Ect JAGUAR S TYPE 1999 1.G Powertrain Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1999, Model line: S TYPE, Model: JAGUAR S TYPE 1999 1.GPages: 75, PDF Size: 3.4 MB

Page 5 of 75

Preface AJ-V6/AJ28

This Technical Guide introduces the engines and transmissions for the new S-TYPE sports sedan.

It is intended to give Jaguar Dealer workshop personnel an overview of their construction and operation,

and is for information purposes only.

The contents of this Technical Guide must not be used as a reference source for servicing procedures; all

servicing must be carried out in accordance with the appropriate JTIS disc.

This Technical Guide will not be updated. While every effort is made to ensure accuracy, changes may

occur between going to press and the equipment being introduced to the market. Once the equipment is

in service, details of changes can be obtained from Service Bulletins and revisions to the JTIS disc.

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or

transmitted, in any form, electronic, mechanical, photocopying, recording or other means without prior

written permission from the Service Division of Jaguar Cars Limited.

Page 6 of 75

ContentsAJ-V6/AJ28

1 G Gl

lo

os

ss

sa

ar

ry

y

Abbreviations 2

I In

nt

tr

ro

od

du

uc

ct

ti

io

on

n

3

V V6

6

E

En

ng

gi

in

ne

e

Introduction 4

Engine Specifications 5

Basic Engine 6

Cylinder Head Assembly 8

Exhaust Manifold 12

Engine Mountings 12

Lubrication System 13

Crankcase Ventilation 15

Exhaust Gas Re-circulation (EGR) 17

Variable Valve Timing (VVT) 19

Air Induction System 21

Throttle Control System 25

Fuel System 29

Ignition System 30

Engine Cooling 31

Front End Accessories Drive 37

Engine Management Sensors 40

V V8

8

E

En

ng

gi

in

ne

e

Introduction 45

Basic Engine 46

Cooling System 49

Air Induction System 51

Variable Valve Timing (VVT) 53

Engine Management Sensors 54

Ignition System 54

Fuel Injection 56

Front End Accessories Drive 59

A Au

ut

to

om

ma

at

ti

ic

c

T

Tr

ra

an

ns

sm

mi

is

ss

si

io

on

n

Introduction 61

Specification 61

Construction and Operation 63

M Ma

an

nu

ua

al

l

T

Tr

ra

an

ns

sm

mi

is

ss

si

io

on

n

Introduction 64

Specification 64

Gear Selector Control 65

Flywheel and Clutch 65

Clutch Pedal Assembly 68

P Po

ow

we

er

rt

tr

ra

ai

in

n

M

Ma

an

na

ag

ge

em

me

en

nt

t

Introduction 69

Powertrain Control Module (PCM) 69

Subject Page

Page 7 of 75

Glossary

2The following abbreviations are used in this document:

A Ab

bb

br

re

ev

vi

ia

at

ti

io

on

nD

De

es

sc

cr

ri

ip

pt

ti

io

on

n

AAC air assisted (injection) control valve

AAI air assisted injection

ABDC after bottom dead centre

A/C air conditioning

AH amp-hour

API American Petroleum Institute

APP accelerator pedal position (sensor)

ATDC after top dead centre

bank 1 A bank

bank 2 B bank

BBDC before bottom dead centre

BTDC before top dead centre

ûC degree Celsius

CHT cylinder head temperature (sensor)

CKP crankshaft position (sensor)

CMP camshaft position (sensor)

ECT engine coolant temperature (sensor)

EFT engine fuel temperature (sensor)

EGR exhaust gas recirculation

EMS engine management system

EOP engine oil pressure (sensor)

EOT engine oil temperature (sensor)

EVAP evaporative emission

ûF degrees Fahrenheit

HO2 heated oxygen (sensor)

Hz Hertz (cycles per second)

IAT intake air temperature (sensor)

IMT intake manifold tuning (valve)

IP injector pressure (sensor)

JTIS Jaguar Technical Information System

KS knock sensor (sensor)

LH lefthand

MAF mass air flow (sensor)

N/A normally aspirated

NAS North American specification

OBDII on-board diagnostics stage 2

PAS power assisted steering

PCM powertrain control module

PCV positive crankcase ventilation

PWM pulse width modulated

RH righthand

RPM revolutions per minute

SAE Society of Automotive Engineers (USA)

SCP standard corporate protocol

TAC throttle actuator control (module)

TP throttle position (sensor)

VVT variable valve timing

W watts

AJ-V6/AJ28

Page 8 of 75

IntroductionAJ-V6/AJ28

3 The new S-TYPE sports sedan has an in-line powertrain and rear wheel drive configuration and is

available with either a 3 Litre V6 or a 4 Litre V8 engine, both normally aspirated. The V6 engine,

designated AJ-V6 is new to the Jaguar range and provides expected Jaguar levels of performance with

smooth power delivery, economy and excellent torque characteristics across the engine speed/load

range. The engine is of a lightweight but rigid design with particular attention paid to minimising noise

and vibration. A major innovation is the use of a variable geometry air intake manifold, which is

controlled, via valves, by the engine management system and produces optimised volumetric efficiency

at all engine speeds. Two stage variable valve timing is also fitted and both systems are optimised

together to achieve the wide torque delivery at all engine speeds.

The V8 engine, designated AJ28, is a developement of the now established engine fitted to the

successfull XK Series sports and XJ Series sedan and incorporates the latest modifications fitted to the

AJ27 variant, in particular the continuously variable valve timing system and air assisted fuel injection.

Both the V6 and V8 engines are fitted with a new, common, electronic throttle which does not require a

mechanical cable. Another new feature, also common to both engines, is the use of a returnless fuel

system to reduce the formation of fuel vapour (evaporative emissions).

A new 5-speed automatic transmission is fitted (with slight differences) to both engines. In certain

markets only, an optional 5-speed manual transmission, with new self-adjusting clutch, is available for

the V6 engine only.

Both engines and the automatic transmission are controlled by a completely new powertrain control

system.

Page 9 of 75

4

Introduction

D.303.1201

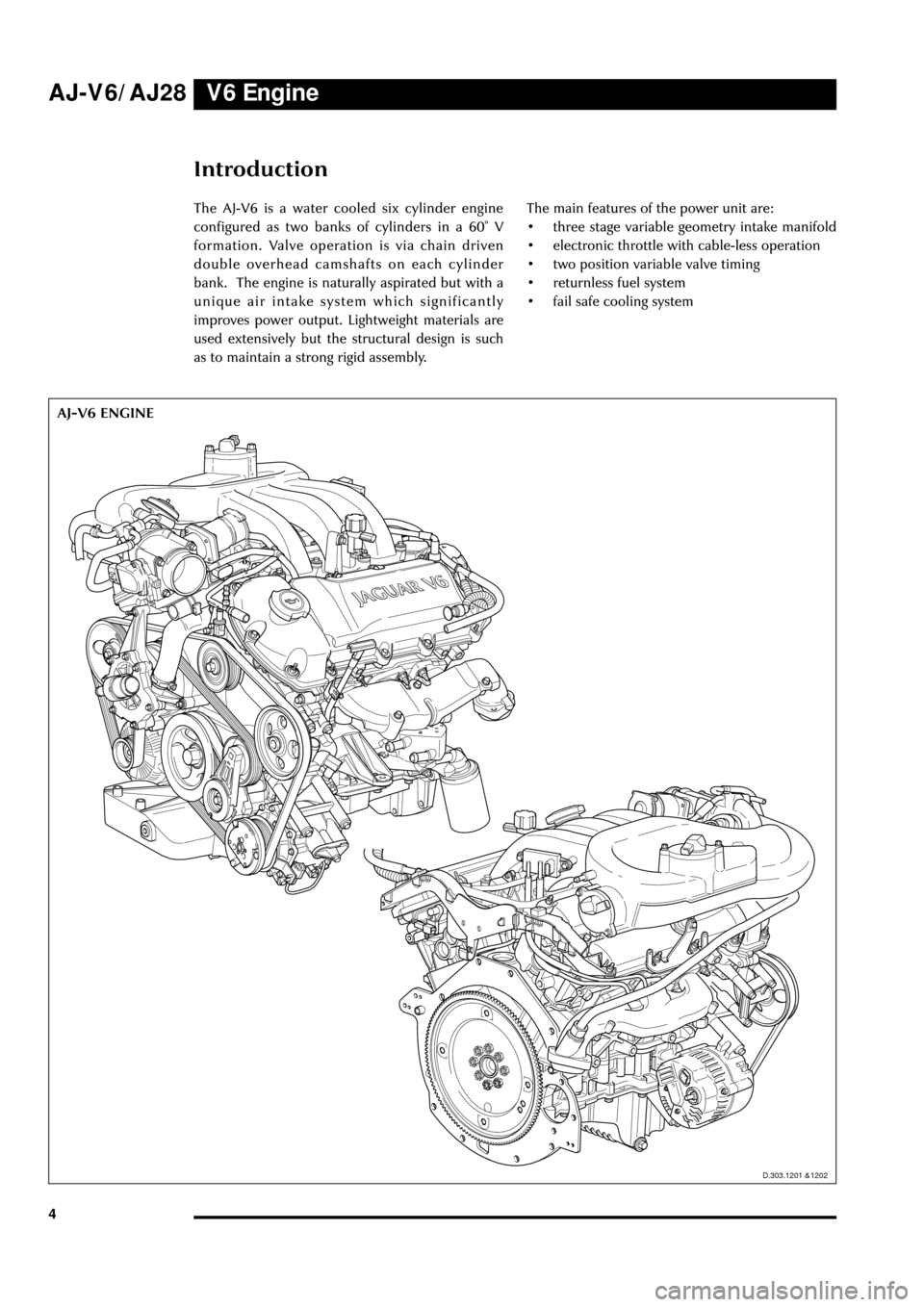

AJ-V6 ENGINEThe AJ-V6 is a water cooled six cylinder engine

configured as two banks of cylinders in a 60û V

formation. Valve operation is via chain driven

double overhead camshafts on each cylinder

bank. The engine is naturally aspirated but with a

unique air intake system which significantly

improves power output. Lightweight materials are

used extensively but the structural design is such

as to maintain a strong rigid assembly.The main features of the power unit are:

¥ three stage variable geometry intake manifold

¥ electronic throttle with cable-less operation

¥ two position variable valve timing

¥ returnless fuel system

¥ fail safe cooling system

V6 Engine

D.303.1202D.303.1201 &1202

AJ-V6/AJ28

Page 11 of 75

V6 Engine

6

Basic Engine

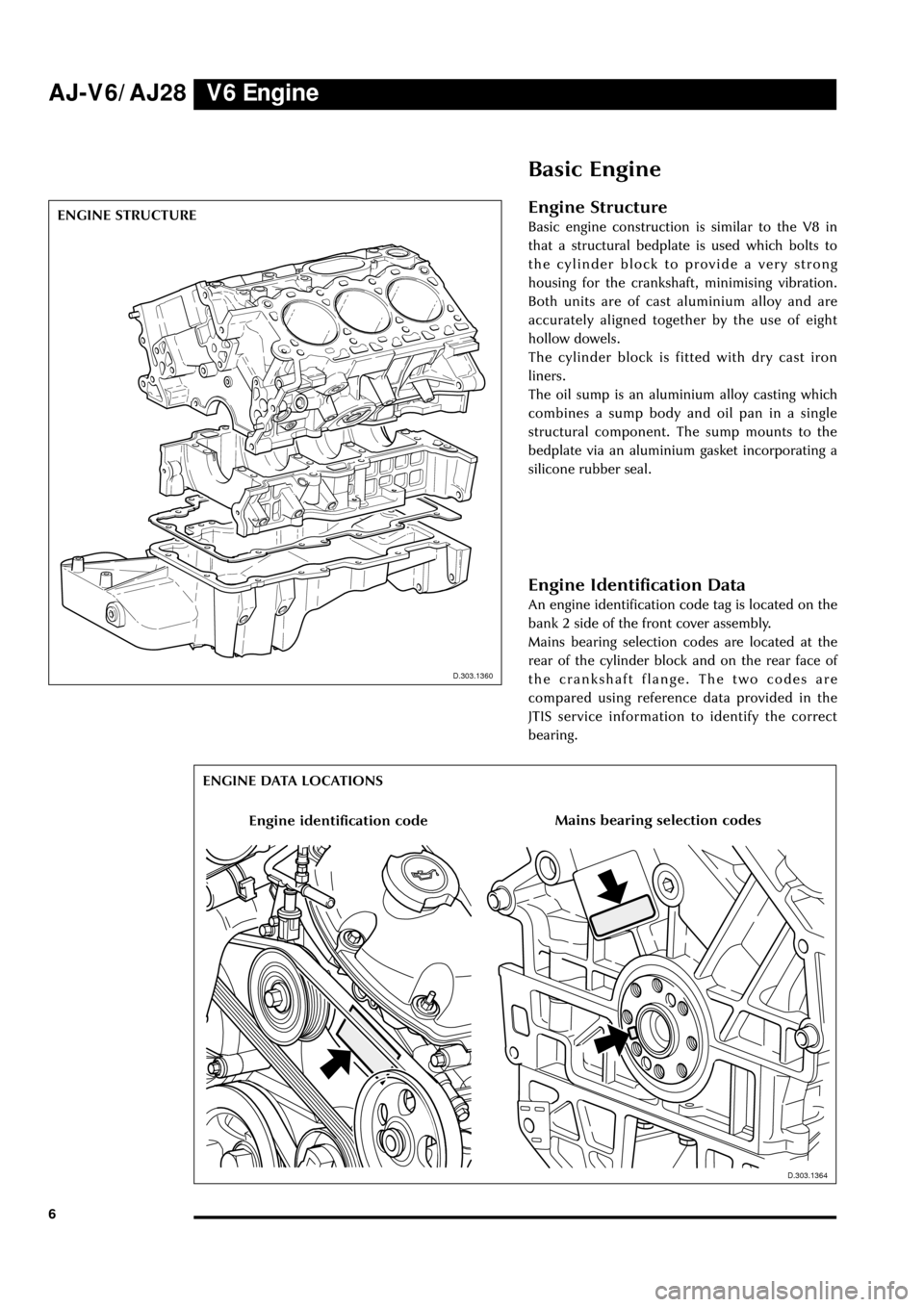

Engine Structure

Basic engine construction is similar to the V8 in

that a structural bedplate is used which bolts to

the cylinder block to provide a very strong

housing for the crankshaft, minimising vibration.

Both units are of cast aluminium alloy and are

accurately aligned together by the use of eight

hollow dowels.

The cylinder block is fitted with dry cast iron

liners.

The oil sump is an aluminium alloy casting which

combines a sump body and oil pan in a single

structural component. The sump mounts to the

bedplate via an aluminium gasket incorporating a

silicone rubber seal.

D.303.1360

D.303.1360

ENGINE STRUCTURE

D.303.1364

ENGINE DATA LOCATIONS

Engine Identification Data

An engine identification code tag is located on the

bank 2 side of the front cover assembly.

Mains bearing selection codes are located at the

rear of the cylinder block and on the rear face of

the crankshaft flange. The two codes are

compared using reference data provided in the

JTIS service information to identify the correct

bearing.

Engine identification codeMains bearing selection codes

D.303.1364

AJ-V6/AJ28

Page 12 of 75

D.303.1210

V6 EngineAJ-V6/AJ28

7 CRANKSHAFT

D.303.1210

D.303.1208

CONNECTING ROD AND PISTON

D.303-1208

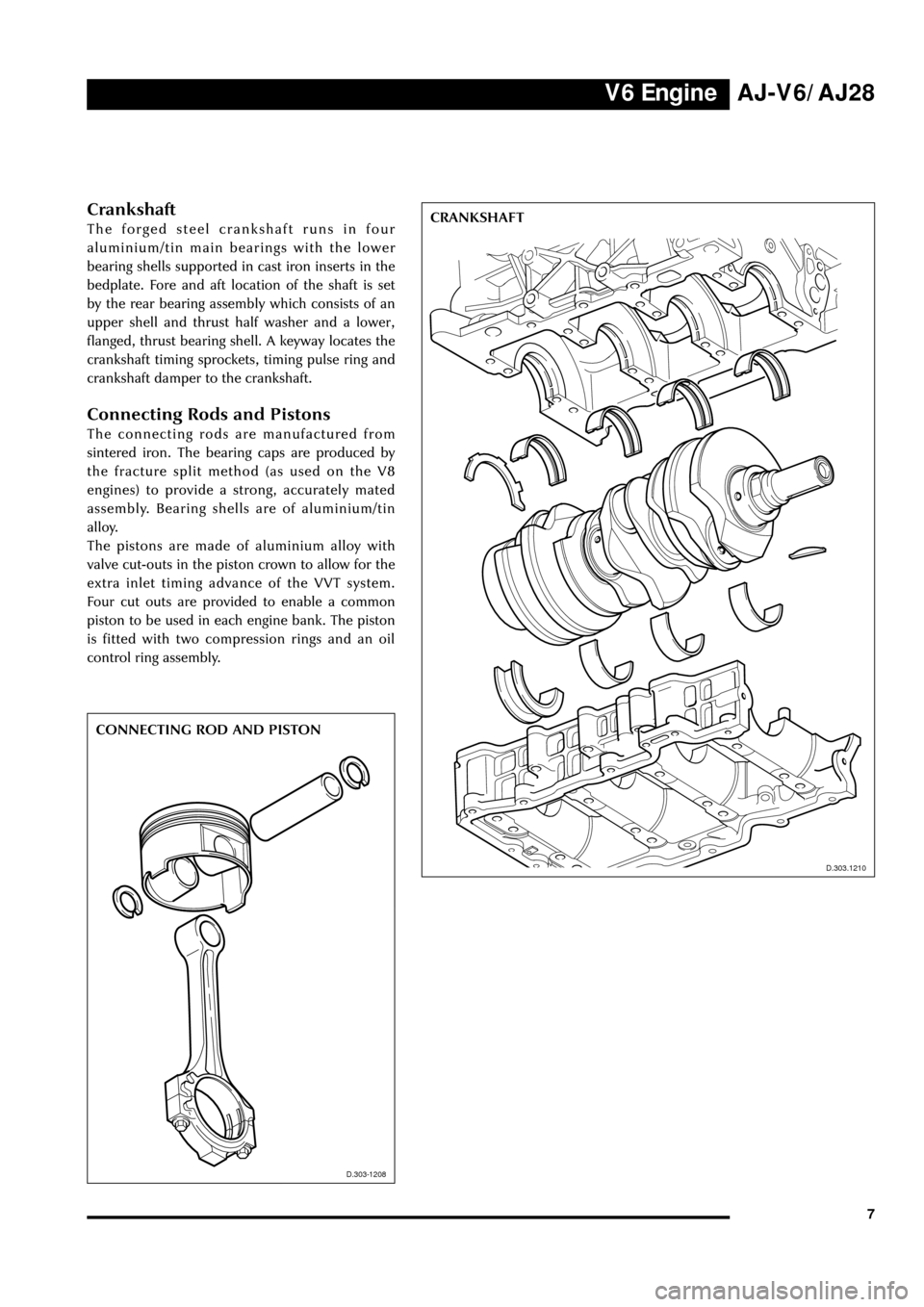

Crankshaft

The forged steel crankshaft runs in four

aluminium/tin main bearings with the lower

bearing shells supported in cast iron inserts in the

bedplate. Fore and aft location of the shaft is set

by the rear bearing assembly which consists of an

upper shell and thrust half washer and a lower,

flanged, thrust bearing shell. A keyway locates the

crankshaft timing sprockets, timing pulse ring and

crankshaft damper to the crankshaft.

Connecting Rods and Pistons

The connecting rods are manufactured from

sintered iron. The bearing caps are produced by

the fracture split method (as used on the V8

engines) to provide a strong, accurately mated

assembly. Bearing shells are of aluminium/tin

alloy.

The pistons are made of aluminium alloy with

valve cut-outs in the piston crown to allow for the

extra inlet timing advance of the VVT system.

Four cut outs are provided to enable a common

piston to be used in each engine bank. The piston

is fitted with two compression rings and an oil

control ring assembly.

Page 14 of 75

V6 EngineAJ-V6/AJ28

9

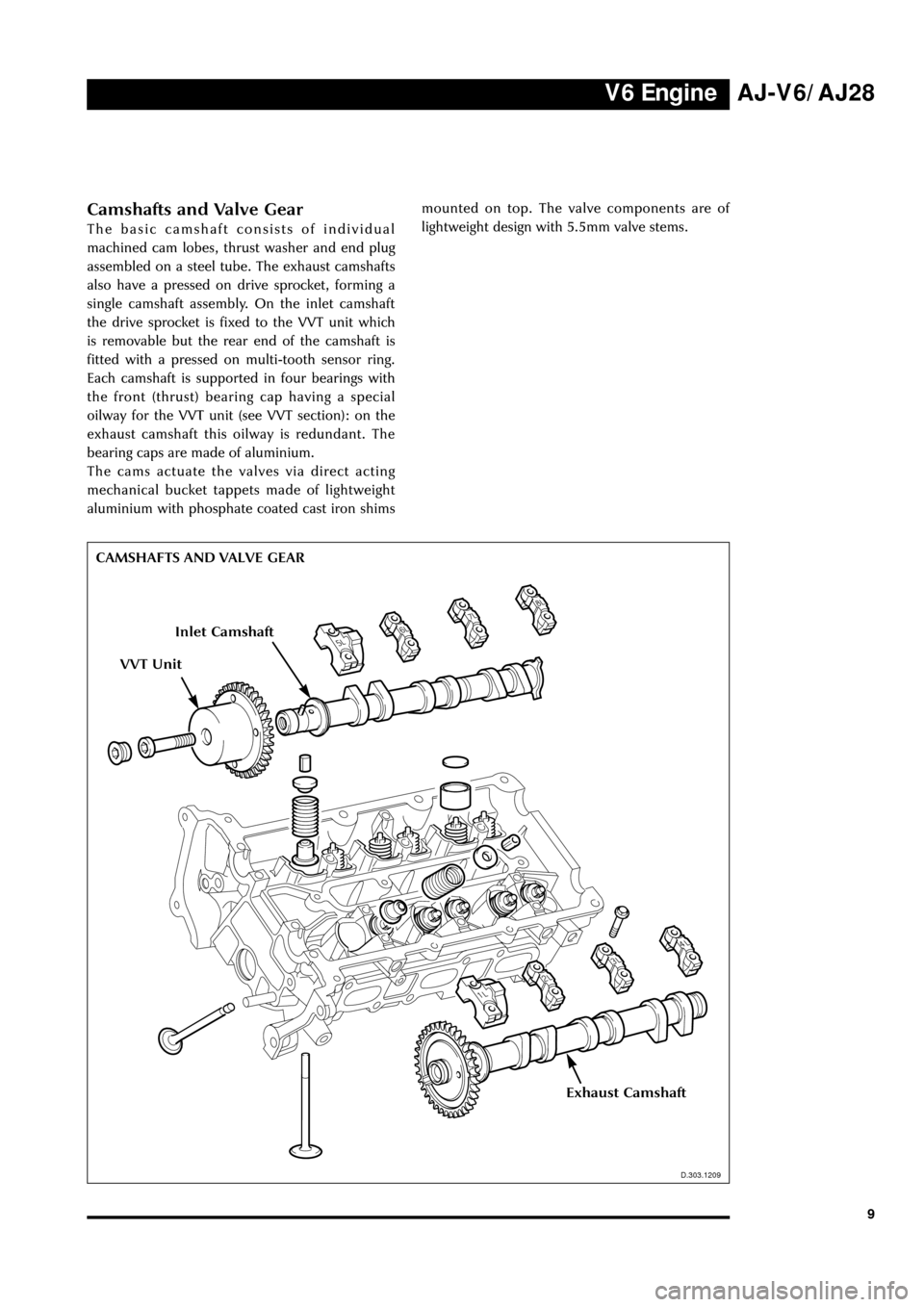

Camshafts and Valve Gear

The basic camshaft consists of individual

machined cam lobes, thrust washer and end plug

assembled on a steel tube. The exhaust camshafts

also have a pressed on drive sprocket, forming a

single camshaft assembly. On the inlet camshaft

the drive sprocket is fixed to the VVT unit which

is removable but the rear end of the camshaft is

fitted with a pressed on multi-tooth sensor ring.

Each camshaft is supported in four bearings with

the front (thrust) bearing cap having a special

oilway for the VVT unit (see VVT section): on the

exhaust camshaft this oilway is redundant. The

bearing caps are made of aluminium.

The cams actuate the valves via direct acting

mechanical bucket tappets made of lightweight

aluminium with phosphate coated cast iron shims

D.303.1209

CAMSHAFTS AND VALVE GEAR

D.303.1209

mounted on top. The valve components are of

lightweight design with 5.5mm valve stems.

VVT Unit

Inlet Camshaft

Exhaust Camshaft

Page 18 of 75

V6 EngineAJ-V6/AJ28

13

Oil Distribution

(see illustration on page 14)

Oil distribution within the block and cylinder

heads is similar to that of the V8 engine, the main

differences being in the filter and cooler

arrangement and the method of supplying the

VVT system.

Oil is drawn from the sump through the strainer

by the crankshaft driven pump, passes through

the externally mounted filter and oil cooler and

returns to the block. Distribution is via the main

gallery and crankshaft oilways to the lower

crankcase components and via branch feeds to

the chain tensioners and then cylinder head

components. Extra oilways in the cylinder heads

provide a built-in feed for the VVT components

(see VVT section).

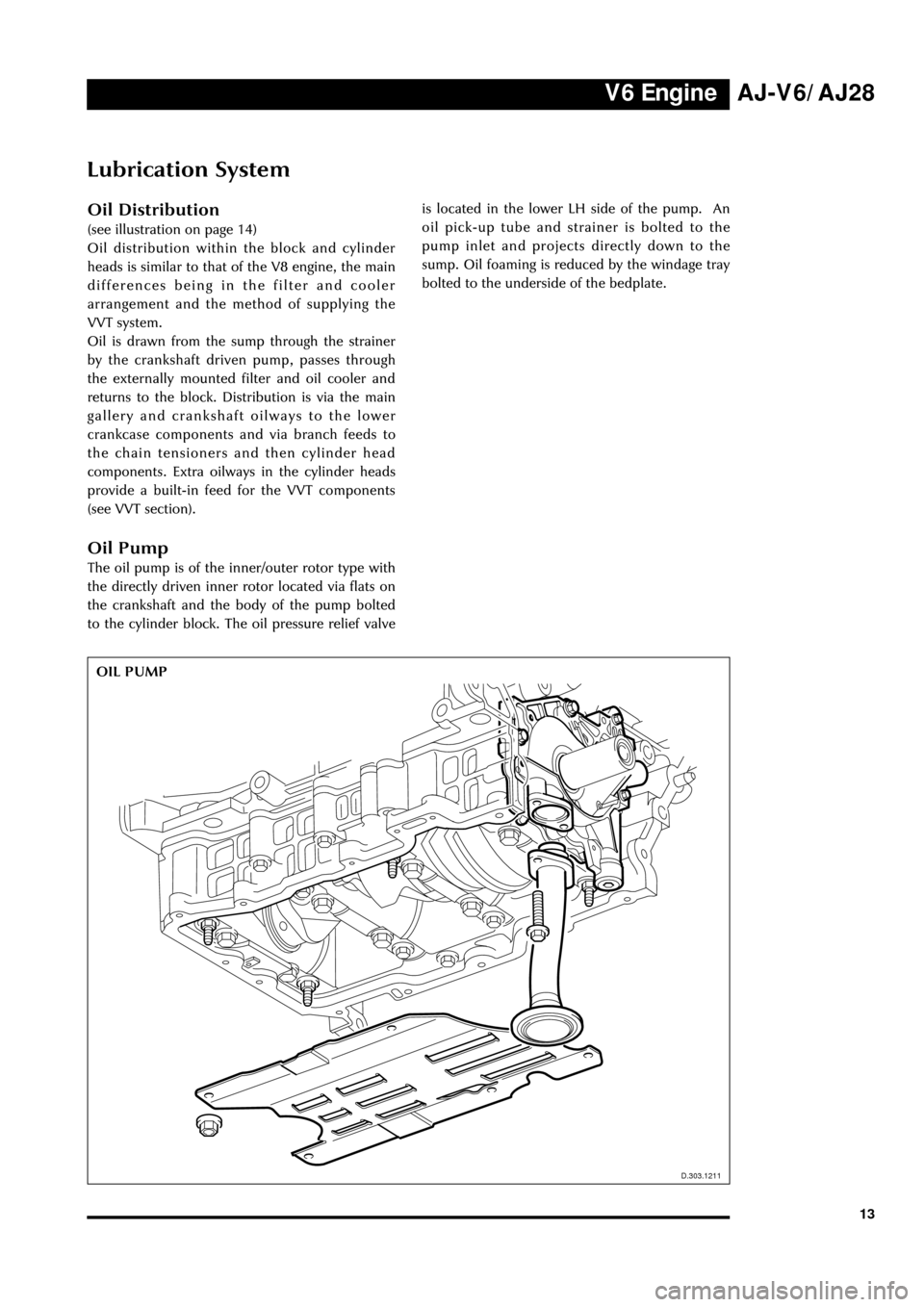

Oil Pump

The oil pump is of the inner/outer rotor type with

the directly driven inner rotor located via flats on

the crankshaft and the body of the pump bolted

to the cylinder block. The oil pressure relief valveis located in the lower LH side of the pump. An

oil pick-up tube and strainer is bolted to the

pump inlet and projects directly down to the

sump. Oil foaming is reduced by the windage tray

bolted to the underside of the bedplate.

D.303.1211

Lubrication System

OIL PUMP

D.303.1211

Page 20 of 75

V6 EngineAJ-V6/AJ28

15

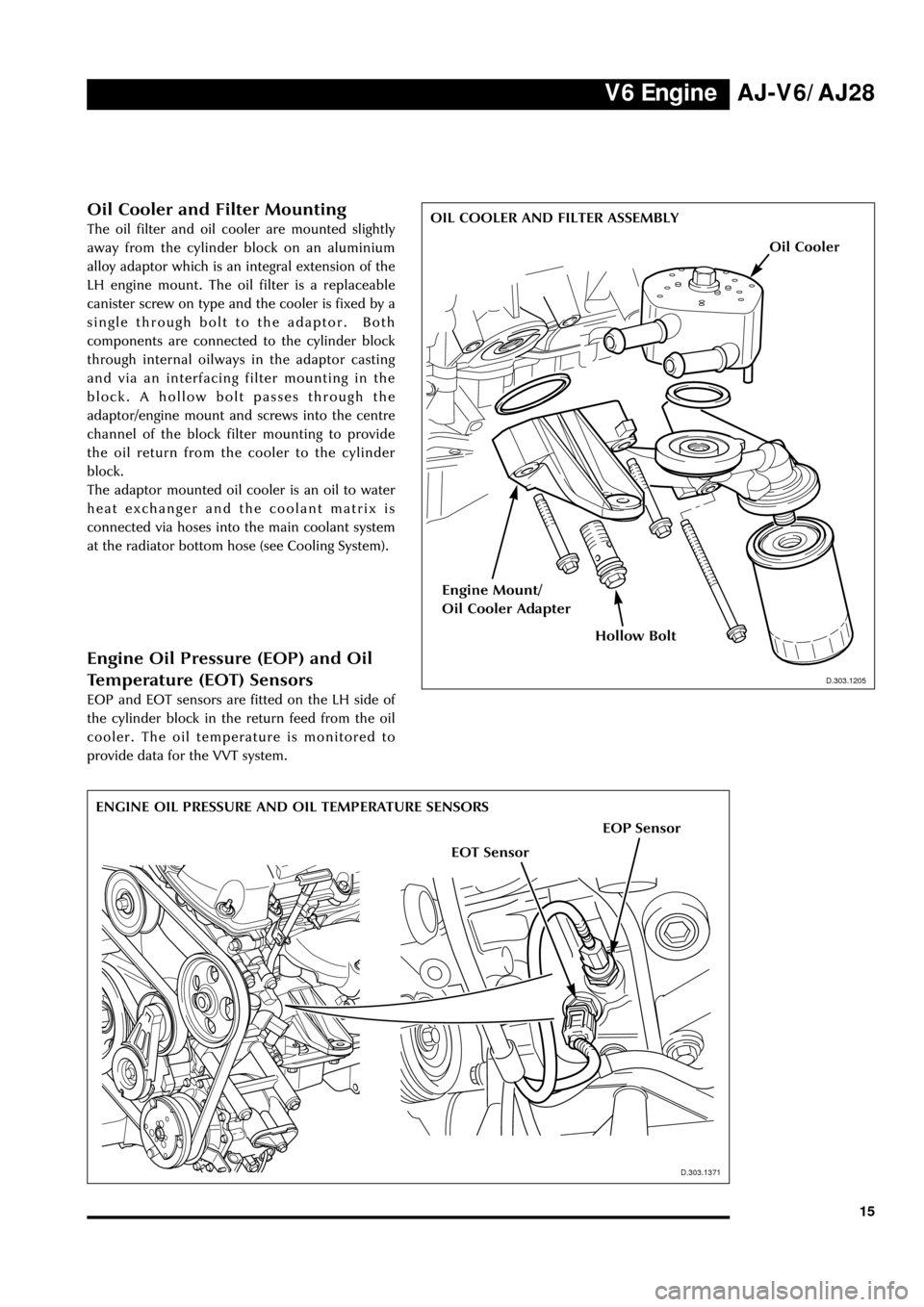

Oil Cooler and Filter Mounting

The oil filter and oil cooler are mounted slightly

away from the cylinder block on an aluminium

alloy adaptor which is an integral extension of the

LH engine mount. The oil filter is a replaceable

canister screw on type and the cooler is fixed by a

single through bolt to the adaptor. Both

components are connected to the cylinder block

through internal oilways in the adaptor casting

and via an interfacing filter mounting in the

block. A hollow bolt passes through the

adaptor/engine mount and screws into the centre

channel of the block filter mounting to provide

the oil return from the cooler to the cylinder

block.

The adaptor mounted oil cooler is an oil to water

heat exchanger and the coolant matrix is

connected via hoses into the main coolant system

at the radiator bottom hose (see Cooling System).

ENGINE OIL PRESSURE AND OIL TEMPERATURE SENSORS

D.303.1205

OIL COOLER AND FILTER ASSEMBLY

EOP Sensor

EOT Sensor

D.303.1205

D.303.1371

Engine Oil Pressure (EOP) and Oil

Temperature (EOT) Sensors

EOP and EOT sensors are fitted on the LH side of

the cylinder block in the return feed from the oil

cooler. The oil temperature is monitored to

provide data for the VVT system.

Oil Cooler

Hollow Bolt

Engine Mount/

Oil Cooler Adapter