air condition JAGUAR S TYPE 1999 1.G Powertrain Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1999, Model line: S TYPE, Model: JAGUAR S TYPE 1999 1.GPages: 75, PDF Size: 3.4 MB

Page 7 of 75

Glossary

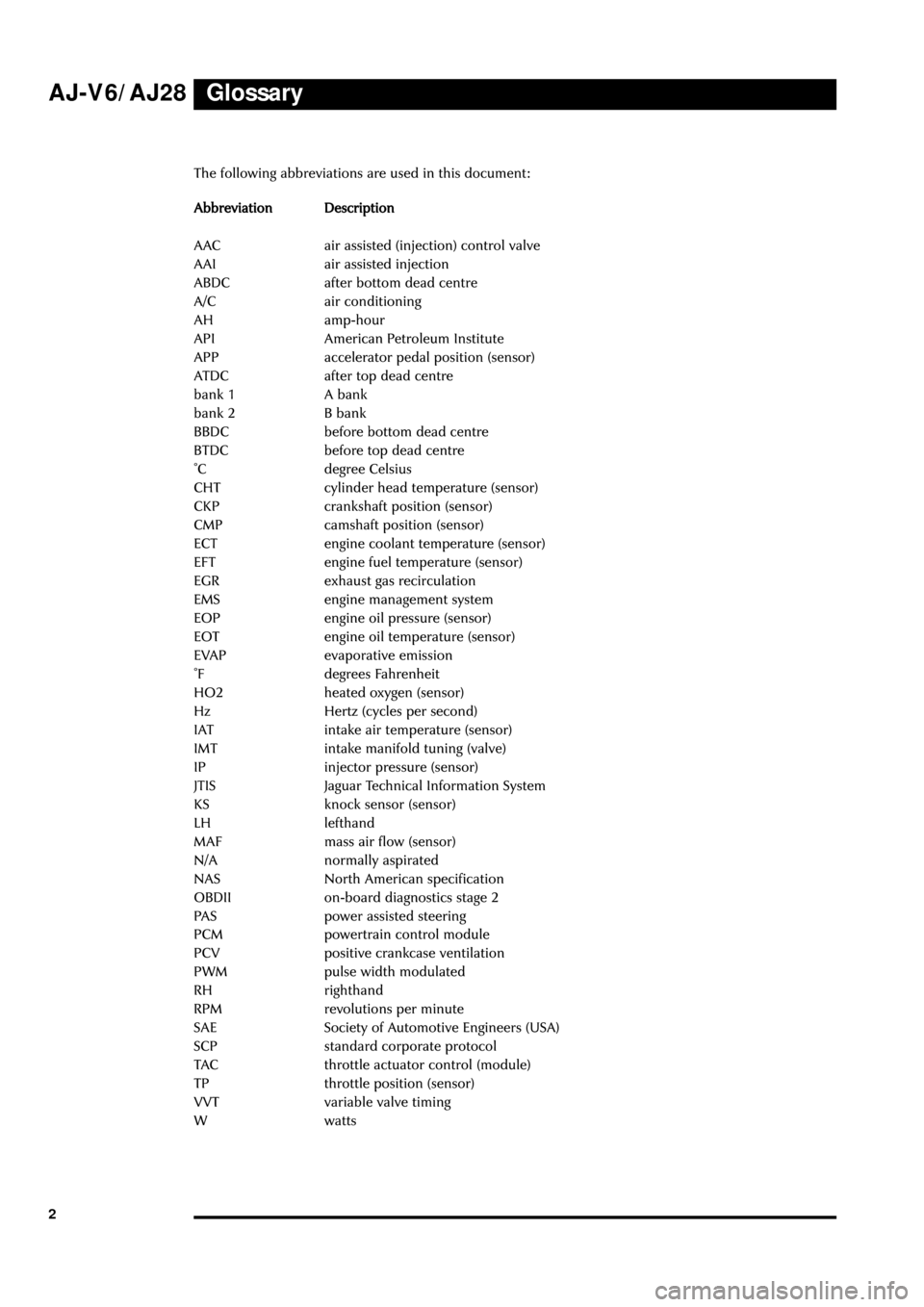

2The following abbreviations are used in this document:

A Ab

bb

br

re

ev

vi

ia

at

ti

io

on

nD

De

es

sc

cr

ri

ip

pt

ti

io

on

n

AAC air assisted (injection) control valve

AAI air assisted injection

ABDC after bottom dead centre

A/C air conditioning

AH amp-hour

API American Petroleum Institute

APP accelerator pedal position (sensor)

ATDC after top dead centre

bank 1 A bank

bank 2 B bank

BBDC before bottom dead centre

BTDC before top dead centre

ûC degree Celsius

CHT cylinder head temperature (sensor)

CKP crankshaft position (sensor)

CMP camshaft position (sensor)

ECT engine coolant temperature (sensor)

EFT engine fuel temperature (sensor)

EGR exhaust gas recirculation

EMS engine management system

EOP engine oil pressure (sensor)

EOT engine oil temperature (sensor)

EVAP evaporative emission

ûF degrees Fahrenheit

HO2 heated oxygen (sensor)

Hz Hertz (cycles per second)

IAT intake air temperature (sensor)

IMT intake manifold tuning (valve)

IP injector pressure (sensor)

JTIS Jaguar Technical Information System

KS knock sensor (sensor)

LH lefthand

MAF mass air flow (sensor)

N/A normally aspirated

NAS North American specification

OBDII on-board diagnostics stage 2

PAS power assisted steering

PCM powertrain control module

PCV positive crankcase ventilation

PWM pulse width modulated

RH righthand

RPM revolutions per minute

SAE Society of Automotive Engineers (USA)

SCP standard corporate protocol

TAC throttle actuator control (module)

TP throttle position (sensor)

VVT variable valve timing

W watts

AJ-V6/AJ28

Page 23 of 75

V6 Engine AJ-V6/AJ28

18diaphragm valve with no electrical connections

which opens the EGR feed pipe to the induction

manifold under the EGR vacuum regulator

control.

Where the EGR system is not fitted, a blanking

plate seals the manifold in place of the EGR valve.

Control Conditions

EGR operates over most of the engine speed/load

range but is disabled by the engine management

system under certain conditions:

¥ during engine cranking

¥ until normal operating temperature is

reached

¥ when the diagnostic system registers a failure

which affects the EGR system (eg a faulty

sensor)

¥ during idling to avoid unstable or erratic

running

¥ during wide open throttle operation

¥ when traction control is operative.

While the main control loop is based on feedback

from the differential pressure feedback EGR

sensor, the EGR rate is also modified by other

engine conditions; coolant, ambient and air

charge temperatures, barometric pressure, VVT

cam position and air charge mass. Note also that

the EGR rate increases gradually after it is enabled

on each drive cycle.

Page 44 of 75

V6 EngineAJ-V6/AJ28

39

D.303.1351D.303.1352

PAS PUMPA/C COMPRESSOR

D.303.1352

D.303.1369

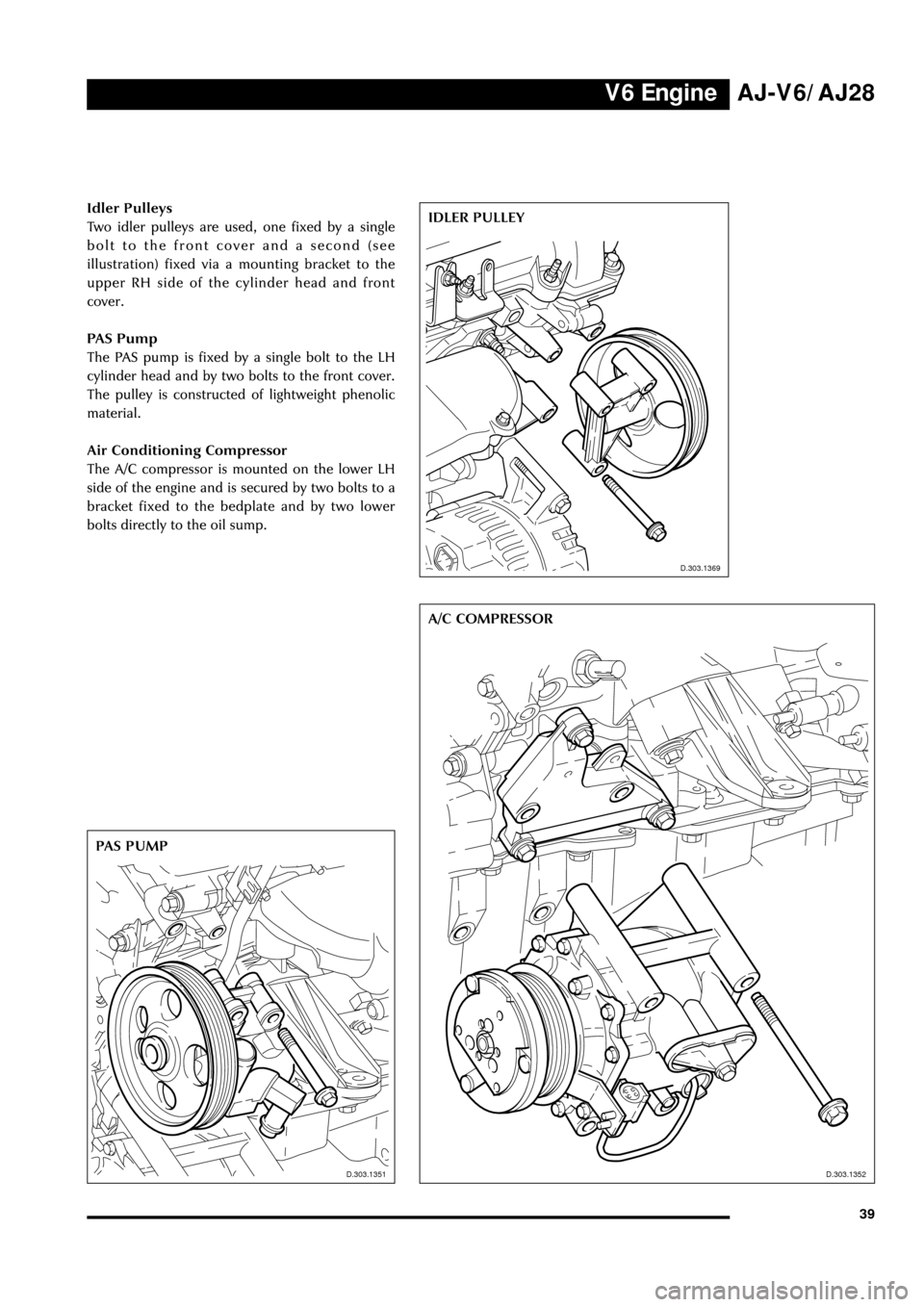

Idler Pulleys

Two idler pulleys are used, one fixed by a single

bolt to the front cover and a second (see

illustration) fixed via a mounting bracket to the

upper RH side of the cylinder head and front

cover.

PAS Pump

The PAS pump is fixed by a single bolt to the LH

cylinder head and by two bolts to the front cover.

The pulley is constructed of lightweight phenolic

material.

Air Conditioning Compressor

The A/C compressor is mounted on the lower LH

side of the engine and is secured by two bolts to a

bracket fixed to the bedplate and by two lower

bolts directly to the oil sump.IDLER PULLEY

D.303.1351

D.303.1369

Page 50 of 75

V8 EngineAJ-V6/AJ28

45

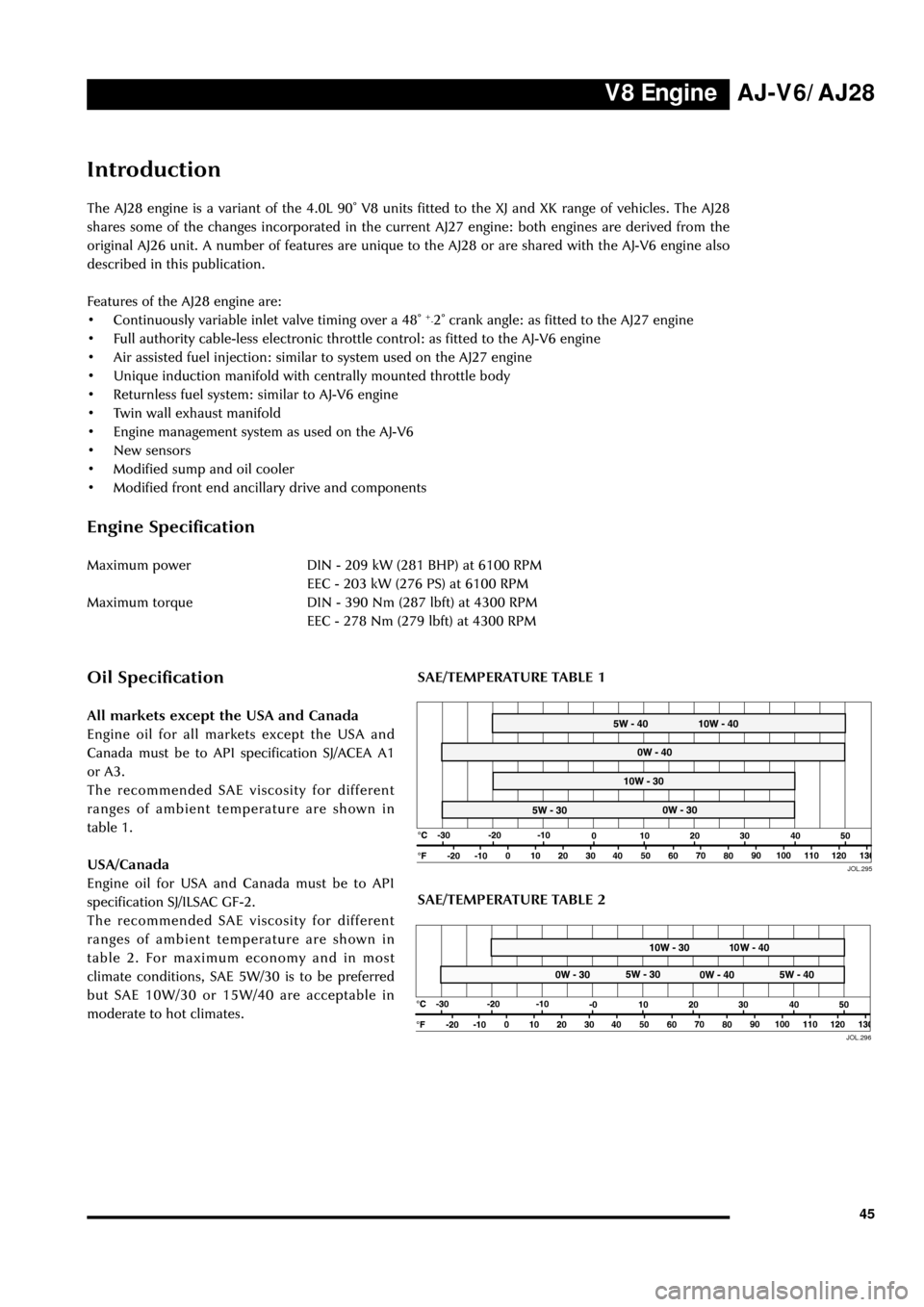

Introduction

The AJ28 engine is a variant of the 4.0L 90û V8 units fitted to the XJ and XK range of vehicles. The AJ28

shares some of the changes incorporated in the current AJ27 engine: both engines are derived from the

original AJ26 unit. A number of features are unique to the AJ28 or are shared with the AJ-V6 engine also

described in this publication.

Features of the AJ28 engine are:

¥ Continuously variable inlet valve timing over a 48û

+

-2û crank angle: as fitted to the AJ27 engine

¥ Full authority cable-less electronic throttle control: as fitted to the AJ-V6 engine

¥ Air assisted fuel injection: similar to system used on the AJ27 engine

¥ Unique induction manifold with centrally mounted throttle body

¥ Returnless fuel system: similar to AJ-V6 engine

¥ Twin wall exhaust manifold

¥ Engine management system as used on the AJ-V6

¥ New sensors

¥ Modified sump and oil cooler

¥ Modified front end ancillary drive and components

Engine Specification

Maximum power DIN - 209 kW (281 BHP) at 6100 RPM

EEC - 203 kW (276 PS) at 6100 RPM

Maximum torque DIN - 390 Nm (287 lbft) at 4300 RPM

EEC - 278 Nm (279 lbft) at 4300 RPM

Oil Specification

All markets except the USA and Canada

Engine oil for all markets except the USA and

Canada must be to API specification SJ/ACEA A1

or A3.

The recommended SAE viscosity for different

ranges of ambient temperature are shown in

table 1.

USA/Canada

Engine oil for USA and Canada must be to API

specification SJ/ILSAC GF-2.

The recommended SAE viscosity for different

ranges of ambient temperature are shown in

table 2. For maximum economy and in most

climate conditions, SAE 5W/30 is to be preferred

but SAE 10W/30 or 15W/40 are acceptable in

moderate to hot climates.

JOL.29550

50JOL.296

SAE/TEMPERATURE TABLE 2

SAE/TEMPERATURE TABLE 1

Page 68 of 75

Automatic TransmissionAJ-V6/AJ28

63 controlled solenoid are mounted on an

integral, replaceable, control module

¥ three speed sensors mounted on the external

casing: turbine speed sensor, intermediate

speed sensor and output speed sensor

¥ an oil temperature sensor is fitted inside the

transmission.

The gear select lever is connected via a Bowden

cable to an operating lever on the left side of the

transmission casing. A digital rotary switch, the

transmission range switch, fits over the shaft of

the operating lever and is fixed by two bolts to

the transmission casing. Selection of a particular

drive function generates a 4 bit binary coded

signal which is transmitted directly to the PCM

over a four wire parallel interface. As on the XK

and XJ Series, lateral movement of the gear select

lever across the gate, D to 4 or 4 to D, operates a

switch which indicates the selected function to

the PCM (the Bowden cable is not actuated

laterally).

The PCM directly controls the transmission

actuators as a response to driver demand, engine

requirements and according to the selected shift

mode. Gear selection is controlled by commands

to the four shift solenoids. If, during gear

selection, the relative speeds monitored by the

speed sensors are not as expected, the PCM

varies the analogue signal to the variable force

solenoids to increase/decrease the clutch pressure

(closed loop control). Increased engagement times

due to ageing are also controlled by adaptive shiftpressure.

Apart from the sports mode and traction mode

selected by the driver, there are pre-programmed

modes selected by the PCM in response to sensed

driving conditions :

¥ increased load such as gradients and trailer

towing

¥ cruise control

¥ hot mode: strategies including clutch lock up

are applied to reduce heat.

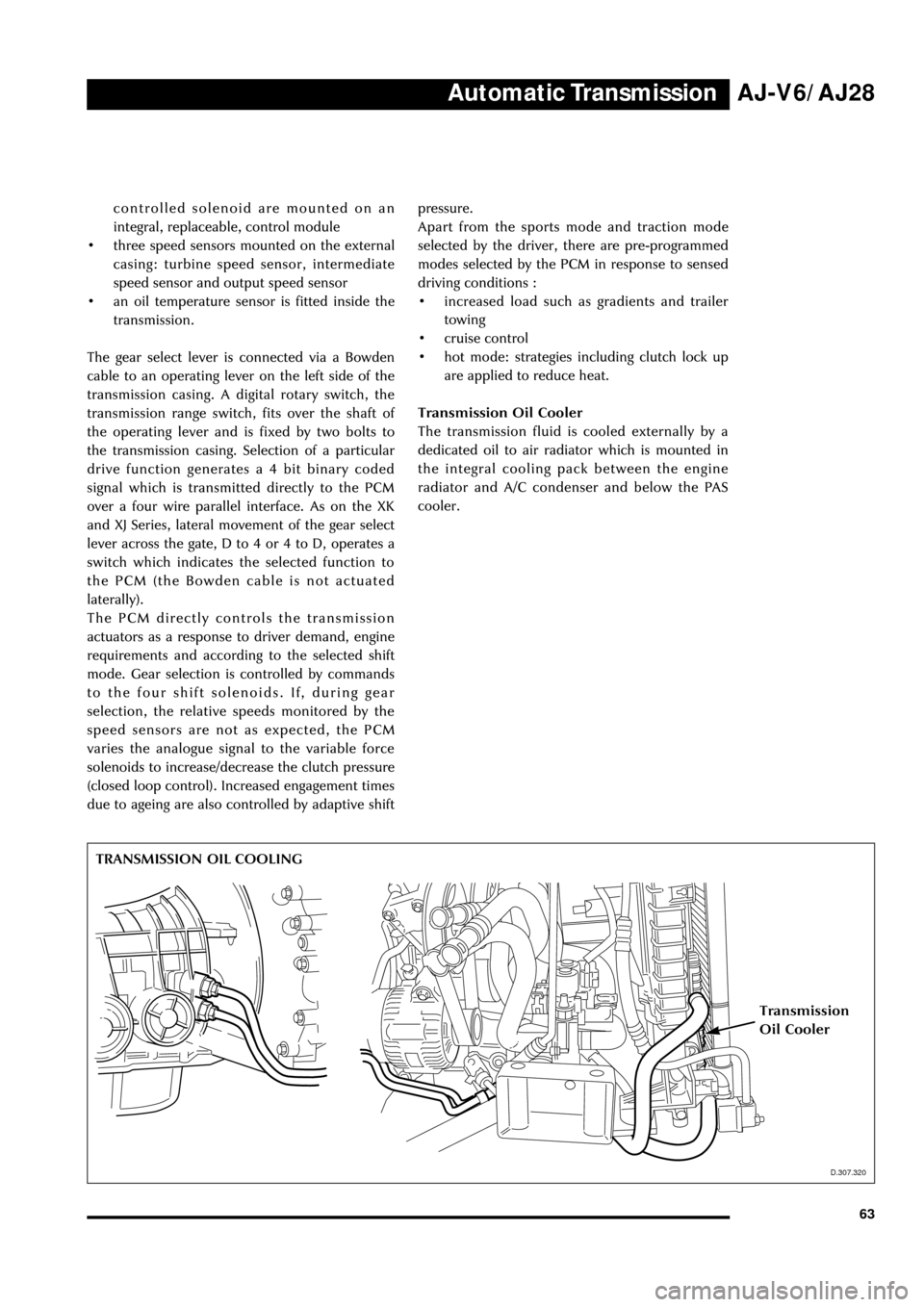

Transmission Oil Cooler

The transmission fluid is cooled externally by a

dedicated oil to air radiator which is mounted in

the integral cooling pack between the engine

radiator and A/C condenser and below the PAS

cooler.

D.307.320

TRANSMISSION OIL COOLING

Transmission

Oil Cooler

D.307.320