Steps

1. Instrument panel assembly

2. Center ventilation upper duct

3. Side ventilation duct

4. Center ventilation lower duct

5. Driver lap duct

6. Center console

7. Rear heater duct

8. Cross beam assembly

9. Side defroster nozzle

10. Center defroster nozzle

Installation Steps

To install, follow the removal steps in the

reverse order.

7

9

9

10

8

6

3

5

1

3

4

2

This illustration is based on LHD

Page 116 of 3573

HEATING AND VENTILATION 1A Ð 21

INSTALLATION

To install, follow the removal steps in the reverse order,

noting the following point:

1. Connect each duct and nozzle securely leaving no

clearance between them and making no improper

matching.

REMOVAL

Preparation:

Disconnect the battery ground cable

1. Instrument panel assembly

·Refer to Section 10 ÒBODYÓ for INSTRUMENT

PANEL ASSEMBLY removal procedure.

2. Center ventilation upper duct

3. Side ventilation duct

4. Center ventilation lower duct

5. Driver lap duct

6. Center console

7. Rear heater duct

·Refer to Section 10 ÒBODYÓ for CONSOLES

removal procedure.

8. Cross beam assembly

·Refer to Section 10 ÒBODYÓ for CROSS BEAM

ASSEMBLY removal procedure.

9. Side defroster nozzle

10. Center defroster nozzle

Page 126 of 3573

HEATING AND VENTILATION 1A Ð 31

REMOVAL

Preparation:

Disconnect the battery ground cable

1. Instrument panel assembly

Refer to Section 10 ÒBODYÓ for ÒINSTRUMENT

PANEL ASSEMBLYÓ removal procedure.

2. Instrument panel center bracket

Refer to Section 10 ÒCROSS BEAM ASSEMBLYÓ

removal procedure.

3. Rear heater duct

4. Ceramic heater

1) Disconnect the connector and remove the heater

fixing screw and heater harness fixing clamps.

2) Pull the ceramic heater out from heater unit.

4a. Full hot switch

Disconnect the switch connector and remove the

switch fixing screw and switch harness fixing clamp.

INSTALLATION

To install, follow the removal steps in the reverse order,

noting the following points.

1. The installation should be made with care so that

there is continuity between the switch side connector

terminals when the knob is set to the ÒFull HotÓ

position.

2. Be sure to handle the EGR and the ABS control unit

with care to avoid the disengagement of connectors.

Page 2568 of 3573

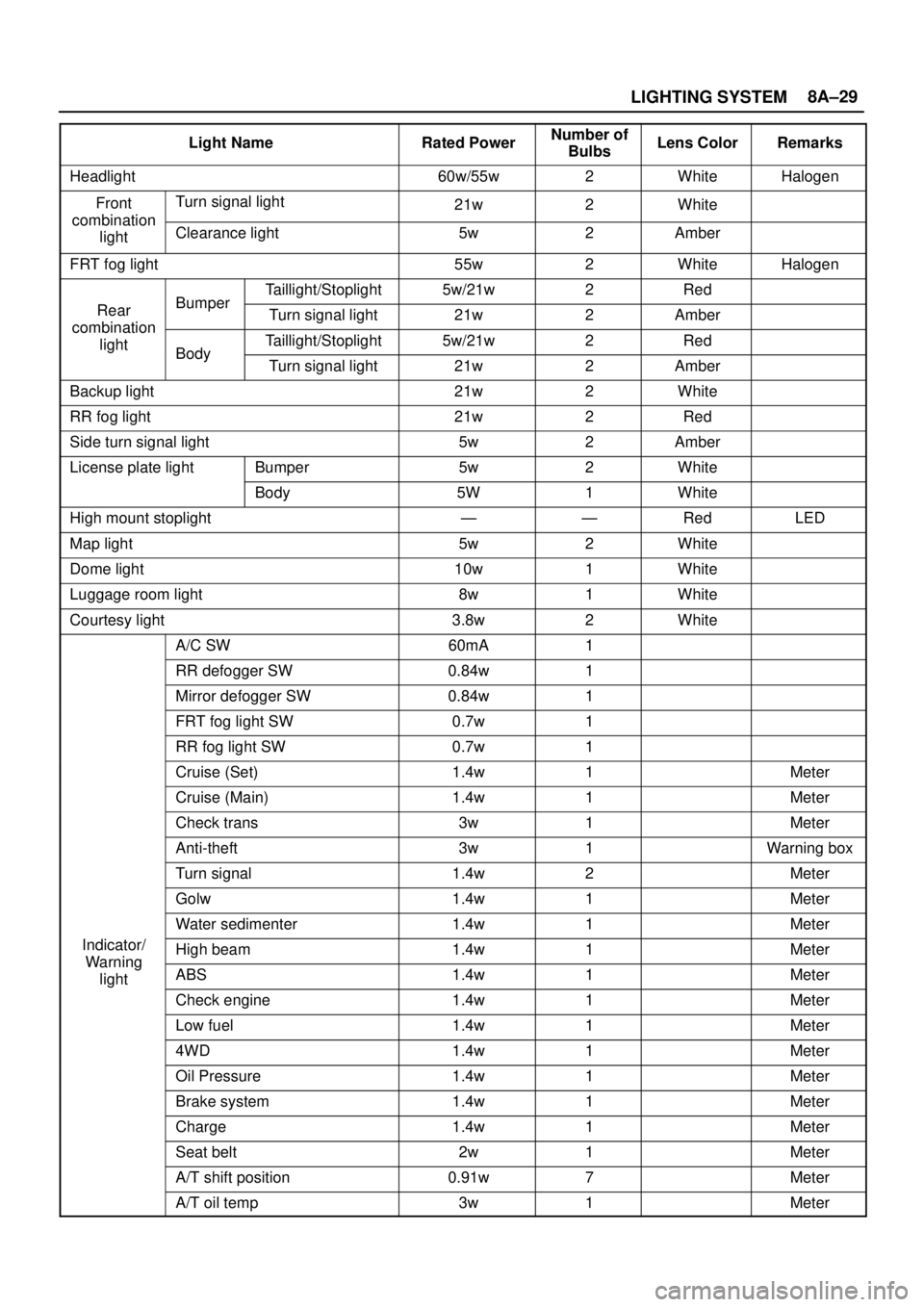

LIGHTING SYSTEM8A–29

Light NameRated PowerNumber of

BulbsLens ColorRemarks

Headlight60w/55w2WhiteHalogen

FrontTurn signal light21w2Whitecombination

lightClearance light5w2Amber

FRT fog light55w2WhiteHalogen

Taillight/Stoplight5w/21w2Red

RearBumperTurn signal light21w2Ambercombination

lightTaillight/Stoplight5w/21w2RedBodyTurn signal light21w2Amber

Backup light21w2White

RR fog light21w2Red

Side turn signal light5w2Amber

License plate lightBumper5w2White

Body5W1White

High mount stoplight——RedLED

Map light5w2White

Dome light10w1White

Luggage room light8w1White

Courtesy light3.8w2White

A/C SW60mA1

RR defogger SW0.84w1

Mirror defogger SW0.84w1

FRT fog light SW0.7w1

RR fog light SW0.7w1

Cruise (Set)1.4w1Meter

Cruise (Main)1.4w1Meter

Check trans3w1Meter

Anti-theft3w1Warning box

Turn signal1.4w2Meter

Golw1.4w1Meter

Water sedimenter1.4w1Meter

Indicator/High beam1.4w1MeterWarning

lightABS1.4w1Meter

Check engine1.4w1Meter

Low fuel1.4w1Meter

4WD1.4w1Meter

Oil Pressure1.4w1Meter

Brake system1.4w1Meter

Charge1.4w1Meter

Seat belt2w1Meter

A/T shift position0.91w7Meter

A/T oil temp3w1Meter

Page 2722 of 3573

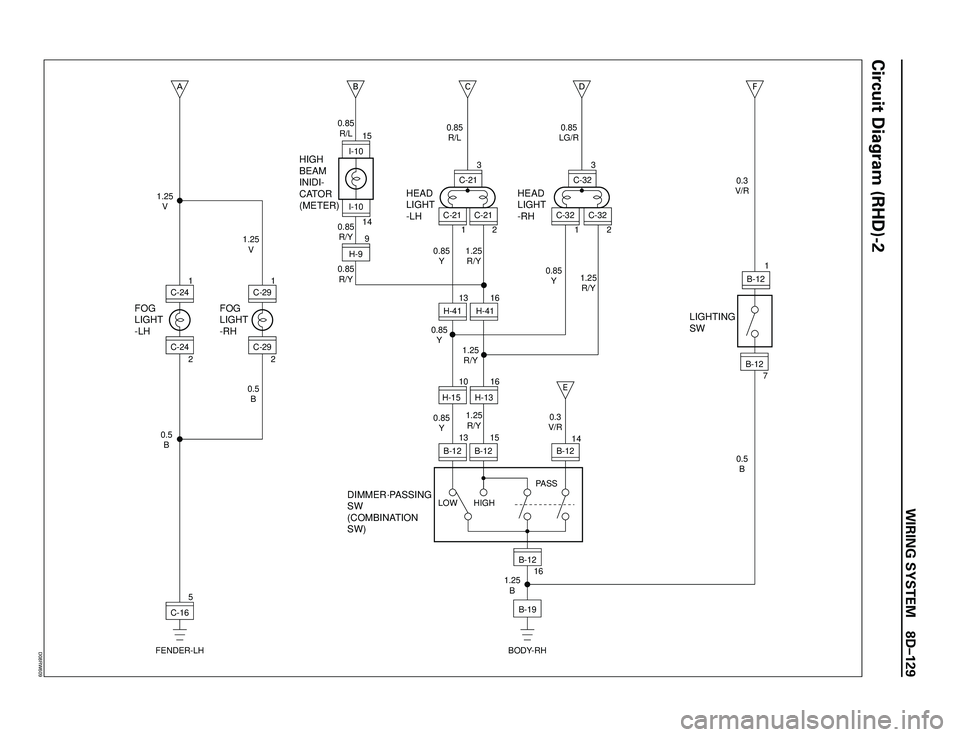

WIRING SYSTEM 8DÐ129

Circuit Diagram (RHD)-2

A

B

C

C-24

FOG

LIGHT

-LHHEAD

LIGHT

-LHHEAD

LIGHT

-RH

LIGHTING

SW

DIMMER·PASSING

SW

(COMBINATION

SW)

1.25

V

1.25

V

0.5

B0.5

B

FOG

LIGHT

-RHHIGH

BEAM

INIDI-

CATOR

(METER)

1

2

C-29

0.85

R/L

0.85

R/Y 0.85

R/Y0.85

R/L

1.25

R/Y

1.25

R/Y

1.25

R/Y0.3

V/R

0.5

B 0.3

V/R

1.25

B

BODY-RH LOW HIGHPASS

H-1510

H-1316

H-4113

H-99

H-4116

14

I-10

I-10

1 C-21

212 C-21

13

B-12

15

B-1214 15

C-213

1

2 C-24 C-29

5

C-16

FENDER-LH

D

E

F

0.85

LG/R

0.85

Y

0.85

Y 0.85

Y

0.85

Y1.25

R/Y

C-32

C-32

C-323

B-12

16

B-12

7

B-19

1

B-12

B-12

D08RW609

Page 2725 of 3573

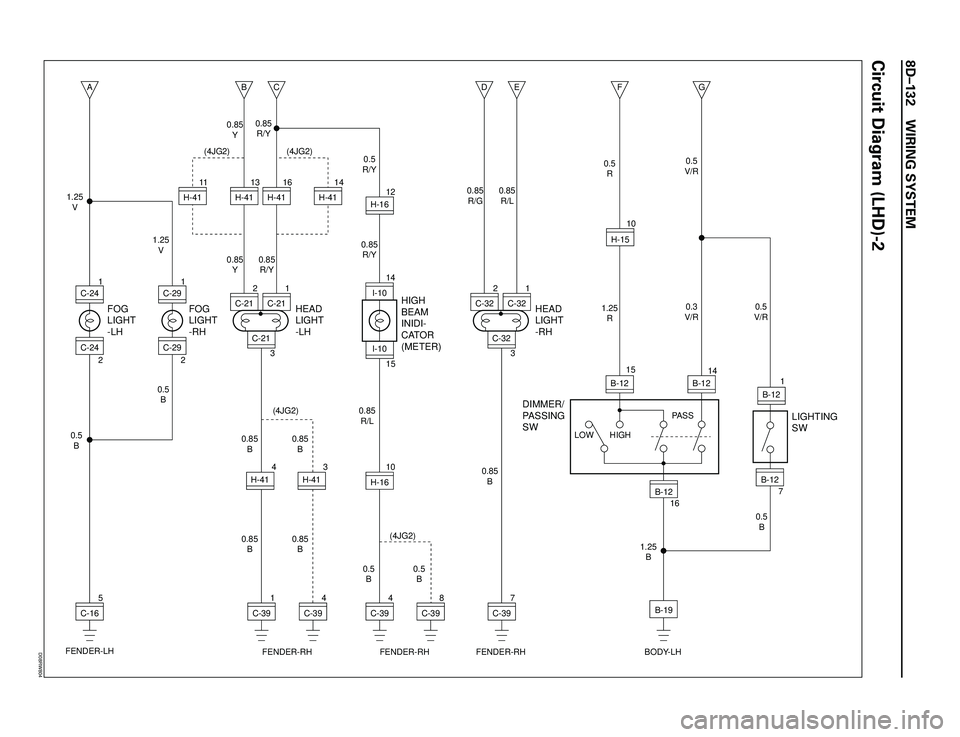

8DÐ132 WIRING SYSTEM

AC-24

FOG

LIGHT

-LHHEAD

LIGHT

-LH

LIGHTING

SW DIMMER/

PASSING

SW

1.25

V

1.25

V

0.5

B0.5

B

FOG

LIGHT

-RHHIGH

BEAM

INIDI-

CATOR

(METER)

1

2

C-290.5

V/R

0.3

V/R0.5

V/R

0.5

B

1.25

B LOW HIGHPASS

H-1510

15

B-1214 1

2 C-24 C-29

5

C-16

FENDER-LH

1

C-39

4

C-39

4

C-39

8

C-39

10 4

H-16

B

C

G

0.85

Y 0.85

Y

0.85

R/Y 0.85

R/Y

(4JG2) (4JG2)

(4JG2)

(4JG2) 0.85

B0.85

B

0.85

B0.85

B

FENDER-RH FENDER-RH FENDER-RH BODY-LH0.5

B0.5

B 3

C-21H-41

C-211

2

B-12

16

B-12

7

B-19

1

B-12

B-12 C-21

H-4116

13

H-41

HEAD

LIGHT

-RH

7

C-39

D

E

F

0.85

R/G0.85

R/L0.5

R

0.85

B3

C-32

C-321

2

C-32

H-4114

12

H-41110.5

R/Y

0.85

R/Y

0.85

R/L

15

I-10

I-10H-16

14

3

H-411.25

R

D08RW804

Circuit Diagram (LHD)-2

Page 2727 of 3573

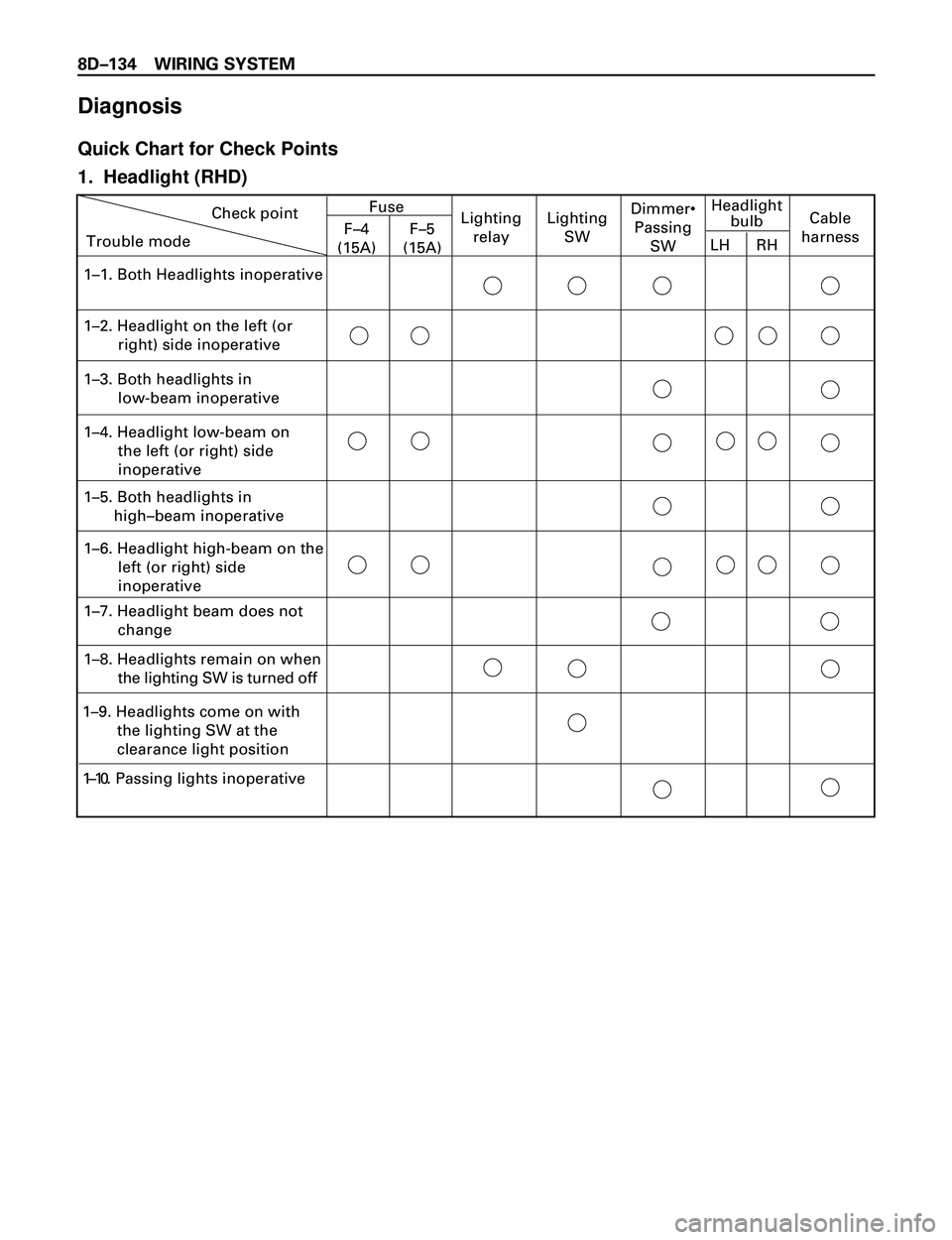

8DÐ134 WIRING SYSTEM

Diagnosis

Quick Chart for Check Points

1. Headlight (RHD)

Check point

Trouble modeFuse

F–4

(15A)F–5

(15A)Lighting

relayLighting

SWDimmer•

Passing

SWCable

harness Headlight

bulb

1–1. Both Headlights inoperative

1–2. Headlight on the left (or

right) side inoperative

1–3. Both headlights in

low-beam inoperative

1–4. Headlight low-beam on

the left (or right) side

inoperative

1–5. Both headlights in

high–beam inoperative

1–6. Headlight high-beam on the

left (or right) side

inoperative

1–7. Headlight beam does not

change

LH RH

1–8. Headlights remain on when

the lighting SW is turned off

1–9. Headlights come on with

the lighting SW at the

clearance light position

1–10. Passing lights inoperative

Page 2728 of 3573

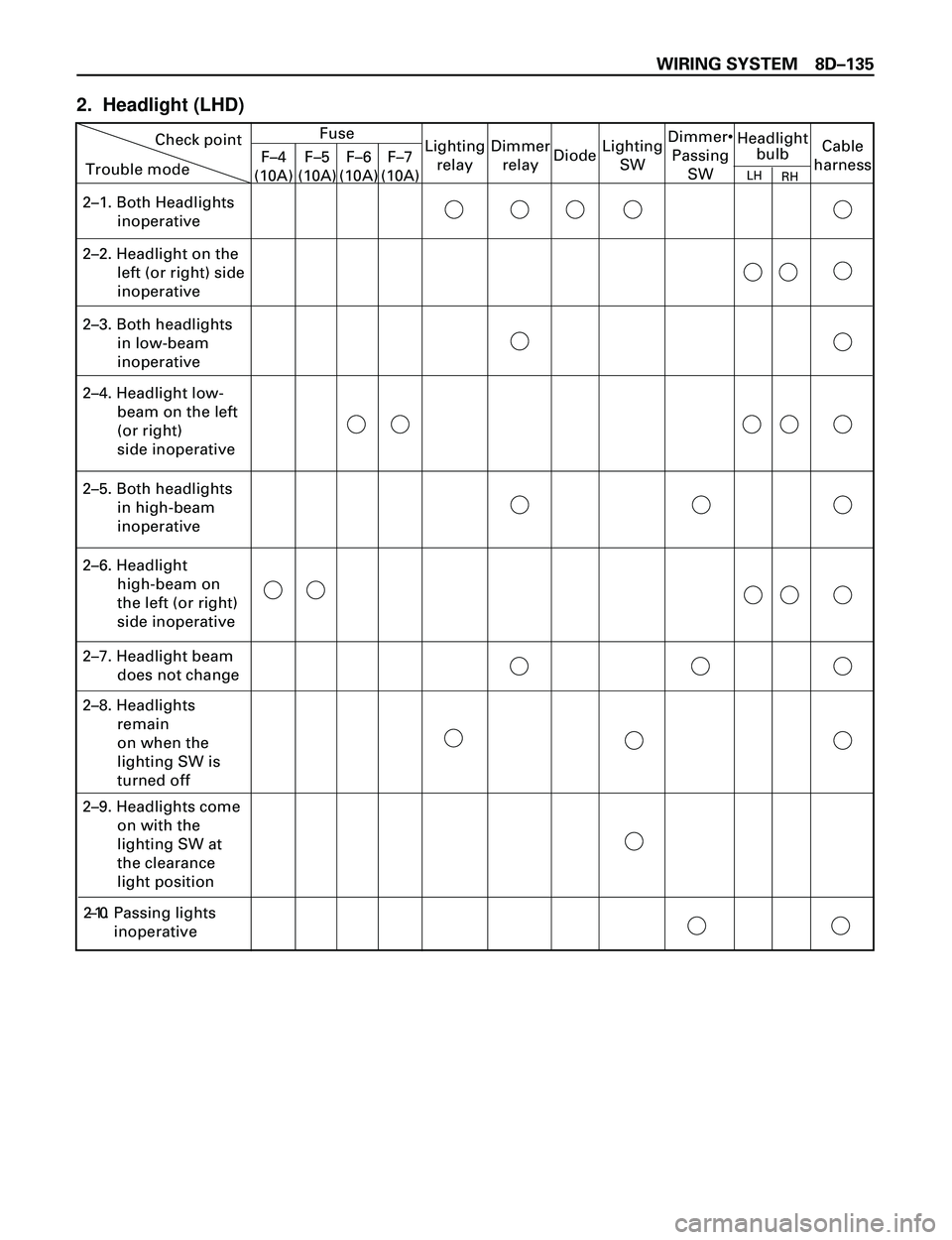

WIRING SYSTEM 8DÐ135

Check point

Trouble modeFuse

F–4

(10A)F–5

(10A)Dimmer

relayLighting

SWDimmer•

Passing

SWCable

harness Headlight

bulb

2–1. Both Headlights

inoperative

2–2. Headlight on the

left (or right) side

inoperative

2–3. Both headlights

in low-beam

inoperative

2–4. Headlight low-

beam on the left

(or right)

side inoperative

2–5. Both headlights

in high-beam

inoperative

2–6. Headlight

high-beam on

the left (or right)

side inoperative

2–7. Headlight beam

does not change

Lighting

relayF–6

(10A)F–7

(10A)

2–8. Headlights

remain

on when the

lighting SW is

turned off

2–9. Headlights come

on with the

lighting SW at

the clearance

light position

Diode

2–10. Passing lights

inoperative

LH

RH

2. Headlight (LHD)

Page 2731 of 3573

8DÐ138 WIRING SYSTEM

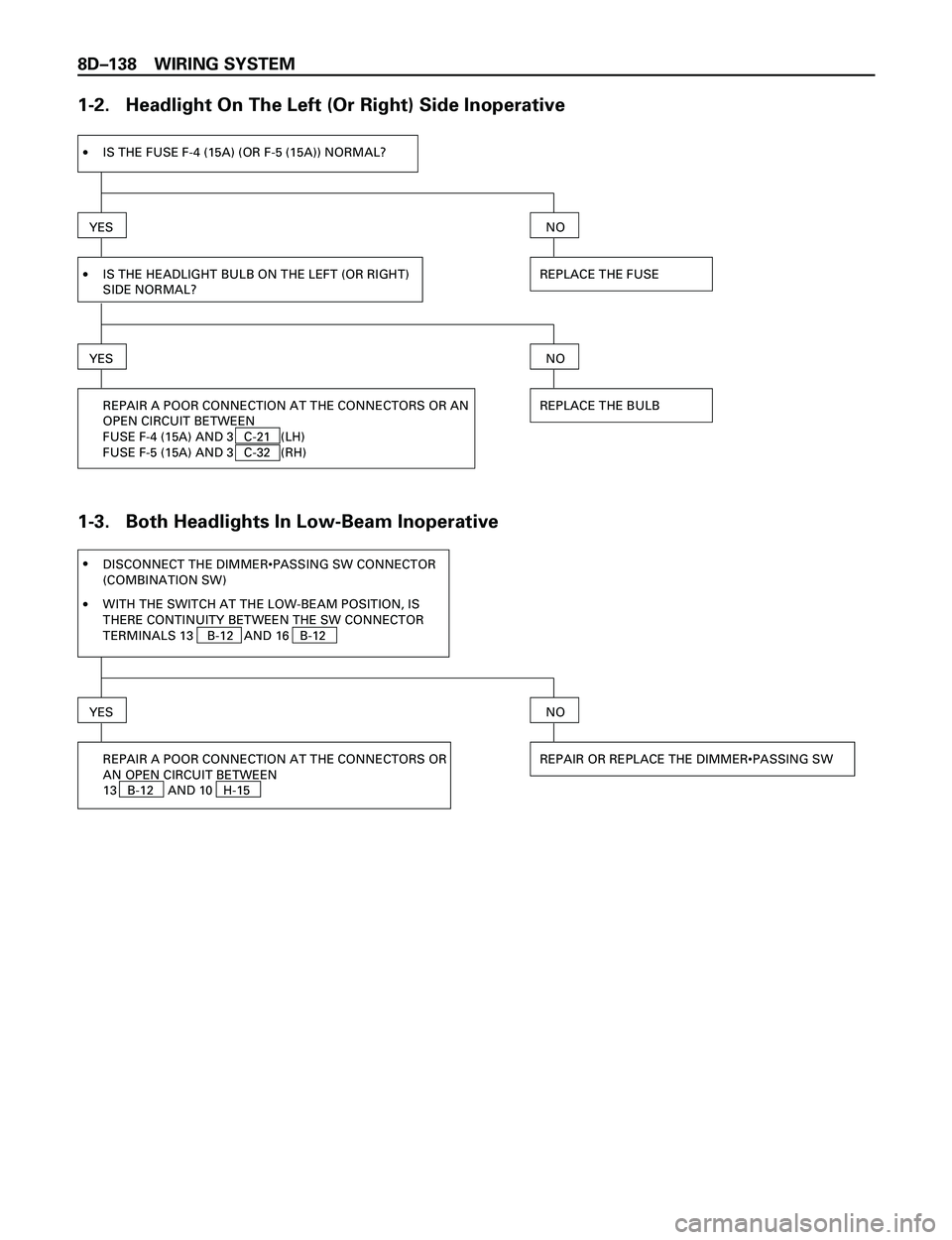

1-2. Headlight On The Left (Or Right) Side Inoperative

1-3. Both Headlights In Low-Beam Inoperative

YES

·IS THE HEADLIGHT BULB ON THE LEFT (OR RIGHT)

SIDE NORMAL?

YES

REPLACE THE FUSE

NO

·IS THE FUSE F-4 (15A) (OR F-5 (15A)) NORMAL?

REPAIR A POOR CONNECTION AT THE CONNECTORS OR AN

OPEN CIRCUIT BETWEEN

FUSE F-4 (15A) AND 3 C-21 (LH)

FUSE F-5 (15A) AND 3 C-32 (RH)REPLACE THE BULB

NO

·

YES

REPAIR A POOR CONNECTION AT THE CONNECTORS OR

AN OPEN CIRCUIT BETWEEN

13 B-12 AND 10 H-15REPAIR OR REPLACE THE DIMMER•PASSING SWNO

·WITH THE SWITCH AT THE LOW-BEAM POSITION, IS

THERE CONTINUITY BETWEEN THE SW CONNECTOR

TERMINALS 13 B-12 AND 16 B-12

DISCONNECT THE DIMMER•PASSING SW CONNECTOR

(COMBINATION SW)

Page 2732 of 3573

WIRING SYSTEM 8DÐ139

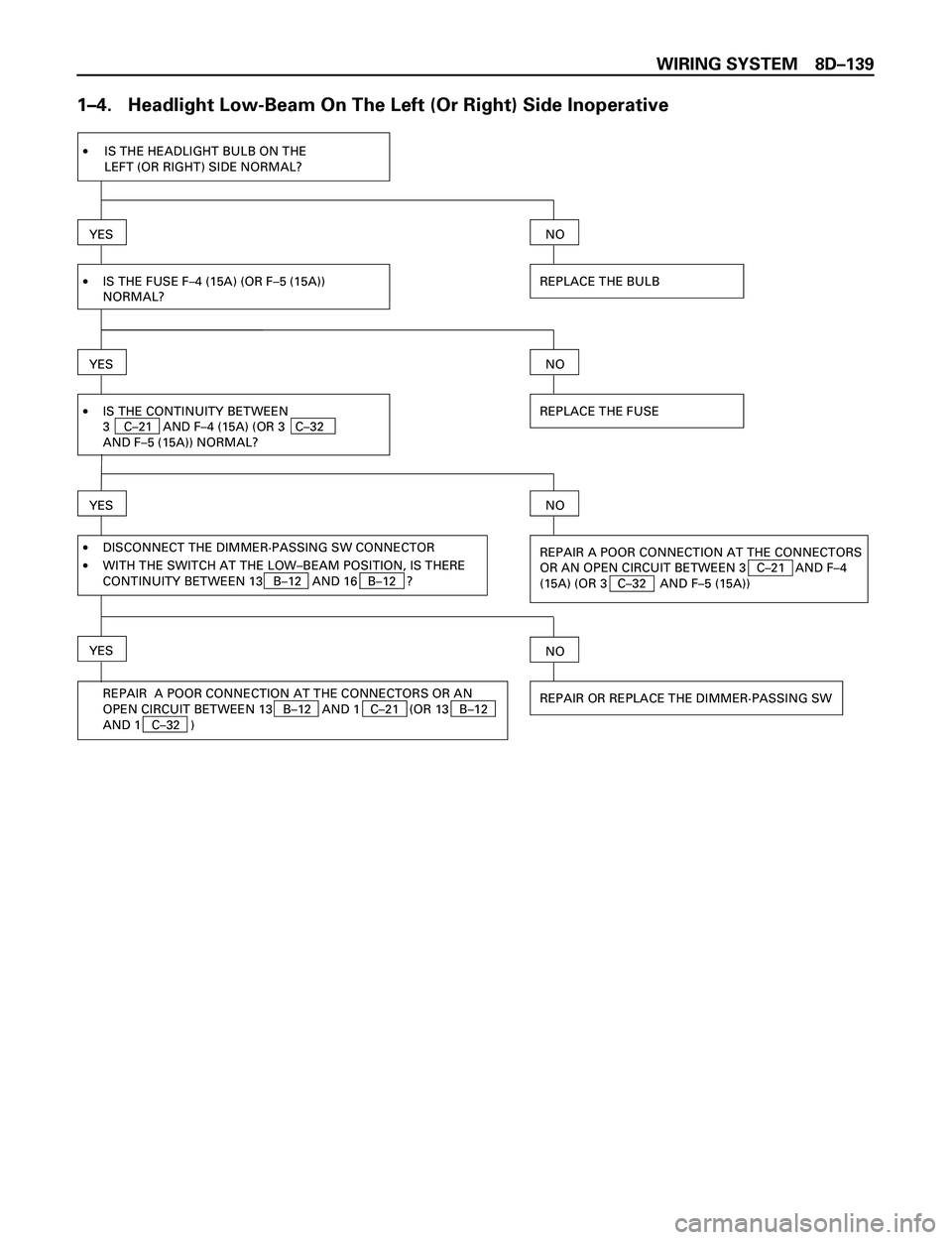

1Ð4. Headlight Low-Beam On The Left (Or Right) Side Inoperative

·IS THE HEADLIGHT BULB ON THE

LEFT (OR RIGHT) SIDE NORMAL?

YES

·IS THE FUSE F–4 (15A) (OR F–5 (15A))

NORMAL?

YES

REPLACE THE BULB

NO

·DISCONNECT THE DIMMER·PASSING SW CONNECTOR

·WITH THE SWITCH AT THE LOW–BEAM POSITION, IS THERE

CONTINUITY BETWEEN 13 B–12 AND 16 B–12 ?

YES

REPLACE THE FUSE

NO

REPAIR A POOR CONNECTION AT THE CONNECTORS

OR AN OPEN CIRCUIT BETWEEN 3 C–21 AND F–4

(15A) (OR 3 C–32 AND F–5 (15A))

NO

REPAIR OR REPLACE THE DIMMER·PASSING SWREPAIR A POOR CONNECTION AT THE CONNECTORS OR AN

OPEN CIRCUIT BETWEEN 13 B–12 AND 1 C–21 (OR 13 B–12

AND 1 C–32 )

·IS THE CONTINUITY BETWEEN

3 C–21 AND F–4 (15A) (OR 3 C–32

AND F–5 (15A)) NORMAL?

NOYES