engine JAGUAR S TYPE 1999 1.G Powertrain Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1999, Model line: S TYPE, Model: JAGUAR S TYPE 1999 1.GPages: 75, PDF Size: 3.4 MB

Page 15 of 75

V6 Engine

10

D.303.1204

CAMSHAFT DRIVE

D.303.1204

AJ-V6/AJ28

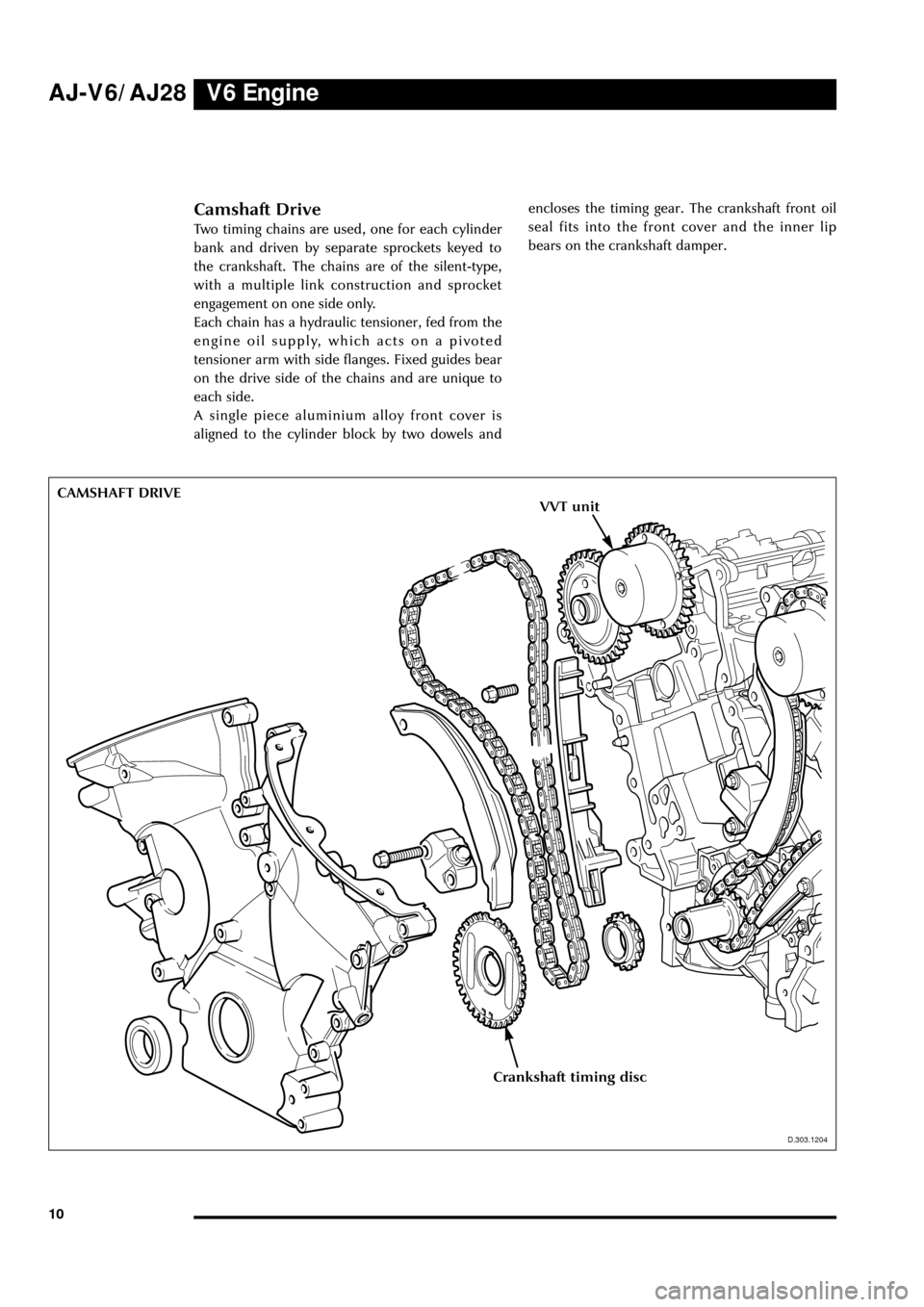

Camshaft Drive

Two timing chains are used, one for each cylinder

bank and driven by separate sprockets keyed to

the crankshaft. The chains are of the silent-type,

with a multiple link construction and sprocket

engagement on one side only.

Each chain has a hydraulic tensioner, fed from the

engine oil supply, which acts on a pivoted

tensioner arm with side flanges. Fixed guides bear

on the drive side of the chains and are unique to

each side.

A single piece aluminium alloy front cover is

aligned to the cylinder block by two dowels andencloses the timing gear. The crankshaft front oil

seal fits into the front cover and the inner lip

bears on the crankshaft damper.

Crankshaft timing disc

VVT unit

Page 16 of 75

V6 EngineAJ-V6/AJ28

11

D.303.1220

IGNITION COIL COVERIgnition Coil Cover

A plastic ignition coil cover, embossed with

ÔJAGUAR V6Õ, is fitted to engine bank 2 only. The

cover is attached via two push fit studs on the

camshaft cover.

D.303.1220

Page 17 of 75

V6 Engine AJ-V6/AJ28

12

D.303.1216

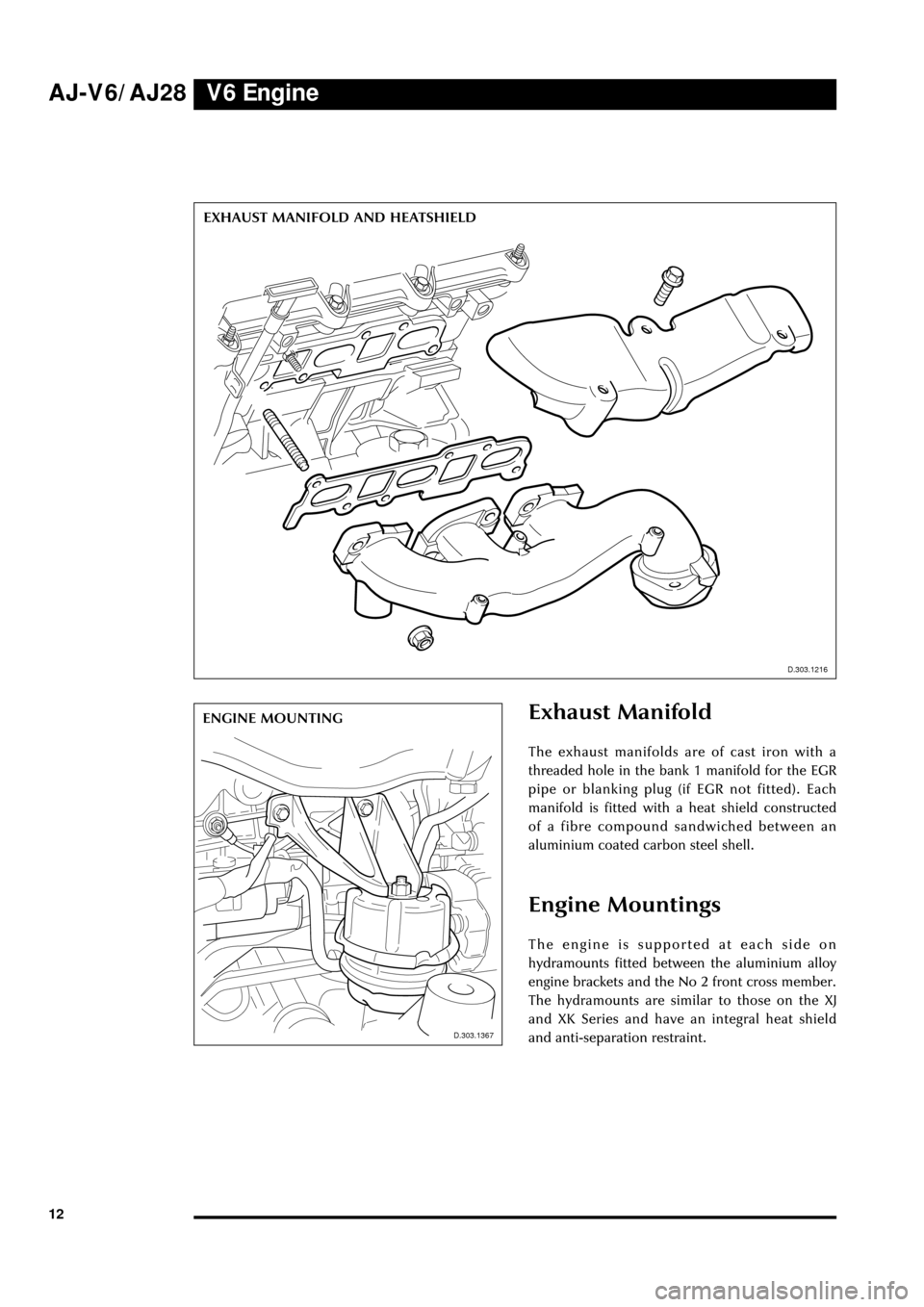

Exhaust Manifold

The exhaust manifolds are of cast iron with a

threaded hole in the bank 1 manifold for the EGR

pipe or blanking plug (if EGR not fitted). Each

manifold is fitted with a heat shield constructed

of a fibre compound sandwiched between an

aluminium coated carbon steel shell.

Engine Mountings

The engine is supported at each side on

hydramounts fitted between the aluminium alloy

engine brackets and the No 2 front cross member.

The hydramounts are similar to those on the XJ

and XK Series and have an integral heat shield

and anti-separation restraint. EXHAUST MANIFOLD AND HEATSHIELD

D.303.1216

D.303.1367D.303.1367

ENGINE MOUNTING

Page 18 of 75

V6 EngineAJ-V6/AJ28

13

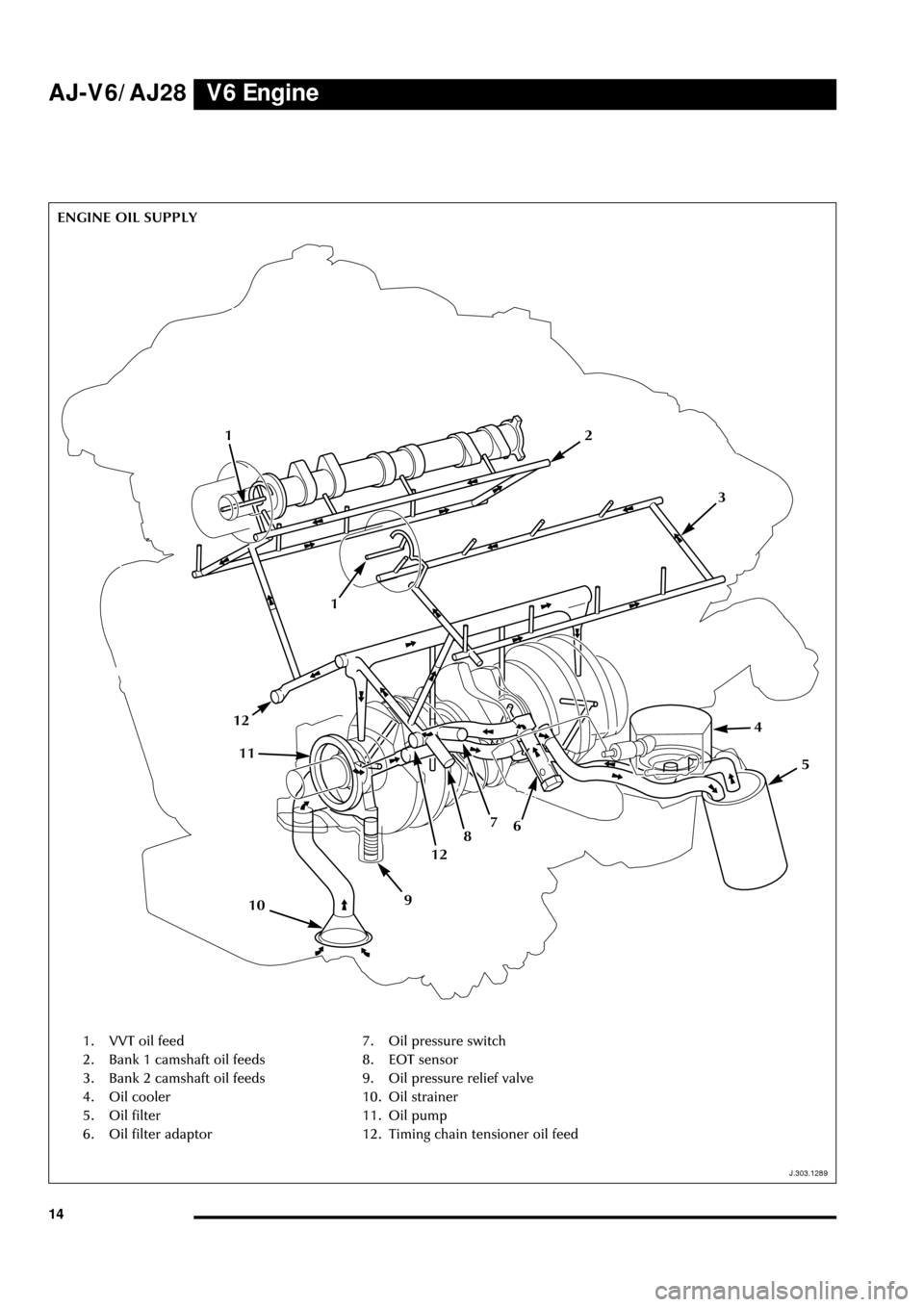

Oil Distribution

(see illustration on page 14)

Oil distribution within the block and cylinder

heads is similar to that of the V8 engine, the main

differences being in the filter and cooler

arrangement and the method of supplying the

VVT system.

Oil is drawn from the sump through the strainer

by the crankshaft driven pump, passes through

the externally mounted filter and oil cooler and

returns to the block. Distribution is via the main

gallery and crankshaft oilways to the lower

crankcase components and via branch feeds to

the chain tensioners and then cylinder head

components. Extra oilways in the cylinder heads

provide a built-in feed for the VVT components

(see VVT section).

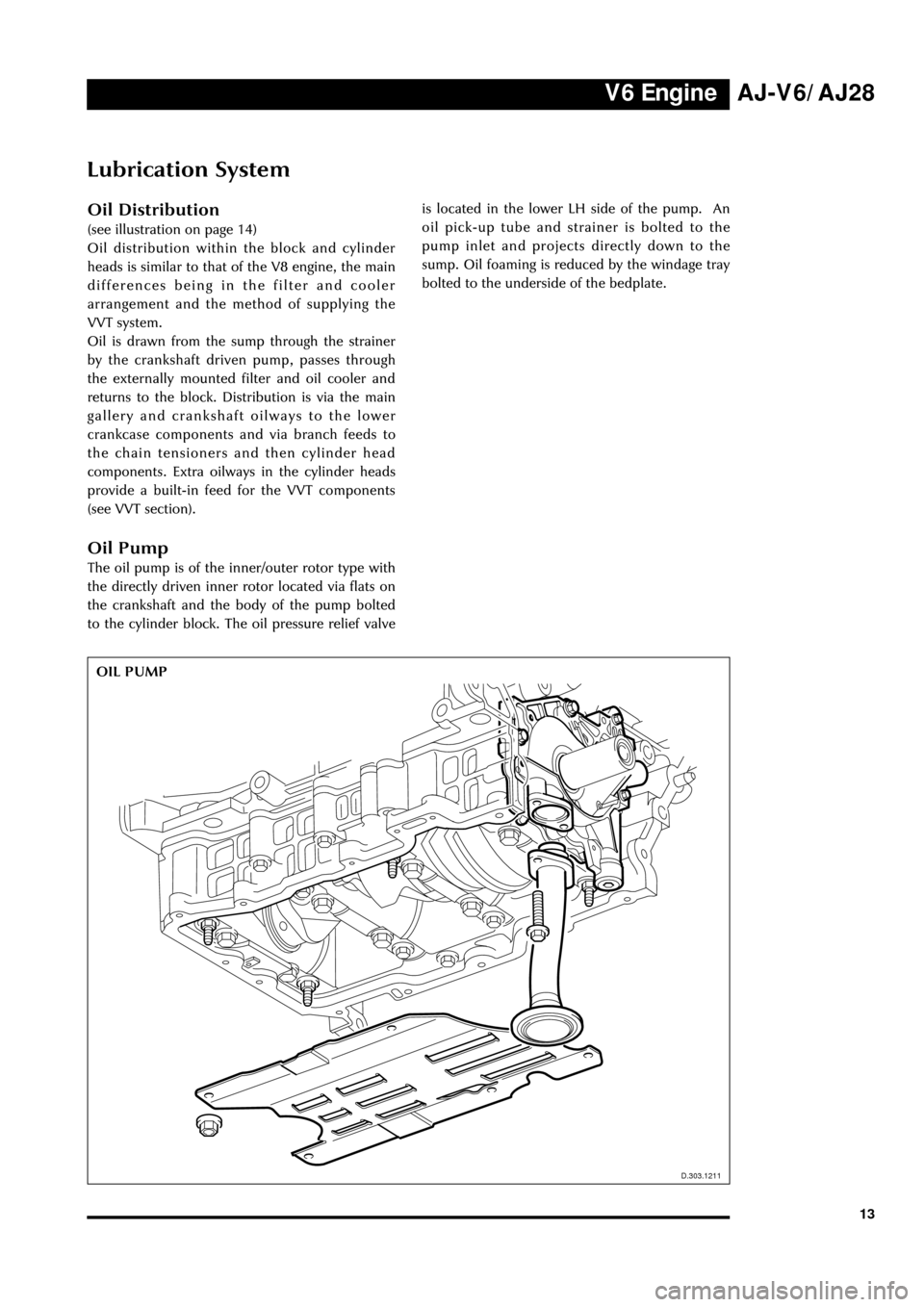

Oil Pump

The oil pump is of the inner/outer rotor type with

the directly driven inner rotor located via flats on

the crankshaft and the body of the pump bolted

to the cylinder block. The oil pressure relief valveis located in the lower LH side of the pump. An

oil pick-up tube and strainer is bolted to the

pump inlet and projects directly down to the

sump. Oil foaming is reduced by the windage tray

bolted to the underside of the bedplate.

D.303.1211

Lubrication System

OIL PUMP

D.303.1211

Page 19 of 75

V6 Engine

14

J.303.1289

ENGINE OIL SUPPLY

J.303.1289

AJ-V6/AJ28

1. VVT oil feed

2. Bank 1 camshaft oil feeds

3. Bank 2 camshaft oil feeds

4. Oil cooler

5. Oil filter

6. Oil filter adaptor7. Oil pressure switch

8. EOT sensor

9. Oil pressure relief valve

10. Oil strainer

11. Oil pump

12. Timing chain tensioner oil feed

1

21

3

4

5

678

12

910

11

12

Page 20 of 75

V6 EngineAJ-V6/AJ28

15

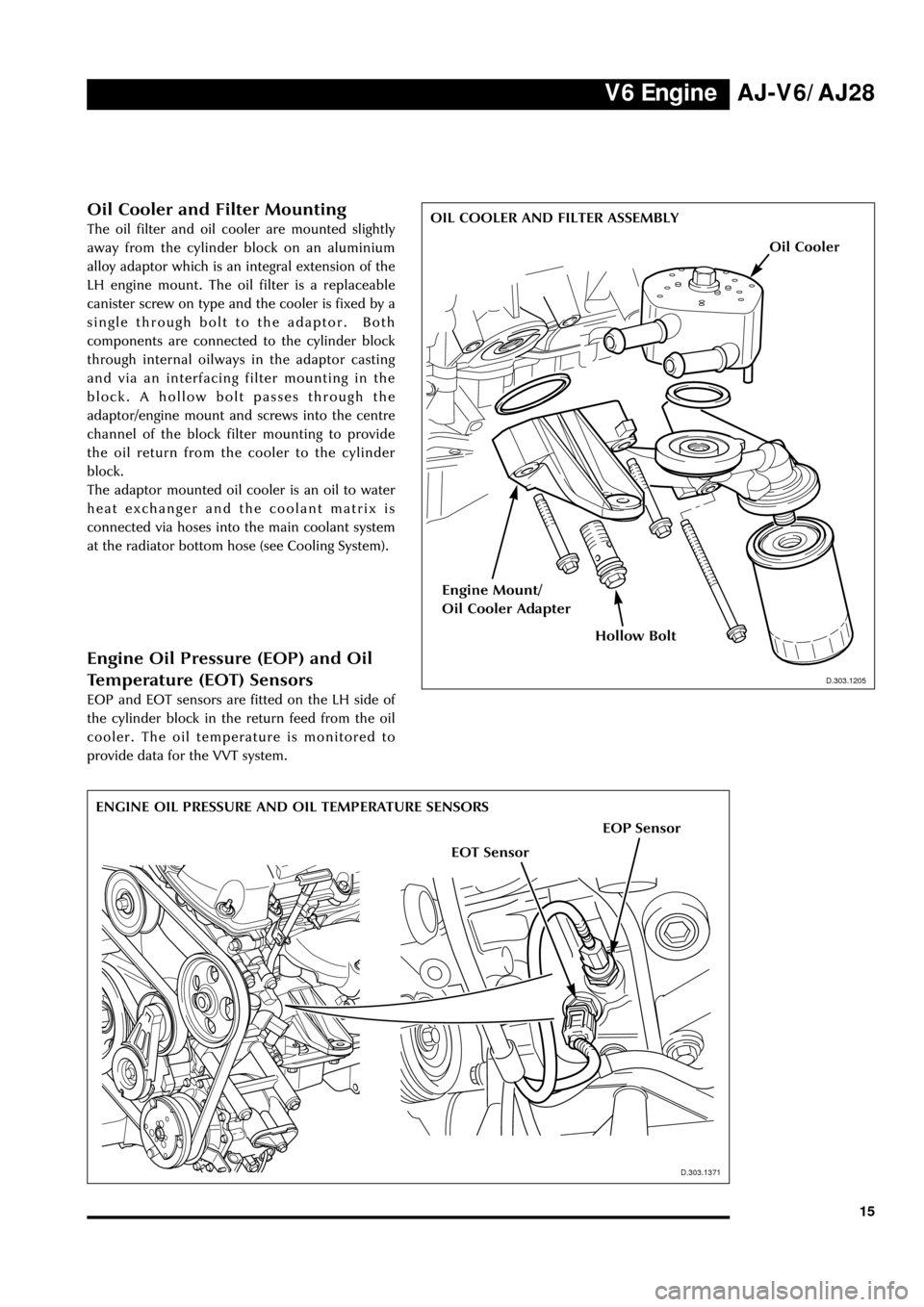

Oil Cooler and Filter Mounting

The oil filter and oil cooler are mounted slightly

away from the cylinder block on an aluminium

alloy adaptor which is an integral extension of the

LH engine mount. The oil filter is a replaceable

canister screw on type and the cooler is fixed by a

single through bolt to the adaptor. Both

components are connected to the cylinder block

through internal oilways in the adaptor casting

and via an interfacing filter mounting in the

block. A hollow bolt passes through the

adaptor/engine mount and screws into the centre

channel of the block filter mounting to provide

the oil return from the cooler to the cylinder

block.

The adaptor mounted oil cooler is an oil to water

heat exchanger and the coolant matrix is

connected via hoses into the main coolant system

at the radiator bottom hose (see Cooling System).

ENGINE OIL PRESSURE AND OIL TEMPERATURE SENSORS

D.303.1205

OIL COOLER AND FILTER ASSEMBLY

EOP Sensor

EOT Sensor

D.303.1205

D.303.1371

Engine Oil Pressure (EOP) and Oil

Temperature (EOT) Sensors

EOP and EOT sensors are fitted on the LH side of

the cylinder block in the return feed from the oil

cooler. The oil temperature is monitored to

provide data for the VVT system.

Oil Cooler

Hollow Bolt

Engine Mount/

Oil Cooler Adapter

Page 21 of 75

V6 Engine AJ-V6/AJ28

16

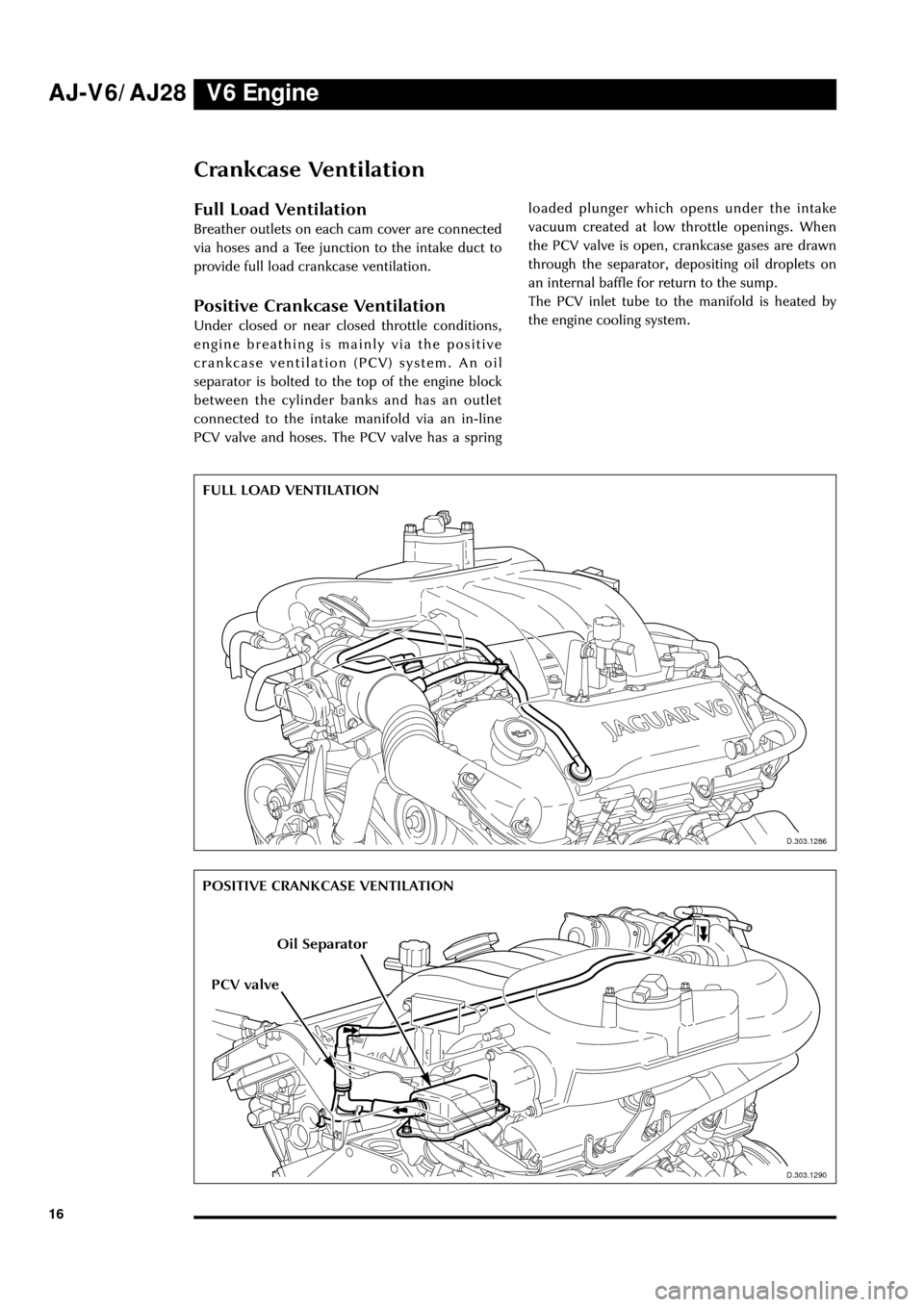

Crankcase Ventilation

Full Load Ventilation

Breather outlets on each cam cover are connected

via hoses and a Tee junction to the intake duct to

provide full load crankcase ventilation.

Positive Crankcase Ventilation

Under closed or near closed throttle conditions,

engine breathing is mainly via the positive

crankcase ventilation (PCV) system. An oil

separator is bolted to the top of the engine block

between the cylinder banks and has an outlet

connected to the intake manifold via an in-line

PCV valve and hoses. The PCV valve has a spring

J.303.1286

FULL LOAD VENTILATION

D.303.1286

loaded plunger which opens under the intake

vacuum created at low throttle openings. When

the PCV valve is open, crankcase gases are drawn

through the separator, depositing oil droplets on

an internal baffle for return to the sump.

The PCV inlet tube to the manifold is heated by

the engine cooling system.

J.303.1290

POSITIVE CRANKCASE VENTILATION

D.303.1290

Oil Separator

PCV valve

Page 22 of 75

V6 EngineAJ-V6/AJ28

17

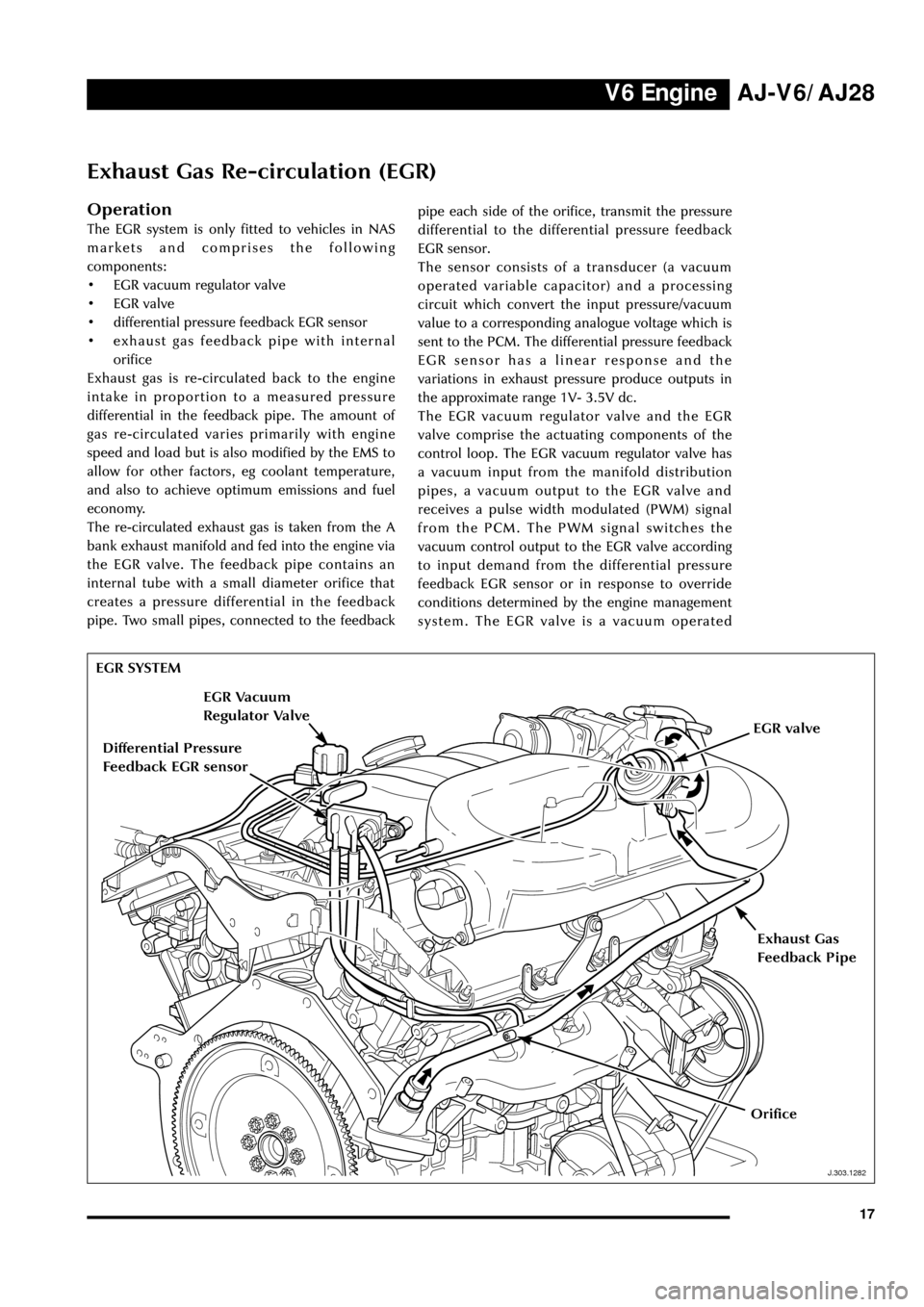

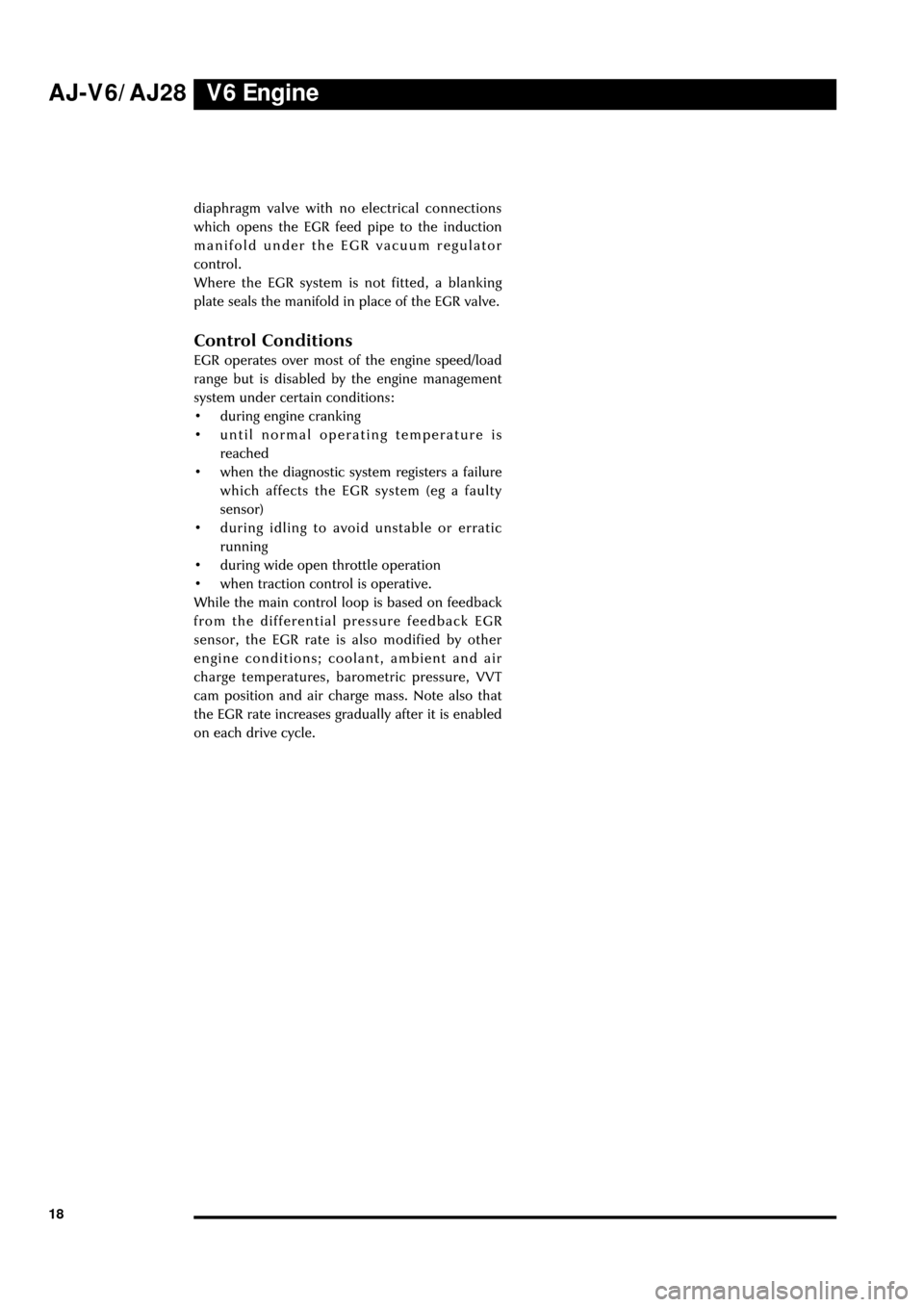

Exhaust Gas Re-circulation (EGR)

Operation

The EGR system is only fitted to vehicles in NAS

markets and comprises the following

components:

¥ EGR vacuum regulator valve

¥ EGR valve

¥ differential pressure feedback EGR sensor

¥ exhaust gas feedback pipe with internal

orifice

Exhaust gas is re-circulated back to the engine

intake in proportion to a measured pressure

differential in the feedback pipe. The amount of

gas re-circulated varies primarily with engine

speed and load but is also modified by the EMS to

allow for other factors, eg coolant temperature,

and also to achieve optimum emissions and fuel

economy.

The re-circulated exhaust gas is taken from the A

bank exhaust manifold and fed into the engine via

the EGR valve. The feedback pipe contains an

internal tube with a small diameter orifice that

creates a pressure differential in the feedback

pipe. Two small pipes, connected to the feedbackpipe each side of the orifice, transmit the pressure

differential to the differential pressure feedback

EGR sensor.

The sensor consists of a transducer (a vacuum

operated variable capacitor) and a processing

circuit which convert the input pressure/vacuum

value to a corresponding analogue voltage which is

sent to the PCM. The differential pressure feedback

EGR sensor has a linear response and the

variations in exhaust pressure produce outputs in

the approximate range 1V- 3.5V dc.

The EGR vacuum regulator valve and the EGR

valve comprise the actuating components of the

control loop. The EGR vacuum regulator valve has

a vacuum input from the manifold distribution

pipes, a vacuum output to the EGR valve and

receives a pulse width modulated (PWM) signal

from the PCM. The PWM signal switches the

vacuum control output to the EGR valve according

to input demand from the differential pressure

feedback EGR sensor or in response to override

conditions determined by the engine management

system. The EGR valve is a vacuum operated

EGR SYSTEM

J.303.1282

Exhaust Gas

Feedback Pipe

Differential Pressure

Feedback EGR sensor

EGR Vacuum

Regulator Valve

EGR valve

Orifice

Page 23 of 75

V6 Engine AJ-V6/AJ28

18diaphragm valve with no electrical connections

which opens the EGR feed pipe to the induction

manifold under the EGR vacuum regulator

control.

Where the EGR system is not fitted, a blanking

plate seals the manifold in place of the EGR valve.

Control Conditions

EGR operates over most of the engine speed/load

range but is disabled by the engine management

system under certain conditions:

¥ during engine cranking

¥ until normal operating temperature is

reached

¥ when the diagnostic system registers a failure

which affects the EGR system (eg a faulty

sensor)

¥ during idling to avoid unstable or erratic

running

¥ during wide open throttle operation

¥ when traction control is operative.

While the main control loop is based on feedback

from the differential pressure feedback EGR

sensor, the EGR rate is also modified by other

engine conditions; coolant, ambient and air

charge temperatures, barometric pressure, VVT

cam position and air charge mass. Note also that

the EGR rate increases gradually after it is enabled

on each drive cycle.

Page 24 of 75

V6 EngineAJ-V6/AJ28

19

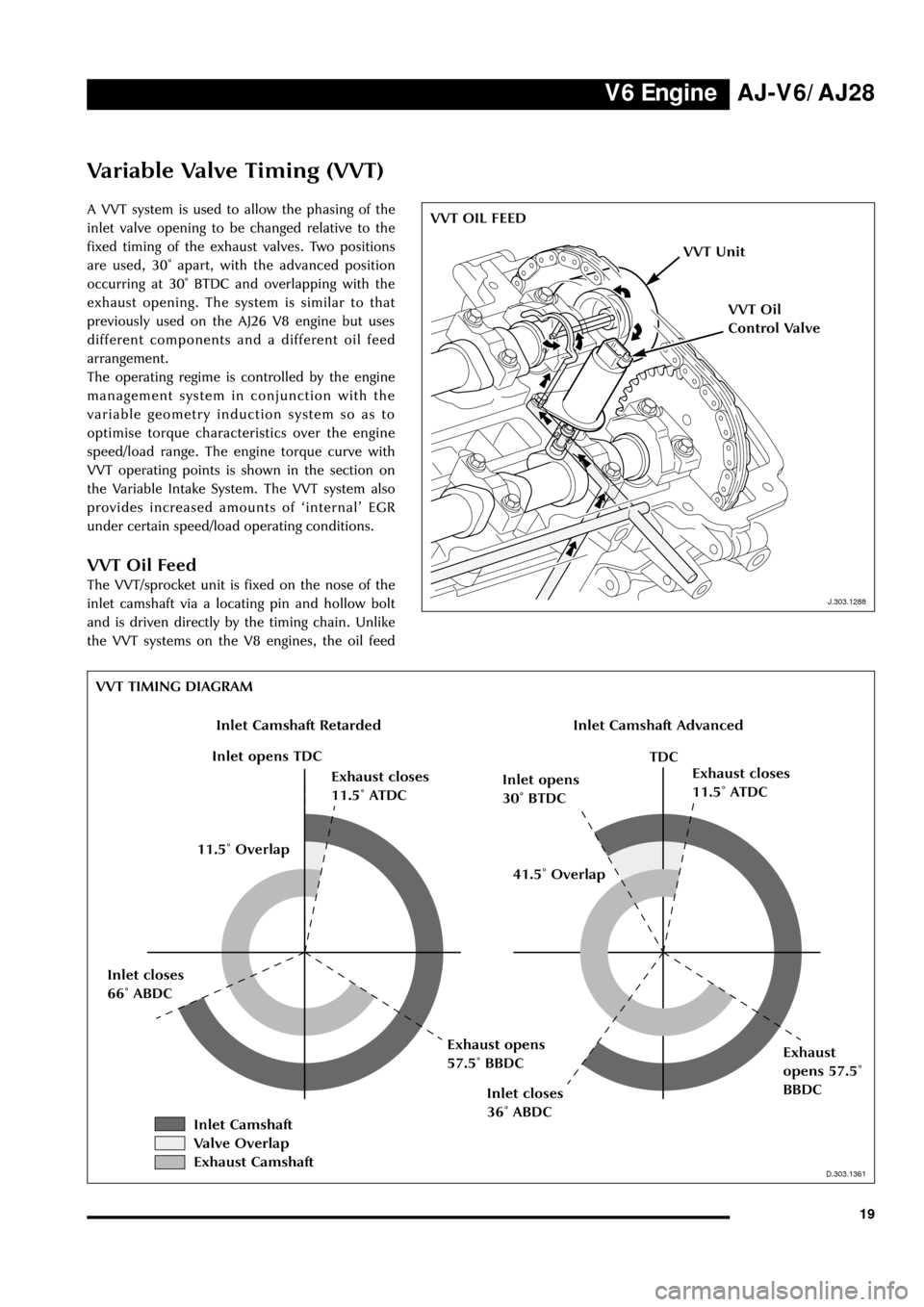

Variable Valve Timing (VVT)

A VVT system is used to allow the phasing of the

inlet valve opening to be changed relative to the

fixed timing of the exhaust valves. Two positions

are used, 30û apart, with the advanced position

occurring at 30û BTDC and overlapping with the

exhaust opening. The system is similar to that

previously used on the AJ26 V8 engine but uses

different components and a different oil feed

arrangement.

The operating regime is controlled by the engine

management system in conjunction with the

variable geometry induction system so as to

optimise torque characteristics over the engine

speed/load range. The engine torque curve with

VVT operating points is shown in the section on

the Variable Intake System. The VVT system also

provides increased amounts of ÔinternalÕ EGR

under certain speed/load operating conditions.

VVT Oil Feed

The VVT/sprocket unit is fixed on the nose of the

inlet camshaft via a locating pin and hollow bolt

and is driven directly by the timing chain. Unlike

the VVT systems on the V8 engines, the oil feed

J.303.1288

VVT OIL FEED

J.303.1288

VVT Unit

VVT Oil

Control Valve

D.303.1361

VVT TIMING DIAGRAM

D.303.1361

Inlet Camshaft RetardedInlet Camshaft Advanced

Inlet opens TDC

Exhaust closes

11.5û ATDCInlet opens

30û BTDCExhaust closes

11.5û ATDC

TDC

Inlet closes

36û ABDC

Exhaust

opens 57.5û

BBDC Inlet closes

66û ABDCExhaust opens

57.5û BBDC41.5û Overlap 11.5û Overlap

Inlet Camshaft

Valve Overlap

Exhaust Camshaft