engine coolant JAGUAR S TYPE 1999 1.G Powertrain Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1999, Model line: S TYPE, Model: JAGUAR S TYPE 1999 1.GPages: 75, PDF Size: 3.4 MB

Page 7 of 75

Glossary

2The following abbreviations are used in this document:

A Ab

bb

br

re

ev

vi

ia

at

ti

io

on

nD

De

es

sc

cr

ri

ip

pt

ti

io

on

n

AAC air assisted (injection) control valve

AAI air assisted injection

ABDC after bottom dead centre

A/C air conditioning

AH amp-hour

API American Petroleum Institute

APP accelerator pedal position (sensor)

ATDC after top dead centre

bank 1 A bank

bank 2 B bank

BBDC before bottom dead centre

BTDC before top dead centre

ûC degree Celsius

CHT cylinder head temperature (sensor)

CKP crankshaft position (sensor)

CMP camshaft position (sensor)

ECT engine coolant temperature (sensor)

EFT engine fuel temperature (sensor)

EGR exhaust gas recirculation

EMS engine management system

EOP engine oil pressure (sensor)

EOT engine oil temperature (sensor)

EVAP evaporative emission

ûF degrees Fahrenheit

HO2 heated oxygen (sensor)

Hz Hertz (cycles per second)

IAT intake air temperature (sensor)

IMT intake manifold tuning (valve)

IP injector pressure (sensor)

JTIS Jaguar Technical Information System

KS knock sensor (sensor)

LH lefthand

MAF mass air flow (sensor)

N/A normally aspirated

NAS North American specification

OBDII on-board diagnostics stage 2

PAS power assisted steering

PCM powertrain control module

PCV positive crankcase ventilation

PWM pulse width modulated

RH righthand

RPM revolutions per minute

SAE Society of Automotive Engineers (USA)

SCP standard corporate protocol

TAC throttle actuator control (module)

TP throttle position (sensor)

VVT variable valve timing

W watts

AJ-V6/AJ28

Page 10 of 75

V6 EngineAJ-V6/AJ28

5

Engine Specifications

Configuration 60û V6

Displacement 2967 cc (181 cu. in)

Bore 89.0 mm (3.504 in)

Stroke 79.5 mm (3.130 in)

Compression ratio 10.5 :1

Cylinder head 2 overhead camshafts per bank, 4 valve per cylinder

Firing order 1-4-2-5-3-6

Maximum power DIN - 179 kW (240 BHP) at 6800 RPM

EEC - 175 kW (238 PS) at 6800 RPM

Maximum torque DIN - 300 Nm (221 lbft) at 4500 RPM

EEC - 293 Nm (216 lbft) at 4500 RPM

Oil specification see below

Oil volume 5.7 Litres (6 quarts)

Coolant specification see page 35

Coolant volume 10.4 Litres (11 quarts)

Weight 174 kg (384 lbs)

JOL.29550

50JOL.296

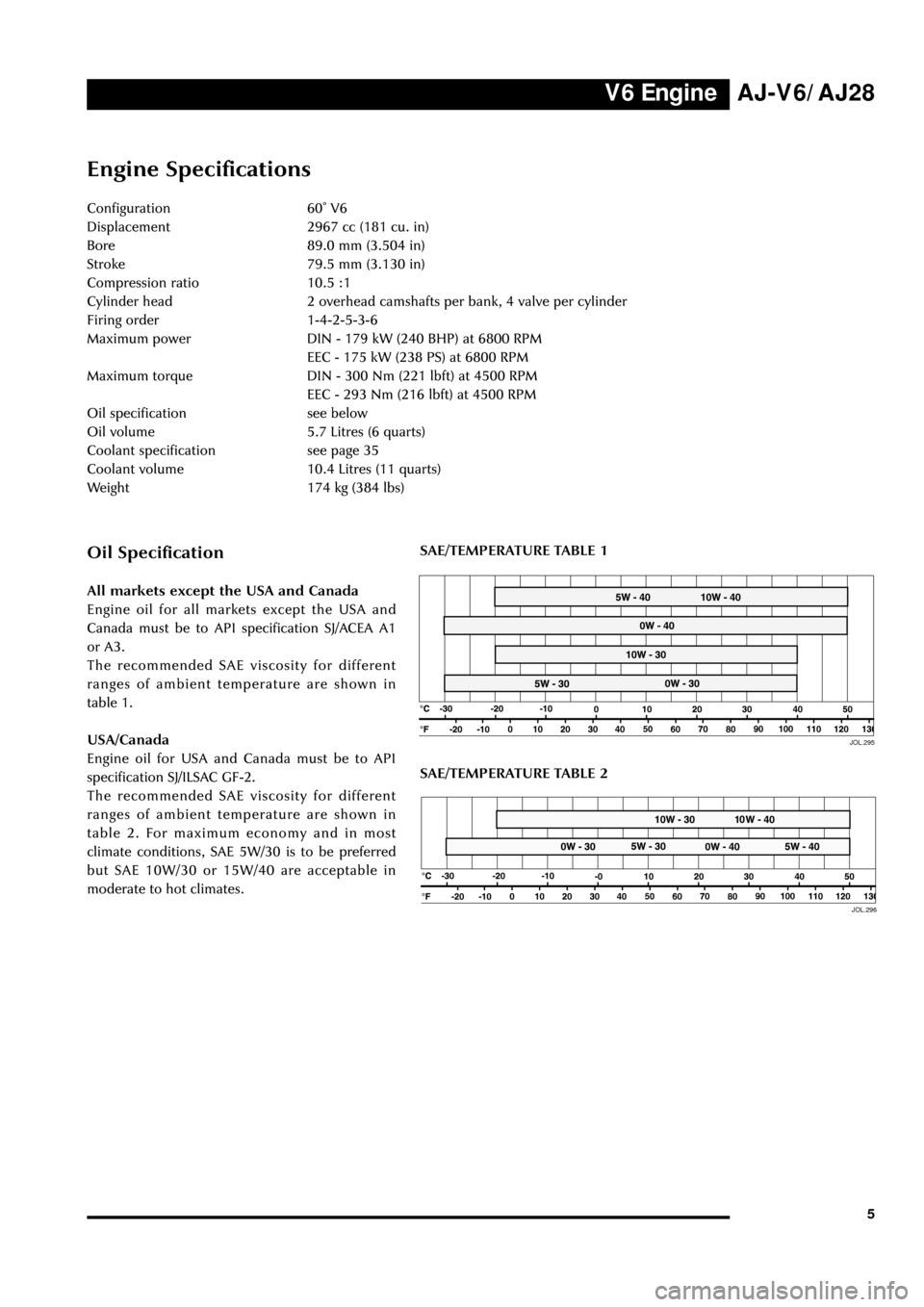

Oil Specification

All markets except the USA and Canada

Engine oil for all markets except the USA and

Canada must be to API specification SJ/ACEA A1

or A3.

The recommended SAE viscosity for different

ranges of ambient temperature are shown in

table 1.

USA/Canada

Engine oil for USA and Canada must be to API

specification SJ/ILSAC GF-2.

The recommended SAE viscosity for different

ranges of ambient temperature are shown in

table 2. For maximum economy and in most

climate conditions, SAE 5W/30 is to be preferred

but SAE 10W/30 or 15W/40 are acceptable in

moderate to hot climates.SAE/TEMPERATURE TABLE 2

SAE/TEMPERATURE TABLE 1

Page 20 of 75

V6 EngineAJ-V6/AJ28

15

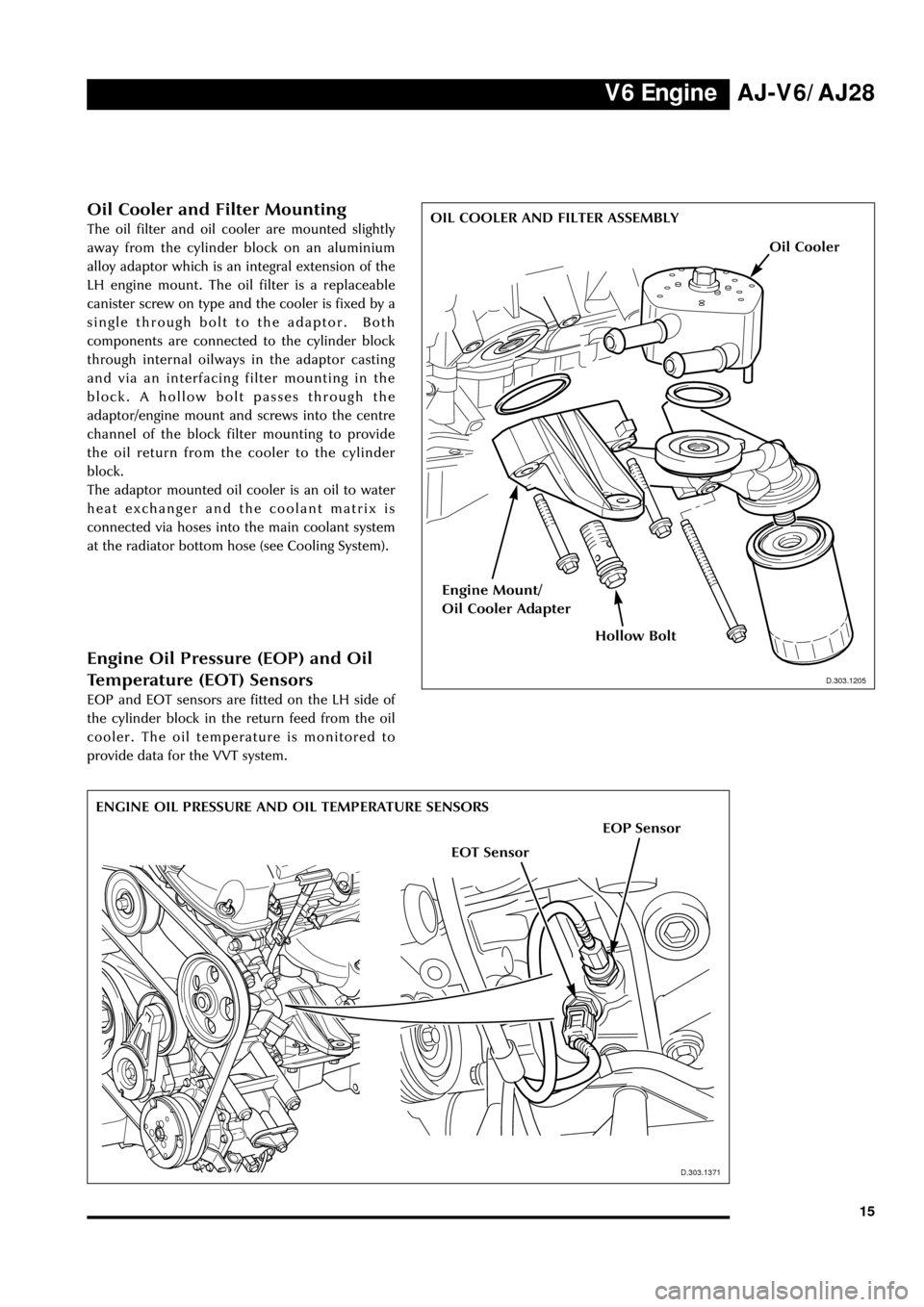

Oil Cooler and Filter Mounting

The oil filter and oil cooler are mounted slightly

away from the cylinder block on an aluminium

alloy adaptor which is an integral extension of the

LH engine mount. The oil filter is a replaceable

canister screw on type and the cooler is fixed by a

single through bolt to the adaptor. Both

components are connected to the cylinder block

through internal oilways in the adaptor casting

and via an interfacing filter mounting in the

block. A hollow bolt passes through the

adaptor/engine mount and screws into the centre

channel of the block filter mounting to provide

the oil return from the cooler to the cylinder

block.

The adaptor mounted oil cooler is an oil to water

heat exchanger and the coolant matrix is

connected via hoses into the main coolant system

at the radiator bottom hose (see Cooling System).

ENGINE OIL PRESSURE AND OIL TEMPERATURE SENSORS

D.303.1205

OIL COOLER AND FILTER ASSEMBLY

EOP Sensor

EOT Sensor

D.303.1205

D.303.1371

Engine Oil Pressure (EOP) and Oil

Temperature (EOT) Sensors

EOP and EOT sensors are fitted on the LH side of

the cylinder block in the return feed from the oil

cooler. The oil temperature is monitored to

provide data for the VVT system.

Oil Cooler

Hollow Bolt

Engine Mount/

Oil Cooler Adapter

Page 22 of 75

V6 EngineAJ-V6/AJ28

17

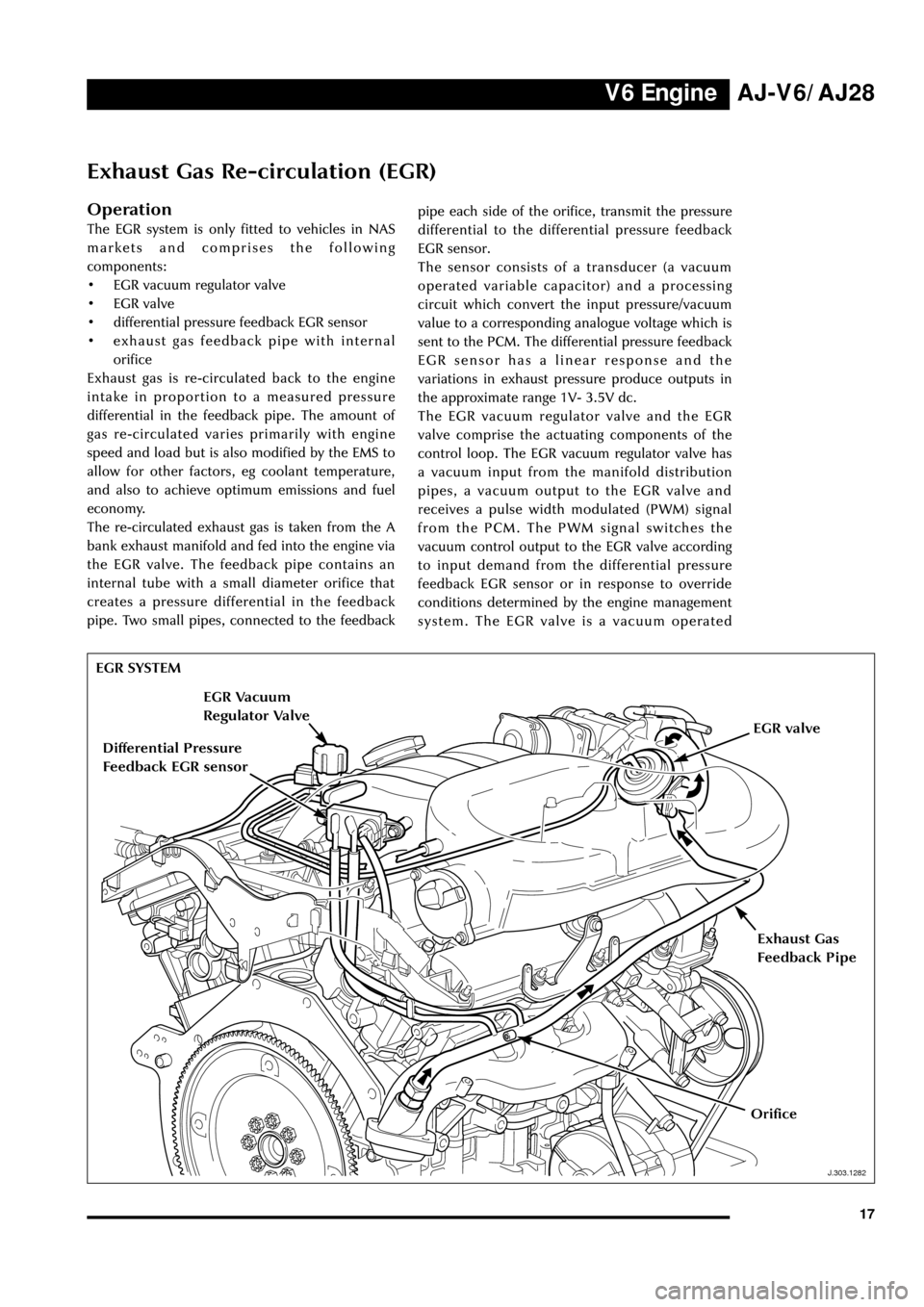

Exhaust Gas Re-circulation (EGR)

Operation

The EGR system is only fitted to vehicles in NAS

markets and comprises the following

components:

¥ EGR vacuum regulator valve

¥ EGR valve

¥ differential pressure feedback EGR sensor

¥ exhaust gas feedback pipe with internal

orifice

Exhaust gas is re-circulated back to the engine

intake in proportion to a measured pressure

differential in the feedback pipe. The amount of

gas re-circulated varies primarily with engine

speed and load but is also modified by the EMS to

allow for other factors, eg coolant temperature,

and also to achieve optimum emissions and fuel

economy.

The re-circulated exhaust gas is taken from the A

bank exhaust manifold and fed into the engine via

the EGR valve. The feedback pipe contains an

internal tube with a small diameter orifice that

creates a pressure differential in the feedback

pipe. Two small pipes, connected to the feedbackpipe each side of the orifice, transmit the pressure

differential to the differential pressure feedback

EGR sensor.

The sensor consists of a transducer (a vacuum

operated variable capacitor) and a processing

circuit which convert the input pressure/vacuum

value to a corresponding analogue voltage which is

sent to the PCM. The differential pressure feedback

EGR sensor has a linear response and the

variations in exhaust pressure produce outputs in

the approximate range 1V- 3.5V dc.

The EGR vacuum regulator valve and the EGR

valve comprise the actuating components of the

control loop. The EGR vacuum regulator valve has

a vacuum input from the manifold distribution

pipes, a vacuum output to the EGR valve and

receives a pulse width modulated (PWM) signal

from the PCM. The PWM signal switches the

vacuum control output to the EGR valve according

to input demand from the differential pressure

feedback EGR sensor or in response to override

conditions determined by the engine management

system. The EGR valve is a vacuum operated

EGR SYSTEM

J.303.1282

Exhaust Gas

Feedback Pipe

Differential Pressure

Feedback EGR sensor

EGR Vacuum

Regulator Valve

EGR valve

Orifice

Page 23 of 75

V6 Engine AJ-V6/AJ28

18diaphragm valve with no electrical connections

which opens the EGR feed pipe to the induction

manifold under the EGR vacuum regulator

control.

Where the EGR system is not fitted, a blanking

plate seals the manifold in place of the EGR valve.

Control Conditions

EGR operates over most of the engine speed/load

range but is disabled by the engine management

system under certain conditions:

¥ during engine cranking

¥ until normal operating temperature is

reached

¥ when the diagnostic system registers a failure

which affects the EGR system (eg a faulty

sensor)

¥ during idling to avoid unstable or erratic

running

¥ during wide open throttle operation

¥ when traction control is operative.

While the main control loop is based on feedback

from the differential pressure feedback EGR

sensor, the EGR rate is also modified by other

engine conditions; coolant, ambient and air

charge temperatures, barometric pressure, VVT

cam position and air charge mass. Note also that

the EGR rate increases gradually after it is enabled

on each drive cycle.

Page 36 of 75

V6 EngineAJ-V6/AJ28

31

J.303.1365

Engine Cooling

Cooling System

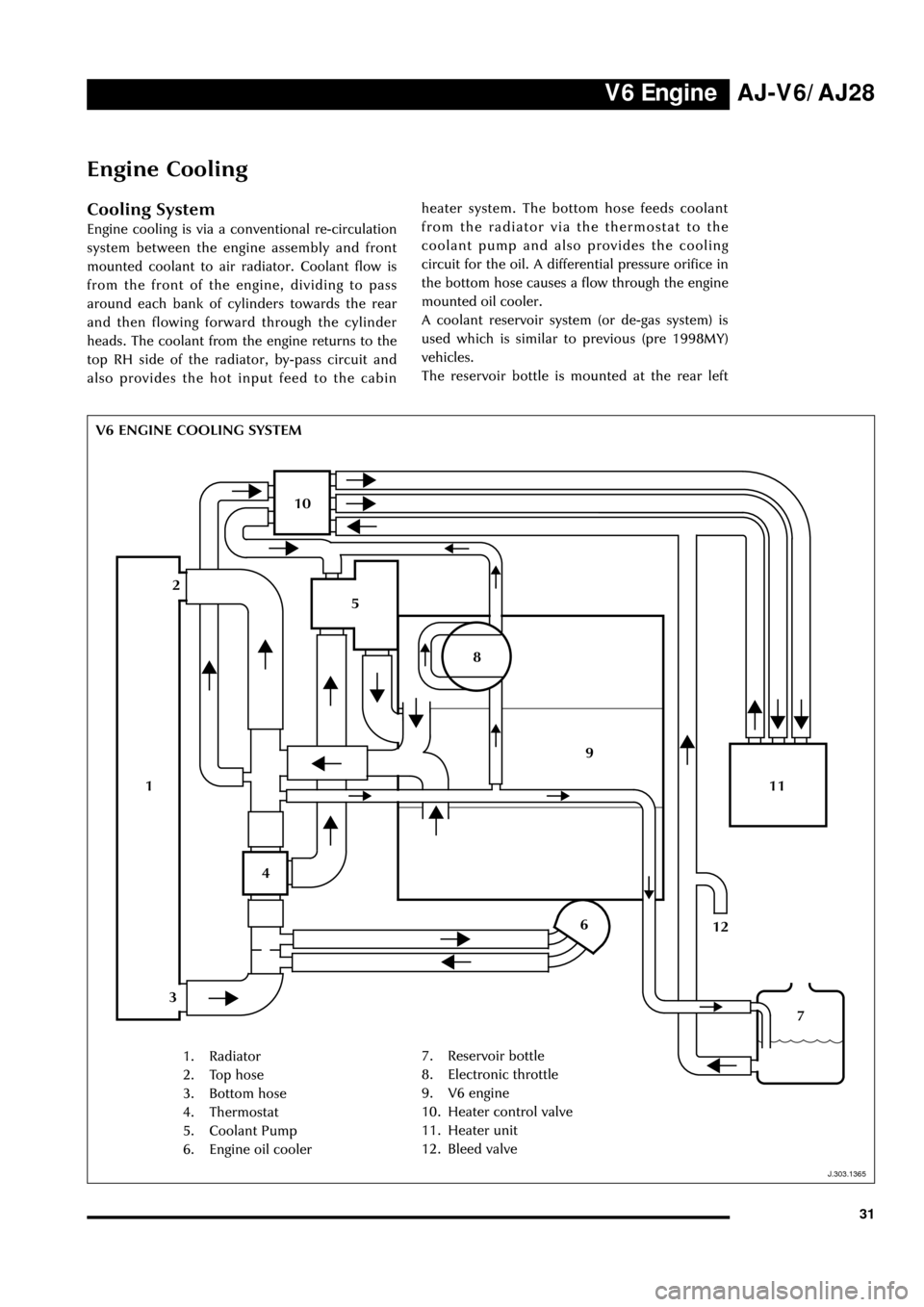

Engine cooling is via a conventional re-circulation

system between the engine assembly and front

mounted coolant to air radiator. Coolant flow is

from the front of the engine, dividing to pass

around each bank of cylinders towards the rear

and then flowing forward through the cylinder

heads. The coolant from the engine returns to the

top RH side of the radiator, by-pass circuit and

also provides the hot input feed to the cabin

V6 ENGINE COOLING SYSTEMheater system. The bottom hose feeds coolant

from the radiator via the thermostat to the

coolant pump and also provides the cooling

circuit for the oil. A differential pressure orifice in

the bottom hose causes a flow through the engine

mounted oil cooler.

A coolant reservoir system (or de-gas system) is

used which is similar to previous (pre 1998MY)

vehicles.

The reservoir bottle is mounted at the rear left

1. Radiator

2. Top hose

3. Bottom hose

4. Thermostat

5. Coolant Pump

6. Engine oil cooler7. Reservoir bottle

8. Electronic throttle

9. V6 engine

10. Heater control valve

11. Heater unit

12. Bleed valve

1

10

5

11

9

4

6

2

3

8

12

7

J.303.1365

Page 37 of 75

V6 Engine AJ-V6/AJ28

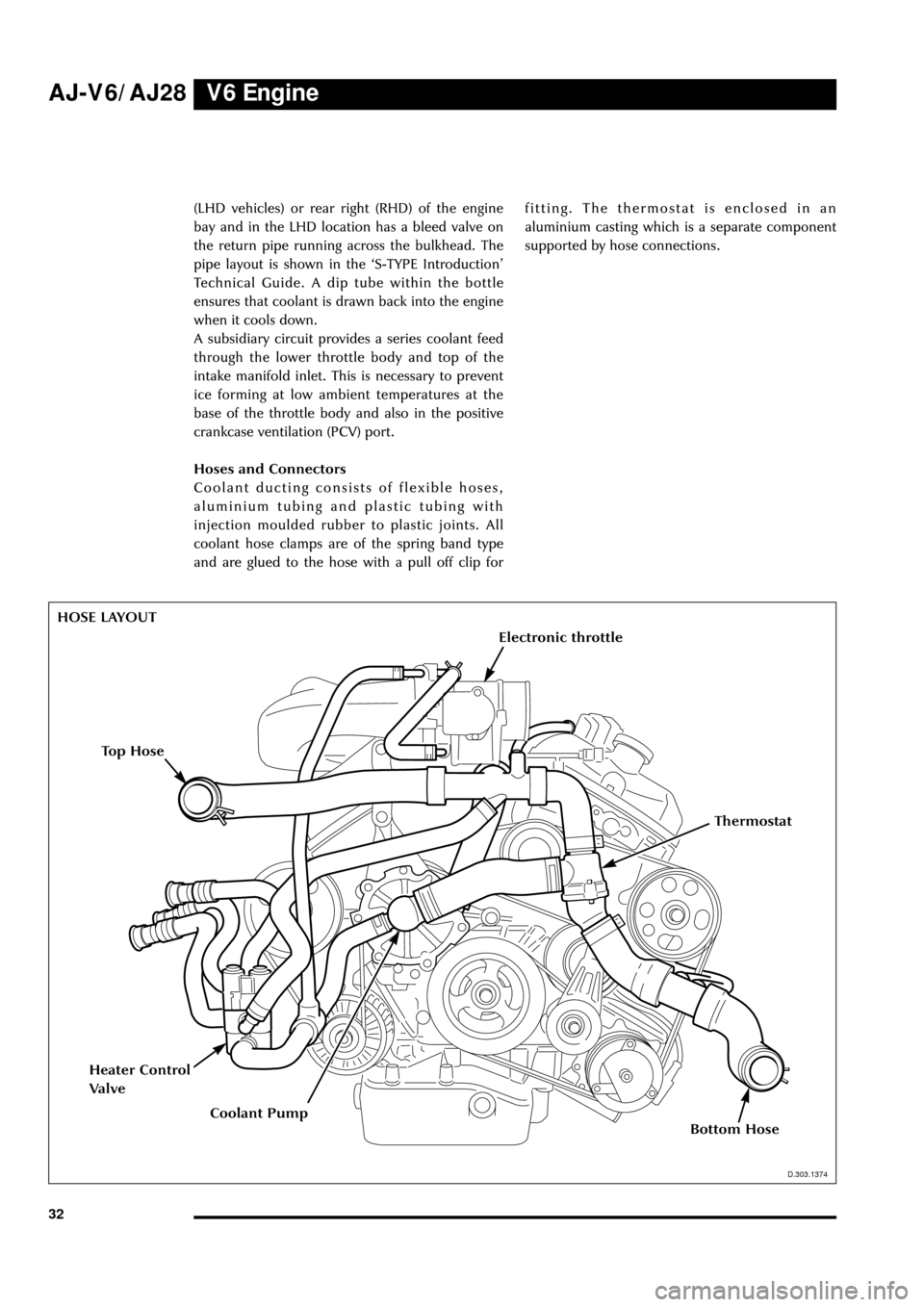

32(LHD vehicles) or rear right (RHD) of the engine

bay and in the LHD location has a bleed valve on

the return pipe running across the bulkhead. The

pipe layout is shown in the ÔS-TYPE IntroductionÕ

Technical Guide. A dip tube within the bottle

ensures that coolant is drawn back into the engine

when it cools down.

A subsidiary circuit provides a series coolant feed

through the lower throttle body and top of the

intake manifold inlet. This is necessary to prevent

ice forming at low ambient temperatures at the

base of the throttle body and also in the positive

crankcase ventilation (PCV) port.

Hoses and Connectors

Coolant ducting consists of flexible hoses,

aluminium tubing and plastic tubing with

injection moulded rubber to plastic joints. All

coolant hose clamps are of the spring band type

and are glued to the hose with a pull off clip for

D.303.1374

HOSE LAYOUT

Electronic throttle

D.303.1374

fitting. The thermostat is enclosed in an

aluminium casting which is a separate component

supported by hose connections.

Top Hose

Bottom Hose

Heater Control

Valve

Thermostat

Coolant Pump

Page 38 of 75

V6 EngineAJ-V6/AJ28

33

J.303.1378

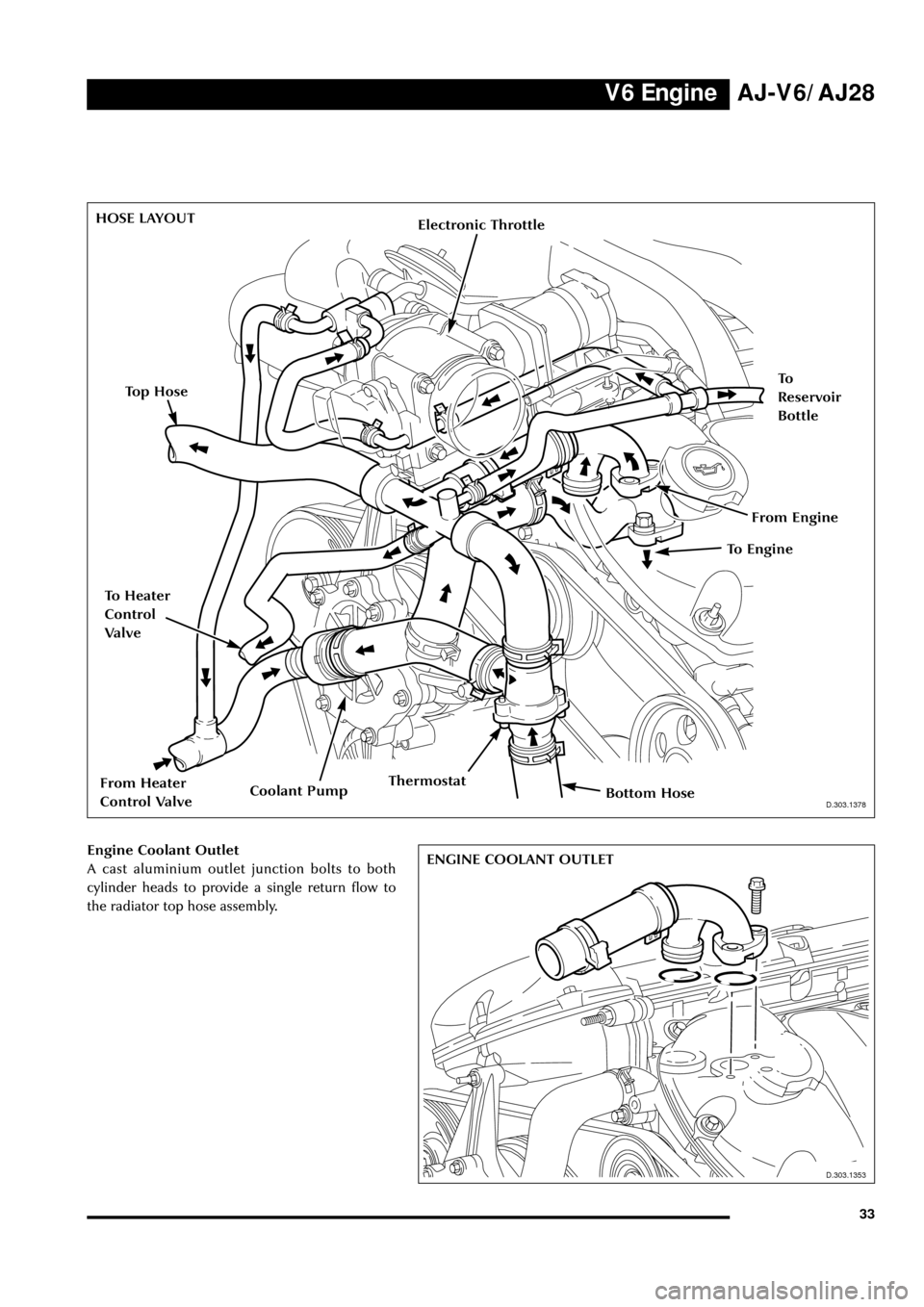

HOSE LAYOUT

D.303.1378

Electronic Throttle

Top Hose

Bottom HoseFrom Heater

Control Valve

To

Reservoir

Bottle

Engine Coolant Outlet

A cast aluminium outlet junction bolts to both

cylinder heads to provide a single return flow to

the radiator top hose assembly.

D.303.1353

ENGINE COOLANT OUTLET

D.303.1353

To Engine

From Engine

To Heater

Control

Valve

ThermostatCoolant Pump

Page 39 of 75

V6 Engine AJ-V6/AJ28

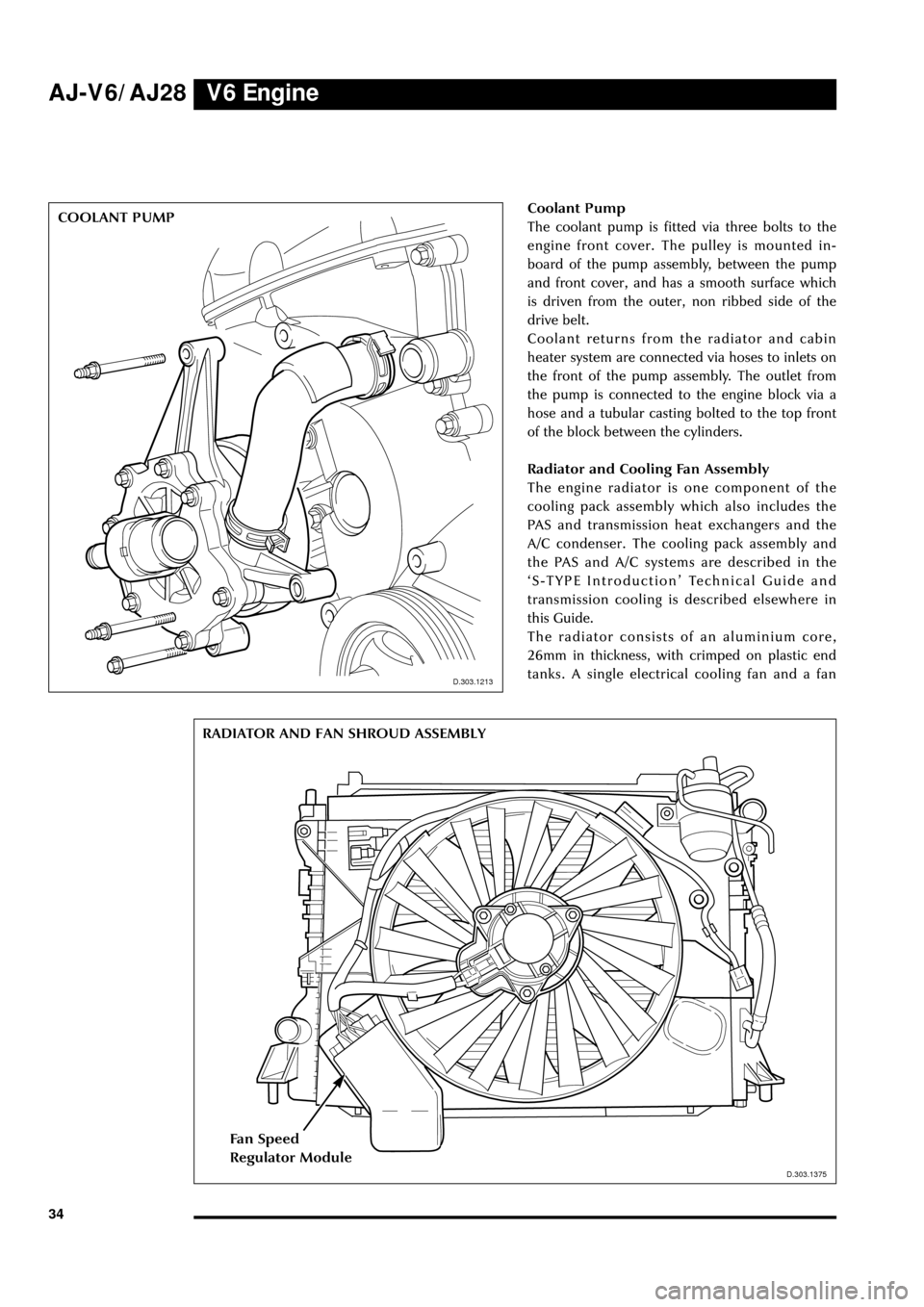

34Coolant Pump

The coolant pump is fitted via three bolts to the

engine front cover. The pulley is mounted in-

board of the pump assembly, between the pump

and front cover, and has a smooth surface which

is driven from the outer, non ribbed side of the

drive belt.

Coolant returns from the radiator and cabin

heater system are connected via hoses to inlets on

the front of the pump assembly. The outlet from

the pump is connected to the engine block via a

hose and a tubular casting bolted to the top front

of the block between the cylinders.

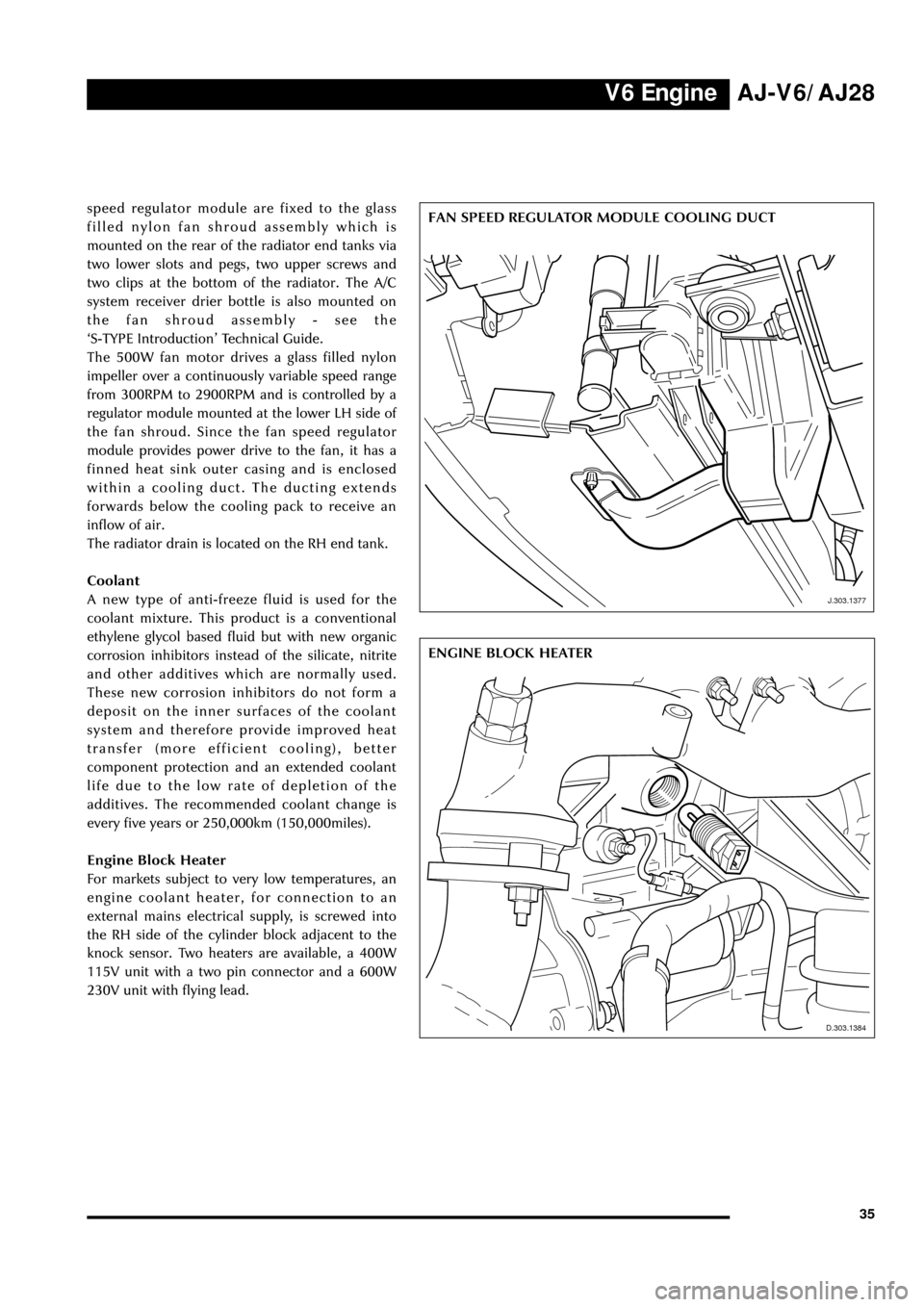

Radiator and Cooling Fan Assembly

The engine radiator is one component of the

cooling pack assembly which also includes the

PAS and transmission heat exchangers and the

A/C condenser. The cooling pack assembly and

the PAS and A/C systems are described in the

ÔS-TYPE IntroductionÕ Technical Guide and

transmission cooling is described elsewhere in

this Guide.

The radiator consists of an aluminium core,

26mm in thickness, with crimped on plastic end

tanks. A single electrical cooling fan and a fan

D.303.1213

COOLANT PUMP

D.303.1213

D.303.1375

RADIATOR AND FAN SHROUD ASSEMBLY

D.303.1375

Fan Speed

Regulator Module

Page 40 of 75

V6 EngineAJ-V6/AJ28

35

J.303.1384

ENGINE BLOCK HEATER

D.303.1384

J.303.1377

FAN SPEED REGULATOR MODULE COOLING DUCT speed regulator module are fixed to the glass

filled nylon fan shroud assembly which is

mounted on the rear of the radiator end tanks via

two lower slots and pegs, two upper screws and

two clips at the bottom of the radiator. The A/C

system receiver drier bottle is also mounted on

the fan shroud assembly - see the

ÔS-TYPE IntroductionÕ Technical Guide.

The 500W fan motor drives a glass filled nylon

impeller over a continuously variable speed range

from 300RPM to 2900RPM and is controlled by a

regulator module mounted at the lower LH side of

the fan shroud. Since the fan speed regulator

module provides power drive to the fan, it has a

finned heat sink outer casing and is enclosed

within a cooling duct. The ducting extends

forwards below the cooling pack to receive an

inflow of air.

The radiator drain is located on the RH end tank.

Coolant

A new type of anti-freeze fluid is used for the

coolant mixture. This product is a conventional

ethylene glycol based fluid but with new organic

corrosion inhibitors instead of the silicate, nitrite

and other additives which are normally used.

These new corrosion inhibitors do not form a

deposit on the inner surfaces of the coolant

system and therefore provide improved heat

transfer (more efficient cooling), better

component protection and an extended coolant

life due to the low rate of depletion of the

additives. The recommended coolant change is

every five years or 250,000km (150,000miles).

Engine Block Heater

For markets subject to very low temperatures, an

engine coolant heater, for connection to an

external mains electrical supply, is screwed into

the RH side of the cylinder block adjacent to the

knock sensor. Two heaters are available, a 400W

115V unit with a two pin connector and a 600W

230V unit with flying lead.

J.303.1377