key JAGUAR S TYPE 1999 1.G Powertrain Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1999, Model line: S TYPE, Model: JAGUAR S TYPE 1999 1.GPages: 75, PDF Size: 3.4 MB

Page 12 of 75

D.303.1210

V6 EngineAJ-V6/AJ28

7 CRANKSHAFT

D.303.1210

D.303.1208

CONNECTING ROD AND PISTON

D.303-1208

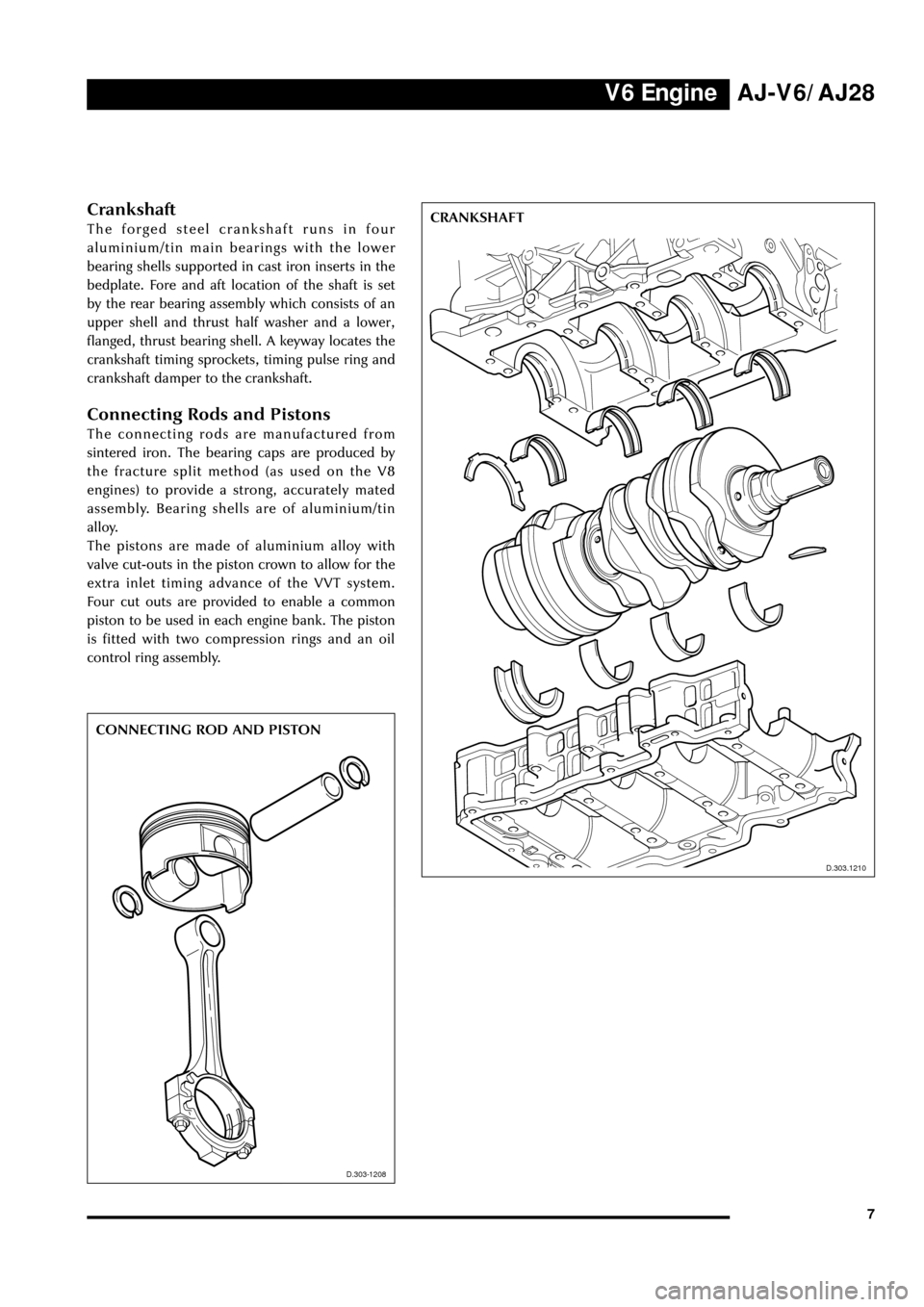

Crankshaft

The forged steel crankshaft runs in four

aluminium/tin main bearings with the lower

bearing shells supported in cast iron inserts in the

bedplate. Fore and aft location of the shaft is set

by the rear bearing assembly which consists of an

upper shell and thrust half washer and a lower,

flanged, thrust bearing shell. A keyway locates the

crankshaft timing sprockets, timing pulse ring and

crankshaft damper to the crankshaft.

Connecting Rods and Pistons

The connecting rods are manufactured from

sintered iron. The bearing caps are produced by

the fracture split method (as used on the V8

engines) to provide a strong, accurately mated

assembly. Bearing shells are of aluminium/tin

alloy.

The pistons are made of aluminium alloy with

valve cut-outs in the piston crown to allow for the

extra inlet timing advance of the VVT system.

Four cut outs are provided to enable a common

piston to be used in each engine bank. The piston

is fitted with two compression rings and an oil

control ring assembly.

Page 15 of 75

V6 Engine

10

D.303.1204

CAMSHAFT DRIVE

D.303.1204

AJ-V6/AJ28

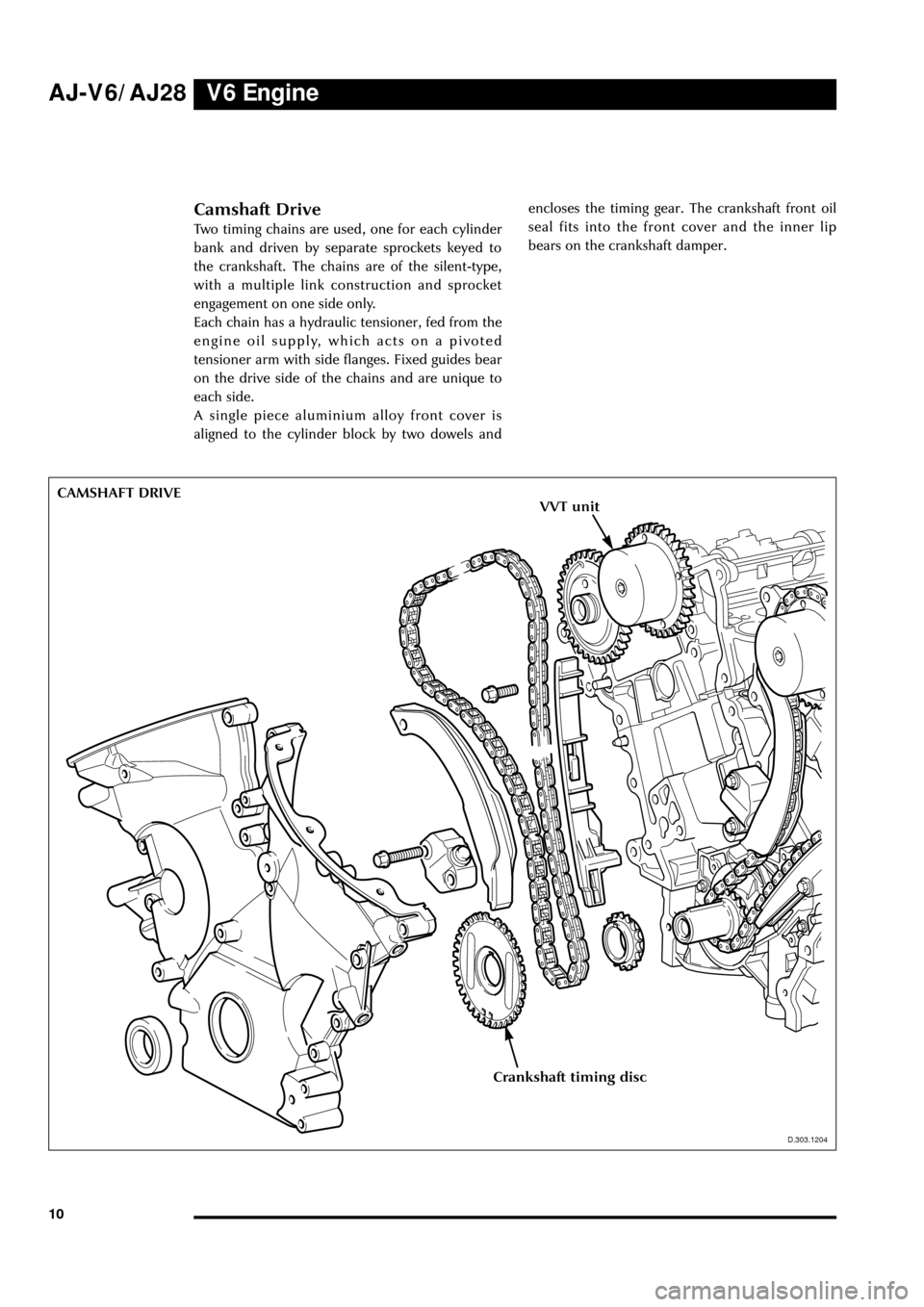

Camshaft Drive

Two timing chains are used, one for each cylinder

bank and driven by separate sprockets keyed to

the crankshaft. The chains are of the silent-type,

with a multiple link construction and sprocket

engagement on one side only.

Each chain has a hydraulic tensioner, fed from the

engine oil supply, which acts on a pivoted

tensioner arm with side flanges. Fixed guides bear

on the drive side of the chains and are unique to

each side.

A single piece aluminium alloy front cover is

aligned to the cylinder block by two dowels andencloses the timing gear. The crankshaft front oil

seal fits into the front cover and the inner lip

bears on the crankshaft damper.

Crankshaft timing disc

VVT unit

Page 45 of 75

V6 Engine AJ-V6/AJ28

40

Engine Management Sensors

Key to illustration on page 41:

1. Throttle motor

2. TP sensor

3. IAT sensor

4. MAF sensor

5. Top IMT valve

6. Bottom IMT valve

7. EFT sensor

8. IP sensor

9. Fuel injectors

10. Coil-on-plug units

11. VVT shuttle valve

12. CMP sensor

13. CHT sensor

14. KS sensors

15. EOT sensor

16. CKP sensor

17. HO2 sensors

18. HO2 sensors (catalyst monitors)

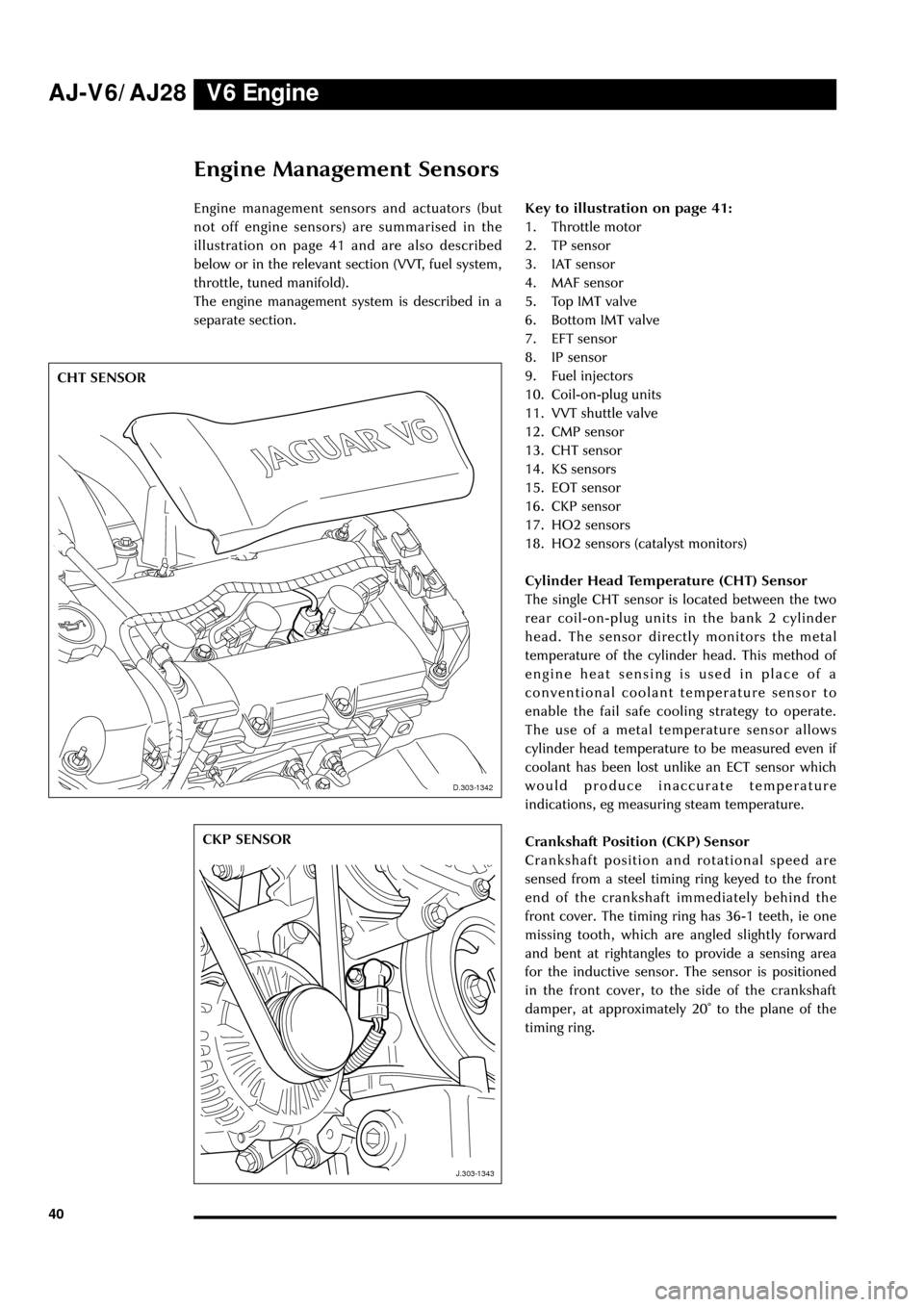

Cylinder Head Temperature (CHT) Sensor

The single CHT sensor is located between the two

rear coil-on-plug units in the bank 2 cylinder

head. The sensor directly monitors the metal

temperature of the cylinder head. This method of

engine heat sensing is used in place of a

conventional coolant temperature sensor to

enable the fail safe cooling strategy to operate.

The use of a metal temperature sensor allows

cylinder head temperature to be measured even if

coolant has been lost unlike an ECT sensor which

would produce inaccurate temperature

indications, eg measuring steam temperature.

Crankshaft Position (CKP) Sensor

Crankshaft position and rotational speed are

sensed from a steel timing ring keyed to the front

end of the crankshaft immediately behind the

front cover. The timing ring has 36-1 teeth, ie one

missing tooth, which are angled slightly forward

and bent at rightangles to provide a sensing area

for the inductive sensor. The sensor is positioned

in the front cover, to the side of the crankshaft

damper, at approximately 20û to the plane of the

timing ring.

D.303.1342

J.303.1343

CHT SENSOR

CKP SENSOR

D.303-1342

J.303-1343

Engine management sensors and actuators (but

not off engine sensors) are summarised in the

illustration on page 41 and are also described

below or in the relevant section (VVT, fuel system,

throttle, tuned manifold).

The engine management system is described in a

separate section.

Page 60 of 75

V8 EngineAJ-V6/AJ28

55

J.303.1389

ENGINE MANAGEMENT SCHEMATIC

13

2

45

6

8

157

9

1110

13

16

J.303-1287

9

10

12

14

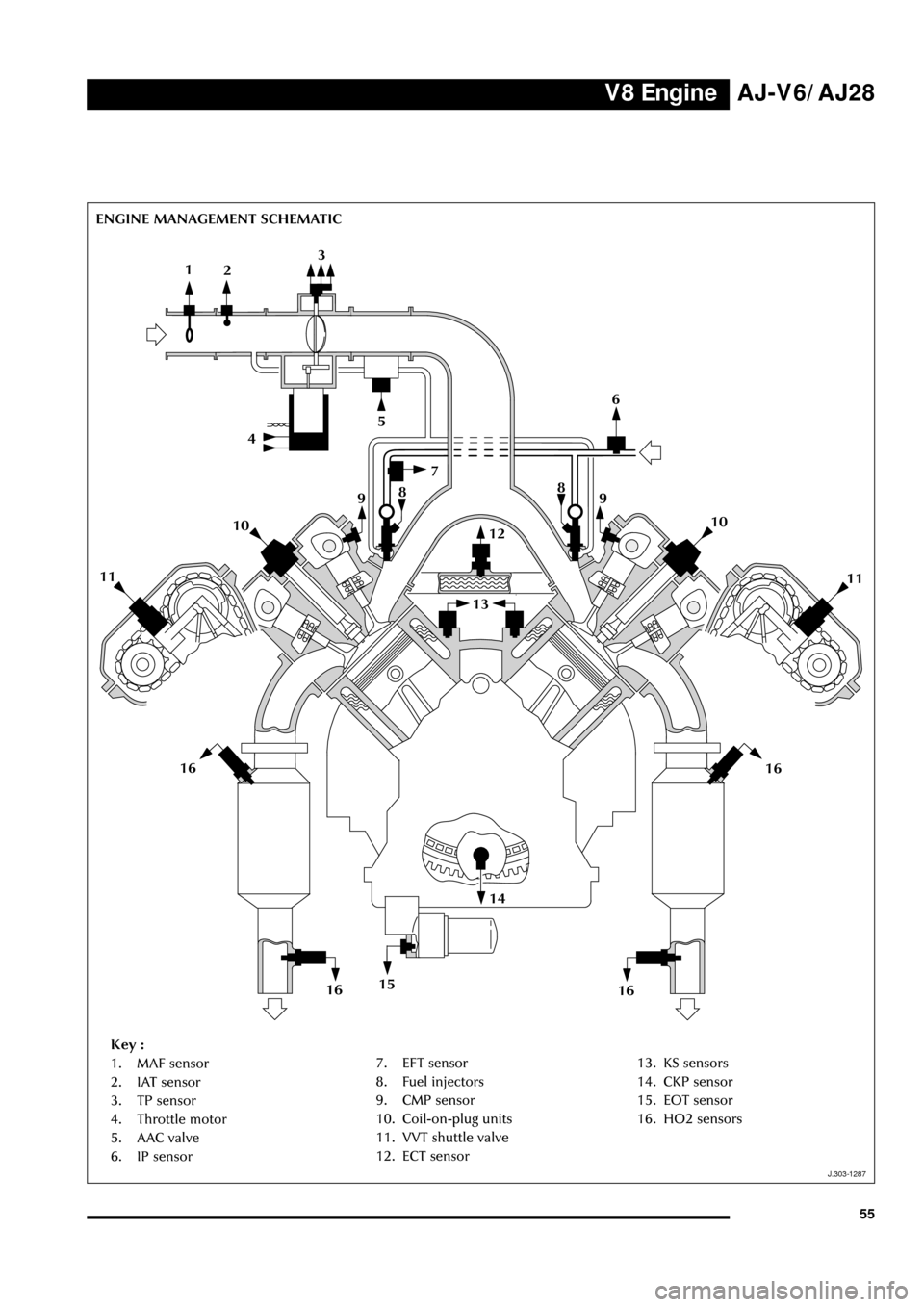

Key :

1. MAF sensor

2. IAT sensor

3. TP sensor

4. Throttle motor

5. AAC valve

6. IP sensor8

11

16

1616

7. EFT sensor

8. Fuel injectors

9. CMP sensor

10. Coil-on-plug units

11. VVT shuttle valve

12. ECT sensor13. KS sensors

14. CKP sensor

15. EOT sensor

16. HO2 sensors